Professional Documents

Culture Documents

Telwin Tehnologi BW 150 170 200 186

Uploaded by

pedroscorpionCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Telwin Tehnologi BW 150 170 200 186

Uploaded by

pedroscorpionCopyright:

Available Formats

cod.

988588

i nver t er

TECHNOLOGY150-170-200-186CE GE /

CONTENTS PAGE

OPERATION AND WIRING DIAGRAMS................ 2

REPAIR GUIDE.......................................................10

SPARE PARTS LIST...............................................20

REPAIR SHEET...................................................... 22

Block diagram 2

Analysis of the block diagram 3

Illustrations 5

Wiring diagrams 6

Equipment required 10

General repair instructions 11

Troubleshooting and remedies 11

Testing the machine 14

Illustrations 17

TROUBLESHOOTING

AND REPAIR MANUAL

TROUBLESHOOTING

AND REPAIR MANUAL

reparation no problem !

2

2

S

E

C

O

N

D

A

R

Y

D

I

O

D

E

S

T

H

E

R

M

O

S

T

A

T

TECHNOLOGY 150-170-200-186CE/GE

- 2 -

6 C

U

R

R

E

N

T

T

R

A

N

S

F

O

R

M

E

R

1

7 P

O

W

E

R

T

R

A

N

S

F

O

R

M

E

R

O

U

T

P

U

T

1

0

S

E

C

O

N

D

A

R

Y

F

IL

T

E

R

E

M

C

2

4

G

A

L

V

A

N

I

C

S

E

P

A

R

A

T

I

O

N

H

Y

B

R

I

D

8 S

E

C

O

N

D

A

R

Y

D

I

A

O

D

E

S

5 C

H

O

P

P

E

R

4 F

I

L

T

E

R

3 P

R

E

-

C

H

A

R

G

E

2 R

E

C

T

I

F

I

E

R

B

R

I

D

G

E

9 IN

D

U

C

T

A

N

C

E

&

S

H

U

N

T

+

-

1

3

P

R

IM

A

R

Y

C

U

R

R

E

N

T

R

E

A

D

E

R

A

N

D

L

IM

IT

E

R

1

1

F

L

Y

-

B

A

C

K

P

O

W

E

R

S

U

P

P

L

Y

2

7

F

A

N

2

6

U

N

D

E

R

V

O

L

T

A

G

E

S

A

F

E

G

U

A

R

D

V

t

2

5

O

V

E

R

V

O

L

T

A

G

E

S

A

F

E

G

U

A

R

D

V

t

1

5

A

D

D

E

R

1

4

D

U

T

Y

C

Y

C

L

E

F

O

R

M

A

T

O

R

2

0

S

H

U

N

T

A

M

P

L

I

F

I

E

R

+ |

2

1

M

A

X

I

M

U

N

C

U

R

R

E

N

T

R

E

G

U

L

A

T

O

R

A

L

A

R

M

B

L

O

C

K

1

6

1

8

C

U

R

R

E

N

T

P

O

T

E

N

T

I

O

M

E

T

E

R

1

2

I

G

B

T

D

R

I

V

E

R

1

7

A

L

A

R

M

L

E

D

S

H

O

R

T

C

I

R

C

U

I

T

D

E

L

A

Y

3

1

3

0

A

R

C

F

O

R

C

E

t

i

2

9

H

O

T

S

T

A

R

T

t

i

1

9

W

E

L

D

I

N

G

M

O

D

E

F

U

N

C

T

I

O

N

S

E

L

E

C

T

O

R

T

I

G

-

L

I

F

T

S

O

F

T

H

A

R

D

2

8

S

H

O

R

T

C

I

R

C

U

I

T

D

E

T

E

C

T

O

R

t

V

2

3

I

N

D

U

C

T

A

N

C

E

T

H

E

R

M

O

S

T

A

T

BLOCK DIAGRAM

OPERATION AND WIRING DIAGRAMS

OPERATION AND WIRING DIAGRAMS

P

R

I

M

A

R

Y

E

M

C

F

I

L

T

E

R

I

N

P

U

T

- 3 -

ANALYSIS OFTHE BLOCK DIAGRAM

NOTE: Unless indicated otherwise, it should be assumed that

the components are assembled on the welding machine.

Consisting of: C3, R5, L1, C8, C9 .

Prevents noise fromthe machine frombeing transmitted along

the main power line and vice versa.

Consisting of: Q1, Q2, Q3, Q4

Converts the continuous voltage from the filter into a high

frequency square wave capable of piloting the power

transformer.

Regulates the power according to the required welding

current/voltage.

Consisting of:T1 .

The C.T. is used to measure the current circulating in the power

transformer primary and transmit the information to block 14

(primary current reader and limiter).

Consisting of:T1.

Adjusts the voltage and current to values required for the

welding procedure. Also forms galvanic separation of the

primary from the secondary (welding circuit from the power

supply line).

Block 1

Block 2

Block 5

Block 6

Block 7

Block 8

EMCFilter

Chopper

Current transformer

Power transformer

(primary board)

Consisting of: D3, D5 (primary board).

Converts the alternating mains voltage to continuous pulsed

voltage No D3 present onTechnology 150).

Consisting of: K1, K2, R1 (primary board).

Prevents the formation of high transient currents that could

damage the main switch, the rectifier bridge and the

electrolytic capacitors. When the power source is switched on

relays K1 and K2 are de-energised, capacitors C2, C4, C5, C6,

C7 are therefore charged via R1. When the capacitors are

charged the relay will be energised. ( No K2 present on

Technology 150).

Consisting of: C2, C4, C5, C6, C7 (primary board).

Converts the pulsed voltage arriving from the rectifier bridge

to continuous voltage ( No C7 present on Technology

150).

(primary board).

(primary board)

Consisting of: D1, D2, D3, D5(secondary board).

- D1 and D2 convert the current circulating in the transformer

to a single direction, preventing saturation of the nucleus.

: No D2 onTechnology 150).

Rectifier bridge

Pre-charge

Filter

Secondarydiodes

(N.B.

N.B.

N.B.

(N.B.

Block 3

Block 4

- D3, D5 recirculate the inductance output current (block 9)

during the time when the IGBT's are not conducting,

bypassing the power transformer (block 7).

Consisting of: L1, R1.

The inductance levels the output current from the secondary

board diodes making it practically direct. The shunt detects the

current circulating in the secondary and sends a voltage signal

toblock 16 (adder), which will process it.

InductanceandShunt

hybrid board.

block 14 (duty

cycle maker).

Block 9

Block 10

Block 11

Block 12

Block 13

Block 14

Block 15

Block 16

SecondaryEMCFilter

Flybackpower supply

IGBTDriver

Primarycurrent reader andlimiter

Dutycyclemaker

Adder

AlarmBlock

Consisting of: CY1, CY2.

Prevents noise from the power source from being transmitted

through the welding cables and vice versa.

Consisting of:T2, U2 (primary board).

Uses switching methods to transformand stabilise the voltage

obtained from block 4 (filter) and supplies auxiliary voltage to

power block 12 (driver) and the

Consisting of: U1A, U1D(primary board).

Takes the signal from block 11 (flyback power supply) and,

controlled by block 14 (duty cycle maker), makes the signal

suitable for piloting block 6 (chopper).

Consisting of: R15 (primary board).

Reads the signal fromblock 6 (current transformer) and scales

it down so it can be processed and compared in

Consisting of: U2 (hybrid board).

Processes the information from block 15 (adder) and block 13

(primary current reader and limiter) and produces a square

wave with variable duty cycle limiting the primary current to a

maximumpre-set value under all circumstances.

Consisting of: U1A, U1D(hybrid board).

Gathers all the information from block 13 (primary current

reader and limiter), from block 16 (alarms) and from block 18

(current potentiometer), and produces a signal with a suitable

voltage for processing by block 14 (duty cycle maker).

Consisting of: Q5, R11, R14, R17 (control board).

When an alarm is detected the power source output current is

drastically reduced by making direct adjustments to block 14

(duty cycle maker) and directly changing the reference signal

obtained fromblock 18 (current potentiometer).

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

- 4 -

Block 25

Block 23

Block 27

Block 28

Block 29

Block 30

Block 31

Overvoltagesafeguard

Undervoltagesafeguard

Fan

Short circuit detector

Hot Start

Arc Force

Short circuit delay

Consisting of: U3A, R62, R68 (primary board).

If the main supply voltage exceeds the maximum value this

safeguard triggers (a tolerance of approx. 15% of the power

supply voltage is allowed: outside this range the safeguard

triggers).

Consisting of: U3B, R61, R67(primary board).

If the main supply voltage falls below the minimum allowed

value this safeguard triggers (a tolerance of approx. 15% of

the power supply voltage is allowed: outside this range the

safeguard triggers).

Consisting of:V1.

Powered directly 230V by block 11 (flyback transformer) and

cools the power components.

Consisting of: U3B (hybrid board).

If the welding voltage is below 10V this circuit causes block 30

(arc force) totrigger.

Consisting of: Q2,Q3,C9 (hybrid board).

At the start of MMA welding, Hot Start generates a temporary

overcurrent based on the current setting made by block 20

(current potentiometer) in order to pre-heat the electrode and

prepare the weld pool.

Consisting of: Q6, Q7, C14 (hybrid board).

If the arc voltage falls below 10V, this block produces a

temporary increase in the output current, so as to detach the

electrode fromthe piece after it has become stuck.

Consisting of: U3B (hybrid board).

If the output shorting persists this block shuts down the

power source via block 16 (alarms).

TECHNOLOGY 150-170-200-186CE/GE

Block 17

Block 18

Block 19

Block 20

Block 21

Block 22

Block 23

Block 24

AlarmLED

Current potentiometer

Welding mode function selector

Shunt Amplifier

Maximumcurrent regulator

Secondarydiodethermostat

Inductancethermostat

Galvanic separation

Consisting of: D9 (primary board).

It is switched on by block 16 (alarms) in the event of:

1) Triggering of thermostatic capsule on inductance.

2) Triggering of thermostatic capsule on secondary diodes.

3) Triggering due toundervoltage.

4) Triggering due toovervoltage.

5) Short circuit at output (electrode holder clamp and earth

cable connected to one another or electrode stuck to piece

being welded).

Consisting of: R16 (primary board).

This is used to set the reference voltage needed to adjust the

output current: when the potentiometer knob is turned the

cursor voltage varies, thus varying the current from the

minimumtothe maximumvalue.

Consisting of: SW1 (primary board)

The switch is used to select the type of welding procedure:

TIG-Lift, Hard or Soft.

Consisting of: U4 (hybrid board)

Amplifies the signal arriving from block 10 (shunt

inductance), making it suitable for block 21 (maximum

current regulator).

Consisting of: R13 (primary board)

Used to regulate the maximum welding current that can be

supplied by the power source.

Consisting of: ST1

When the temperature of the secondary diode dissipator is too

high the thermostat cuts in, sending an alarmsignal to block 24

(galvanic separation). It is reset automatically when this alarm

condition is no longer present.

Consisting of: ST2

When the temperature of the inductance is too high the

thermostat cuts in, sending an alarm signal to block 24

(galvanic separation). It is reset automatically when this alarm

condition is no longer present.

Consisting of: ISO3(primary board).

The signals arriving from blocks 22 and 23 (transformer

thermostat and inductance thermostat) are separated

galvanically and sent to block 16 (alarms) for detection of a

possible alarmevent.

TECHNOLOGY 150-170-200-186CE/GE

(12)

DRIVER

IGBT (5)

CHOPPER

(8)

SECONDARY DIODES

(2)

RECTIFIER

BRIDGE

(5)

CHOPPER (18)

CURRENT

POTENTIOMETER

(11)

FLY-BACK

POWER SUPPLY

(4)

FILTER

(1)

EMC

FILTER

(9)

SHUNT

(10)

FILTER

SECONDARY

EMC

(8)

DIODES SECONDARY

(3)

PRE-CHARGE

(17)

ALARM

LED

HYBRID BOARD

(25-26)

OVER/UNDER VOLAGE

SAFEGUARD

(22)

THERMOSTAT

SECONDARY DIODES

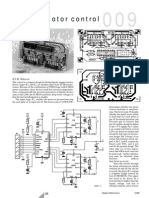

ILLUSTRATIONS

- 5 -

Primary board

Secondary board

(6)

CURRENT

TRASFORMER

(24)

GALVANIC

SEPARATION

(19)

FUNCTIONS

SELECTOR

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

General wiring diagram

- 6 -

WIRING DIAGRAMS

TECHNOLOGY 150-170-200-186CE/GE

- 7 -

Schema elettrico scheda primario - Driver

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

Wiring diagram primary board - Power

- 8 -

TECHNOLOGY 150-170-200-186CE/GE

Wiring diagram primary board - Power supply

Wiring diagram primary board - Driver

- 9 -

Wiring diagram secondary board

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

Wiring diagram hybrid board

4

3 8

1

2

9

5

7

6

- 10 -

TECHNOLOGY 150-170-200-186CE/GE

(*)The instruments with codes can be supplied by Telwin. The sale price is available on request.

REPAIR GUIDE

REPAIR GUIDE

EQUIPMENT REQUIRED

ESSENTIAL INSTRUMENTS

USEFUL INSTRUMENTS

1 Dual trace oscilloscope cod. 802401 (*)

2 Static load generator cod. 802110 (*)

3 Variac 0 - 300v 1500 VA cod. 802402 (*)

4 Digital multimeter

8 Unsoldering station

9 Miscellaneous tools

5 Differential probe 1/200

6 Hall Probe cod. 802406

cod. 802403

(*)

(*) 7 HV Power supply

WARNING:

WARNING:

WARNING:

BEFORE PROCEEDING WITH REPAIRS TO

THE MACHINE READ THE INSTRUCTION

MANUALCAREFULLY.

EXTRAORDINARY MAINTENANCE SHOULD

BE CARRIED OUT ONLY AND EXCLUSIVELY

BY EXPERT OR SKILLED ELECTRICAL-

MECHANICALPERSONNEL.

ANY CHECKS CARRIED OUT INSIDE THE

MACHINEWHENIT ISPOWEREDMAYCAUSE

SERIOUS ELECTRICSHOCKDUETODIRECT

CONTACTWITHLIVEPARTS.

HVPOWERSUPPLYMODULE

THE HV POWER SUPPLY is used to ensure operation of the

switching power supply (the circuit on the primary board supplying

auxiliary voltages), even when the machine is operating at low

voltage.

It is easy to build using the electrical diagrams in fig. A for

reference and using the following components or, alternatively, it

can be ordered fromTelwin.

T1=insulation transformer 230-230V 50VA(*)

D1 =rectifier bridge 36MB80 (cod. 112357)

C1 =electrolytic capacitor 470uF400VALL

(cod.112514)

R1 =resistor 10 ohm5W5%

R2 =resistor 100Kohm2W5%

F1=delayed action fuse 1.5 A Fuse holder 5X20mm

Female red and black faston

Plastic box.

The following is a list of practical rules which must be strictly

adhered toif repairs are tobe carried out correctly.

A) When handling the active electronic components, the IGBT's

and Power DIODES in particular, take elementary antistatic

precautions (use antistatic footwear or wrist straps, antistatic

working surfaces etc.).

B) To ensure the heat flow between the electronic components

and the dissipator, place a thin layer of thermo-conductive

grease (e.g. COMPOUND GREASIL MS12) between the

contact zones.

C) The power resistors (should they require replacement) should

always be soldered at least 3 mmabove the board.

D) If silicone is removed fromsome points on the boards, it should

be re-applied. Use only non-conducting neutral or oximic

reticulating silicones (e.g. DOW CORNING 7093). Otherwise,

silicone that is placed in contact with points at different

potential (rheophores of IGBT's, etc.) should be left to

reticulate before the machine is tested.

E) When the semiconductor devices are soldered the maximum

temperature limits should be respected (normally 300 Cfor no

more than 10 seconds).

F) It is essential to take the greatest care at each disassembly

and assembly stage for the various machine parts.

G) Take care to keep the small parts and other pieces that are

dismantled fromthe machine so as to be able to position them

in the reverse order when re-assembling (damaged parts

should never be omitted but should be replaced, referring to

the spare parts list given at the end of this manual).

H) The boards (repaired when necessary) and the wiring should

never be modified without prior authorisation fromTelwin.

I) For further information on machine specifications and

operation, refer tothe Instruction Manual.

J) When the machine is in operation there are

dangerously high voltages on its internal parts so do not touch

the boards when the machine is live.

Every operation should be carried out in complete

safety with the power supply cable disconnected from the mains

outlet:

- Undo the 8 screws fastening the 2 plastic covers (4 each) to the

front and back .

- Undo the 8 screws fastening the top cover to the structure

.

- Slide out the top cover by pulling gently outwards .

After completing the repairs, proceed in the reverse order to re-

assemble the cover and do not forget to insert the toothed washer

on the ground screw.

Using suitably dried compressed air, carefully clean the

components of the power source since dirt is a danger to parts

subject to high voltages and can damage the galvanic separation

between the primary and secondary.

To clean the electronic boards we advise decreasing the air

pressure toprevent damage tothe components.

It is therefore important to take special care when cleaning the

following parts

Check whether dirt has been deposited on the front and back air

vents or has damaged the correct rotation of the blades, if there is

still damage after cleaning replace the fan.

rheofores of IGBT's Q1, Q2, Q3, Q4;

rheofores of recirculating diodes D4, D8;

rheofores of snubber network diodes D1, D6;

GENERALREPAIRINSTRUCTIONS

TROUBLESHOOTINGANDREMEDIES

N.B.

WARNING!

WARNING!

(figure1A)

(figure1B)

(figure1B)

-

-

-

1.0 Disassemblingthemachine

2.0 Cleaningtheinsideof themachine

Fan fig. 2B

Primaryboard(fig. 3:)

( )

- 11 -

10 5

F1 R1

R2

D1

T1

FIGURE A

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

ELECTRICAL DIAGRAM FOR POWER SUPPLY (HV OUTPUT):

THE INSULATIONTRANSFORMER CAN BE REPLACED WITH

TWO TRANSFORMERS OF THE SAME POWER,

CONNECTING THE SECONDARIES ACCORDING TO THE

FOLLOWINGDIAGRAM:

-

-

N.B.

-

fig. 3

fig. 3

WARNING!

fig. 3

fig. 3

fig. 3

WARNING!

WARNING!

fig. 3

rheofores of opto-couplers ISO1and ISO2;

rheofores of connectors J4 and J6;

Do this if it is necessary to remove the primary board, otherwise it

is possible to clean the part superficially from the side of the

secondary board.

If the primary and secondary boards are removed (with the

diaphragm), carefully clean all the parts fastened to the base, or

clean the base partially fromthe sides of the machine.

Make sure there is no mechanical deformation, dent, or damaged

and/or disconnected connector.

Make sure the power supply cable has not been damaged or

disconnected internally and that the fan works with the machine

switched on. Inspect the components and cables for signs of

burning or breaks that may endanger operation of the power

source. Check the following elements:

Probable cause:

- see main power supply switch. If the relay contacts are

stuck together or dirty, do not attempt to separate them and

clean them, just replace the relay.

Probable cause:

- mechanical shock;

- machine connected to power supply voltage much higher than

the rated value;

- broken rheophore on one or more capacitor: the remainder will

be overstressed and become damaged by overheating;

- ageing after a considerable number of working hours;

- overheating caused by thermostatic capsule failure.

Probable cause:

- discontinuation in snubber network,

- fault in driver circuit

- poorly functioning thermal contact between IGBT and

dissipator (e.g. loosened attachment screws: check),

- excessive overheating related tofaulty operation

Probable cause:

- excessive overheating related tofaulty operation.

Probable cause:

- mechanical shock.

Probable cause:

- discontinuation in snubber network;

- poorly functioning thermal contact between IGBT and

dissipator (e.g. loosened attachment screws: check);

- faulty output connection.

Check it for colour changes.

Probable cause:

overheating due to loosening of the screws connecting the shunt

tothe PCB.

Inspect the windings for colour changes.

Probable causes:

- aging after a substantial number of working hours;

- excessive overheating related tofaulty operation.

It is important to check that all the connections are in good

condition and the connectors are inserted and/or attached

correctly. To do this, take the cables between finger and thumb (as

close as possible to the fastons or connectors) and pull outwards

gently: the cables should not come away from the fastons or

connectors. N.B. If the power cables are not tight enough this could

cause dangerous overheating.

A) With the multimeter set on diode testing check the following

components (joint voltages not less than 0.2V):

- rectifier bridges D3, D5 ( );

- IGBT's Q1, Q2, Q3, Q4, (no short circuits between collector-

gate and collector-emitter ( );

Before proceeding with faultfinding, we should remind

you that during these tests the power source is powered and

therefore the operator is exposed tothe danger of electric shock.

The tests described below can be used to check the operation of

the power and control parts of the power source.

A) From the primary board, disconnect fastons CN3 (XF+) and

CN10 (XF-) for the power transformer ( ).

B) Onthe primary board disconnect the jumper on JP1.

C) Connect the HV power supply OUT (code 802403) on the

primary board as follows ( ):

- (+) Positive (clamp) to rheofore of resistor R35 towards JP1

(after removing jumper JP1);

- (-) Negative (faston) tonegative faston of diode bridge D3.

D) Set up the oscilloscope with the voltage probe x100 connected

between the rheofore of R40B (collector Q10) towards JP1

(probe) and the negative of diode bridge D3 (earth) to the primary

board ( ).

the high frequency voltage will permanently damage

any instrument connected to the generator. Before proceeding

make very sure that the fastons listed above are disconnected and

completely isolated fromone another.

F) Connect the power supply cable to a single phase variac with

variable output 0-300Vac.

during testing prevent contact with the metal part of

the torch because of the presence of high voltages that are

hazardous tothe operator.

A) Switch on the HV power supply (HV OUT) and make sure that

( ):

- pre-charge relays K1 and K2 close;

- the fan starts toturn for the power transformer;

Power transformer andinductanceassembly

Partsfastenedtothebase

RelaysK1, K2primaryboard fig. 3

ElectrolyticcapacitorsC2,C4,C6,C7primaryboard(fig. 3

IGBT's Q1, Q2, Q3, Q4 primary board (fig. 3)

PrimarydiodesD1, D4, D6, D8 primaryboard(fig. 3)

Mode selector switchesSW1 andSW3primaryboard

(fig. 3)

SecondarydiodesD1, D2, D3, D5 secondaryboard(fig. 4)

Shunt R1secondaryboard(fig. 6)

Power transformer andfilter inductance

3.0 Visual inspection of the machine

4.0 Checkingthepower andsignal wiring

5.0 Electrical measurements with the machine

switchedoff

6.0 Electrical measurements with the machine in

operation

( )

)

.

6.1 Preparationfor testing

6.2Scheduledtests

Secondaryboard(fig. 4):)

-

-

-

fig. 4

fig. 3

fig. 3

fig. 4

fig. 4

rheofores of secondary power diodes D1, D2, D3, D5 (N.B. not

present onTechnology 150);

thermostat ST1on secondary diode dissipator;

shunt R1.

- secondary diodes D1, D2, D3, D5 between anode and

cathode ( ). The secondary diodes can be tested without

removing the primary board, placing a prod on the secondary

diode dissipator and the other in sequence on the 2 power

transformer output terminals.

B) With the multimeter in ohm mode check the following

components:

- resistor R1: 47 ohm(precharge ).

- resistors R2, R6: 10 ohm(primary snubber ).

- resistor R1: 10 ohm(secondary snubber ).

- thermostat continuity test on inductance and secondary

dissipator: disconnect connector J2 from the primary board

and make sure the resistance between pins 4 and 5 is approx.

0ohm( ).

E) Position the current potentiometer R16 on maximum (turn

clockwise as far as it will go) and switch SW1 to SOFT(as far down

as it will go);

Current potentiometer R16(fig. 3)

Probable cause:

- mechanical shock.

- 12 -

TECHNOLOGY 150-170-200-186CE/GE

- yellowled alarmis turn off.

Make sure the waveform shown on the oscilloscope

resembles .

if there is no signal it may be necessary to replace the

integrated circuit U2 or IGBTQ10 on the primary board ( ).

C) Set up the multimeter in volt mode and make sure the primary

board has the following voltages: ( ):

- between the cathode of diode D32 (+) and the negative of diode

bridge D5 (-): equal to+15Vdc 3%;

- between pin 3 (+) and the dissipator (-) of U4: equal to +12Vdc

5%;

- between pin 3 (+) and pin 1 (-) of U6: equal to-12Vdc 5%;

- between pin 8 (+) and pin 7 (-) of ISO1: equal to+26Vdc 5%;

- between pin 8 (+) and pin 7 (-) of ISO2: equal to+26Vdc 5%;

D) Switch off the HVpower supply.

E) Set up the oscilloscope with the voltage probe x10 connected

between the gate (probe) and the emitter (earth) of IGBT Q4 on

the primary board ).

F) Switch on the HV power supply (HV out) and make sure the

waveformdisplayed on the oscilloscope resembles .

G) Repeat this test on Q1, Q2, Q3as well.

if the signal is not present there could be a fault in the IGBT

driver circuit, specifically ISO1 and ISO2 ( ), or in the hybrid

board ( , in which case we recommend replacing the board).

H) Switch off the HV and replace the 2 fastons connecting the

primary board and the power transformer (CN3 and CN10).

I) Switch on the HV and the variac (initially set to 0V), close the

main power supply switch on the machine and gradually increase

the voltage generated by the variac until it reaches 26Vac.

J) Set up the oscilloscope with the voltage probe x100 connected

between the collector (probe) and the emitter (earth) of IGBT Q4

on the primary board ( ).

K) Make sure the waveform shown on the oscilloscope

resembles

L) Repeat this test on Q2as well, using the differential probe.

If the signal is not present there may be a fault in the IGBT's

( ).

M) Return the variac voltage to 0V, switch off the machine and the

HVpower supply.

N) Disconnect the HV power supply, replace jumper JP1 on the

board.

P) Increase the voltage on the variac to 230Vac and make sure

the alarmceases (yellowLEDD9 goes off).

Q) Increase the voltage on the variac yet again to 275Vac 5%

and make sure the machine registers an alarm again. Return the

variac voltage immediately to 230Vac and switch off the machine.

if an alarm persists (and is not caused by a fault in the hybrid

board) there could be a fault in opto-isolator ISO3 or integrated

circuit U3 on the primary board ( ).

If repairing the board is complicated or impossible, it should be

completely replaced.

The board is identified by a 6-digit code (printed in white on the

component side after the initialsTW).This is the reference code for

requesting a replacement: Telwin may supply boards that are

compatible but with different codes.

before inserting a new board check it carefully for

damage that may have occurred in transit. When we supply a

board it has already been tested and so if the fault is still present

after it has been replaced correctly, check the other machine

components. Unless specifically required by the procedure, never

alter the board trimmers.

If the fault is in the primary board remove it from the machine

structure as follows:

- with the machine disconnected from the main power supply

disconnect all the wiring fromthe primary board;

- cut any bands restricting the board (e.g. on the power supply

cable and primary connections);

- undo the screws fastening the front and back panels and

remove the panels fromthe machine structure;

- undo the screws fastening the primary board to the machine

structure ;

- remove the primary board by lifting it upwards.

for assembly proceed in the reverse order.

B)

Fig. B

N.B.

fig. 3

fig. 3

(fig. 3

fig. C

N.B.

fig. 3

fig. 3

fig. 3

fig. D.

N.B.

fig.5

N.B.

fig. 3

WARNING!

(fig.2B)

N.B.

7.0Repairs, replacingtheboards

7.1Removingtheprimaryboard(fig. 3)

O) Switch the machine on again and gradually increase the

voltage generated by the variac to 115Vac 5%then make sure an

alarmis registered with yellowLEDD9 lit up.

- remove the current adjustment knob on the front panel of the

machine;

- 13 -

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

FIGURE B

SETTINGS:

PROBE x100;

100 V/Div;

10 sec/Div.

THE FREQUENCY

IS 35KHz 15%;

AMPLITUDE IS

450V 10%;

VERIFY THAT

SETTINGS:

PROBE x10;

10V/Div;

10 sec/Div.

POSITIVE AMPLITUDE

IS +18V 10%;

NEGATIVE AMPLITUDE

IS -10V 10%.

VERIFY THAT

FIGURE C

FIGURE D

SETTINGS:

PROBE x100;

10V/Div;

10 sec/Div.

AMPLITUDE ON

CH1 IS 35V 20%;

VERIFY THAT

Please read the procedure for replacing the IGBT's

carefully (fig. 3).

ohm

NOTE.

WARNING!

figure3

WARNING!

The 4 IGBT's are attached to 2 different dissipators and whenever

a replacement is required, both IGBT's should be replaced.

- Unscrewthe four (4) nuts that fix the dissipator onto the card;

- unscrew the four (4) screws that fix the four (4) IGBT onto the

dissipator;

- unscrew the two (2) screws that fix the two diode bridges onto

the dissipator;

- remove the four (4) IGBT and the two (2) diode bridges by

unwelding the reophores, then remove tin fromthe p r i n t e d

plates;

- remove dissipator fromcard.

Before making the replacement make sure the components

piloting the IGBT's are not also damaged:

- with the multimeter set in mode make sure there is no

short circuit on the PCB between the 1 and 3 bump contacts

(between gate and emitter) corresponding to each

component;

- alternatively, resistors R3, R4, R7, R8 could have burst and/or

diodes D11, D12, D15, D16 may be unable to function at the

correct Zener voltage (this should have shown up in the

preliminary tests);

- clean any irregularity or dirt from the dissipators. If the IGBT's

have burst the dissipators may have been irreversibly

damaged: in this case they should be replaced;

- apply thermo-conductive grease following the general

instructions.

- prepare the components for replacement. For the IGBT's,

bend the rheofores at 90(never bend and/or place the parts

under tension near the case).

- position the components on the dissipator with the fastening

screws, but do not tighten the screws completely

- join the dissipator/component assembly to the printed board,

inserting all the rheofores in the bump contacts and the

threaded spacers on the 4 attachment holes.

- attach the dissipators with the nuts and lock themonce and for

all in the following order:

- the nuts fastening the dissipators to the printed circuit with a

torque wrench setting of 2 Nm20%;

- the screws fastening the rectifiers to the dissipators with a

torque wrench setting of 2 Nm20%;

- the screws fastening the IGBT's to the dissipators with a

torque wrench setting of 1 Nm20%.

- solder the terminals taking care not to let the solder run along

them.

- on the component side cut away the protruding part of the

rheofores and check they are not shorted (especially the gate

and emitter).

The 4 IGBT's should belong to the same selection kit

supplied byTelwin.

- remove the 4 diodes by unsoldering the rheofores and also

remove the solder fromthe bump contacts on the PCB;

- clean any irregularities or dirt from the dissipators. If the diodes

have burst the dissipator may be irreparably damaged: in such a

case it should be replaced;

- apply thermoconductive paste following the general

instructions;

- place the dissipator with the new components on the bump

contacts of the PCB and fasten it down with the screws (torque

wrench setting 1 Nm20%);

- solder the terminals taking care not to let the solder run along

them;

- on the soldering side cut the protruding part of the rheofores

and make sure they have not shorted (between cathode and

anode).

Tests should be carried out on the assembled machine before

closing it with the top cover. During tests with the machine in

operation never commute the selectors or activate the ohmic load

contactor.

Before proceeding to test the machine, we should

remind you that during these tests the power source is powered

and therefore the operator is exposed to the danger of electric

shock.

The tests given below are used to verify power source operation

under load.

A) Connect the machine to the static load generator (code

802110) using cables fittedwith the appropriate dinse connectors.

B) Set up the dual trace oscilloscope with the voltage probe

CH1x100 connected between the collector (probe) and the emitter

of Q4(earth) on the primary board ( ).

C) Pass the current probe of the Hall effect transducer along the

cable connecting the power transformer at faston CN10 with the

reference arrowpointing into CN10.

D) Lastly, connect the Hall Probe and the current probe to the

oscilloscope.

E) Set up a multimeter in DC volt mode and connect the prods to

the OUT+and OUT- dinse connections.

F) On the front panel set switch SW1 to SOFT (as low as it will

go).

the high frequency voltage will permanently damage

any instrument connected to the generator. Before proceeding

make very sure that the fastons listed above are disconnected and

completely isolated fromone another.

st rd

TESTINGTHE MACHINE

1.1 Preparationfor testing

7.2 Removingthehybridboard(fig. 3)

7.3 Removingthesecondaryboard(fig. 4)

If the fault is in the hybrid board remove it from the primary board

as follows:

with the primary board removed from the machine structure

unsolder the rheofores from the hybrid board on the soldering

side;

remove the solder fromthe bump contacts on the PCB;

remove the hybrid board fromthe primary board;

for assembly proceed in the reverse order.

If the fault is in the hybrid board we strongly advise replacing it

without further intervention.

If the fault is in the secondary board, unless the dissipator has

been damaged by a destructive explosion of the diodes, the board

does not generally need to be removed and the diodes can be

replaced directly with the board mounted on the machine. In any

case, it should be specified that to remove it, it is necessary to

separate the base fromthe machine structure as follows:

- with the machine disconnected fromthe main supply undo the 4

side screws (2 on the front and 2 on the back) that attach the

board tothe base;

- turn the machine upside down and undo the 2 screws fastening

the base tothe structure;

- finally remove the base fromthe structure.

Complete removal of the secondary board fromthe structure:

- undo the 4 side screws fastening the board to the machine

structure;

- remove the 3 hexagonal-head screws that fasten the shunt and

connect the power transformer;

- disconnect the wiring for the thermostatic capsule.

for assembly proceed in the reverse order.

The 4 secondary DIODES are attached to the dissipator and

whenever a replacement is made, all 4 diodes should be replaced:

make sure that resistor R1 and capacitor C1 of the snubber

are soldered correctly ( ).

-

-

-

N.B.

N.B.

Take special note of the procedure for replacing the

secondary diodes:

N.B.

fig. 3

- 14 -

TECHNOLOGY 150-170-200-186CE/GE

G) Connect the power supply cable tothe 230Vac power supply.

during testing prevent contact with the metal part of

the torch because of the presence of high voltages that are

hazardous tothe operator.

Switch on the machine, gradually increase the power supply

voltage from0Vto230Vac and make sure that:

- the pre-charge relays on the primary board close;

- the fan starts operating correctly;

- the waveform displayed on the oscilloscope resembles

and the frequency is equal to+32.5KHz 20%;

WARNING!

A) Loadless test:

Fig. E

1.2 Scheduledtests

- the output voltage over dinse + and dinse is equal to 95Vdc

10%.

- set up the ohmic load with the switch settings as in the table in

;

- on the front panel position the current potentiometer on

minimum(turn anti-clockwise as far as it will go);

- switch on the main switch;

- start up on the ohmic load and make sure that:

- the waveforms displayed on the oscilloscope resemble

those in ;

- the output current is equal to +5Adc 20% and the output

voltage is equal to+20.2Vdc %.

- switch off the ohmic load and switch off the main switch.

- set up the ohmic load with the switch settings as in the table in

;

- on the front panel position the current potentiometer on approx.

80A;

- start up the ohmic load and make sure that:

- the waveforms displayed on the oscillscope resemble

those in ;

- the output current is equal to +80Adc 10%and the output

voltage is equal to+23.2.Vdc 10%.

- switch off the ohmic load and switch off the main switch.

- the ohmic load with the switch settings according to the

relevant Technology model (see tables in );

- on the front panel position the current potentiometer on

maximum(turn clockwise as far as it will go)

- start up on the ohmic load and make sure that:

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +130Adc 3% and the output

voltage is equal to +25.2Vdc 5%; if the output current reading

is not 130A 3%, adjust the current using trimmer IMAX R13

on the primary board ( ).

B) Ratedloadtest:

fig. G

Fig. F

C) Intermediate loadtest:

fig. G

Fig. G

A) Ratedloadtest:

Figs. H, I, J, K

Fig. H

fig. 3

For the Technology 150

10

- 15 -

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

FIGURE E

SETTINGS

THE FREQUENCY IS

60KHz 5%;

AMPLITUDE CH1 IS

340V 10%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =1A;

10mV/Div;

105 sec/Div.

VERIFY THAT

Number switch

Position switch

FIGURE E

6 3 2 1 4 5

3 3 3 2 2 2

FIGURE H

SETTINGS

THE FREQUENCY IS

32.5KHz 20%;

AMPLITUDE CH1 IS

340V 10%;

AMPLITUDE CH4 IS

56A 10%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =20A;

10mV/Div;

10 sec/Div.

VERIFY THAT

FIGURE E

FIGURE F

6 3 2 1 4 5

1 0 0 0 0 0

Number switch

Position switch

SETTINGS

THE FREQUENCY IS

60KHz 5%;

AMPLITUDE CH1 IS

340V 10%;

AMPLITUDE CH4 IS 7A

20%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =5A;

10mV/Div;

10 sec/Div.

VERIFY THAT

Number switch

Position switch

FIGURE E

6 3 2 1 4 5

2 2 2 2 1 0

FIGURE G

SETTINGS

THE FREQUENCY IS

60KHz 5%;

AMPLITUDE CH1 IS

340V 10%;

AMPLITUDE CH4 IS

26A 20%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =20A;

10mV/Div;

10 sec/Div.

VERIFY THAT

For the Technology 170

For the Technology 200

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +160Adc 3% and the output

voltage is equal to +26.4Vdc 5%; if the output current reading

is not 160A 3%, adjust the current using trimmer IMAX R13

on the primary board ( ).

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +180Adc 3% and the output

voltage is equal to +27.7Vdc 5%; if the output current reading

is not 180A 3%, adjust the current using trimmer IMAX R13

on the primary board ( ).

Fig. I

fig. 3

Fig. J

fig. 3

For the Technology 186CE/GE

- the waveforms displayed on the oscillscope resemble those in

;

- the output current is equal to +145Adc 3% and the output

voltage is equal to +25.8Vdc 5%; if the output current reading

is not 145A 3%, adjust the current using trimmer IMAX R13

on the primary board ( ).

- switch off the ohmic load and switch off the main switch.

- set up the dual trace oscilloscope, connecting probe CH1 x

100 to the anode of diode D1 or D2 and probe CH2x100 to the

anode of diode D3 or D5. Earth connections are both made to

the secondary dissipator;

- remove the multimeter from the OUT+ and OUT- bump

contacts;

- set up the ohmic load with the switch settings according to the

relevant Technology model (see tables at point 1.2D);

- on the front panel position the current potentiometer R7 to the

maximum (turn the knob clockwise as far as it will go) and

switch on the main switch;

- activate the static load generator and make sure that the

waveforms displayed on the oscilloscope resemble those in

- deactivate the static load generator and switch off the main

switch.

Set up the ohmic load as shown in the table in and the

current potentiometer on approx. 80A. Position switch SW1 on

HARD (in the centre), start the ohmic load and make sure the

output current reading shows approx. 110A 10% then returns to

the current setting

.

On the front panel set switch SW1 to SOFT (as lowas it will go and

the welding current to maximum). Under the relevant load

Fig. K

fig. 3

E) Checkingthesecondary diodevoltages:

fig. L;

A)Arc Force test

Fig. G

B)Runningtime test andclosingthemachine

1.3Operational tests

- 16 -

FIGURE E

6 3 2 1 4 5

3 3 3 3 3 2

FIGURE J

TECHNOLOGY 150-170-200-186CE/GE

Number switch

Position switch

FIGURE E

FIGURE I

Number switch

Position switch

6 3 2 1 4 5

3 3 3 2 2 2

SETTINGS

THE FREQUENCY IS

32.5KHz 20%;

AMPLITUDE CH1 IS

340V 10%;

AMPLITUDE CH4 IS

60A 10%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =20A;

10mV/Div;

10 sec/Div.

VERIFY THAT

FIGURE E

6 3 2 1 4 5

3 3 3 2 2 2

FIGURE K

Number switch

Position switch

SETTINGS

THE FREQUENCY IS

32.5KHz 20%;

AMPLITUDE CH1 IS

340V 10%;

AMPLITUDE CH4 IS

58A 10%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =20A;

10mV/Div;

10 sec/Div.

VERIFY THAT

SETTINGS

THE FREQUENCY IS

32.5KHz 20%;

AMPLITUDE CH1 IS

340V 10%;

AMPLITUDE CH4 IS

60A 10%;

:

PROBE CH1 x100;

100 V/Div;

PROBE CH4 =20A;

10mV/Div;

10 sec/Div.

VERIFY THAT

FIGURE E

FIGURE L

SETTINGS

REVERSE AMPLITUDE

ON CH1

250V.

REVERSE AMPLITUDE

ON CH2

250V.

:

PROBE CH1 x100;

50V/Div;

PROBE CH2 x100;

50V/Div;

10 sec/Div.

VERIFY THAT

DOES NOT

EXCEED

DOES NOT

EXCEED

conditions for the particular Technology model (see tables at point

1.2 D), switch on the machine and leave it running until the

thermostatic capsules trigger (machine in alarm). After making

sure the internal wiring is positioned correctly assemble the

machine once and for all.

with the machine set up according to the instructions in the

handbook make a test weld with an electrode diam. 2.5 and the

current setting at 80A. Monitor the dynamic behaviour of the power

source, also checking for the presence of the Arc Force SW1 on

HARD(in the centre)

C)Weldingtest

MMA:

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

FIG. 1A

FIG. 1B

ILLUSTRATIONS

TO

COVER SCREWS

TOP

COVER SCREWS

TOP

COVER SCREWS

- 17-

SCREWS

FASTENING

BACK PANEL

SCRAWS

FASTENING

BACK PANEL

SCREWS

FASTENING

FRONT PANEL

SCREWS

FASTENING

FRONT PANEL

- 18 -

TECHNOLOGY 150-170-200-186CE/GE

FIG. 2A

FIG. 2B

POSITIVE DINSE

D9

YELLOW LED

ALARM

BOTTOM

COVER SCREWS

NEGATIVE DINSE

SW1

SWITCH

SELECTION

TIG/LIFT-HARD-SOFT

BOTTOM

COVER SCREWS

BOTTOM

COVER SCREWS

BOTTOM

COVER SCREWS

MAINS CABLE

GENERAL SWITCH

FAN

CURRENT

POTENTIOMETER

BOTTOM

COVER SCREWS

- 19 -

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

FIG. 4

FIG. 3

D4 D8 R6 Q4, Q3 D5, D3 CN10 C7, C2, C4, C6 JP1 U2 R40B Q10

ISO2, ISO1 Q2, Q1 R2 R1 K2, K1 R13 D32 D9 U4 U6

D1, D2 SHUNT R1

R1, C1

D3, D5 THERMOSTAT

CABLE

ST1

SW1 R16

CN3 HYBRID BOARD

- 20 -

TECHNOLOGY 150-170-200-186CE/GE

ELENCO PEZZI DI RICAMBIO - LISTE PIECES DETACHEES

SPARE PARTS LIST - ERSATZTEILLISTE - PIEZAS DE REPUESTO

Per richiedere i pezzi di ricambio senza codice precisare: codice del modello; il numero di matricola; numero di riferimento del particolare sull'elenco ricambi.

Pour avoir les pieces detachees, dont manque la reference, il faudra preciser: modele, logo et tension de I'appareil; denomination de la piece; numero de matricule.

When requesting spare parts without any reference, pls specify: model-brand and voltage of machine; list reference number of the item; registration number.

Wenn Sie einen Ersatzteil, der ohne Artikel Nummer ist, benoetigen, bestimmen Sie bitte Folgendes: Modell-zeichen und Spannung des Geraetes; Teilliste Nuemmer; Registriernummer.

Por pedir una pieza de repuesto sin referencia precisar: modelo-marca e tension de la maquina; numero di riferimento de lista; numero di matricula.

Esploso macchina, Dessin appareil, Machine drawing, Explosions Zeichnung des Gerts, Diseo seccionado maquina.

15

25

27

19

13

8

16

20

1 5 21 14

26 6 9 18

10 7 4 2 3 12 23 17

11 24 22

- 21 -

TECHNOLOGY 150-170-200-186CE/GE TECHNOLOGY 150-170-200-186CE/GE

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

REF. REF. REF. REF. REF.

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

ELENCO PEZZI DI RICAMBIO

PIECES DETACHEES

SPARE PARTS LIST

ERSATZTEILLISTE

PIEZAS DE REPUESTO

Potenziometro

Potentiometre

Potentiometer

Potentiometer

Potenciometro

Resistenza

Resistance

Resistor

Wiederstand

Resistencia

Rele'

Relais

Relais

Relais

Relais

Raddrizzatore Monofase

Redresseur Monophase

Single-phase Rectifier

Einphasiger Gleichrichter

Rectificador Monofasico

Condensatore

Condensateur

Capacitor

Kondensator

Capacitor

Condensatore

Condensateur

Capacitor

Kondensator

Condensador

Interruttore

Interrupteur

Switch

Schalter

Interruptor

Deviatore

Gareur

Switch

Schalter

Interruptor

Termostato

Thermostat

Thermal Switch

Thermostat

Cavo Alim.

Cable Alim.

Mains Cable

Netzkabe

Cable Alim.

Ventilatore

Ventilateur

Fan

Ventilator

Ventilador

Trasformatore Di Corrente Ta

Transformateur De Courant Ta

Current Transformer Ta

Stromwandler Ta

Transformador De Corriente Ta

Fibbia

Boucle

Buckle

Schnalle

Hebilla

Pressacavo

Presse Cable

Cable Bushing

Kabelhalter

Prensa Cable

Cinghia

Courroie

Belt

Gurt

Correa

Cornice

Cadre

Frame

Rahmen

Marco

Frontale

Partie Frontal

Front Panel

Geraetefront

Frontal

Retro

Partie Arriere

Back Panel

Rueckseite

Fondo

Chassis

Bottom

Bodenteil

Base

Presa Dinse

Prise Dix

Dinse Socket

Dinse Steckdose

Enchufe Dinse

Kit Diodi-igbt-resistenza

Kit Diodes-igbt-resistance

Kit Diodes-igbt-resistance

Kit Diodes-igbt-wiederstand

Kit Diodos-igbt-resistencia

Kit Scheda Secondario

Kit Fiche Secondaire

Kit Secondary Pcb

Kit Sekundaertrafokarte

Kit Tarjeta Secundario

Kit Scheda Primario

Kit Fiche Primaire

Kit Primary Pcb

Kit Primrtrafokarte

Kit Tarjeta Primario

Kit Diodo

Kit Diode

Kit Diode

Kit Diode

Kit Diodo

Kit Manopola

Kit Poignee

Knob Kit

Griff Kit

Kit Manija

Kit Trasformatore + Induttanza

Kit Tranformateur + Reactance

Kit Transformer + Reactance

Kit Trafo + Reaktanz

Kit Transformador + Reactancia

Kit Mantello

Kit Capot

Kit Cover

Kit Deckel

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

TECHNICALREPAIRCARD.

In order to improve the service, each servicing centre is requested to fill in the technical card on the following page at the end of every repair

job. Pleasefill inthis sheet as accurately as possibleandsendit toTelwin. Thank youinadvancefor your co-operation!

- 22 -

TECHNOLOGY 150-170-200-186CE/GE

Official servicing centers

Repairing sheet

Date:

Inverter :

Serial number:

Company:

Technician:

model

In which place has the inverter been used?

Building yard

Workshop

Others:

Supply:

Power supply

From mains without extension

: From mains with extension m

Mechanichal stresses the machine has undergone to

cription: Des

Dirty grade

Dirty inside the machine

Description:

Rectifier bridge

Electrolytic capacitors

Relais

In-rush limiter resistance

IGBT

Snubber

Secondary diodes

Potentiometer

Others

Kind of failure Component ref.

Substitution of primary circuit board: yes no

Substitution of primary control board: yes no

Troubles evinced during repair :

TELWIN S.p.A.

800 801

- Via della Tecnica, 3

36030 VILLAVERLA (Vicenza) Italy

Tel. +39 - 0445 - 858811

Fax +39 - 0445 - 858 / 858

E-mail: telwin@telwin.com http://www.telwin.com

You might also like

- Telwin Technika 145 165 200 BDocument12 pagesTelwin Technika 145 165 200 BDennis Xenos100% (3)

- Inverter Technology 175 210 188GEDocument24 pagesInverter Technology 175 210 188GEandtib100% (4)

- Telwin Tecnica 150 152 170 168ge Welding Inverter SMDocument21 pagesTelwin Tecnica 150 152 170 168ge Welding Inverter SMdanieltoader69No ratings yet

- Technology 150-170-200Document12 pagesTechnology 150-170-200andtib100% (1)

- SM MastertigMLS 3003 ACDC EN v1.2 PDFDocument32 pagesSM MastertigMLS 3003 ACDC EN v1.2 PDFValiBarda100% (1)

- Minarc Evo 150 Service ManualDocument31 pagesMinarc Evo 150 Service Manualcatalin949493% (15)

- Dynaudio Passa 3C BuildDocument20 pagesDynaudio Passa 3C BuildSoca AlexandruNo ratings yet

- Miele Fault CodesDocument22 pagesMiele Fault CodesSinisa MalesevicNo ratings yet

- Arc 200Document11 pagesArc 200Muhammad Shakeel100% (1)

- Mig Sonic 200 CVCC Service ManualDocument65 pagesMig Sonic 200 CVCC Service Manualbuggy bugger100% (1)

- Met 13Document1 pageMet 13gilmeanualexmihai100% (1)

- Variator TensiuneDocument8 pagesVariator TensiuneCristyMitre100% (1)

- Inverter Service ManualDocument81 pagesInverter Service ManualKy Vo100% (5)

- Fabricantes PSU 2the MaxDocument51 pagesFabricantes PSU 2the Maxhoaxnet100% (1)

- AY-At Color Kit Tester ManualDocument5 pagesAY-At Color Kit Tester ManualAnais Cullon BermejoNo ratings yet

- LZ Series: 1 POLE-1, 3, 5, 10 ADocument10 pagesLZ Series: 1 POLE-1, 3, 5, 10 ALucian SinpetruNo ratings yet

- Caddy LHL 130 PDFDocument58 pagesCaddy LHL 130 PDFTiago Anibaletto80% (5)

- TELWIN Technology 175 210 188GE PDFDocument24 pagesTELWIN Technology 175 210 188GE PDFAugustoferreira Ferreira100% (1)

- Esab Caddy Arc-151i A31 803-XxxDocument32 pagesEsab Caddy Arc-151i A31 803-XxxAnonymous nC9gpUWPNo ratings yet

- LD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsDocument27 pagesLD1117 Series: Low Drop Fixed and Adjustable Positive Voltage RegulatorsDavid EstebanNo ratings yet

- DS Power SH SHP Manual Three Phase UPS Tescom PDFDocument70 pagesDS Power SH SHP Manual Three Phase UPS Tescom PDFShakir Ali SayyedNo ratings yet

- Altivar® 61 - 71 Spare Parts Kits PDFDocument108 pagesAltivar® 61 - 71 Spare Parts Kits PDFNavegador9100% (1)

- 2011 Catalogue GenwayDocument36 pages2011 Catalogue GenwayMarino MatevskiNo ratings yet

- Kompakt 160Document180 pagesKompakt 160mihai37No ratings yet

- Skoda Fabia Electric RepairDocument152 pagesSkoda Fabia Electric RepairCentaguroDanNo ratings yet

- Driver L297 + L6203Document2 pagesDriver L297 + L6203TatiiieleeeNo ratings yet

- Esab Caddy Tig-2200i Ac-Dc 718-xxx To 843-xxxDocument64 pagesEsab Caddy Tig-2200i Ac-Dc 718-xxx To 843-xxxhitano12100% (1)

- At S Generator Wiring DiagramsDocument4 pagesAt S Generator Wiring Diagramscontact_egypt2No ratings yet

- 100 Watt Inverter CircuitDocument2 pages100 Watt Inverter Circuitmaster chibukingNo ratings yet

- Ecomax402502602 Service Manual PDFDocument36 pagesEcomax402502602 Service Manual PDFMihai LunguNo ratings yet

- Yaesu FT-707 Service ManualDocument128 pagesYaesu FT-707 Service ManualYayok S. Anggoro100% (1)

- XD Hardware ManualDocument157 pagesXD Hardware ManualNguyen Quang HuyNo ratings yet

- TV Sony Kv-pg14l70Document43 pagesTV Sony Kv-pg14l70Emilio Pinato100% (3)

- Zertifikat CE EMC Fuer Huawei SUN2000 10KTL M1 WechselrichterDocument1 pageZertifikat CE EMC Fuer Huawei SUN2000 10KTL M1 WechselrichterCristi Catalin100% (1)

- EDS Leakseeker 82BDocument8 pagesEDS Leakseeker 82Bbojan 2100% (1)

- Industrial Motors HANNINGDocument28 pagesIndustrial Motors HANNINGBeenish MirzaNo ratings yet

- Tda8588aj, Tda8588bj, Tda8588j PhilipsDocument55 pagesTda8588aj, Tda8588bj, Tda8588j PhilipsYeferson RodriguezNo ratings yet

- Digital ICDocument5 pagesDigital ICacidreignNo ratings yet

- Bladeups 12 Kva User'S Guide: EatonDocument120 pagesBladeups 12 Kva User'S Guide: EatonjorfameiNo ratings yet

- APC Symmetra PX Operation Manual 208V (10kW - 80kW)Document42 pagesAPC Symmetra PX Operation Manual 208V (10kW - 80kW)Goran JovanovicNo ratings yet

- DC-MOTOR-SPEED-CONTROLLER-1 Using 3525 Circuit of Oscillator PDFDocument1 pageDC-MOTOR-SPEED-CONTROLLER-1 Using 3525 Circuit of Oscillator PDFChAmirShokatGujjar100% (2)

- High Performances in Small Dimensions: InverterDocument19 pagesHigh Performances in Small Dimensions: InverterСДММ ГЕВГЕЛИЈАNo ratings yet

- 4 X 45W Quad Bridge Car Radio Amplifier Plus HSD: 1 FeaturesDocument11 pages4 X 45W Quad Bridge Car Radio Amplifier Plus HSD: 1 FeaturesAngel Quiñones0% (1)

- Zero Drop SpecDocument9 pagesZero Drop SpecSunu Karthikappallil100% (1)

- HAIER - HSU-09 12HC Service ManDocument109 pagesHAIER - HSU-09 12HC Service ManaircoolplusNo ratings yet

- Ac Inverter Service Manual-Aac-18ischDocument54 pagesAc Inverter Service Manual-Aac-18ischZoran Erceg100% (1)

- Tridonic-Catalogue 2012 2013 enDocument510 pagesTridonic-Catalogue 2012 2013 enPetru Bumb100% (1)

- Wharfedale Pro-Mp2800 SMDocument10 pagesWharfedale Pro-Mp2800 SMJavierNo ratings yet

- Growatt ShineWiFi User Manual 20160818Document2 pagesGrowatt ShineWiFi User Manual 20160818hitosnapNo ratings yet

- Axia Price List 130901Document33 pagesAxia Price List 130901Stephen Walker-WeinshenkerNo ratings yet

- Telwin Superior 240 AP - Sudura InverterDocument24 pagesTelwin Superior 240 AP - Sudura Inverterservicetv_clujNo ratings yet

- Tecnica 144-164Document21 pagesTecnica 144-164TedyS1959No ratings yet

- Telwin 111 RepairDocument20 pagesTelwin 111 RepairKlavdija CankarNo ratings yet

- Telwin PDFDocument24 pagesTelwin PDFmatjaz555No ratings yet

- Telwin Tecnica 144-164 Welding-Inverter SMDocument21 pagesTelwin Tecnica 144-164 Welding-Inverter SMAndreea TudoseNo ratings yet

- Aparat Sudura Tecnica - 144-164Document21 pagesAparat Sudura Tecnica - 144-164florin071No ratings yet

- Welding Inverter Tecnica - 141-161Document20 pagesWelding Inverter Tecnica - 141-161IvanSHNo ratings yet

- تشريح شاشة DELL D1025TMDocument23 pagesتشريح شاشة DELL D1025TMzizo6636No ratings yet

- Arduino 220V Full Wave Controlled Bridge Rectifier - Simple CircuitDocument15 pagesArduino 220V Full Wave Controlled Bridge Rectifier - Simple CircuitbasharfarhanNo ratings yet

- UC3848Document9 pagesUC3848Sergio Daniel BarretoNo ratings yet

- Tektronix TDS 220 User Instructions For ScopeDocument4 pagesTektronix TDS 220 User Instructions For ScopepedroscorpionNo ratings yet

- Chi Mei v260b1-l04 LCD Panel Repair InfoDocument19 pagesChi Mei v260b1-l04 LCD Panel Repair InfopedroscorpionNo ratings yet

- Whirlpool AWT2084Document9 pagesWhirlpool AWT2084jjchristy34100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- STR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFETDocument25 pagesSTR-A6100 Series Data Sheet: Off-Line PRC Controllers With Integrated Power MOSFETRaja RajaNo ratings yet

- Lecture Notes 2013Document231 pagesLecture Notes 2013alper senemNo ratings yet

- Stryker Xenon 6000 Light Source: Troubleshooting GuideDocument1 pageStryker Xenon 6000 Light Source: Troubleshooting GuideHealthcare repair and serviceNo ratings yet

- Cloud Computing Security From Single To Multi-CloudsDocument14 pagesCloud Computing Security From Single To Multi-CloudsMuthukumar KusalavanNo ratings yet

- Service Manual Lex MX 310 410 510.PDF 2Document394 pagesService Manual Lex MX 310 410 510.PDF 2Wellington SantosNo ratings yet

- Distillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelDocument8 pagesDistillation Operation, Control, Design and Troubleshooting Course For Maintenance PersonnelBadiuzzama AzmiNo ratings yet

- OnCall HR&IT Services IT27082020Document12 pagesOnCall HR&IT Services IT27082020Seshadri Vijayaraghavan Agaram MaangaduNo ratings yet

- ISO26262 and IEC61508Document12 pagesISO26262 and IEC61508최재호100% (1)

- Informacion TransferenciaDocument4 pagesInformacion TransferenciaHector Lizardo AndinoNo ratings yet

- Arabic Course - 12 - AppendixDocument6 pagesArabic Course - 12 - AppendixadeelNo ratings yet

- Swpe06 en Pss e Iec 60909 Fault Calculations s4Document2 pagesSwpe06 en Pss e Iec 60909 Fault Calculations s4Fitz Gerald Vidal100% (1)

- Updated List of OS Version Queries For WMI FiltersDocument13 pagesUpdated List of OS Version Queries For WMI FiltersPrivate ProfileNo ratings yet

- Swift Programming LanguageDocument14 pagesSwift Programming LanguagepharezeNo ratings yet

- TA400/800 FXS Gateway User Manual: Yeastar Information Technology Co. LTDDocument59 pagesTA400/800 FXS Gateway User Manual: Yeastar Information Technology Co. LTDIliescu CristianNo ratings yet

- VerizonWireless AffDocument2 pagesVerizonWireless Affjbjkhb hibNo ratings yet

- CatalogDocument66 pagesCataloggmconNo ratings yet

- HTML Question PaperDocument14 pagesHTML Question PaperNarendran88% (41)

- Further Pure Mathematics F1: Pearson EdexcelDocument32 pagesFurther Pure Mathematics F1: Pearson EdexcelLukeTayNo ratings yet

- DIODES - Total Solutions For NB Application 20100304 PDFDocument36 pagesDIODES - Total Solutions For NB Application 20100304 PDFsorintvrNo ratings yet

- CXCI Cordex 2v0 Quick RefDocument2 pagesCXCI Cordex 2v0 Quick RefGuillermo OvelarNo ratings yet

- C4H260 Participants HandbookDocument187 pagesC4H260 Participants HandbookRavi Dutt RamanujapuNo ratings yet

- Expo SysDocument2 pagesExpo SysEDWIN FABIAN ORTEGA GUEVARANo ratings yet

- Simulaids 2011 CatalogDocument68 pagesSimulaids 2011 CatalogAlfred De Jesús ToledoNo ratings yet

- Last Clean ExceptionDocument4 pagesLast Clean ExceptionHavanna G.No ratings yet

- NRC50Document2 pagesNRC50Krisi KostadinovaNo ratings yet

- Service Manual: - CD6000 / CD6000OSEDocument28 pagesService Manual: - CD6000 / CD6000OSELeonardo SantanaNo ratings yet

- Laptop Use Policy FormDocument2 pagesLaptop Use Policy FormVigNeshNo ratings yet

- Digital Development in Korea: Building An Information SocietyDocument273 pagesDigital Development in Korea: Building An Information SocietyBarbara BavoleoNo ratings yet

- Data Privacy and Online LearningDocument23 pagesData Privacy and Online LearningReymart de VeraNo ratings yet

- Vezbi Za Natprevar 1Document9 pagesVezbi Za Natprevar 1Zorica ArnaudovaNo ratings yet