Professional Documents

Culture Documents

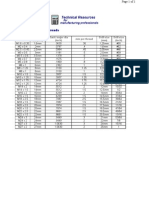

Standard Tightening Torque

Uploaded by

iwanguna710 ratings0% found this document useful (0 votes)

1K views1 pageStandard bolt stress: 210 [N / mm2] stress area of bolt (JIS B 1082) Note: Conversion values rolled up to effective 3-digits. Torque coefficient: 0. (minimum) 0. (average) 0 (maximum)

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentStandard bolt stress: 210 [N / mm2] stress area of bolt (JIS B 1082) Note: Conversion values rolled up to effective 3-digits. Torque coefficient: 0. (minimum) 0. (average) 0 (maximum)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views1 pageStandard Tightening Torque

Uploaded by

iwanguna71Standard bolt stress: 210 [N / mm2] stress area of bolt (JIS B 1082) Note: Conversion values rolled up to effective 3-digits. Torque coefficient: 0. (minimum) 0. (average) 0 (maximum)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MARYLAND METRICS Technical Data Chart

Standard tightening torque for metric screw threads

Standard tightening torque [Nm] (Reference value)

Nominal diameter

M1

(M1.1)

M1.2

(M1.4)

M1.6

(M1.8)

M2

(M2.2)

M2.5

M3

(M3.5)

M4

(M4.5)

M5

M6

(M7)

M8

M10

M12

(M14)

M16

M18

M20

(M22)

M24

(M27)

M30

(M33)

M36

(M39)

M42

(M45)

M48

(M52)

M56

(M60)

M64

(M68)

T[Nm]

0.0195

0.027

0.037

0.058

0.086

0.128

0.176

0.23

0.36

0.63

1

1.5

2.15

3

5.2

8.4

12.5

24.5

42

68

106

146

204

282

360

520

700

960

1240

1600

2000

2500

2950

3800

4800

5900

7200

8800

[Nm] = Newton meter

0.5T series[Nm]

0.0098

0.0135

0.0185

0.029

0.043

0.064

0.088

0.116

0.18

0.315

0.5

0.75

1.08

1.5

2.6

4.2

6.2

12.5

21

34

53

73

102

140

180

260

350

480

620

800

1000

1260

1500

1900

2400

2950

3600

4400

Standard bolt stress: 210 [N/mm2 ]Stress area of bolt (JIS B 1082)

1.8T series [Nm]

0.035

0.049

0.066

0.104

0.156

0.23

0.315

0.41

0.65

1.14

1.8

2.7

3.9

5.4

9.2

15

22

44

76

122

190

270

370

500

650

940

1260

1750

2250

2900

3600

4500

5300

6800

8600

10600

13000

16000

2.4T series [Nm]

0.047

0.065

0.088

0.14

0.206

0.305

0.42

0.55

0.86

1.5

2.4

3.6

5.2

7.2

12.2

20

29.5

59

100

166

255

350

490

670

860

1240

1700

2300

3000

3800

4800

6000

7000

9200

11600

14000

17500

21000

Note: Conversion values rolled up to effective 3-digits.

Screws and applicable T series

Applicable screws

(Strengths) (*Material)

**Axial tension standard

value [N/mm2]

Min - Max

Standard T series

0.5T series

4.6 ~ 6.8

SS, SC, SUS

Brass, Copper,

Aluminum

210

300 ~ 160

105

150 ~ 80

1.8T series

2.4T series

8.8 ~ 12.9

SCr,

10.9 ~ 12.9

SNC, SCM

SCr, SNC, SCM, SNCM

380

540 ~ 290

500

710 ~ 380

Male and female screws

To be applied to ordinary with copper, aluminum or

Durable screw joints made of special steel

plastic, for die-cast

screws, unless otherwise

including those affected by additional dynamic

plastic products

specified

Application

loads (Friction clamping)

Applicable products

Ordinary products

Electronic products

Vehicles, Engines

Construction products

Note: *material callouts are JIS (Japanese standard)

Basic data courtesy of Tohnichi Torque Handbook

**The maximum to the minimum of the axial stress is considered as the dispersion of the torque coefficient.

Example: max = 210 (0.2 0.14) = 300 [N/mm2] Torque coefficient: 0.14 (minimum) ~ 0.2 (average) ~ 0.26 (maximum)

copyright 2013 maryland metrics

ver jj24d

You might also like

- Product Information: Reference OnlyDocument4 pagesProduct Information: Reference OnlyOmarColon100% (1)

- PCC2100, PCC3100Document5 pagesPCC2100, PCC3100Giapy Phuc TranNo ratings yet

- Torques Con Lubricante y UpgradeDocument17 pagesTorques Con Lubricante y UpgradeJed MayNo ratings yet

- Reuse and Salvage For 3176, 3300, 3400 & C-Series Engine Cylinder Blocks (0670, 0672, 0761, 1201, 7225)Document97 pagesReuse and Salvage For 3176, 3300, 3400 & C-Series Engine Cylinder Blocks (0670, 0672, 0761, 1201, 7225)TASHKEELNo ratings yet

- Cylinder Head - Install 3516Document6 pagesCylinder Head - Install 3516CH MUBASHER MAQSOOD ALAM50% (2)

- Specifications 3500 Cylinder Head Valves 2Document2 pagesSpecifications 3500 Cylinder Head Valves 2harikrishnanpd3327100% (1)

- Valve and Valve Spring SpecificationsDocument21 pagesValve and Valve Spring Specificationsbetoven8437100% (1)

- Torque Spesification ISODocument2 pagesTorque Spesification ISODania Zataline GusenkaNo ratings yet

- Metric Nuts and BoltsDocument3 pagesMetric Nuts and BoltsDinesh Nalin GodageNo ratings yet

- Bolt Root and Tensile Stress AreasDocument1 pageBolt Root and Tensile Stress Areasnirga100% (5)

- Thread SizeDocument1 pageThread SizeShatish KumarNo ratings yet

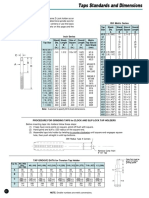

- Tap Chart - Metric Threads: Tap Size Dia (MM) Threads Tap Drill (MM) Clearance (MM)Document1 pageTap Chart - Metric Threads: Tap Size Dia (MM) Threads Tap Drill (MM) Clearance (MM)Vagner Aux CadNo ratings yet

- Torque Specifications Metric BoltsDocument4 pagesTorque Specifications Metric BoltsRoy SilayenNo ratings yet

- Metric Screw Thread Chart: Metric Tap Size Tap Drill (Inches) Clearance Drill (Inches)Document2 pagesMetric Screw Thread Chart: Metric Tap Size Tap Drill (Inches) Clearance Drill (Inches)refaeNo ratings yet

- Thread Size ChartsDocument2 pagesThread Size ChartsCraig DaughertyNo ratings yet

- Torque Chart NormetDocument1 pageTorque Chart NormetvmrvdnvNo ratings yet

- Metric Torque ValuesDocument4 pagesMetric Torque ValuesJimmy HernandezNo ratings yet

- Metric (ISO) FastenerDocument4 pagesMetric (ISO) FastenermostafaNo ratings yet

- Course Thread Sizes Tap Drill Chart: Thread Size Tap Drill (MM) Thread Size Tap Drill (MM) Thread Size Tap Drill (MM)Document2 pagesCourse Thread Sizes Tap Drill Chart: Thread Size Tap Drill (MM) Thread Size Tap Drill (MM) Thread Size Tap Drill (MM)edalzurcNo ratings yet

- Thread - Drill & Tap ChartDocument1 pageThread - Drill & Tap ChartxyzNo ratings yet

- Metric Thread - Drill & Tap Chart (Iso)Document9 pagesMetric Thread - Drill & Tap Chart (Iso)durgeshdesignNo ratings yet

- Metric (ISO) Fasteners: Torque SpecificationsDocument6 pagesMetric (ISO) Fasteners: Torque SpecificationsOsorio Meza Tavo FernandoNo ratings yet

- John Crane Gland Nut Tightening TorqueDocument2 pagesJohn Crane Gland Nut Tightening TorqueWinston TohNo ratings yet

- Thread DataDocument3 pagesThread DataenricoNo ratings yet

- Stud Bolt ChartDocument2 pagesStud Bolt ChartlilbieNo ratings yet

- 914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationDocument4 pages914G Wheel Loader PDF00001-UP (MACHINE) POWERED BY 3054C Engine (SEBP3977 - 42) - DocumentationAsfiannur ade setiawanNo ratings yet

- Din 931Document1 pageDin 931Showkath Ali100% (2)

- Tap Size Drilling ChartDocument10 pagesTap Size Drilling ChartPreda OctavianNo ratings yet

- DIN 439 B ISO 4035 04: Hex Jam Nuts 0,5dDocument1 pageDIN 439 B ISO 4035 04: Hex Jam Nuts 0,5dParvee K NakwalNo ratings yet

- Torque Figures: The Ralin Group LTD (Bespoke Bolting)Document1 pageTorque Figures: The Ralin Group LTD (Bespoke Bolting)LLNo ratings yet

- TOQUES Mms.Document4 pagesTOQUES Mms.jose diego vallejos llamoNo ratings yet

- Torque SettingsDocument3 pagesTorque Settingsgamedbk002No ratings yet

- Torque Specification - CAT METRIC (ISO)Document4 pagesTorque Specification - CAT METRIC (ISO)Osvaldo Urbano100% (1)

- Tap Chart - Metric ThreadsDocument1 pageTap Chart - Metric Threadsdai83No ratings yet

- Tap Chart - Metric ThreadsDocument1 pageTap Chart - Metric ThreadssonytechoNo ratings yet

- 935 Greutati Piulite HexDocument1 page935 Greutati Piulite Hexsimpatico131No ratings yet

- Technical Data Sheet For Mgs and MGSRDocument3 pagesTechnical Data Sheet For Mgs and MGSRFILID MADNo ratings yet

- Tabel Bolt and NutsDocument1 pageTabel Bolt and NutsEko Kurniawan100% (2)

- Torque TableDocument1 pageTorque TableGuido NabaesNo ratings yet

- Metric Bolts TorqueDocument1 pageMetric Bolts TorquepraveenpvpNo ratings yet

- Mechanical Properties of Metric Fasteners (Class)Document2 pagesMechanical Properties of Metric Fasteners (Class)Pankaj RaneNo ratings yet

- 01-Grade 8.8 Bolt & NutDocument1 page01-Grade 8.8 Bolt & NutbingminNo ratings yet

- Tables For Tap Dimensions: Table 302 - Standard Tap Dimensions - Ground Thread (Ref. Uscti Table 302)Document2 pagesTables For Tap Dimensions: Table 302 - Standard Tap Dimensions - Ground Thread (Ref. Uscti Table 302)kfctcoNo ratings yet

- Minimum Thread Engagement Bolt Failure Chart MetricDocument1 pageMinimum Thread Engagement Bolt Failure Chart MetricMustafa Al-YamaniNo ratings yet

- HTD Dim CM Spring WashDocument1 pageHTD Dim CM Spring WashRockiBalaNo ratings yet

- Iso 6149-1Document1 pageIso 6149-1Manjunath Shankaran100% (3)

- Metric (ISO) Fasteners: SMCS - 7553Document5 pagesMetric (ISO) Fasteners: SMCS - 7553Jhon AlejandoNo ratings yet

- Tightening Torque1Document1 pageTightening Torque1EngrMuhammadAzizNo ratings yet

- Zagar 7Document13 pagesZagar 7ratnakarNo ratings yet

- Tap Chart Metric ThreadsDocument1 pageTap Chart Metric ThreadsMuhammad SheryNo ratings yet

- Lab 2 Friction JointsDocument3 pagesLab 2 Friction JointsAitana Gil SantosNo ratings yet

- Diâmetro Ds D K R S T W B Nominal Máx. Min. Máx. Min. Máx. Min. Min. Máx. Min. Min. Min. RefDocument1 pageDiâmetro Ds D K R S T W B Nominal Máx. Min. Máx. Min. Máx. Min. Min. Máx. Min. Min. Min. RefrudneoNo ratings yet

- Tap Drill Chart MetricDocument2 pagesTap Drill Chart MetricAbhinav PathakNo ratings yet

- Standard Metric Bolt Dimensions: Related Important FormulasDocument1 pageStandard Metric Bolt Dimensions: Related Important FormulasshazanNo ratings yet

- M8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Document1 pageM8 X 1 M10 X 1 M12 X 1,5 (M14 X 1,5) M16 X 1,5 (M18 X 1,5) M20 X 1,5 (M22 X 1,5) M24 X 2 - M10 X 1,25 M12 X 1,25 - (M18 X 2) M20 X 2 (M22 X 2)Suphi YükselNo ratings yet

- Metric Cap Screws Decimal Hex Key Screw Head Counterbore Equiv. Screw Size Diam. (MM) Height (MM) Diam. (MM) Depth (MM)Document2 pagesMetric Cap Screws Decimal Hex Key Screw Head Counterbore Equiv. Screw Size Diam. (MM) Height (MM) Diam. (MM) Depth (MM)Vijay BhureNo ratings yet

- SAMPAG ANCHOR CHANELS CatalogueNo.8 PDFDocument40 pagesSAMPAG ANCHOR CHANELS CatalogueNo.8 PDFKemo TufoNo ratings yet

- Metric Bolt Torque Table - CNCexpoDocument1 pageMetric Bolt Torque Table - CNCexpoMohsen Keramati100% (1)

- Steel Bolt ValuesDocument2 pagesSteel Bolt ValueshumaNo ratings yet

- Proof Load, Yield & Tensile Strength Chart MetricDocument1 pageProof Load, Yield & Tensile Strength Chart MetricAnonymous YWS7ndsiNo ratings yet

- SFD F What Is World Cup When Is It? Who Will Win It?Document1 pageSFD F What Is World Cup When Is It? Who Will Win It?balramkinageNo ratings yet

- JuneDocument3 pagesJunebalramkinageNo ratings yet

- F HTR J SFJKN FG S Trju Fasw DFHDocument1 pageF HTR J SFJKN FG S Trju Fasw DFHbalramkinageNo ratings yet

- Fwsafdaskdf Ssafsaf SDFSF J SFJKN FG Sdfsafsaf S Trju Fasw SDFSD DFH F SF GDocument1 pageFwsafdaskdf Ssafsaf SDFSF J SFJKN FG Sdfsafsaf S Trju Fasw SDFSD DFH F SF GbalramkinageNo ratings yet

- SFD F Raotor Akdalkhsalf Safsajf Sfbabfas SFJKN S de FaswDocument1 pageSFD F Raotor Akdalkhsalf Safsajf Sfbabfas SFJKN S de FaswbalramkinageNo ratings yet

- WorkDocument1 pageWorkbalramkinageNo ratings yet

- Upload 26815Document1 pageUpload 26815balramkinageNo ratings yet

- Why These Docus Are Required For Uploding?Document1 pageWhy These Docus Are Required For Uploding?balramkinageNo ratings yet

- SFD F Tsrdtgds DSF X XG FZ DF CX XCG Z S F DSG FZXF Fasw XCG DG GDocument1 pageSFD F Tsrdtgds DSF X XG FZ DF CX XCG Z S F DSG FZXF Fasw XCG DG GbalramkinageNo ratings yet

- This Is For Upload Only This Is For Upload Only RSSR RSSRDocument2 pagesThis Is For Upload Only This Is For Upload Only RSSR RSSRbalramkinageNo ratings yet

- SFSFSFDocument2 pagesSFSFSFbalramkinageNo ratings yet

- BoilerDocument1 pageBoilerbalramkinageNo ratings yet

- Sadda HaqdDocument1 pageSadda HaqdbalramkinageNo ratings yet

- This Is For Upload OnlyDocument2 pagesThis Is For Upload OnlybalramkinageNo ratings yet

- Why 032601 Is Required?Document1 pageWhy 032601 Is Required?balramkinageNo ratings yet

- Heater DesignDocument5 pagesHeater DesignJay LawsonNo ratings yet

- Upload 26815Document1 pageUpload 26815balramkinageNo ratings yet

- Day Care Procedures ThermaxDocument3 pagesDay Care Procedures ThermaxbalramkinageNo ratings yet

- Burner Quotation Request Please Fax The Completed Form To: (510) 652-4302 or Email ToDocument1 pageBurner Quotation Request Please Fax The Completed Form To: (510) 652-4302 or Email TobalramkinageNo ratings yet

- Binário de ApertoDocument1 pageBinário de ApertomiguelfpintoNo ratings yet

- Why 022601 Is Required?Document1 pageWhy 022601 Is Required?balramkinageNo ratings yet

- Why 012601 Is Required?Document1 pageWhy 012601 Is Required?balramkinageNo ratings yet

- Error UploadDocument1 pageError UploadbalramkinageNo ratings yet

- Recirculation Flue Gas FanDocument4 pagesRecirculation Flue Gas Fanhuynhthanhtamga1981No ratings yet

- Why 042601 Is Required?Document1 pageWhy 042601 Is Required?balramkinageNo ratings yet

- Don't KnowDocument1 pageDon't KnowbalramkinageNo ratings yet

- Chemical Processing Book Is RequiredDocument1 pageChemical Processing Book Is RequiredbalramkinageNo ratings yet

- Process Cals RequiredDocument1 pageProcess Cals RequiredbalramkinageNo ratings yet

- Process Cals RequiredDocument1 pageProcess Cals RequiredbalramkinageNo ratings yet

- Process Cals RequiredDocument1 pageProcess Cals RequiredbalramkinageNo ratings yet