Professional Documents

Culture Documents

Fired Heater Design

Uploaded by

Marisela Burke50%(2)50% found this document useful (2 votes)

1K views36 pagesTypical flue gas side heat transfer coefficient is between 15 - 20%. Minimum radiation loss ( based on LHV): Without APH=1.5% With APH=2.5% Arch pressure: Normal Value -2 MMWG TECHNIP FIRED HEATER DESIGN 3 PROCESS CONSIDERATIONS (cont.)

Original Description:

Original Title

36512435-Fired-Heater-Design.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTypical flue gas side heat transfer coefficient is between 15 - 20%. Minimum radiation loss ( based on LHV): Without APH=1.5% With APH=2.5% Arch pressure: Normal Value -2 MMWG TECHNIP FIRED HEATER DESIGN 3 PROCESS CONSIDERATIONS (cont.)

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

1K views36 pagesFired Heater Design

Uploaded by

Marisela BurkeTypical flue gas side heat transfer coefficient is between 15 - 20%. Minimum radiation loss ( based on LHV): Without APH=1.5% With APH=2.5% Arch pressure: Normal Value -2 MMWG TECHNIP FIRED HEATER DESIGN 3 PROCESS CONSIDERATIONS (cont.)

Copyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF, TXT or read online from Scribd

You are on page 1of 36

TECHNIP

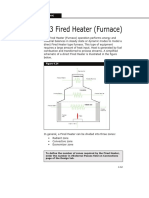

FIRED HEATER DESIGN

1

FIRED HEATER DESIGN

TECHNIP

FIRED HEATER DESIGN

2

PROCESS CONSIDERATIONS:

Maintain hydraulic symmetry:-Pipe lengths, fittings shall be

same for all passes.

Vaporizing Fluids Min.no. of passes.

Min. radiation loss ( based on LHV):

Without APH=1.5% With APH=2.5%

Arch pressure:

Normal Value -2.5 MMWG

TECHNIP

FIRED HEATER DESIGN

3

PROCESS CONSIDERATIONS (cont.)

Min. excess air:

(A) Natural Draft:-

Gas Firing 10%

Oil Firing 15%

(B) Forced Draft:-

Gas Firing 5%

Oil Firing 10%

TECHNIP

FIRED HEATER DESIGN

4

RADIANT SECTION DESIGN

Radiant average flux ( Kcal/Hr/M2 ):

Crude 32500

Vacuum / Naphtha / DHDS 27100

Delayed coker / Visbreaker 25000

Maximum film temp shall not be exceeded.

Maximum metal temp shall not be exceeded.

Max. volumetric heat release:

Oil Firing 107 Kcal/M3

Gas Firing 142 Kcal/M3

TECHNIP

FIRED HEATER DESIGN

5

RADIANT SECTION DESIGN (cont.)

Vertical cylindrical heaters:

H / D < 2.75

Horizontal tube heaters:

H / W < 2.75

Max. length for Vertical tubes = 18.3 M

Max. unsupported length for Horizontal tubes = lesser of 35 OD or 6M

Min. distance b/w refractory & tube center = 1.5Xnominal diameter

Duty absorbed in radiant = 60-70% of total absorbed duty

Normal Bridge wall temp = 600 - 800 deg C

Min design temp for tube support = 871 deg C

TECHNIP

FIRED HEATER DESIGN

6

CONVECTION SECTION DESIGN

Flue gas mass velocity ( Kg/S/M2):

Natural draft : 1.5 - 3.0

Forced draft : 3.0 - 4.5

Process mass velocity = 1220 - 1710 Kg/S/M2

Typical flue gas side heat transfer coefficient is between 15 - 25

Kcal/Hr/M2/K.

Types of extended surfaces:

Studs : for heavy fuels ( viz. Fuel oil )

Fins : for lighter fuels ( viz. Fuel gas, Bio gas)

TECHNIP

FIRED HEATER DESIGN

7

CONVECTION SECTION DESIGN (cont.)

Normally first 3 rows are considered as shield tubes. Hence no

extended surfaces are provided to prevent overheating of these tubes.

Never exceed critical velocity.

Maximum film temp shall not be exceeded.

Maximum metal (tube & extended surfaces) temp shall not be

exceeded.

TECHNIP

FIRED HEATER DESIGN

8

STACK DESIGN

Stack is designed to maintain -2.5 MMWG pressure at minimum 120%

of design heat release with design excess air & max. ambient temp.

Draft Analysis:

Draft = 0.1203 * Pa * ( ( Mwa / Ta ) - ( MWf / Tf ) ) * ( Z2-Z1 )

Where,

Pa = Ambient air pressure @ grade level (KPa)

Ta, Tf = Ambient air & Flue gas temp respectively ( K)

Mwa , MWf = Mol. Wt. of air & flue gas respectively ( Kg/Kg mol )

Z2, Z1 = Elevation of point 1 & 2 respectively (M)

TECHNIP

FIRED HEATER DESIGN

9

STACK DESIGN (cont.)

Total draft Gain = draft gain in convection + draft gain in stack.

Total pressure loss = pressure loss in convection ( entry loss, loss

across tubes & exit loss ) + pressure loss in stack

( entry loss,damper loss, friction loss & exit loss )

For viable design,

Arch pressure - Total pressure loss = Total draft gain

Normal Flue gas velocity in stack:

Natural draft 8 M / S

Induced draft 15 - 20 M / S

TECHNIP

FIRED HEATER DESIGN

10

STACK DESIGN (cont.)

Flue gas condensation:

Sulfur dioxide produced as a result of combustion converts into SO3

and reacts with water vapor present in the flue gas to form sulfuric acid.

This sulfuric acid at low temperature condenses on the inside surface

of the refractory. This is harmful for both the refractory & the casing.

Flue gas dew point depends on:

(A) Fuel sulfur content

(B) Flue gas O2 content

(C) Flue gas moisture content

(D) Combustion temp

(E) Fuel & flue gas additives

To avoid flue gas condensation, the flue gas temp is kept min 20-30

deg C above the flue gas dew point.

TECHNIP

FIRED HEATER DESIGN

11

FORCED DRAFT FAN

FD fans are designed with min 15 % margin over air flow rate

corresponding to design heat release.

FD fan discharge pressure should be capable enough to over come:

(A)Combustion air duct pressure loss ( straight & fittings )

(B)APH

(C)Burners

Design velocities in combustion air duct:

Straight, Tee, Turns ~15 M / S

Burner air supply & Plenum duct 7.5 - 10.5 M / S

Normally Centrifugal fan with fixed speed drive are used. Capacity

control is done by either Inlet guide vans / Inlet / Outlet damper.

TECHNIP

FIRED HEATER DESIGN

12

FORCED DRAFT FAN (cont.)

For critical applications ( viz. CDU/VDU etc.) 2 FD fans are provided.

Two options are used in case of 2 FD fans provided:

(A) 1 fan is running, other is standby - simple & cheaper but less

reliable.

(B) Both the fans are running at 50 % load - costly but more reliable.

MOC of casing - CS

MOC of Impeller - CS

TECHNIP

FIRED HEATER DESIGN

13

FORCED DRAFT FAN (cont.)

Following parameters to be specified for the selection of FD fan:

(A) Flow rate: Min / Nor / Max

(B) Temp: Min / Nor / Max / Design

(C) Inlet Pressure: Min / Nor

(D) Outlet Pressure : Nor / Max

(E) Air composition

(F) Driver : Motor / Steam turbine

(G) Spares

TECHNIP

FIRED HEATER DESIGN

14

INDUCED DRAFT FAN

ID fans are designed with min 20 % margin over flue gas flow rate

corresponding to design heat release.

Normal discharge pressure of ID fan is ambient pressure.

Suction pressure = arch pressure - total pressure loss in convection -

total pressure loss in off take duct- pressure drop

in inlet damper.

Design velocities in off take duct:

Straight, Tee, Turns ~12 M / S

MOC of casing - CS / SS

MOC of Impeller - CS / SS / Corten Steel A

TECHNIP

FIRED HEATER DESIGN

15

INDUCED DRAFT FAN (cont.)

Types of drive:

( A) Fixed speed drive (1000 or 1500 rpm ) - Capacity control by Inlet

guide vans/ Inlet damper

(B) Variable speed drive ( Fluid coupling, VFD ) - Capacity control by

varying speed.

Q n , H n2 , P n3

Care must be taken to avoid flue gas condensation on the Impeller.

Hence the minimum temperature at ID fan inlet shall be about 25-30

deg C above dew point.

TECHNIP

FIRED HEATER DESIGN

16

INDUCED DRAFT FAN (cont.)

Following parameters to be specified for the selection of ID fan:

(A) Flow rate: Min / Nor / Max

(B) Temp: Min / Nor / Max / Design

(C) Inlet Pressure: Min / Nor

(D) Outlet Pressure : Nor / Max

(E) Flue gas composition

(F) Driver : Motor / Steam turbine

(G) Spares

TECHNIP

FIRED HEATER DESIGN

17

BURNERS

Types of Burners:

(A) Gas Firing

(B) Oil Firing

(C) Combination Firing

No. of burners required for a given heat release shall be optimized

based on following criteria:

(A) In normal cases, max heat release per burner shall not exceed 3.0

MMKCal/Hr.

(B) Turndown requirements

(C) Flame dimension: ( Flame impingement on tubes, refractory &

adjacent burners shall be avoided )

(D) Heat distribution requirements

TECHNIP

FIRED HEATER DESIGN

18

BURNERS (cont.)

Component of Burner:

Main Gas/Oil tips , Pilot tip , Main flame scanner ( IR / UV ) , Pilot flame

scanner ( Ionization rod ) , Igniter , Sight ports.

No. of Burners Max./Nor. Heat Release

<5 1.25

6-7 1.20

>8 1.15

Min Pilot heat release 20000 Kcal/Hr

Type of Oil atomization:

(A) Pressure atomization = min oil pr. ~ 10 Kg/Cm2g

(B) Steam atomization = steam/oil ~ 0.3 Kg/Kg & Delta P ~2.1 Kg/Cm2

For Oil fired burners, max. viscosity is 43 CSt.

TECHNIP

FIRED HEATER DESIGN

19

BURNERS (cont.)

Generation of pollutants from Burner:

(A) SOx : Sox (SO2 & SO3 ) generation chiefly depends on the sulfur

content of the fuel.

(B) NOx : NOx (NO & NO2 ) is generated thermally by the reaction

occurring above 700-800 deg C. Methods of NOx reduction are:

Splitting fuel within burner

Splitting combustion air within burner

Diluting air-fuel mixture by flue gas mixing.

Normal limit is 50-125 ppmv for gas firing & 200-250 ppmv for oil firing.

(C) Unburnt hydrocarbon: Result of improper mixing of fuel with air.

(D) SPM: Soot, ash etc. Refraction method is used to monitor the SPM

content in flue gas.

TECHNIP

FIRED HEATER DESIGN

20

BURNERS (cont.)

Min parameters required for burner selection:

(A) Heat release : Min / Nor / Max

(B) Type of burner : Natural draft, Forced Draft, Low Nox, Combination.

(C) Fuel details : Composition, LHV, Pressure, Temperature

(D) Combustion air details: Temperature, Pressure, Relative humidity

(E) Nos. of burners, Ignition details.

(F) Emission requirements: SOx, NOx, UHC, SPM, CO etc.

(G) Noise limitation: 85 dBA A 1M from burner.

TECHNIP

FIRED HEATER DESIGN

21

AIR PREHEATER

Advantages of APH :

(A) Enhance efficiency ( up 92-93 %).

(B) To enhance air-fuel mixing ( High air velocity ).

(C) Reduce oil burner fouling

(D) More complete combustion of difficult fuels.

Disadvantages of APH:

(A) Increases potential of SO3 & NOx generation as adiabatic flame

temperature is high.

(B) Reduces the stack temp., so either ID fan or taller stack will be

required.

TECHNIP

FIRED HEATER DESIGN

22

AIR PREHEATER (cont.)

Steam air preheater (SAPH) is used when ambient air temp. falls to a

very low value.

Type of Air preheaters (recuperative type ) normally used in refinery

services:

(A) Tube Type: Tubes made of cast iron or glass. When cast iron tubes

are provided, the min. metal temp is kept 10-15 deg above dew point.

Adv: Very low leakage, Easy to design & fabricate, normally Low

unit cost, easy for maintainence.

Disadv: Higher pressure drop as compared to plate type, Heavy

so increases the structural cost if placed onboard, glass tubes

may damage during transportation..

TECHNIP

FIRED HEATER DESIGN

23

AIR PREHEATER (cont.)

(B) Plate Type: Typically it contains carbon steel plates(typically 2mm

thick) assembled in a frame. These modules are standard in size and

required capacity is obtained by increasing the number of modules.

Adv: Low pressure drop, Light in weight & compact, so mostly

used as onboard unit.

Disadv: Costly maintenance, easy to foul & corrode(sometimes

porcelain enameled plates are used ), high unit cost.

TECHNIP

FIRED HEATER DESIGN

24

AIR PREHEATERS (cont.)

Min data required for air preheater specification:

(A) Air / Flue gas flowrates : Min / Nor / Max

(B) Air / Flue gas temperatures (in/out): Min / Nor / Max / Des

(C) Air / Flue gas pressures (in) : Min / Nor / Max / Des

(D) Type of APH

(E) Duty : Nor/ Max

(F) Allowable pressure drop ( Air side / Flue gas side )

(G) Sulfur dew point of flue gas

(H) Flue gas composition

(I) Requirements of tube skin thermocouple.

TECHNIP

FIRED HEATER DESIGN

25

SOOTBLOWERS

Soot is generated as a result of improper combustion in burners.

Soot has to be removed to maintain heat transfer coefficient.

Type of soot blowers:

(A) Retractable type: Mostly use for high temperature & dirtier fuel

application. It is more costly but has better cleaning characteristics.

Normally it is used in fully automatic sequential mode.

(B) Fixed Rotary type: It is cheaper than Retractable type but can not

be used in high temperature or dirty fuel services.

(C) Vibration type: Ultrasound waves are used in this type to create

vibration to disengage the soot from the coils. Very limited experience

is available for this type.

TECHNIP

FIRED HEATER DESIGN

26

SOOT BLOWERS (cont.)

Min steam flowrate required : 4535 Kg/Hr

Min steam pressure required : 10 Kg/Cm2 g

Each soot blower should cover maximum 1.2M or 5 rows, whichever is

less.

Some times steam lancing nozzles are provided to remove soot for

smaller installations.

TECHNIP

FIRED HEATER DESIGN

27

DAMPERS

Type of Dampers:

(A) Control damper: It controls the draft in the heater. It can be either

manual or automatic in operation. It always has some leakage ( ~3%).

It can be single blade ( like butterfly damper ) or multiple blade ( like

louver damper ). Multiple blade damper can have parallel blade

opening or opposed blade opening ( better control but complex in

operation).

No. of Blades ~ inside area of the duct or stack (M2) / 1.2

Control damper is normally use in stack, FD/ID fan and combustion air

bypass around the APH.

TECHNIP

FIRED HEATER DESIGN

28

DAMPERS (cont.)

(B) Shut off damper:It is used to prevent the flow through a duct. It can be

operable manually by chain & pulley arrangement ( as in Guillotine

blind ) or by an electric motor ( as in swing gate ). It is designed for a

very high sealing efficiency ( 99.9%).

(C) Diverter damper: It is used to divert the flow of air or flue gas from one

duct to another duct.

TECHNIP

FIRED HEATER DESIGN

29

INSTRUMENTATIONS

Applicable code is OISD 111.

Following instruments are normally provided:

Draft gauge for radiant, convection, stack.

High / low arch pressure ( trip / alarm ).

High arch temperature ( alarm ).

Oxygen / CO analyzer in arch ( Alarm ).

Convection outlet temperature / pressure.

Stack outlet temperature / pressure.

SPM / NOx / SOx analyzers.

TECHNIP

FIRED HEATER DESIGN

30

INSTRUMENTATIONS (cont.)

Nozzles for pollution monitoring.

Tube skin temperatures in coil / APH.

Process fluid inlet & outlet temperature / pressure.

TECHNIP

FIRED HEATER DESIGN

31

REFRACTORIES

Type of refractories:

(A) High Density Fire Bricks(HDFB): These are normally placed on

the floor to protect the mechanically weak castables / bricks. They have

excellent mechanical strength but very poor thermal insulation

properties.They are laid loose on the floor. Exp. AC30 etc.

(B) Insulating Fire Bricks(IFB): These are normally placed on radiant

floor (below HDFB), radiant wall and sometimes in vertical flue gas

ducts. They are lighter than HDFB and hence mechanically poor.

Application of IFB requires more time than castables / ceramic fibres.

They are laid with mortar and expansion gaps are provided to

accommodate the thermal expansion of the bricks. Exp. JM 23, JM 26

etc.

TECHNIP

FIRED HEATER DESIGN

32

REFRACTORIES (cont.)

(C) Castables: Castable are placed in all parts of fired heater. They can be

mechanically very strong ( as Insulyte 15Li ) or thermally very superior (

like Firelite 124). They are applied on the surface by pouring or

gunning. Anchors (CS or SS-304, depending on the tip temperature)

are used to hold the castable with the casing. Normally V, Y or chain

link type anchors are used.

Castable can be applied in dual layer also. In dual layer construction, a

mechanically superior castable is used on hot face & thermally superior

castable on cold surface.

Sometimes ceramic blocks are used in place of castables. Exp.

Cerablok-800 etc.

TECHNIP

FIRED HEATER DESIGN

33

REFRACTORIES (cont.)

(D) Ceramic Fibres: These refractory materials are very light weight,

thermally superior but mechanically poor material. They are used as

loose fibres for filling gaps, blankets or module for application on

casing plates. They can not be used where the flue gas velocity is

40fps ( for blankets) or 80fps( for modules). Further, they can not be

applied where the total metal content exceeds 100 ppm. They are fixed

to the casing by studs & nuts. Application is very fast. Due to their low

weight, they can potentially reduce the structural cost. Normally a

vapour barrier (0.1 mm SS-304 foil) and an anticorrosive paint are used

to avert the flue gas condensation on the casing plate. Exp:

Cerablanket 1260, Cerablanket 1450 etc.

TECHNIP

FIRED HEATER DESIGN

34

METALLURGY

Process affects the material selection:

(A) Oxidation at high temperature.

(B) Vanadium & sodium attack in presence of sulfur.

(C) Attack by H2S.

(D) Attack by Polythionic acid.

(E) Attack by Chlorine.

(F) Attack by H2.

(G) Carburisation.

TECHNIP

FIRED HEATER DESIGN

35

METALLURGY (cont.)

Following tube materials are normally used:

Carbon Steel - 525 deg C

Low alloy steel (P11,P22) - 525 deg C

High alloy steel ( P5, P9) -600 deg C

Austenitic Stainless Steel

( SS304 / 310 / 321 / 347) -820 deg C

Following support materials are normally used:

CS : 427

o

C, 25Cr-20Ni : 871

o

C, 50Cr-50Ni-Cb : 982

o

C

Heater casing is always made of carbon steel.

TECHNIP

FIRED HEATER DESIGN

36

METALLURGY (cont.)

Typical tube material for various services:

Crude P5

Vacuum P9

Delayed coker / Visbreaker P9

Hydrotreater SS 321 / SS 347

Hot Oil Heater CS

Reboilers CS

You might also like

- Fired Heater DesignDocument36 pagesFired Heater DesignBladimir Soliz PardoNo ratings yet

- Furnace or Fired Heater 3Document13 pagesFurnace or Fired Heater 3Nia Syafiqq100% (1)

- AB-507 Installed Fired Heaters GuidelineDocument36 pagesAB-507 Installed Fired Heaters GuidelineRosa galindoNo ratings yet

- 01heat Exchanger-FOPE05Document30 pages01heat Exchanger-FOPE05kuldeep mohiteNo ratings yet

- Fired Heater Components-1Document8 pagesFired Heater Components-1ahmed atwaNo ratings yet

- DS-TI Tower InternalsDocument10 pagesDS-TI Tower Internalschris100% (1)

- Section 09 - Heat Transfer & ExchangersDocument54 pagesSection 09 - Heat Transfer & Exchangershwang2No ratings yet

- Heat ExchangersDocument56 pagesHeat ExchangersGeeva Prasanth ANo ratings yet

- Methods of Ethane Liquid Recovery From Natural GasDocument35 pagesMethods of Ethane Liquid Recovery From Natural GasJeff Formica100% (1)

- Heat ExchangerDocument12 pagesHeat ExchangeremergingengineerNo ratings yet

- Re Boilers 1Document16 pagesRe Boilers 1mamtNo ratings yet

- Fired HeatersDocument1 pageFired HeatersalikajbafNo ratings yet

- Boiler Components FunctionDocument2 pagesBoiler Components FunctionMuhammad Adli Bin Ja'affarNo ratings yet

- Air Cooled Heat Exchanger !Document17 pagesAir Cooled Heat Exchanger !RehinaNo ratings yet

- Fired Heater PDFDocument28 pagesFired Heater PDFzaza100% (1)

- Fired HeatersDocument19 pagesFired HeatersCelestine OzokechiNo ratings yet

- Prof. DR: Nazih Noaman BayomiDocument139 pagesProf. DR: Nazih Noaman Bayomirgopinath5100% (1)

- Floating Head Heat Exchanger HydrotestDocument15 pagesFloating Head Heat Exchanger Hydrotestjohn0% (1)

- Introduction To Column InternalsDocument7 pagesIntroduction To Column InternalsamitNo ratings yet

- Fire HeatDocument231 pagesFire HeatprabhuarunkumarNo ratings yet

- Energy Systems Presentation MaterialDocument208 pagesEnergy Systems Presentation MaterialLuis Enrique Leyva OvalleNo ratings yet

- HTFS Presentation 2Document57 pagesHTFS Presentation 2Divyesh Patel100% (1)

- Vessel Trays and InternalsDocument13 pagesVessel Trays and InternalsswatkoolNo ratings yet

- 8752.chapter 11 (Packed Column)Document32 pages8752.chapter 11 (Packed Column)AnaBelenMedranoBarrientosNo ratings yet

- 4 Rules of Fired Heater OperationDocument17 pages4 Rules of Fired Heater OperationIman KhavvajiNo ratings yet

- Crude DistillationDocument35 pagesCrude DistillationraisNo ratings yet

- Two Reboiler Simultaneously RunDocument16 pagesTwo Reboiler Simultaneously RunteddyNo ratings yet

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- P10 Natural Gas - Removal of Acid GasesDocument73 pagesP10 Natural Gas - Removal of Acid GasesWalid Ben Husein100% (2)

- Sieve Tray Column: Design of HC Process Equipments PE 350Document14 pagesSieve Tray Column: Design of HC Process Equipments PE 350Shreya Sahajpal KaushalNo ratings yet

- Positive Displacement CompressorDocument30 pagesPositive Displacement CompressorchaitanyaNo ratings yet

- Tray Sizing Presentation PDFDocument105 pagesTray Sizing Presentation PDFLuis Enrique Leyva OvalleNo ratings yet

- Paradeep Refinery Project: A Sunrise Project For A Sunshine FutureDocument35 pagesParadeep Refinery Project: A Sunrise Project For A Sunshine Futuremujeebtalib80% (5)

- Column & Vessel - NSDocument144 pagesColumn & Vessel - NSmujeebtalibNo ratings yet

- ENCON Handbook Fired HeaterDocument18 pagesENCON Handbook Fired HeaterArulvalavan DuraikannanNo ratings yet

- Sthe SSDocument43 pagesSthe SSNathanianNo ratings yet

- Air Cooled Heat Exchangers - TrainingDocument73 pagesAir Cooled Heat Exchangers - Trainingdivakar100% (2)

- Petrochemical Industries Company (K.S.C) Aromatics Complex ProjectDocument26 pagesPetrochemical Industries Company (K.S.C) Aromatics Complex Projectranjitkumar1977100% (1)

- 4 ReboilersDocument33 pages4 ReboilersĀĥMệd HĀşşan100% (3)

- 8-0241-4503-Flare System Design PDFDocument8 pages8-0241-4503-Flare System Design PDFVinothrajaNo ratings yet

- Kettle ReboilersDocument4 pagesKettle ReboilersMuhammad Usman100% (1)

- Fired Heater Design PDFDocument12 pagesFired Heater Design PDFSterlingNo ratings yet

- Fired Heater Presentation - Final97 2003Document40 pagesFired Heater Presentation - Final97 2003Altif Abood100% (2)

- Coloumn and VesselDocument144 pagesColoumn and VesselTung LamNo ratings yet

- ATM Storage TankDocument10 pagesATM Storage TanksameerpecNo ratings yet

- C:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchDocument1 pageC:/Users/UDI/Job/PUSTEK E&T/PROJECT FOSTER/Air Cooler - Htri: 48 InchFadhila Ahmad AnindriaNo ratings yet

- Distillation Column InternalsDocument17 pagesDistillation Column InternalsAhmed Omar AmineNo ratings yet

- DCU HeaterDocument46 pagesDCU Heatermujeebtalib100% (2)

- Total - VESSELSDocument18 pagesTotal - VESSELSTala RamezaniNo ratings yet

- Flare SystemDocument29 pagesFlare SystemBaba Johneh100% (1)

- Distillation TowwerDocument154 pagesDistillation TowwerAmmar HashimNo ratings yet

- AIChE 2018 Improving Catalytic Reformer Heaters Using Split Flow TechnologyDocument31 pagesAIChE 2018 Improving Catalytic Reformer Heaters Using Split Flow Technologyashutosh_garg_10No ratings yet

- Ahmed Deyab: Senior Process Engineer Process Simulation ConsultantDocument154 pagesAhmed Deyab: Senior Process Engineer Process Simulation ConsultantHamza AliNo ratings yet

- Fired Heater DesignDocument36 pagesFired Heater Designsaminasritn100% (6)

- Gas TurbineDocument93 pagesGas TurbineShubhankit Porwal100% (2)

- Nitric Acid Plant DetailsDocument21 pagesNitric Acid Plant DetailsBon BonNo ratings yet

- Fired Heater - 2013 FW TalkDocument38 pagesFired Heater - 2013 FW TalkSong Hoe100% (2)

- Turbine Heat Rate and EfficiecyDocument48 pagesTurbine Heat Rate and EfficiecyPralay Raut100% (6)

- Overiew of Comb Cycle Rev 6.0 - Part 1Document73 pagesOveriew of Comb Cycle Rev 6.0 - Part 1SamNo ratings yet

- Designing of Steam Reformer& Heat Recovery Unit in Direct Reduced Iron Production (DRI)Document71 pagesDesigning of Steam Reformer& Heat Recovery Unit in Direct Reduced Iron Production (DRI)Engr Faiq Chauhdary100% (2)

- Style Alpha FC: Installation InstructionsDocument2 pagesStyle Alpha FC: Installation InstructionsAjiCiangsanaNo ratings yet

- Waste Treatment and Biogas Quality in Small-Scale Agricultural DigestersDocument10 pagesWaste Treatment and Biogas Quality in Small-Scale Agricultural DigestersMarisela BurkeNo ratings yet

- Le Pen - No Free School For Foreigners - BBC NewsDocument9 pagesLe Pen - No Free School For Foreigners - BBC NewsMarisela BurkeNo ratings yet

- PT. Burangkeng Maju Tehnik Steel Fabricator and Minning Support EquipmentDocument8 pagesPT. Burangkeng Maju Tehnik Steel Fabricator and Minning Support EquipmentMarisela BurkeNo ratings yet

- Biogas Rate Waste Water Industrial - Google SearchDocument2 pagesBiogas Rate Waste Water Industrial - Google SearchMarisela BurkeNo ratings yet

- Style Alpha FC: Installation InstructionsDocument2 pagesStyle Alpha FC: Installation InstructionsAjiCiangsanaNo ratings yet

- 04 06 Alpha FCA InstallDocument16 pages04 06 Alpha FCA InstallMarisela BurkeNo ratings yet

- Trump Picks Climate Sceptic Pruitt For Environment Chief - BBC NewsDocument12 pagesTrump Picks Climate Sceptic Pruitt For Environment Chief - BBC NewsMarisela BurkeNo ratings yet

- China Introduces 10% Extra Tax On 'Super Cars' - BBC NewsDocument9 pagesChina Introduces 10% Extra Tax On 'Super Cars' - BBC NewsMarisela BurkeNo ratings yet

- Seven People Dead in Tennessee Wildfire - BBC NewsDocument12 pagesSeven People Dead in Tennessee Wildfire - BBC NewsMarisela BurkeNo ratings yet

- 'My Alcoholic Brother Chose Euthanasia' - BBC NewsDocument3 pages'My Alcoholic Brother Chose Euthanasia' - BBC NewsMarisela BurkeNo ratings yet

- Gambia Election - Estate Agent Challenges Yahya Jammeh - BBC NewsDocument12 pagesGambia Election - Estate Agent Challenges Yahya Jammeh - BBC NewsMarisela BurkeNo ratings yet

- 'Grizzly Bear Spirit' Case at Canada's Supreme Court - BBC NewsDocument10 pages'Grizzly Bear Spirit' Case at Canada's Supreme Court - BBC NewsMarisela BurkeNo ratings yet

- Australia's Dreamworld Theme Park To Reopen After Ride Deaths - BBC NewsDocument10 pagesAustralia's Dreamworld Theme Park To Reopen After Ride Deaths - BBC NewsMarisela Burke0% (1)

- Ohio Attacker Abdul Ali Artan Was 'Somali Refugee' - BBC NewsDocument12 pagesOhio Attacker Abdul Ali Artan Was 'Somali Refugee' - BBC NewsMarisela BurkeNo ratings yet

- 'Trump Effect' Led To Hate Crime Surge, Report Finds - BBC NewsDocument12 pages'Trump Effect' Led To Hate Crime Surge, Report Finds - BBC NewsMarisela BurkeNo ratings yet

- Brazil Chapecoense Football Team in Colombia Plane Crash - BBC NewsDocument14 pagesBrazil Chapecoense Football Team in Colombia Plane Crash - BBC NewsMarisela BurkeNo ratings yet

- Samsung Electronics Considers Splitting Firm in Two - BBC NewsDocument10 pagesSamsung Electronics Considers Splitting Firm in Two - BBC NewsMarisela BurkeNo ratings yet

- French Confectioners Battle Chinese Firm Over Calissons D'aix - BBC NewsDocument10 pagesFrench Confectioners Battle Chinese Firm Over Calissons D'aix - BBC NewsMarisela BurkeNo ratings yet

- Chapecoense Plane Crash - Football Rallies Around Brazilian Team - BBC NewsDocument11 pagesChapecoense Plane Crash - Football Rallies Around Brazilian Team - BBC NewsMarisela BurkeNo ratings yet

- Migrant Crisis - Italy Sees Record Arrivals From North Africa - BBC NewsDocument10 pagesMigrant Crisis - Italy Sees Record Arrivals From North Africa - BBC NewsMarisela BurkeNo ratings yet

- Zika Virus - Texas Reports First Case From Local Mosquito - BBC NewsDocument10 pagesZika Virus - Texas Reports First Case From Local Mosquito - BBC NewsMarisela BurkeNo ratings yet

- Fidel Castro Death - Cubans Queue To Pay Their Respects - BBC NewsDocument11 pagesFidel Castro Death - Cubans Queue To Pay Their Respects - BBC NewsMarisela BurkeNo ratings yet

- Islam - WikipediaDocument30 pagesIslam - WikipediaMarisela BurkeNo ratings yet

- Plans To Curb House of Lords Powers 'Dropped' - BBC NewsDocument9 pagesPlans To Curb House of Lords Powers 'Dropped' - BBC NewsMarisela BurkeNo ratings yet

- Brazil - Protesters Storm Congress Seeking Military Rule - BBC NewsDocument11 pagesBrazil - Protesters Storm Congress Seeking Military Rule - BBC NewsMarisela BurkeNo ratings yet

- Animals Still Poached in 'Horrifying Numbers' - Prince William - BBC NewsDocument10 pagesAnimals Still Poached in 'Horrifying Numbers' - Prince William - BBC NewsMarisela BurkeNo ratings yet

- Minnesota Court Jails Leader of Islamic State Plot For 35 Years - BBC NewsDocument10 pagesMinnesota Court Jails Leader of Islamic State Plot For 35 Years - BBC NewsMarisela BurkeNo ratings yet

- Mayan 'Nesting Doll Pyramid' Discovered in Mexico - BBC NewsDocument11 pagesMayan 'Nesting Doll Pyramid' Discovered in Mexico - BBC NewsMarisela BurkeNo ratings yet

- Hundreds of Rohingya Try To Escape Myanmar Crackdown - BBC NewsDocument9 pagesHundreds of Rohingya Try To Escape Myanmar Crackdown - BBC NewsMarisela BurkeNo ratings yet

- AIATS Schedule For RM (XII Passed) 2020-21 - Version 3.0-2Document2 pagesAIATS Schedule For RM (XII Passed) 2020-21 - Version 3.0-2Saksham SharmaNo ratings yet

- Stem 11 - Genbio 1 NotesDocument6 pagesStem 11 - Genbio 1 NotesELIZABETH ANNE SABIANONo ratings yet

- Modul 2 - 1. Tambahan 2016Document67 pagesModul 2 - 1. Tambahan 2016RIKI GUNAWANNo ratings yet

- Instructions For UseDocument2 pagesInstructions For Usefreebass08No ratings yet

- HAC-10143-MS-CIV-003-Method Statement For Concrete RepairDocument26 pagesHAC-10143-MS-CIV-003-Method Statement For Concrete RepairHema playsNo ratings yet

- Presentation 1Document8 pagesPresentation 1Shahood JuttNo ratings yet

- Pancreatic JuiceDocument11 pagesPancreatic JuiceZahidKhanNo ratings yet

- Chem Trails Joe DeBrouseDocument2 pagesChem Trails Joe DeBrouseDave WaltonNo ratings yet

- Technical Data Sheet Jaz Coilex Pe Intermediate JP-17001: DescriptionDocument2 pagesTechnical Data Sheet Jaz Coilex Pe Intermediate JP-17001: DescriptionAhmad BougeisNo ratings yet

- Determination of The % Acetic Acid in Vinegar Samples: (Citation Pit18 /L 1033)Document6 pagesDetermination of The % Acetic Acid in Vinegar Samples: (Citation Pit18 /L 1033)Blest 13No ratings yet

- 30074b PDFDocument9 pages30074b PDFUanaid Van RooyenNo ratings yet

- Chapter 1 - Week 1Document67 pagesChapter 1 - Week 1Auni AdenanNo ratings yet

- Labbio - Tue - Lab Report 4 - Group 5 TuesdayDocument6 pagesLabbio - Tue - Lab Report 4 - Group 5 TuesdayVân Anh Nguyễn NgọcNo ratings yet

- 64464eaa680fe80019394cbe - ## - Mole Concept - DPP 04 (Of Lec 06) - Arjuna JEE 2024Document3 pages64464eaa680fe80019394cbe - ## - Mole Concept - DPP 04 (Of Lec 06) - Arjuna JEE 2024vishal754906No ratings yet

- Designation & Selection of Welding ConsumablesDocument16 pagesDesignation & Selection of Welding ConsumablesAd Man GeTigNo ratings yet

- Process Analyzer Sample Systems: Home BlogDocument8 pagesProcess Analyzer Sample Systems: Home BlograhulNo ratings yet

- CHAPTERSDocument46 pagesCHAPTERSnjoku danielNo ratings yet

- Colori Siser-HiresDocument6 pagesColori Siser-HiresjohnNo ratings yet

- Fire and ExplosionDocument10 pagesFire and ExplosionrutvikNo ratings yet

- 9 Module9 Disinfection 29-03 2022 LFPDocument27 pages9 Module9 Disinfection 29-03 2022 LFPArjun RanabhatNo ratings yet

- Molecules 28 04005Document26 pagesMolecules 28 04005Cemerlang StudiNo ratings yet

- IV Drug IncompatibilitiesDocument29 pagesIV Drug IncompatibilitiesMichael Freudiger100% (2)

- Polycarbonate Sheets NotesDocument7 pagesPolycarbonate Sheets NotesAdrian PerezNo ratings yet

- 6RemovalofIronFromAluminum ReviewDocument61 pages6RemovalofIronFromAluminum ReviewJohn TorrezNo ratings yet

- Foxboro Flow Meters - 9700ADocument2 pagesFoxboro Flow Meters - 9700AJuan Nicolas Altamirano HerreraNo ratings yet

- Salcare Super 7 at 1Document1 pageSalcare Super 7 at 1xeon585100% (1)

- Foliar Sprays Soil Nutrition 2016Document4 pagesFoliar Sprays Soil Nutrition 2016aruizca93No ratings yet

- Importance of WetlandsDocument5 pagesImportance of WetlandsTopNo ratings yet

- Guava IrshadDocument14 pagesGuava IrshadPedro de SouzaNo ratings yet

- Brochure ProFlake EnglishDocument4 pagesBrochure ProFlake EnglishDhruv SevakNo ratings yet