Professional Documents

Culture Documents

Capacity

Uploaded by

BabarKalamCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capacity

Uploaded by

BabarKalamCopyright:

Available Formats

Introduction to Materials

Management

Chapter 5 Capacity Management

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Basic Capacity Definitions

Capacity Required capacity needed to

produce a desired output in a given time

period

Capacity Planning determining the

resources and methods needed to meet the

priority plan

Capacity Control monitoring production,

comparing with the capacity plan, and taking

appropriate corrective actions

Capacity Management determining capacity

needed as well as providing, monitoring, and

controlling the capacity

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Capacity versus Load

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Capacity Planning Levels

Resource Planning Long range

resource requirements linked to the

production plan

Rough-cut Capacity Planning Used to

check feasibility of MPS

Capacity Requirements Planning

Detailed work center capacity plans

linked to MRP

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Capacity Planning Levels

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Capacity Requirements Planning

Inputs

Open Order File found as scheduled

receipts on MRP

Planned order releases from MRP

Potential future orders

Work Center file

Information on capacity in the work center

Move, wait, and queue time information

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Routing file the path that the work

will follow

Operations to be performed

Operation sequence

Work centers used

Potential alternative work centers

Tooling needed

Standard setup times and run times

Capacity Requirements Planning

Inputs - Continued

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

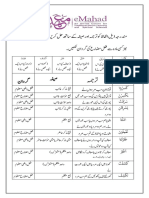

Sample Routing File

Figure 5.3 Routing file

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Capacity Available

Impacted by:

Product specification

Product mix

Methods used to make product

Pace of work

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Finding Capacity Available

Rated Capacity = (available time) x

(utilization) x (efficiency)

Available time number of hours a work

center can be used

Utilization = [(hours worked)/(available

hours)] x 100%

Efficiency = [(actual production

rate)/(standard production rate)] x 100%

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Capacity Load Sum of all time required

for orders on a work center - Example

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Example Load Profile

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Scheduling Orders

Back scheduling (the typical approach)

Start with the due date, use lead time

to find the proper start date for each

operation

Forward scheduling Launch the order

into the first (gateway) work center,

then use the lead times to find when

the order will be completed at each

work center

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Back Scheduling Example

An order for 150 of a component is due on

day 135

An order starts at the beginning of a day and

finished at the end of a day

Operation times for the 150 ordered:

Operation 10 4 days in work center 12

Operation 20 5 days in work center 14

Operation 30 1 day in work center 17

Operation 40 2 days in work center 03

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Data from the work center file

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

The resulting work schedule

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

The work schedule shown

graphically

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Making the plan

Introduction to Materials Management, 7

th

Edition

Arnold, Chapman, Clive

2012, 2008, 2004, 2001, 1998, 1996 Pearson Education, Upper Saddle River, NJ 07458.

All Rights Reserved.

Managing the Plan Adjusting

Capacity

Use Overtime or Undertime

Adjust the number of workers

Shift workers from other work centers

Use alternative work centers to shift

load

Subcontract work

You might also like

- Advanced Styl4Document32 pagesAdvanced Styl4dominik1236083No ratings yet

- Have A Conversation in Arabic - 0Document6 pagesHave A Conversation in Arabic - 0BabarKalamNo ratings yet

- Arabic Verb Chart Enhanced LayoutDocument1 pageArabic Verb Chart Enhanced LayoutNoorikiran HarisNo ratings yet

- EViews 7 Users Guide IDocument686 pagesEViews 7 Users Guide Iitaliano5100% (3)

- Usul Al ShashiDocument166 pagesUsul Al Shashihafizurahman100% (1)

- Vega-Redondo F. Evolution, Games, and Economic Behaviour (OUP, 1996) (ISBN 0198774737) (O) (222s) - GG - PDFDocument222 pagesVega-Redondo F. Evolution, Games, and Economic Behaviour (OUP, 1996) (ISBN 0198774737) (O) (222s) - GG - PDFBabarKalamNo ratings yet

- Mae To Upload KarongaDocument1 pageMae To Upload KarongaBabarKalamNo ratings yet

- Zakah (IBin Baz) PDFDocument24 pagesZakah (IBin Baz) PDFUsman ArifNo ratings yet

- Raheysalamat Bab 4Document23 pagesRaheysalamat Bab 4BabarKalamNo ratings yet

- Raheysalamat Bab 5Document13 pagesRaheysalamat Bab 5BabarKalamNo ratings yet

- Raheysalamat Bab 9Document48 pagesRaheysalamat Bab 9BabarKalamNo ratings yet

- Raheysalamat Bab 5Document13 pagesRaheysalamat Bab 5BabarKalamNo ratings yet

- Raheysalamat Bab 8Document53 pagesRaheysalamat Bab 8BabarKalamNo ratings yet

- Eviews User Guide 2Document822 pagesEviews User Guide 2Rana Muhammad Arif KhanNo ratings yet

- Raheysalamat Bab 3Document31 pagesRaheysalamat Bab 3BabarKalamNo ratings yet

- Raheysalamat Bab 2Document19 pagesRaheysalamat Bab 2BabarKalamNo ratings yet

- Barae Meherbani Upload HojaoDocument1 pageBarae Meherbani Upload HojaoBabarKalamNo ratings yet

- Why Are Artists PoorDocument369 pagesWhy Are Artists PoorWhatnoW_No ratings yet

- Raheysalamat Bab 1Document18 pagesRaheysalamat Bab 1BabarKalamNo ratings yet

- Work Sheet3-Answer PDFDocument2 pagesWork Sheet3-Answer PDFBabarKalamNo ratings yet

- Pre SessiomathsbookDocument85 pagesPre SessiomathsbookBabarKalamNo ratings yet

- Work Sheet 7Document1 pageWork Sheet 7BabarKalamNo ratings yet

- Work Sheet3 AnswerDocument2 pagesWork Sheet3 AnswerBabarKalamNo ratings yet

- 110 - Hadith - Qudsi - Page 22Document1 page110 - Hadith - Qudsi - Page 22BabarKalamNo ratings yet

- 110 - Hadith - Qudsi - Page 22Document1 page110 - Hadith - Qudsi - Page 22BabarKalamNo ratings yet

- Work Sheet 2Document2 pagesWork Sheet 2BabarKalamNo ratings yet

- Renaming HTML files to CHMDocument14 pagesRenaming HTML files to CHMyahoo_maverickNo ratings yet

- Math For EcoDocument65 pagesMath For EcoBabarKalamNo ratings yet

- Work Sheet 3Document1 pageWork Sheet 3BabarKalamNo ratings yet

- Why Are Artists PoorDocument369 pagesWhy Are Artists PoorWhatnoW_No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Translate - Google SDocument1 pageTranslate - Google SJoan VeranoNo ratings yet

- XXXXX XXX LTD: Presenter: XXX, XXXX & XXX. Topic: Demo ClientDocument7 pagesXXXXX XXX LTD: Presenter: XXX, XXXX & XXX. Topic: Demo ClientSanjayNo ratings yet

- Guia de Aprendizaje - Internet ReadingDocument9 pagesGuia de Aprendizaje - Internet ReadingAndrea AvilaNo ratings yet

- Datasheet Eprom ST 27C512Document19 pagesDatasheet Eprom ST 27C512Rafael SaranholiNo ratings yet

- What Is HCI & Its ImportanceDocument50 pagesWhat Is HCI & Its ImportanceMirza AlibaigNo ratings yet

- Multithreaded Programming Using Java Threads: Prof. Rajkumar BuyyaDocument46 pagesMultithreaded Programming Using Java Threads: Prof. Rajkumar BuyyaSyed AbusaliNo ratings yet

- Join Seon-ho's Fan Cafe in 7 Easy StepsDocument33 pagesJoin Seon-ho's Fan Cafe in 7 Easy StepsTyas PuspitaningrumNo ratings yet

- HPE ProLiant HPE ML350 Gen10 4110, 877621-371Document4 pagesHPE ProLiant HPE ML350 Gen10 4110, 877621-371ediNo ratings yet

- Proteccion df30Document406 pagesProteccion df30Rodrigo AndresNo ratings yet

- The 10th TSSA Program Book v1.0 Final Version PDFDocument19 pagesThe 10th TSSA Program Book v1.0 Final Version PDFAyu Rosyida zainNo ratings yet

- Color Iqc / Color Imatch Installation NotesDocument3 pagesColor Iqc / Color Imatch Installation NotesSohel NomanNo ratings yet

- Abandoned Cart Emails: A Data-Driven Guide To Recovering Lost SalesDocument37 pagesAbandoned Cart Emails: A Data-Driven Guide To Recovering Lost SalesTochi Krishna AbhishekNo ratings yet

- 514 Advances in Core ImageDocument126 pages514 Advances in Core ImageDiamond LewisNo ratings yet

- What Is The 5G Charging Function?Document6 pagesWhat Is The 5G Charging Function?aliNo ratings yet

- Bài 1: thiết kế mạch giải mã 3 -8Document7 pagesBài 1: thiết kế mạch giải mã 3 -8Thắng TrầnNo ratings yet

- Backing Up and Restoring A Hyperion Essbase DatabaseDocument11 pagesBacking Up and Restoring A Hyperion Essbase DatabaseSreedhar ThatipallyNo ratings yet

- Mid ServerDocument2 pagesMid ServerranjithgottimukkalaNo ratings yet

- Compare Samsung Tab A8 Wifi (X200) Vs Tab A8 LTE (X205)Document3 pagesCompare Samsung Tab A8 Wifi (X200) Vs Tab A8 LTE (X205)anikfajar136No ratings yet

- Visual C# Programming BasicsDocument19 pagesVisual C# Programming BasicsDavide Vitelaru100% (6)

- Menu - 634637063125928485 - CS6105 Compiler Design SyllabusDocument1 pageMenu - 634637063125928485 - CS6105 Compiler Design SyllabusArchit100% (1)

- CIT-110 Assignment 03 Body Mass IndexDocument4 pagesCIT-110 Assignment 03 Body Mass IndexStephen RamosNo ratings yet

- 1.13938525 24098318Document5 pages1.13938525 24098318Sam VuppalNo ratings yet

- 2021 03 10 Debug Embedded Systems Part 1 V 1.01Document95 pages2021 03 10 Debug Embedded Systems Part 1 V 1.01RakshithNo ratings yet

- ArduBotics ManualDocument8 pagesArduBotics ManualMURUGAN100% (1)

- Dji Phantom 4 RTK Book F-2Document18 pagesDji Phantom 4 RTK Book F-2Liu Purnomo100% (1)

- USB Flash DriveDocument5 pagesUSB Flash DriveMuhammad FaizNo ratings yet

- Which Food Delivery App is Best Based on Pugh Matrix AnalysisDocument3 pagesWhich Food Delivery App is Best Based on Pugh Matrix AnalysisJohannie ClaridadNo ratings yet

- Temp RegDocument12 pagesTemp RegPr RabariNo ratings yet

- TVL-ICT (Computer System Servicing) Activity Sheet Quarter 2 - Lesson 3Document13 pagesTVL-ICT (Computer System Servicing) Activity Sheet Quarter 2 - Lesson 3Jayram JavierNo ratings yet

- Offline Assessment For Exchange ServerDocument2 pagesOffline Assessment For Exchange ServerHieu PhamNo ratings yet