Professional Documents

Culture Documents

Compressive and Flexural Strength Test of Hydraulic Cement Mortar

Uploaded by

MayolitesCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compressive and Flexural Strength Test of Hydraulic Cement Mortar

Uploaded by

MayolitesCopyright:

Available Formats

Technological University of the Philippines

Ayala Boulevard, Ermita, Manila

College of Engineering

Department of Civil Engineering

CE 49L 4A

Construction Materials and Testing, Lab.

Experiment No. 4

COMPRESSIVE AND FLEXURAL STRENGTH TEST

OF HYDRAULIC CEMENT MORTAR

Fesalbon, Mayson R.

10-205-041

Date of Submission: September 19, 2013

Engr. Reynaldo O. Baarde

Instructor

EXPERIMENT NO. 4

COMPRESSIVE AND FLEXURAL STRENGTH TEST

OF HYDRAULIC CEMENT MORTAR

I. OBJECTIVE

To determine the compressive and flexural strength of hydraulic cement mortar

II. MAIN PRINCIPLE

Strength of cement usually gives an overall picture of the quality of the resulting concrete. The

strength of concrete structure is directly related to the strength of hardened cement paste.

Strength gain in concrete is the result of hardening of the cement paste. Direct compressive test

of mortar specimen is a form of evaluation to determine the quality of cement.

Flexural stress is expressed in terms of the modulus od rupture that corresponds to the maximum

tensile strength at peak flexural load. Prior to this, a mortar mix is prepared and then molded to

form beam specimens. These specimens are then cured for different ages. After the specimens

attained the specimen age, they are then subjected to flexural strength test. The ages are usually

24 hours, 3 days, 7 days and 28 days.

III. APPARATUS NEEDED

1. Universal Testing Machine (UTM) and accessories

2. Upper spherical block and fixed lower seat block

3. Mechaelis Flexure tester

4. Weighing Scale

IV. PREPARATION

1. Proper accessories of UTM should be attached (upper spherical seat, lower fixed seat block)

prior to zero calibration of the machine.

2. All test specimens shall be tested within the permissible tolerance.

Test Age Tolerance (hr.)

24 Hours + 0.5

3 Days + 1.0

7 Days + 3.0

28 Days + 12.0

3. All surfaces of the specimen where the load will be applied must be flat and smooth.

4. The operator of the UTM must have thorough knowledge of the machine.

V. TEST PROCEDURE

A. Preparation of UTM

1. Attach the accessories. Warm-up the machine for at least 5 minutes in order to

ensure smooth circulation of oil in the hydraulic system.

2. Calibrate to zero the UTM as follows:

a. Move the lower crosshead by pressing the UP/DOWN crosshead button to a

significant clearance from the table (preferably not less than 5cm)

b. Adjust the load control knob to OPEN position to raise the UTM table to a

height of about 2cm, and then put knob in HOLD position.

c. Set the zero knob at the bottom of the dynamometer such that the pointer will

be in zero position.

d. It is preferably to keep the UTM table in this raised position and the load

control knob in HOLD position.

p

B. Compression Test Using the UTM

1. Position the specimen between the raised table and lower crosshead. There should

be enough clearance of about 2 to 3mm between the specimen and the lower

crosshead. It is very important to prevent sudden contact between the crossheads or

the lower crosshead and specimen for this will result in a gear lock-up.

2. Load is applied by raising the UTM table gradually. This is done by adjusting the load

control knob beyond LOAD markto raise the table. As soon as the lower crosshead

touches the specimen, the load control knob should be returned to LOAD mark. Initial

loading is indicated by the movement of the auxiliary pointer to the center.

3. Adjust the loading rate by turning the load control knob. See to it that the desired

loading rate is attained immediately while the specimen is still at its elastic stage.

Make no more adjustment in the load control when the specimen is already yielding.

If a load pacer is available, the loading rate at the elastic range should be in

accordance to the movement of the pacer.

4. As the pointer goes back to zero, return also the control knob to zero. This is an

indication that the specimen had already failed. Record the reading indicated by the

maximum load pointer. The load is divided by the area will give the strength in force

per unit area units.

5. The report shall include the following:

a. Specimen identification, age, diameter, length and cross-sectional area

b. Maximum load

c. Compressive strength

d. Remarks

C. Flexural Test Using the Mechaelis Flexure Tester

1. Place the Mechaelis flexure tester flat on a rigid spot.

2. Each part of the tester must be cleaned and checked.

3. Remove the beam specimen from the curing tank within the permissible tolerance

time for the given test age.

4. Wipe the specimen with damp cloth to remove the dirt.

5. Weigh each specimen.

6. Detach the bucket and upper roller from the main unit so that the specimen can be

positioned to the specimen attachment. In positioning the specimen, the observing

hole should be in line with the central line of the specimen. Note that the specimen

should be turn to its side with respect to its position as molded.

7. Adjust the balance weight so that the lever where the bucket is attached would be

horizontal. After balancing the lever, do not re-adjust the balance weight until the test

for that particular specimen is finished.

8. Insert the upper roller to its position.

9. Attach the bucket to the main unit. Balance the adjusting handle so that the lead

shots will directly fall in the bucket during the loading operation.

10. To start loading, the loading lever should be pulled up and quickly released.

Immediately after the loading lever is pulled, the lead shots will start to fall to the

bucket.

11. When the specimen breaks the bucket drops to the bucket receiver causing the time

gate to close and stops the loading. Weigh the bucket together with the lead shots.

The resulting weight multiplied by 11.71875 would give the flexural strength of the

specimen.

12.

VI. CALCULATIONS

Compressive Strength

Where: = Compressive strength (kg/cm

2

)

P

= Maximum applied force (kg)

A = Cross-sectional area of the specimen (cm

2

)

Flexural Strength

Where: f

= Flexural strength (kg/cm

2

)

W = Weight of bucket and and the lead shots

b,h =Dimensions of the cross-sectional area of the

beam (cm)

VII. DATA AND RESULTS

For Compressive Strength

Weight

(kg)

Length

(cm)

D

1

(cm)

D

2

(cm)

D

ave

(cm)

Area

(cm

2

)

UTM

Reading

(kgf)

Compressive

Strength

(kgf/cm

2

)

Cylinder

1

0.43808 10.20 5.20 5.20 5.20 21.237 1810 85.228

Cylinder

2

0.43600 10.30 5.10 5.20 5.15 20.831 1460 70.089

Weight

(kg)

Sides

(cm)

Area

(cm

2

)

UTM

Reading

(kgf)

Compressive

Strength

(kgf/cm

2

)

Cube 0.29070 5.20 27.04 2900 107.249

For Flexural Strength

Weight

(kg)

Length

(cm)

Width

(cm)

Depth

(cm)

W

(kg)

Flexural

Strength

(kgf/cm

2

)

Beam 1 0.55200 16.30 4.10 4.10 3.185 34.659

Beam 2 0.55639 16.25 4.20 4.10 2.995 31.816

Beam 3 0.55408 16.30 4.10 4.10 2.970 32.320

VIII. SAMPLE COMPUTATIONS

For Compressive Strength

Cylinder 1

Cylinder 2

Cube

For Compressive Strength

Beam 1

Beam 2

Beam 3

IX. DISCUSSION AND OBSERVATION

A. Discussion

Compressive Strength Test. The test comprises of the determination of the maximum applied

force by the Universal Testing Machine (UTM) which causes failure on the specimen. As

exhibited in real-life scenario, mortar acts as a binder so that materials will be intact. Consider

a wall which is applied by a compressive force. The force was transmitted to the hollow

blocks that makes up the wall and then transmitted to mortar. Failure for the mortar to resist

the load means a failure in the whole structure. But this test cannot assure the real strength

of a mortar. It is just only one of the many parameters that can measure how strong a mortar

is.

Flexural Strength Test. This test accounts for the resistance of beam to bending. In real-life

scenario, structures must also resist applied moments acted on them. Since these moments

are also transmitted to the joints of the structure, the flexural strength of the mortar must be

determined. This can be determined using the Mechaelis flexure test where the total weight

of the lead shots material that causes the beam to break serves as the moment applied on

both ends of the beam.

B. Observations

During the experiment, the following was observed:

1. The mode of failure of the cubic and cylindrical specimen is cracking at its

surface at about equal to its height

2. Lead shots in the Mechaelis flexure test are very small and cannot be

magnetized.

3. The mode of failure of beams in Mechaelis flexure test is breaking at about the

midspan of the beam.

4. Compression Test in the UTM takes more time than the flexural test using the

Mechaelis flexure test.

X. CONCLUSION

The compressive strength is determined as the maximum applied force per unit area of the that

cause the specimen to crack.

Where: = Compressive strength (kg/cm

2

)

P

= Maximum applied force (kg)

A = Cross-sectional area of the specimen (cm

2

)

The flexural strength is determined as the maximum applied moment that causes rupture of the

beam in the Mechaelis flexure apparatus

Where: f

= Flexural strength (kg/cm

2

)

W = Weight of bucket and and the lead shots

b,h =Dimensions of the cross-sectional area of the

beam (cm)

You might also like

- The 20 Cases - Cases Involving Ethical Issues in Civil Engineering ProfessionDocument81 pagesThe 20 Cases - Cases Involving Ethical Issues in Civil Engineering ProfessionMayolites71% (21)

- Civil Engineering Material Lab ReportDocument13 pagesCivil Engineering Material Lab Reportsharrmaa100% (1)

- Determination of Aggregate Crushing ValueDocument10 pagesDetermination of Aggregate Crushing ValueArivalagan Revichandran100% (1)

- Discussions Design Mix Concrete (Slump, Compacting, Design Form)Document6 pagesDiscussions Design Mix Concrete (Slump, Compacting, Design Form)Salmah AbasNo ratings yet

- For Highway Aggregate Crushing Value Lab Report (Ombz)Document7 pagesFor Highway Aggregate Crushing Value Lab Report (Ombz)ombani100% (5)

- Design of Wall Footing with LoadsDocument16 pagesDesign of Wall Footing with LoadsMayolitesNo ratings yet

- Design of Wall Footing with LoadsDocument16 pagesDesign of Wall Footing with LoadsMayolitesNo ratings yet

- Specific Gravity of Coarse AggregatesDocument5 pagesSpecific Gravity of Coarse AggregatesMayolitesNo ratings yet

- Unit Weight of AggregatesDocument5 pagesUnit Weight of AggregatesMayolites33% (3)

- Design and Analysis of G+8 Commercial Building Using Staad ProDocument8 pagesDesign and Analysis of G+8 Commercial Building Using Staad ProVikaskumar ReddyNo ratings yet

- Soil Lab Report Format 1Document10 pagesSoil Lab Report Format 1ZiaullahNo ratings yet

- Conrete Mix LabDocument22 pagesConrete Mix LabTarek Cheaib100% (4)

- Compressive Strength of ConcreteDocument9 pagesCompressive Strength of ConcreteAmos kiprutoNo ratings yet

- Slump TestDocument8 pagesSlump TestEn Long Bglong100% (2)

- 4 Unconfined CompressionDocument12 pages4 Unconfined CompressionShoaib Alam100% (1)

- Geotechnical Engineering Lab Report 2Document7 pagesGeotechnical Engineering Lab Report 2IanNo ratings yet

- UU Triaxial Test (Quick TestDocument4 pagesUU Triaxial Test (Quick TestSharunieRavikumar33% (3)

- Flexural Strength of ConcreteDocument3 pagesFlexural Strength of ConcretevikasNo ratings yet

- CBR TestDocument13 pagesCBR TestFaeez ZainNo ratings yet

- Los Angeles Abrasion TestDocument5 pagesLos Angeles Abrasion Testদেওয়ানসাহেবNo ratings yet

- Direct Shear TestDocument24 pagesDirect Shear TestObaid Khalid100% (14)

- Compressive Strength of ConcreteDocument3 pagesCompressive Strength of ConcreteNitisha Rathore100% (3)

- Highway California Bearing Ratio TestDocument17 pagesHighway California Bearing Ratio TestJibul temulakNo ratings yet

- Determination of Aggregate CrushingDocument8 pagesDetermination of Aggregate CrushingPoovan Rajaratnam100% (2)

- Strength Test On ConcreteDocument23 pagesStrength Test On ConcreteMukesh Kumar SamotaNo ratings yet

- Proctor Compaction TestDocument8 pagesProctor Compaction TestIreneNo ratings yet

- Determination of Field Density by Core Cutter MethodDocument3 pagesDetermination of Field Density by Core Cutter MethodYogendra Patil100% (1)

- 34) Extraction of Bitumen From Paving MixturesDocument6 pages34) Extraction of Bitumen From Paving MixturesPn EkanayakaNo ratings yet

- Lab7 ReportDocument4 pagesLab7 ReporthelensongyNo ratings yet

- Group 3b Setting Time of CementDocument7 pagesGroup 3b Setting Time of CementKenghie Dela CruzNo ratings yet

- Lab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Document3 pagesLab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Kashif IqbaljNo ratings yet

- Unconfined Compression TestDocument8 pagesUnconfined Compression TestMohdIkrami100% (1)

- CBR Test Determines Subgrade StrengthDocument5 pagesCBR Test Determines Subgrade StrengthSamanta Pandey100% (1)

- Falling Head Permeability Lab ReportDocument11 pagesFalling Head Permeability Lab ReportfatinNo ratings yet

- Concrete Lab Manual Normal Consistency TestDocument3 pagesConcrete Lab Manual Normal Consistency TestKamran AliNo ratings yet

- Determination of PenetrationDocument57 pagesDetermination of Penetrationtunlaji0% (2)

- Objective of Concrete Mix DesignDocument11 pagesObjective of Concrete Mix DesignJude Prasanna0% (1)

- Civil Lab Test 1Document4 pagesCivil Lab Test 1Kalomenni90% (10)

- Design of timber compression membersDocument28 pagesDesign of timber compression membersPablo CartagenaNo ratings yet

- Penetration Test On BituminousDocument3 pagesPenetration Test On BituminousM Zeeshan Haider100% (1)

- Compressive Strength Test ProcedureDocument9 pagesCompressive Strength Test ProcedureAnique Ur RehmanNo ratings yet

- Hydrometer Analysis Lab Report: Soil Particle Size DistributionDocument7 pagesHydrometer Analysis Lab Report: Soil Particle Size DistributiondexNo ratings yet

- Liquid Limit TestDocument14 pagesLiquid Limit TestKin Hamzah100% (1)

- Compressive Strength of Hydraulic CementDocument3 pagesCompressive Strength of Hydraulic CementEr Mansoor HussainNo ratings yet

- Unit Weight Determination in SoilDocument11 pagesUnit Weight Determination in SoilJoyzelle Janiola100% (1)

- Aggregate Impact ValueDocument8 pagesAggregate Impact ValueAnis Nurfarahanim Abdul HalimNo ratings yet

- Experiment Penetration TestDocument6 pagesExperiment Penetration TestKyra Claire Zaharr90% (42)

- Experiment 3 Compaction TestDocument5 pagesExperiment 3 Compaction TestAnis Nurfarahanim Abdul Halim0% (1)

- 6bitumen Extraction TestDocument4 pages6bitumen Extraction TestSushrutNo ratings yet

- Falling Head Permeability Lab TestDocument6 pagesFalling Head Permeability Lab TestHamierul MohamadNo ratings yet

- Highway Lab Report 9,10 and 11Document22 pagesHighway Lab Report 9,10 and 11Abdallah AlhasanNo ratings yet

- Falling Heat Permeability TestDocument10 pagesFalling Heat Permeability TestAiryn UyienNo ratings yet

- Experiment Specific GravityDocument7 pagesExperiment Specific Gravitypj_bankNo ratings yet

- CONCLUSION Bitumen TestDocument1 pageCONCLUSION Bitumen TestFirash Imran100% (1)

- Unconfined Compression TestDocument11 pagesUnconfined Compression TestAmiruddin JSNo ratings yet

- Standard Proctor Compaction TestDocument7 pagesStandard Proctor Compaction TestGnabBang75% (4)

- Falling Head Permeability TestDocument8 pagesFalling Head Permeability Testdwivediashish2100% (2)

- Compressive Strength of Concrete - Cube Test, Procedure, Apparatus & ResultsDocument30 pagesCompressive Strength of Concrete - Cube Test, Procedure, Apparatus & ResultsAnonymous Qm0zbNkNo ratings yet

- Consolidation Test by RatiyalaDocument6 pagesConsolidation Test by RatiyalaBhawanujan PerinparajaNo ratings yet

- Practical 2 Soil CompactionDocument5 pagesPractical 2 Soil CompactionBanujan KuhaneswaranNo ratings yet

- Celebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985From EverandCelebrating Literacy in the Rwenzori Region: Lest We Forget: a Biographical Narrative of Uganda’S Youngest Member of Parliament, 1980-1985No ratings yet

- CMT Chapter7 UTMDocument9 pagesCMT Chapter7 UTMAidan Paul Arlanza EscotoNo ratings yet

- BASIC CIVIL ENGINEERING MANUAL Updated On 28.6.22Document14 pagesBASIC CIVIL ENGINEERING MANUAL Updated On 28.6.22Not RookieNo ratings yet

- Civil Engineering Department Lab ManualDocument47 pagesCivil Engineering Department Lab Manualubaid quaziNo ratings yet

- SM Lab ManualsDocument27 pagesSM Lab ManualspraveenampilliNo ratings yet

- Strength of Materials Lab TestsDocument38 pagesStrength of Materials Lab Testsamns99No ratings yet

- SpecificationDocument4 pagesSpecificationMayolitesNo ratings yet

- Your Guide To The Magic and Mystery of APA StyleDocument27 pagesYour Guide To The Magic and Mystery of APA StylemodlieNo ratings yet

- Types of Shoring for Building ConstructionDocument7 pagesTypes of Shoring for Building ConstructionMayolites100% (1)

- Math Set 2Document5 pagesMath Set 2MayolitesNo ratings yet

- Staad - Pro V8iDocument42 pagesStaad - Pro V8iMayolites0% (1)

- Problem Set in MathematicsDocument8 pagesProblem Set in MathematicsMayolitesNo ratings yet

- Introduction To Water Resources EngineeringDocument11 pagesIntroduction To Water Resources EngineeringMayolites100% (1)

- Water HammerDocument34 pagesWater HammerM Favio Palacios Solórzano100% (1)

- TUP Soil Mechanics AssignmentDocument15 pagesTUP Soil Mechanics AssignmentMayolitesNo ratings yet

- Tensile Strength of Reinforcement Steel Bar PDFDocument4 pagesTensile Strength of Reinforcement Steel Bar PDFMayolitesNo ratings yet

- TUP Soil Mechanics AssignmentDocument15 pagesTUP Soil Mechanics AssignmentMayolitesNo ratings yet

- Mechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownDocument1 pageMechanics of Solids: Bela I. Sandor Ryan Roloff Stephen M. Birn Maan H. Jawad Michael L. BrownkprasannanNo ratings yet

- Engineering Structures: SciencedirectDocument12 pagesEngineering Structures: Sciencedirectyasemin bürüngüzNo ratings yet

- Offshore Pipeline Hydraulic and Mechanical AnalysesDocument25 pagesOffshore Pipeline Hydraulic and Mechanical AnalysesEslam RedaNo ratings yet

- Effect of Speration in Modified BitumenDocument12 pagesEffect of Speration in Modified BitumenyadavameNo ratings yet

- Physics Grade 11 Gas Laws and WavesDocument6 pagesPhysics Grade 11 Gas Laws and WavesNatalia WhyteNo ratings yet

- Physics: Pearson EdexcelDocument16 pagesPhysics: Pearson EdexcelRichard Davidson12100% (1)

- Comparison of Design of Steel Roof Truss Using IS 875 and SP 38Document3 pagesComparison of Design of Steel Roof Truss Using IS 875 and SP 38anbugobiNo ratings yet

- Structural Health Monitoring: Abin Paul Roll No:4 S7, CE-ADocument34 pagesStructural Health Monitoring: Abin Paul Roll No:4 S7, CE-AAnjana kpNo ratings yet

- CGN 3421 - Numerical Methods Lecture 3Document15 pagesCGN 3421 - Numerical Methods Lecture 3sori1386No ratings yet

- 79 PDFDocument4 pages79 PDFHolayilNo ratings yet

- 1 4 Bookmark A Crash Course in Forces MotionDocument2 pages1 4 Bookmark A Crash Course in Forces Motionapi-115513756No ratings yet

- NCHRP RPT 242 PDFDocument85 pagesNCHRP RPT 242 PDFDavid Drolet TremblayNo ratings yet

- Name: Teacher: Date: Score:: Identify The Properties of MathematicsDocument2 pagesName: Teacher: Date: Score:: Identify The Properties of MathematicsMacPapitaNo ratings yet

- Cara SamplingDocument8 pagesCara SamplingAngga Dwi PutrantoNo ratings yet

- PRC New ShowDocument31 pagesPRC New ShowxyxyquazNo ratings yet

- Docc 1990Document7 pagesDocc 1990swchenNo ratings yet

- Ewald SphereDocument57 pagesEwald SphereMohammad Rameez0% (1)

- Geogrids in Walls and SlopesDocument6 pagesGeogrids in Walls and SlopesYong Cheng Hung100% (1)

- Dr. Mezmer's Psychopedia of Bad PsychologyDocument378 pagesDr. Mezmer's Psychopedia of Bad PsychologyArt Marr100% (5)

- Electrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 CreditsDocument43 pagesElectrical Engineering BA (B), Analog Electronics, ET065G 6 Credits ET064G 7.5 Creditsdev-nullNo ratings yet

- Design of A Digital Control System and Path Planning Module For The ED-7220C Robot ArmDocument66 pagesDesign of A Digital Control System and Path Planning Module For The ED-7220C Robot ArmTarek Bmr100% (3)

- Levee Drain Analysis in SlideDocument12 pagesLevee Drain Analysis in SlideAdriRGNo ratings yet

- 2 4228Document13 pages2 4228Huneza AtaNo ratings yet

- MechanicsDocument558 pagesMechanicsfejiloNo ratings yet

- Computer Networks Radio Waves: Submitted By: 1.naina Gupta 2.sunidhi Dwivedi Submitted To: Ms. Asha Ma'amDocument9 pagesComputer Networks Radio Waves: Submitted By: 1.naina Gupta 2.sunidhi Dwivedi Submitted To: Ms. Asha Ma'amsantaNo ratings yet

- A2 Chapter 14 OscillationDocument61 pagesA2 Chapter 14 OscillationkwaikunNo ratings yet

- Airborne Wind Energy SystemDocument27 pagesAirborne Wind Energy SystemAbin BabyNo ratings yet

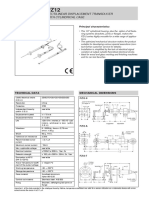

- Rectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical DimensionsDocument2 pagesRectilinear Displacement Transducer With Cylindrical Case: Technical Data Mechanical Dimensionsl561926No ratings yet

- JEE Class Companion Physics: Module-9Document227 pagesJEE Class Companion Physics: Module-9RupakNo ratings yet