Professional Documents

Culture Documents

Molybdenum DiSulphide

Uploaded by

Jitendra KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Molybdenum DiSulphide

Uploaded by

Jitendra KumarCopyright:

Available Formats

Molybdenum DiSulphide

MoS2 is extracted from small veins in granite by crushing and flotation. In its purified state it

has a low coefficient of friction, resists heat, oxidation, common solvents , and chemicals and can be used

under extreme pressures. It shears readily and bond with ordinary engineering materials and plastics.

Due to high cost it is not seen as a replacement lubricant but offers a solution to difficult problems.

Molybdenised lubricants exist with combinations of MoS2 and oils, greases, water, soap,

solvents, silicones, and other fluids.

MoS2 is in the form of a laminar structure with a slice of molybdenum atoms being held

between to slices of Sulphur atoms. The low coefficient of friction is due to the ease of shear between

adacent Sulphur slices.

MoS2 has a melting point of !!"#

o

$

$are should be ta%en with the use of this product in relation to tightening tor&ues.

Manufacturers may be &uote figures under the assumption that lubrication of the nut is by light mineral oil

only. 'lternately they may give different tor&ues for (ight oil, copaslip and moly%ote.

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Oxygen AnalysersDocument2 pagesOxygen AnalysersJitendra KumarNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Pilgrim NutDocument2 pagesPilgrim NutJitendra KumarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Overall Arrangement: Description of The Salient PartsDocument6 pagesOverall Arrangement: Description of The Salient PartsJitendra KumarNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

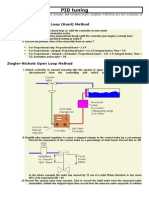

- PID TuningDocument4 pagesPID TuningJitendra Kumar100% (1)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Overview of Microbiological AttackDocument10 pagesOverview of Microbiological AttackJitendra KumarNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Brochure o Pumps Deepwell Gas CarriersDocument4 pagesBrochure o Pumps Deepwell Gas CarriersJohn MarxisNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Parallel Operation of GeneratorsDocument5 pagesParallel Operation of GeneratorsJitendra KumarNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Oil WhirlDocument2 pagesOil WhirlJitendra KumarNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Oil Distribution Within A Journal BearingDocument2 pagesOil Distribution Within A Journal BearingAnkit DedhiyaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Increasing Propulsive EfficiencyDocument6 pagesIncreasing Propulsive EfficiencyJitendra KumarNo ratings yet

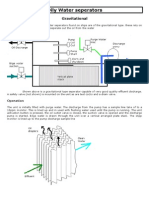

- Oily Water SeperatorsDocument2 pagesOily Water SeperatorsJitendra KumarNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarNo ratings yet

- Operation of A Centrifugal Oil PurifersDocument3 pagesOperation of A Centrifugal Oil PurifersJitendra KumarNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Navigation LightingDocument1 pageNavigation LightingJitendra KumarNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Microbes of Microbiological Attac1Document3 pagesMicrobes of Microbiological Attac1Jitendra KumarNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Motor Ship Steam Plan1Document3 pagesMotor Ship Steam Plan1Jitendra KumarNo ratings yet

- Marpol 73Document12 pagesMarpol 73Jitendra KumarNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Tooth Design: Forces Acting On Spur GearsDocument77 pagesTooth Design: Forces Acting On Spur GearsJitendra KumarNo ratings yet

- LNG Containment DesignsDocument3 pagesLNG Containment DesignsJitendra KumarNo ratings yet

- Motor Ship Steam Plant ControlDocument1 pageMotor Ship Steam Plant ControlJitendra KumarNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Metallurgical TestingDocument1 pageMetallurgical TestingJitendra KumarNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Mechanical GovernorsDocument1 pageMechanical GovernorsJitendra KumarNo ratings yet

- Materials Used in Ships Sea Water SystemsDocument1 pageMaterials Used in Ships Sea Water SystemsAnkit DedhiyaNo ratings yet

- LNG Reliquifactio1Document1 pageLNG Reliquifactio1Jitendra KumarNo ratings yet

- Lifting Using Accessories: Calculation of LoadDocument2 pagesLifting Using Accessories: Calculation of LoadJitendra KumarNo ratings yet

- Liquified Gas CargoesDocument2 pagesLiquified Gas CargoesJitendra KumarNo ratings yet

- Low Sulphur FuelsDocument1 pageLow Sulphur FuelsJitendra KumarNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Lube Oil Requirements For Diesel EnginesDocument3 pagesLube Oil Requirements For Diesel EnginesJitendra KumarNo ratings yet

- Jacket Water SystemDocument2 pagesJacket Water SystemJitendra KumarNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)