Professional Documents

Culture Documents

Loading Unloading Temperature Welding Progression

Uploaded by

Rajesh OwaiyarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Loading Unloading Temperature Welding Progression

Uploaded by

Rajesh OwaiyarCopyright:

Available Formats

to Group No 2 2

Loading / Unloading

Temperature, Max

300C

Diameter > 6 mm (1/4 in.)

Type

Time Range, min

Welding Progression

Rate of Cooling Max.

Time Range, max

Rate of Heating

100C

Change of Alloy Element

150C

NA

All

NA

Position

Position(s) of Fillet

Material Specification

Fillet Base Metal

Chemical Analysis

Pipe Diameter

Mechanical Properties

POSITIONS (QW-405)

1 G Preheat Temperature, min.

Electrode Flux (Classification)

Consumable Insert

NA

NA

Backing Material

Refer Sketch

Welding Process GMAW

BASE METALS (QW-403)

2mm

2mm

605

Yes

Weld area

Nil

PPI/L&T/PQR/014 PQR No.

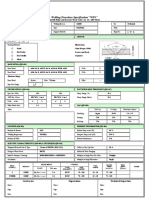

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

Date

Company Name Precision profiles India , Chennai.

WPS No. PPI/L&T/WPS/014 Rev 0 Date 6/4/2014

Retainer

100C

300C

Backing

JOINTS (QW-402)

Joint Design

Root land (B)

Bevel Angle

Root Space (A)

This procedure applying for fabrication welding/repair welding of P 1

material with PWHT

Scope

P.NO 1 Group No. 2

PREHEAT (QW-406)

Interpass Temperature, max.

620-640C

1 1/2hr min

2 hrs

A5.18

E R70S-6

6

1

1.2mm Dia

Wire

NA

NA

NA

Preheat Maintenance

Holding Temperature

Max.

Weld Metal Thickness Range

A-No.

POST WELD HEAT TREATMENT (QW-407)

Weld pass thickness 13 mm

Fillet

Size of Electrode / Filler Metal

Filler Metal Product Form

FILLER METALS (QW-404)

Manufacturer

ESAB MW1

ESAB INDIA

LTD

Consumables Brand Name

Supplemental Filler Metal

Specification No. (SFA)

AWS No. (Classification)

F-No.

Powder Feed Rate

Thickness Range

NIL

5-200mm All Size Fillet

P. No. 1(all P.NO 1 material)

Grade GR 70

Yes

Type: MANUAL

All size

All dia

5-200mm

Greater than 73mm

As per specification

As per specification

SA516

WELDING PROCEDURE SPECIFICATION

(WPS) (QW-482)

In accordance with QW-200.1, Section IX, ASME BPVC

FlowRate(litres/minute)

Signature: Signature:

Name: Name:

Method of back gouging

1.2 DC RP 120-160 20-24

Travel Speed

(range)

(mm/min)

120-180

120-180

Wire brushing & Chipping

String or Weave Bead

Oriffice, Nozzle and Gas cup size

Root run

NA NA

ELECTRICAL CHARACTERISTICS (QW-409)

Backing Gas NA

Both (Weave not more than 3 times of the electrode)

NA

Gas

Diameter

(mm)

CO2 99.99 15-20

Peening

Multiple or single electrode

Welding Process

Initial and interpass cleaning method

NA

GAS (QW-408)

Mode of metal transfer

Pulsing Current

Mixture composition (%)

NA

Note:

The filler metal shall be stored, issued and controlled as per manufacturer's recommendation / Precision Profiles India

procedures.

1.2 DC RP 150-220 20-30

GMAW E R70S-6

Sub sequence

layers

GMAW

Filler Metal Current

Weld Pass Process

Volt

(Range)

Heat input (max)

Shielding Gas

Electrode wire feed speed range

Type Amps (Range) Polarity

Name:

Signature:

NA

NA

NA

Globular Transfer

4-6 m/min

TECHNIQUE (QW-410)

NA

Grinding

NA

Multiple Pass

Multiple

single

NA

GMAW

NA

NA

Tungsten Electrode Size & Type

Use of thermal process

Multiple or single layer

Oscillation

Multiple or single pass (per side)

Electrode Spacing

PPI DNV FLOWSERVE

E R70S-6

Classification

Trailing Gas

Precision Profiles India,Chennai.

PPI/L&T/WPS/014 Date

PPI/L&T/PQR/014 Date

Refer Sketch

1 2 1 2

620-640 c

1.2mm dia

Both (weave not more than 3 times of the electrode)

Wire brushing & Chipping

Multiple pass

Multiple

Grinding

GMAW :Manual

weld area

nil

2mm

yes

2mm

150c

300c

nil

SA516

GR 70

NA

1hr

100c

100c

400c

Type Polarity

Amps

(Range)

DC RP 120-160

DC RP

String or Weave Bead

Weld Pass

ELECTRICAL CHARACTERISTICS (QW-409)

Current

Volt (Range)

Travel Speed (range)

(mm/min.)

20-25 120-180

Diameter

(mm)

Root run GMAW E R70S-6 1.2

Process

Filler Metal

Classification

Sub

sequence

layers

GMAW E R70S-6 1.2 150-220 20-30 120-180

Backing Gas

Weld metal thickness

na

120-180mm/min

TECHNIQUE (QW-410)

.

5.18

ER70S-6

13mm

99.99 15-20

1G Position

Shielding Gas

wire

Travel Speed

NA

SFA Specification

AWS Classification

Filler Metal F-No.

Weld Metal Analysis A-No.

Filler Metal Product Form

Size of Filler metal

NA

NA

6

Trailing Gas

Multiple or single electrode

Peening

Use of thermal process

Welding Process

Single

NA

GMAW

Multiple or single layer

FILLER METALS (QW-404)

1

300x150x32 Size (l x w x t) (mm)

C02

Flow Rate

(lpm)

32mm

PREHEAT (QW-406)

Preheat temperature

Preheat Maintenance

Rate of Heating

Diameter of test coupon na

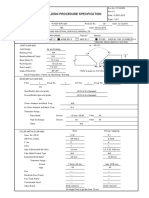

In accordance with QW-200.2, Section IX, ASME BPVC

JOINTS (QW-402)

Company Name

WPS NO

PQR No.

WELDING PROCEDURE QUALIFICATION RECORD

(PQR) (QW-483)

Type Welding Process

Date of Welding

Root gap / Space

Root land

Backing

Material Specification

.

Bevel Angle

P.No Gr. No.

BASE METALS (QW-403)

605

Grade Interpass temperature

Initial and interpass cleaning

Weld Progression

POSITION (QW-405)

Thickness of test coupon

P.No

Method of back gouging

Gr. No. to

Rate of Cooling

Temperature

POST WELD HEAT TREATMENT (QW-407)

Weld pass thickness <13mm Yes

Time

Oscillation

Multiple or single pass (per side)

10/29/2013 REV 0

REV 0

Loading / Unloading Temperature (max.)

HT

NA

Gas Mixture composition(%)

GAS (QW-408)

Joint Design

Backing Material

29-Oct-13

Retainer

Form No: QP-051-R0

In accordance with QW-200.2, Section IX, ASME BPVC

WELDING PROCEDURE QUALIFICATION RECORD

(PQR) (QW-483)

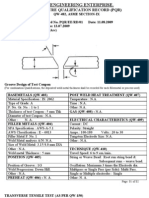

FILLET-WELD TESTS (QW-180)

Results

Penetration into parent metal

Macro - Results

NA

NA

NA

180 Sample ID-SB(1)

Sample ID-SB(2)

Sample ID-SB(3)

Bend Angle

610.37

Type and Figure No.QW462.3a`

Specimen No. Area, mm

2

Ultimate total

load, kN

Ultimate unit stress, MPa Thickness, mm Width, mm

Type of failure

& location

No cracks or fissures observed Sample ID-SB(4)

OTHER TESTS

Result

Free from spatters

182

181

No cracks or fissures observed

No cracks or fissures observed

No cracks or fissures observed

2

3

Macro Examination

1

Sl. No

183

Type of Examination

Visual Examination

Liquid Penetrant Examination

Radiographic Examination

Hardness (HV

10

)

Base

Weld

HAZ

No indication found in weld areas

Report no:PPIL 004/13-14

145 / 164

157 / 191

168 / 194

Specimen did not reveal any cracks or other defects

Result

Specimen Size(mm) 300 x 33 x 10.4

GUIDED-BEND TESTS (QW-160)

19.08

19.31 31.85 615.02 319.3

320.95

TENSILE TEST (QW-150)

31.99 BASE

BASE

525.83

519.17 T2

T1

O.Rajesh

Quality Assurance

E.X.Xavier

Quality Assurance

Reviewed & Approved by

4

5

We certify that the statements in this record are correct and that the test welds were prepared, welded, and tested in

accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Test Conducted by

M/s Precision Profiles India

PP

Prepared by

Welder's Name P.PANDIYAN Identification No.

Form No: QP-051-R0

M/s Precision Profiles India

70

GMAW

Manual

with backing

Plate

1 to 1

ER70S-6

6

NA

2mm

6mm

1G

NA

CO2

GMAW

We certify that the statements in this record are correct and that the test coupons were prepared, welded, and

tested in accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code.

Type Result Type Result

Quality Assurance Quality Assurance

Prepared by Reviewed & Approved by

O.Rajesh E.X.Xavier

Radiographic Examination results (QW-190) Report no:PPIL 004/13-14

M/s.PrecisionProfiles India

Side Bend

No cracks or

fissures observed

- - -

Bend test results (QW-462.2)

Welding qualification conducted by

Type Result

Mechanical Test conducted by M/s.MICRO LAB

Hardness Test conducted by

RESULTS

Visual Examination Results (QW-302.4)

Liquid Penetrant Examination results(QW-195.2)

M/s.MICRO LAB

Macro Examination conducted by M/s.MICRO LAB

5.18

Type of fuel gas (OFW)

Inert gas backing (GTAW, PAW, GMAW)

Position qualified (1G, 6G, 3F, etc.)

Vertical progression (uphill or downhill)

Deposit thickness for each proces , mm

Deposit thickness for each process (3 layers min)

Consumable insert (GTAW or PAW)

Filler Metal Product Form (solid/metal or flux cored/powder)

(GTAW or PAW)

Filler metal or electrode classification(s) (info. only)

Filler metal F-Number(s)

solid wire

32mm

Date of Welding 15-Nov-13

Base metal P-Number to P-Number

Filler metal or electrode specification(s) (SFA) (info. only)

Backing (with / without)

Plate or Pipe (enter diameter if pipe or tube)

Welding Process(es)

Type (i.e.; manual, semi-automatic) used

TESTING VARIABLES AND QUALIFICATION LIMITS

Welding Variables (QW-350)

WELDER PERFORMANCE QUALIFICATION

(WPQ) (QW-484A)

In accordance with QW-301, Section IX, ASME BPVC

WPQ No. PPI/L&T/WPQ/014 Date 1/2/2014

Welder's Name P.Pandiyan Identification No. PP

Weld Shop .

TEST DESCRIPTION

Identification of WPS followed PPI/L&T/WPS/014

Test Coupon or Production Weld Test Coupon

Material Specification SA516 Grade

Base Metal Thickness

Form No: QP-051-R0

You might also like

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- Draft WPS For Carbon Steel PipeDocument2 pagesDraft WPS For Carbon Steel Pipeabet_singkong893025% (4)

- Smaw Wps FinalDocument3 pagesSmaw Wps FinalsheikmoinNo ratings yet

- WPS and PQRDocument4 pagesWPS and PQRdandiar1No ratings yet

- WPSDocument6 pagesWPSNur Wijianto100% (1)

- WPS MigDocument3 pagesWPS MigAJOJOY00960% (5)

- Sample Wps-Carbon Steel GTAW+SMAWDocument2 pagesSample Wps-Carbon Steel GTAW+SMAWchetan85100% (7)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpDocument1 pagePQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarNo ratings yet

- WELDING PROCEDURE SPECIFICATION DETAILSDocument2 pagesWELDING PROCEDURE SPECIFICATION DETAILStuatk60% (5)

- Welding Procedure Specification For Storage Tank & Piping SystemDocument3 pagesWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadNo ratings yet

- Wps PQR For Reference p1 To p1 Smawxls PDF FreeDocument6 pagesWps PQR For Reference p1 To p1 Smawxls PDF FreeMahmoud GaberNo ratings yet

- QW-483 BlankDocument2 pagesQW-483 BlankCraftyBob100% (1)

- Mark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)Document6 pagesMark Technologies Company W.L.L: Preliminary Welding Procedure Specification (PWPS)vijay rajNo ratings yet

- Wps For SS 304Document3 pagesWps For SS 304MuraliKrishna87% (23)

- Welder Performance Qualification-Interactive Form QW-484ADocument1 pageWelder Performance Qualification-Interactive Form QW-484AJaved Mohammed100% (5)

- ASME 9 Calculator Approval RangesDocument2 pagesASME 9 Calculator Approval RangesEmel Besir100% (1)

- ASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesDocument9 pagesASME-Sec-IX, WPS, Quick Guide To Fix-Essential & Non-Essential VariablesAnnamalai Ram JGC100% (2)

- LBW WOPQ REV. 2010a Interactive FormDocument1 pageLBW WOPQ REV. 2010a Interactive Formcosmicbunny100% (1)

- Specification Type or Grade AWS Group No. Thickness Size (NPS) Schedule DiameterDocument3 pagesSpecification Type or Grade AWS Group No. Thickness Size (NPS) Schedule Diametercentaury2013No ratings yet

- WPS PQR-02Document8 pagesWPS PQR-02Ranjan Kumar100% (1)

- PQRDocument2 pagesPQRSreenivas Kamachi Chettiar100% (1)

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyraNo ratings yet

- PT Kuwera Karya Me: PanduDocument2 pagesPT Kuwera Karya Me: PanduGalang Pratama PutraNo ratings yet

- Preliminary WPS for 12.7mm SMAW WeldingDocument3 pagesPreliminary WPS for 12.7mm SMAW WeldingAnonymous 4e7GNjzGW100% (1)

- WPS For Different Materail by BhelDocument176 pagesWPS For Different Materail by Bhelsaisssms911691% (46)

- WPS PQR A36.20Document5 pagesWPS PQR A36.20gchaves504100% (2)

- Wps Gmaw SawDocument2 pagesWps Gmaw Sawupedro26No ratings yet

- ASME IX Sample WPS GTAW SMAWDocument1 pageASME IX Sample WPS GTAW SMAWDeepak ShrivastavNo ratings yet

- GTAW Welding Procedure SpecificationDocument3 pagesGTAW Welding Procedure SpecificationVimin Prakash100% (1)

- WPS For Structure Mild Steel Fillet Weld PDFDocument2 pagesWPS For Structure Mild Steel Fillet Weld PDFHarshit AdwaniNo ratings yet

- PQR 014 (Qualified Sa 106 GR BDocument5 pagesPQR 014 (Qualified Sa 106 GR Bersenthil100% (1)

- WPQT CertificateDocument104 pagesWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- WPQ Sample PrintoutDocument1 pageWPQ Sample PrintoutKannan VelNo ratings yet

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSDocument2 pagesSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPSsuria qaqcNo ratings yet

- (Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Document2 pages(Section IX, ASME Boiler and Pressure Vessel Code) : Welding Procedure Specification (WPS)Quality LaveenaNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- QIR-104-Welding Parameters Record SheetDocument1 pageQIR-104-Welding Parameters Record SheetSamer Bayati100% (1)

- Sample API 1104 WpsDocument6 pagesSample API 1104 Wpsjacquesmayol100% (2)

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- WPSDocument3 pagesWPSKhurram Burjees100% (1)

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- WPS FormatDocument2 pagesWPS FormatAmit SarkarNo ratings yet

- PQRDocument2 pagesPQRalokbdasNo ratings yet

- PQR & WPQ Standard Testing Parameter WorksheetDocument4 pagesPQR & WPQ Standard Testing Parameter WorksheetcosmicbunnyNo ratings yet

- PQR - 152Document3 pagesPQR - 152MAT-LIONNo ratings yet

- Super Duplex Stainless SteelDocument1 pageSuper Duplex Stainless SteelUma Shankar100% (1)

- QW-403 6Document1 pageQW-403 6Solikhul HarisNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- Superduplex Welding Procedure Specification (WPSDocument4 pagesSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- API 1104 welding defect acceptance criteria guideDocument1 pageAPI 1104 welding defect acceptance criteria guidehakamaffaqNo ratings yet

- Fit-Up Inspection Report PDFDocument1 pageFit-Up Inspection Report PDFAlfian Imaduddin100% (1)

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345No ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Document1 pageQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)proxywarNo ratings yet

- Weld Joint 1Document81 pagesWeld Joint 1rajibali27100% (1)

- PV Elite WebinarDocument24 pagesPV Elite WebinarAndrea Hank LattanzioNo ratings yet

- Engineering Design Basis Static EqptDocument52 pagesEngineering Design Basis Static EqptRajesh OwaiyarNo ratings yet

- Small File FastFerment ManualDocument36 pagesSmall File FastFerment ManualRajesh OwaiyarNo ratings yet

- Electrical NotesDocument1 pageElectrical NotesRajesh OwaiyarNo ratings yet

- Reactor & Dryer DesignDocument19 pagesReactor & Dryer DesignSepribo BraideNo ratings yet

- Equipment Calculation 05 Sep 15Document12 pagesEquipment Calculation 05 Sep 15Rajesh OwaiyarNo ratings yet

- Mechanical NotesDocument6 pagesMechanical NotesRajesh OwaiyarNo ratings yet

- Reactor & Dryer DesignDocument19 pagesReactor & Dryer DesignSepribo BraideNo ratings yet

- Thickness Calculation 31 Oct 16Document15 pagesThickness Calculation 31 Oct 16Rajesh OwaiyarNo ratings yet

- 21 Pressure Vessel HandbookDocument499 pages21 Pressure Vessel HandbookFelipe Arturo Biela Cornejo100% (22)

- Partial Liquid Volume in Horizontal Vessel-14-Feb-16Document3 pagesPartial Liquid Volume in Horizontal Vessel-14-Feb-16Rajesh OwaiyarNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Storage Tank Detail Calculation-21-Sep-16Document1 pageStorage Tank Detail Calculation-21-Sep-16Rajesh OwaiyarNo ratings yet

- Spray Dried Coconut Cream PowderDocument10 pagesSpray Dried Coconut Cream PowderRajesh OwaiyarNo ratings yet

- Vacuum Details PDFDocument2 pagesVacuum Details PDFRajesh OwaiyarNo ratings yet

- Condenser - Valuable Book PDFDocument6 pagesCondenser - Valuable Book PDFRajesh OwaiyarNo ratings yet

- ThicknessDocument3 pagesThicknessRajesh OwaiyarNo ratings yet

- PT ReportDocument49 pagesPT ReportRajesh Owaiyar100% (1)

- ThicknessDocument3 pagesThicknessRajesh OwaiyarNo ratings yet

- Heat Exchanger SizingDocument6 pagesHeat Exchanger Sizingshoaib705No ratings yet

- ThicknessDocument3 pagesThicknessRajesh OwaiyarNo ratings yet

- PV Elite 2011Document21 pagesPV Elite 2011chagar_harshNo ratings yet

- Minutes of The Event: : Dr. MGR Janaki College of Arts & Science For WomenDocument1 pageMinutes of The Event: : Dr. MGR Janaki College of Arts & Science For WomenRajesh OwaiyarNo ratings yet

- Saddle support and anchor bolting loads for ship moduleDocument12 pagesSaddle support and anchor bolting loads for ship modulemsraja77No ratings yet

- PT ReportDocument49 pagesPT ReportRajesh Owaiyar100% (1)

- Saddle support and anchor bolting loads for ship moduleDocument12 pagesSaddle support and anchor bolting loads for ship modulemsraja77No ratings yet

- 10mm Plate IdentificationDocument1 page10mm Plate IdentificationRajesh OwaiyarNo ratings yet

- Level 2 - H2S CertificateDocument51 pagesLevel 2 - H2S CertificateHadi HendizadehNo ratings yet

- LG, Sharp, and Toshiba TV Parts ListDocument27 pagesLG, Sharp, and Toshiba TV Parts ListAsep ZaenalNo ratings yet

- Sheet MetalDocument21 pagesSheet Metalt5gc4yqrptNo ratings yet

- Aircraft Materials, Construction and RepairDocument34 pagesAircraft Materials, Construction and RepairJoshua BarteNo ratings yet

- Notice: Antidumping: Brass Sheet and Strip From— MexicoDocument8 pagesNotice: Antidumping: Brass Sheet and Strip From— MexicoJustia.comNo ratings yet

- Lagro High School - SMAW Unit Test in 3rd GradingDocument4 pagesLagro High School - SMAW Unit Test in 3rd GradingLunilyn Ortega100% (1)

- The Future of Productivity: Wire Arc Additive Manufacturing: 3dprintDocument4 pagesThe Future of Productivity: Wire Arc Additive Manufacturing: 3dprintItziarNo ratings yet

- Metal Spinning: Jump To Navigation Jump To SearchDocument8 pagesMetal Spinning: Jump To Navigation Jump To SearchMaaz Uddin SiddiquiNo ratings yet

- Stair Tread Sizes & Weights ChartDocument1 pageStair Tread Sizes & Weights ChartAli Imran AliharNo ratings yet

- Mechanical Fastening TechniquesDocument17 pagesMechanical Fastening TechniquesNurhuda HayatiNo ratings yet

- The D and F-Block Elements: SolutionsDocument20 pagesThe D and F-Block Elements: SolutionsAnil AggaarwalNo ratings yet

- Provisional Cut Off MarksDocument6 pagesProvisional Cut Off MarksJahangir MollaNo ratings yet

- Ngoc Thao Drains PDFDocument80 pagesNgoc Thao Drains PDFDương HoàngNo ratings yet

- Maraging Steel 300 - C300 (UNS K93120) - Aircraft MaterialsDocument4 pagesMaraging Steel 300 - C300 (UNS K93120) - Aircraft MaterialsVysakh VasudevanNo ratings yet

- ASTM A247-10 Standard Test Method For Evaluating The Microstructure of Graphite in Iron CastingsDocument3 pagesASTM A247-10 Standard Test Method For Evaluating The Microstructure of Graphite in Iron CastingsJesus Talledo Bermudez75% (4)

- Material para BombasDocument3 pagesMaterial para BombasPeñaloz GustavoNo ratings yet

- MEng3181-Manufacturing Engineering I-Course Outline - 103309Document2 pagesMEng3181-Manufacturing Engineering I-Course Outline - 103309Yonael MezmureNo ratings yet

- EPMA Proceedings 2009 Sintering PDFDocument200 pagesEPMA Proceedings 2009 Sintering PDFEugene PaiNo ratings yet

- Chemistry (Whitten), 10th Ed - 2Document3 pagesChemistry (Whitten), 10th Ed - 2juan herreraNo ratings yet

- Stainless Steel 202 Material Chemical CompositionDocument3 pagesStainless Steel 202 Material Chemical CompositionLelka2000No ratings yet

- SIAM Commodity Prices - Monthly Monitor Report - April 2022Document44 pagesSIAM Commodity Prices - Monthly Monitor Report - April 2022vinay guptaNo ratings yet

- Directory of Rolling Mill Cluster JaipurDocument5 pagesDirectory of Rolling Mill Cluster JaipurShabbir Moizbhai100% (2)

- Presentation On Heat TreatmentsDocument34 pagesPresentation On Heat TreatmentsVinothkumarNo ratings yet

- Materials Science and Technology Review of Bainite Transformation TheoriesDocument46 pagesMaterials Science and Technology Review of Bainite Transformation TheoriesCoca CocaNo ratings yet

- Hydrogen Permeability and Integrity of Hydrogen Transfer PipelinesDocument52 pagesHydrogen Permeability and Integrity of Hydrogen Transfer PipelineslaercioudescNo ratings yet

- Tempcore ProcessDocument4 pagesTempcore Processvikassolanki2010No ratings yet

- ASTM A789 Stainless Steel TubingDocument6 pagesASTM A789 Stainless Steel TubingPlinio PazosNo ratings yet

- F 1667 - 05 Standard Specification for Driven FastenersDocument4 pagesF 1667 - 05 Standard Specification for Driven FastenerscsanchezptyNo ratings yet

- Guram Gongadze - Geologiis SafuzvlebiDocument332 pagesGuram Gongadze - Geologiis SafuzvlebiMari TatishviliNo ratings yet

- Osa International FairDocument4 pagesOsa International FairHernan MartNo ratings yet