Professional Documents

Culture Documents

Waukesha Knock Index

Uploaded by

Achmad Nizar ZulmiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Waukesha Knock Index

Uploaded by

Achmad Nizar ZulmiCopyright:

Available Formats

GE Energy

Gas Engines Waukesha Knock Index* (WKI*)

Page 1 of 5

220GL Derating Schedules And

Theory Of Application

EN: 153107

DATE: 3/11

Ref.

S

9200-18

12V / 18V 220GL Derating Schedules and Theory of Application

The 220GL engine is available only for continuous operating power (COP) according to ISO 8528. COP is the available output

for continuous electricity supply during an unlimited number of hours per year, in between normal maintenance intervals

and under specified ambient conditions, the maintenance being made according to engine manufacturer specifications. No

overload or overspeed is available.

Certain installations of the 220GL product will require the application of derating due to fuel, ambient, or other site

conditions that are beyond the scope of standard application. This specification is meant to document the process and

technical data for applying the appropriate derates based on the following factors:

Fuel WKI

Air inlet temperature to the turbocharger compressor (not site ambient temperature)

Intake manifold temperature

Altitude

Fuel pressure at gas train inlet

The information under DERATING METHODOLOGY (page 1 and 2) is meant to provide a basis for the process to be followed

when determining the applicable derates for the site in question. Each K-factor is to be calculated either from the graphs

(pages 3-10) or the equations (pages 11-13). It is recommended to use the specific equations for greater accuracy in the

end result.

These K-factors, along with the calculations for KTOTAL, , and other variables, are used to determine the maximum power

that is available under all site conditions. Pages 14-15 of this specification contain two examples of applying this derating

methodology utilizing the information contained within this specification.

It is critically important that the right configuration graph and equations are being studied to match the site requirements

for engine speed/generator frequency, NOx emissions output, and LT (auxiliary) water inlet temperature. Each graph can be

used whether a 12V220GL or 18V220GL is under study.

NOTES:

Refer to the WKI program (version 1.17 or newer) for accurate calculation of site fuel WKI to be used for engine derating prediction.

If the engine output has been adjusted for WKI, site ambient conditions, or gas feed pressure to gas train, the specific fuel consumption

and heat balance has to be adjusted accordingly. Refer to S-sheet S-8154-101, latest revision, for more information.

Contact Waukesha Engine Application Engineering for assistance.

DERATING METHODOLOGY

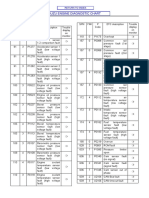

K1 = derate factor due to WKI (Waukesha Knock Index)

K2 = derate factor due to MCAIT (Maximum Charge Air Inlet Temperature air temperature before turbocharger

compressor)

K3 = derate factor due to IMAT (Intake Manifold Air Temperature)

K4 = derate factor due to Altitude

GE Energy

Gas Engines Waukesha Knock Index (WKI)

Page 2 of 5

220GL Derating Schedules And

Theory Of Application

EN: 153107

DATE: 3/11

Ref.

S

9200-18

Prated = maximum allowable power (no derates, no overload allowed)

PX1 = adjusted output for WKI

PX1 = Prated x K1

PX2 = adjusted output for site ambient conditions

PX2 = PX1 x

( ) |

.

|

\

|

= 1

9 . 0

1

1 7 . 0

TOTAL TOTAL

K K o

Where KTOTAL = K2 x K3 x K4

PX TOTAL = service output (adjusted output for ALL site conditions)

PX TOTAL = PX2 if PX2 < PX3

PX TOTAL = PX3 if PX3 < PX2

If Pgas > Pref for the corresponding engine configuration, calculation of PX3 is not needed and PX TOTAL = PX2

PX3 = adjusted power output for gas feed pressure (when Pgas < Pref)

PX3 = Prated x [1 0.4 x (Pref Pgas)] Pgas = GAGE gas pressure at gas train inlet

NOX SETTING ENGINE SPEED

CHARGE AIR COOLING (LT) INLET

TEMPERATURE (C)

PREF (BARGAGE)

T.A. Luft

(500 mg/m

3

N at 5% O2 dry)

1500 RPM (50Hz)

45 2.6

55 2.6

1200 RPM (60Hz)

45 2.9

55 2.8

1/2 T.A. Luft

(250 mg/m

3

N at 5% O2 dry)

1500 RPM (50Hz)

45 2.7

55 2.8

1200 RPM (60Hz)

45 3.2

55 3.0

NOTES:PREF AND PGAS MUST BE IN BARGAGE

GE Energy

Gas Engines Waukesha Knock Index (WKI)

Page 3 of 5

220GL Derating Schedules And

Theory Of Application

EN: 153107

DATE: 3/11

Ref.

S

9200-18

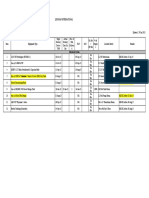

SPEED NOX SETTING LT INLET TEMPERATURE DERATING METHODOLOGY

K1 WKI

1500 RPM (50Hz) T.A. Luft 45C (113F)

WKI 84.6 K1 = 1

73.3 WKI 84.6 K1 = 0.0079*WKI + 0.3281

66.5 WKI 73.3 K1 = 0.0236*WKI 0.8197

1500 RPM (50Hz) T.A. Luft 55C (131F)

WKI 93.0 K1 = 1

64.0 WKI 93.0 K1 = 0.0086*WKI + 0.2

1500 RPM (50Hz) 1/2 T.A. Luft

45C (113F) &

55C (131F)

WKI 80.1 K1 = 1

41.0 WKI 80.1 K1 = 0.0115*WKI + 0.0780

1200 RPM (60Hz) T.A. Luft

45C (113F) &

55C (131F)

WKI 90.2 K1 = 1

80.1 WKI 90.2 K1 = 0.0099*WKI + 0.1046

73.3 WKI 80.1 K1 = 0.0206*WKI 0.7535

1200 RPM (60Hz) 1/2 T.A. Luft 45C (113F)

WKI 80.1 K1 = 1

66.5 WKI 80.1 K1 = 0.0074*WKI + 0.4095

58.8 WKI 66.5 K1 = 0.0206*WKI 0.4720

1200 RPM (60Hz) 1/2 T.A. Luft 55C (131F)

WKI 90.2 K1 = 1

80.1 WKI 90.2 K1 = 0.0099*WKI + 0.1046

73.3 WKI 80.1 K1 = 0.0206*WKI - 0.7535

K2 MCAIT

1500 RPM (50Hz) &

1200 RPM (60Hz)

T.A. Luft &

1/2 T.A. Luft

45C (113F) &

55C (131F)

MCAIT 40C K2 = 1

40C MCAIT 50C K2 = 1 + 0.004*(40 MCAIT)

NOTES:

1. MCAIT MUST BE IN C

2. Minimum MCAIT is 0C

3. Maximum MCAIT is 50C

K3 IMAT

1500 RPM (50Hz) &

1200 RPM (60Hz)

T.A. Luft &

1/2 T.A. Luft

45C (113F)

IMAT 55C K3 = 1

55C IMAT 65C K3 = 1 + 0.01*(55 IMAT)

NOTES:

1. IMAT MUST BE IN C

2. Maximum IMAT is 65C

3. The charged air temperature is approximately 10C higher than the charge air coolant temperature.

1500 RPM (50Hz) &

1200 RPM (60Hz)

T.A. Luft &

1/2 T.A. Luft

55C (131F)

IMAT 65C K3 = 1

65C IMAT 75C K3 = 1 + 0.01*(65 IMAT)

NOTES:

1. IMAT MUST BE IN C

2. Maximum IMAT is 75C

3. The charged air temperature is approximately 10C higher than the charge air coolant temperature.

K4 ALTITUDE

1500 RPM (50Hz) &

1200 RPM (60Hz)

T.A. Luft

45C (113F) &

55C (131F)

ALTITUDE 1500m K4 = 1

1500m ALTITUDE 3000m K4 = 1 + 0.0001*(1500 ALTITUDE)

1500 RPM (50Hz) &

1200 RPM (60Hz)

1/2 T.A. Luft

45C (113F) &

55C (131F)

ALTITUDE 500m K4 = 1

500m ALTITUDE 3000m K4 = 1 + 0.0001*(500 ALTITUDE)

NOTES: 1. ALTITUDE MUST BE IN METERS

2. If altitude is higher than 3000 meters contact Waukesha Application Engineering.

GE Energy

Gas Engines Waukesha Knock Index (WKI)

Page 4 of 5

220GL Derating Schedules And

Theory Of Application

EN: 153107

DATE: 3/11

Ref.

S

9200-18

EXAMPLE 1: Derates for WKI, MCAIT, and altitude are applied. No IMAT or fuel pressure derating.

GIVEN INFORMATION

18V220GL

1500 RPM (50Hz)

1/2 T.A. Luft (250 mg/m

3

N at 5% O2 dry)

LT Inlet Temperature = 45 C

Prated = 3200 kWe

WKI = 78

MCAIT = 42 C

IMAT = 32 C

Altitude = 750 meters

Pgas = 5.1 BARGAGE

SOLUTION

Using equations determine K1, K2, K3, and K4

41.0 WKI 80.1 K1 = 0.0115* WKI + 0.0780 K1 = 0.0115*78 + 0.0780

K1 = 0.975

40C MCAIT 50C K2 = 1 + 0.004*(40 MCAIT) K2 = 1 + 0.004*(40 42 C)

K2 = 0.992

IMAT 55C

K3 = 1

500m ALTITUDE 3000m K4 = 1 + 0.0001*(500 ALTITUDE) K4 = 1 + 0.0001*(500 750 meters)

K4 = 0.975

Determine PX1

PX1 = Prated x K1 = 3200 x 0.975 = 3120

Determine KTOTAL, , and PX2

KTOTAL = K2 x K3 x K4 = 0.992 x 1 x 0.975 = 0.967

( ) |

.

|

\

|

= 1

9 . 0

1

967 . 0 1 7 . 0 967 . 0 o = 0.964

PX2 = PX1 x = 3120 x 0.964 = 3007

Determination of PX3 is not needed since Pgas is greater than Pref therefore PTOTAL = PX2

PTOTAL = 3007 kWe

GE Energy

Gas Engines Waukesha Knock Index (WKI)

Page 5 of 5

220GL Derating Schedules And

Theory Of Application

EN: 153107

DATE: 3/11

Ref.

S

9200-18

EXAMPLE 2: Derates for MCAIT and fuel pressure are applied. No WKI, IMAT, or altitude derating.

GIVEN INFORMATION

12V220GL

1200 RPM (60Hz)

T.A. Luft (500 mg/m

3

N at 5% O2 dry)

LT Inlet Temperature = 45 C

Prated = 2100 kWe

WKI = 93

MCAIT = 43 C

IMAT = 50 C

Altitude = 500 meters

Pgas = 2.9

SOLUTION

Using equations determine K1, K2, K3, and K4

WKI 90.2 K1 = 1

K1 = 1

40C MCAIT 50C K2 = 1 + 0.004*(40 MCAIT) K2 = 1 + 0.004*(40 43 C)

K2 = 0.988

IMAT 55C

K3 = 1

ALTITUDE 1500m K4 = 1

K4 = 1

Determine PX1

PX1 = Prated x K1 = 2100 x 1 = 2100

Determine KTOTAL, , and PX2

KTOTAL = K2 x K3 x K4 = 0.988 x 1 x 1 = 0.988

( ) |

.

|

\

|

= 1

9 . 0

1

988 . 0 1 7 . 0 988 . 0 o = 0.987

PX2 = PX1 X = 2100 X 0.987 = 2072

Determine Px3

PX3 = Prated x [1 0.4 x (Pref Pgas)] = 2100 x [1 0.4 x (3.15 2.9)] = 1890

PX TOTAL = PX3 since PX3 < PX2

PX TOTAL = 1890 kWe

*Trademark of General Electric Company. All other trademarks are the property of their respective owners.

You might also like

- Waukesha VHP Serie 5Document45 pagesWaukesha VHP Serie 5dfmolina100% (1)

- GE Waukesha Special Tools CatalogDocument94 pagesGE Waukesha Special Tools CatalogMuhammadShadab90% (10)

- f1197g o M Manual - KPCDocument123 pagesf1197g o M Manual - KPCroalcalo_uan100% (1)

- 6286-2 Web - AFM PDFDocument434 pages6286-2 Web - AFM PDFshahzad100% (1)

- Rod ReversalDocument21 pagesRod ReversalandresNo ratings yet

- VHP Parts BookDocument19 pagesVHP Parts Bookhuskerchamps100% (6)

- Waukesha 12 Cyl Extender Parts (Complete)Document185 pagesWaukesha 12 Cyl Extender Parts (Complete)Stephen Cox94% (17)

- 01.412833 - A9. Engine - VGF F18se-H24se 6&8 Cyl Parts CatalDocument224 pages01.412833 - A9. Engine - VGF F18se-H24se 6&8 Cyl Parts CatalJorge RiquelmeNo ratings yet

- 6277-4 VPH 6-12-16 Cylinder O&MDocument310 pages6277-4 VPH 6-12-16 Cylinder O&Mchejoman1979100% (1)

- Wuaukesha EnginesDocument4 pagesWuaukesha EnginesVirbiirNo ratings yet

- 6277-5 WebDocument356 pages6277-5 WebTravisNo ratings yet

- WaukeshaDocument18 pagesWaukeshaOmar Alexander Cañon Ortegon100% (9)

- Cristian Makes and ModelsDocument54 pagesCristian Makes and ModelsIgnacio Real BuffelliNo ratings yet

- 7044 GSI S4 Spare Parts ManualDocument216 pages7044 GSI S4 Spare Parts ManualEng Mohamed Hanafy100% (3)

- Waukesha Gas Engines: GE Power & WaterDocument10 pagesWaukesha Gas Engines: GE Power & WaterdfmolinaNo ratings yet

- Waukesha Gas Engine SparesDocument122 pagesWaukesha Gas Engine Sparesakamalapuri388100% (6)

- Listado de PartesDocument299 pagesListado de PartesAlexander RodriguezNo ratings yet

- Ajax Igtb Electronic GovernorDocument2 pagesAjax Igtb Electronic GovernorAnonymous CD0suI9No ratings yet

- Waukesha V HP Series 4Document4 pagesWaukesha V HP Series 4rohizatNo ratings yet

- Waukesha Gas Engines: WarningDocument3 pagesWaukesha Gas Engines: WarningdfmolinaNo ratings yet

- 1091 11 Installation Chapters RevDocument250 pages1091 11 Installation Chapters RevLenin Marcel Fajardo Almeida100% (2)

- Parts Manual 7042 Series 2 ESM - Form 6311-2 (2016)Document180 pagesParts Manual 7042 Series 2 ESM - Form 6311-2 (2016)dfmolina100% (1)

- Installation of Waukesha Engines and Enginator SystemsDocument264 pagesInstallation of Waukesha Engines and Enginator SystemsTERRY_HENRRY100% (16)

- Gas Engine Emissions Technology 4th EditionDocument16 pagesGas Engine Emissions Technology 4th EditionLenin Marcel Fajardo AlmeidaNo ratings yet

- Waukesha CatalogueDocument57 pagesWaukesha CataloguesparthaelfNo ratings yet

- ESM PresentationDocument30 pagesESM Presentationnicol_sgNo ratings yet

- VHP 7042GSI MaintenanceDocument4 pagesVHP 7042GSI MaintenanceFernando Bravo100% (2)

- Waukesha Gas Engine Service BulletinDocument15 pagesWaukesha Gas Engine Service BulletinAlva Kurnia L Wirekso100% (2)

- Ajax-Integral Engine CompressorDocument8 pagesAjax-Integral Engine CompressorShahzad AhmadNo ratings yet

- 6388-1 Web PDFDocument466 pages6388-1 Web PDFjonathan50% (2)

- ESM O&M 3rd EditionDocument202 pagesESM O&M 3rd EditionLibardo RuzNo ratings yet

- G3600 A4 Brochures PDFDocument4 pagesG3600 A4 Brochures PDFVictor NunezNo ratings yet

- Especificaciones Motor Waukesha 9390Document2 pagesEspecificaciones Motor Waukesha 9390joseantoniogoncorNo ratings yet

- 2b) Waukesha VHP Mainenance Cosiderations - Hour IntervalsDocument6 pages2b) Waukesha VHP Mainenance Cosiderations - Hour IntervalsDibyendu Chakraborty100% (1)

- Waukesha 7044 SparesDocument7 pagesWaukesha 7044 SparesHisham Elsayed100% (1)

- L7042GDocument2 pagesL7042GRose MarieNo ratings yet

- JGR JGJ enDocument137 pagesJGR JGJ enKarlosant MJ100% (1)

- Dresser-Rand: Service ManualDocument1 pageDresser-Rand: Service ManualTu PhamNo ratings yet

- Waukesha Gas Engines VHP L7042GLDocument2 pagesWaukesha Gas Engines VHP L7042GLrohizatNo ratings yet

- Waukesha ESM II Packaging GuideDocument48 pagesWaukesha ESM II Packaging Guidefery100% (3)

- VHP Series Five L7044Gsi S5: 1900 BHP (1416 KWB) at 1200 RPMDocument2 pagesVHP Series Five L7044Gsi S5: 1900 BHP (1416 KWB) at 1200 RPMJeff LangleyNo ratings yet

- 0pen First 6264Document1 page0pen First 6264Camilo Andres Tabares50% (2)

- Waukeshau - Installation and Application Manual PDFDocument272 pagesWaukeshau - Installation and Application Manual PDFRashid Mahmood100% (1)

- VHP Alarms & Shutdown Setpoints S-8382-02Document2 pagesVHP Alarms & Shutdown Setpoints S-8382-02Asif Mahmood100% (1)

- WSHA SB 14-3071 - Engine Vibration and Vibration Level Acceptability Guidelines For Waukesha Gas EngineDocument4 pagesWSHA SB 14-3071 - Engine Vibration and Vibration Level Acceptability Guidelines For Waukesha Gas EngineCamilo Andres Cardozo Fajardo100% (4)

- Waukesha Engines & Enginator Systems InstallationDocument274 pagesWaukesha Engines & Enginator Systems InstallationAgustinus KNo ratings yet

- Waukesha 7101 SpecDocument4 pagesWaukesha 7101 SpecDennis Daniel100% (1)

- Cec Ignition Madule O&m PDFDocument142 pagesCec Ignition Madule O&m PDFFaisal Naeem100% (3)

- Troubleshooting G3600A4 PDFDocument9 pagesTroubleshooting G3600A4 PDFEustacio MenesesNo ratings yet

- FORM 398 - 6 Special Tools CatalogDocument102 pagesFORM 398 - 6 Special Tools CatalogAlexandrNo ratings yet

- CH 13Document32 pagesCH 13hirenpatel_universalNo ratings yet

- Solved ProblemsDocument15 pagesSolved ProblemsMichaelle Angela Arnedo70% (10)

- Homework 12 SolutionsDocument6 pagesHomework 12 Solutionscalebgriffin31No ratings yet

- Jhon Sammuel - 110401044 - Tugas Motor BakarDocument5 pagesJhon Sammuel - 110401044 - Tugas Motor BakarAkhun NastiNo ratings yet

- Thermal CyclesDocument6 pagesThermal CyclesSathish Kasilingam0% (1)

- Gas Power CyclesDocument76 pagesGas Power CyclesJuan JoseNo ratings yet

- Air Standard CycleDocument15 pagesAir Standard CyclePrakhar Deep RanaNo ratings yet

- Doc. No. 14 - 42 12 140 - VADocument40 pagesDoc. No. 14 - 42 12 140 - VAAtandho Gama MagwasyarNo ratings yet

- ThermodynamicsDocument79 pagesThermodynamicstixy2013No ratings yet

- CAT Care Seminar On Trouble Shooting For Gas Engine: Presented by Md. Kamal Pervez, Manager Trouble Shooting AshuliaDocument30 pagesCAT Care Seminar On Trouble Shooting For Gas Engine: Presented by Md. Kamal Pervez, Manager Trouble Shooting Ashuliashakibur rahmanNo ratings yet

- CPI Rlx100-Engine PDFDocument34 pagesCPI Rlx100-Engine PDFFelipe Naxo Becerra ArriagadaNo ratings yet

- Application of Variable Geometry Turbine Turbochargers To Gasoline Engines-A ReviewDocument16 pagesApplication of Variable Geometry Turbine Turbochargers To Gasoline Engines-A ReviewTugulschi NichitaNo ratings yet

- ESP PRP: EngineDocument7 pagesESP PRP: EngineThanh Trúc Đặng HuỳnhNo ratings yet

- Timing Belt Replacement IntervaDocument5 pagesTiming Belt Replacement IntervaDale PercyNo ratings yet

- Formula Sheet: Steam Power PlantDocument2 pagesFormula Sheet: Steam Power Planthamza ahmadNo ratings yet

- 2020 - Mincon MP80 DTH Hammer - Parts and Specifications SheetDocument2 pages2020 - Mincon MP80 DTH Hammer - Parts and Specifications SheetEmrah MertyürekNo ratings yet

- Dynapac CA150Document2 pagesDynapac CA150arief priyantoNo ratings yet

- Assembly and Part Drawing: Water-Cooled Diesel EngineDocument2 pagesAssembly and Part Drawing: Water-Cooled Diesel Enginenelson moralesNo ratings yet

- 5.0/5.7 Torque Values: Connecting Rod NutDocument4 pages5.0/5.7 Torque Values: Connecting Rod Nutjuan carlos tavizonNo ratings yet

- YBR 125 Service Manual Pt1Document330 pagesYBR 125 Service Manual Pt1sirlancelotksaNo ratings yet

- Shaft Sagging and HogingDocument3 pagesShaft Sagging and Hoging'Sam Kay' Olorunsola50% (2)

- Isuzu Engine Diagnostics PDFDocument2 pagesIsuzu Engine Diagnostics PDFJorge R RojasNo ratings yet

- Information Service: Electric EGR Valves (Renault, Opel)Document3 pagesInformation Service: Electric EGR Valves (Renault, Opel)Popa AurelNo ratings yet

- FDB - Parts Manual Vol I 793D Dec 2011Document1,206 pagesFDB - Parts Manual Vol I 793D Dec 2011Oliver100% (1)

- Stirling Engine PDFDocument14 pagesStirling Engine PDFKhandmaa BayarbatNo ratings yet

- Thermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodDocument6 pagesThermal Analysis and Optimization of I.C. Engine Piston Using Finite Element MethodAnirudhNo ratings yet

- Cg47ej Cg47ej (L) Cg47ej (T) Cg47ey (T) PDFDocument156 pagesCg47ej Cg47ej (L) Cg47ej (T) Cg47ey (T) PDFGabriel Reiriz SanchezNo ratings yet

- (Electrical) M & E Major Equipment Delivery ScheduleDocument1 page(Electrical) M & E Major Equipment Delivery SchedulePaul KwongNo ratings yet

- Ariel Compressor JGH-EDocument4 pagesAriel Compressor JGH-EDante Cabrera GuzmanNo ratings yet

- Blacktop ServiceDocument2 pagesBlacktop ServiceRenzo GarciaNo ratings yet

- Jennings Pipe CalcDocument3 pagesJennings Pipe CalcWhyspeedkingNo ratings yet

- Description and Operation: 303-01B-10 Engine - 3.0L 303-01B-10Document11 pagesDescription and Operation: 303-01B-10 Engine - 3.0L 303-01B-10Troy J GautreauNo ratings yet

- Interface Spec NY 20080318 Komplett Ver2Document28 pagesInterface Spec NY 20080318 Komplett Ver2Thong Chan100% (1)

- October 2021 in Cal DVD Cover LetterDocument4 pagesOctober 2021 in Cal DVD Cover LetterJohn MkCito KINo ratings yet

- 439-445 Small EngineDocument8 pages439-445 Small EngineLarry CarrNo ratings yet

- 1 ManualDocument441 pages1 ManualMaksym KovalchukNo ratings yet

- Manual Motor 721-821e Parte 1Document50 pagesManual Motor 721-821e Parte 1Diego ResendeNo ratings yet

- Dakar 150Document87 pagesDakar 150zepedaguzmanNo ratings yet

- Mechanical (Including Torque) (Cylinder Head Assembly) - ALLDATA Repair - Sienna 3.5LtsDocument8 pagesMechanical (Including Torque) (Cylinder Head Assembly) - ALLDATA Repair - Sienna 3.5LtsFran SanchezNo ratings yet