Professional Documents

Culture Documents

Coal Mill Heat Balance

Uploaded by

rashm006ranjan0 ratings0% found this document useful (0 votes)

139 views2 pagesl Mill Heat Balanc

Original Title

53129976 Coal Mill Heat Balance

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentl Mill Heat Balanc

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

139 views2 pagesCoal Mill Heat Balance

Uploaded by

rashm006ranjanl Mill Heat Balanc

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

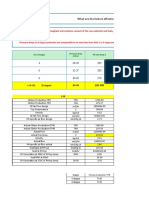

Total wet feed to mill 55 TPH

Feed Moisture 18.489 %

Residual Moisture 1.5 %

False Air 18 %

Mass

TPH

Sp. Heat

(Kcal/kg/oC)

Temp

oC

Heat

Cont.

(Kcal/h)

*1000

Material 44.831 0.27 25 304.6

Water 10.169 1.00 25 254.2

Cooler Hot Air 121.49 0.24 280 8321.1

Recirculation Air 10 0.24 60 143.6

False Air 18.532 0.24 30 132.7

Grinding Heat(Mot. KW)------> 425 KW 347.7

9504.0

Material 44.831 0.29 907.9

Residual Water 0.6625 1.00 46.4

Evaporated water 9.5063 0.45 5958.5

Air 150.02 0.24 2498.7

Radiation 92.5

9504.0

0.0

Total Output

Total Input

HEAT BALANCE FLAG(Green if Heat Balance is OK)>>>>>

Coal Mill Heat Balance ( Non-Inert : Cooler Gases)

70.0

INPUT:

OUTPUT:

Press To Adjust outlet temperature for Balance

Press to Adjust Cooler Hot Air Quantity for Balance

Press to Adjust Feed Moisture for Balance

Press to Adjust Cooler Hot Air Temperaturefor Balance

This sheet has been created by Rajiv Sadavarti on November 20, 2008. Rev 0.

1. This sheet is valid only for Non- Inert Coal Mill.

2. While loading the sheet; macros shall be enabled.

3. All the data appearing in yellow boxes can be changed as per the requirements.

4. Buttons at the bottom are "coded" to do an auto heat balance based on the button caption.

5. With changes if the Heat is not balanced the flag will turn red.

6. Pressing any of the Heat Balance buttons at the bottom will do the balancing and turn the flag green.

7. This Heat Balance is Preliminary and will be reviewed.

You might also like

- Coal MillDocument6 pagesCoal MillAnonymous NxpnI6jCNo ratings yet

- Cement Cooler EffDocument1 pageCement Cooler Effsafwat hassanNo ratings yet

- Benchmarks IndiaDocument78 pagesBenchmarks IndialafecapoNo ratings yet

- Lucie MillDocument50 pagesLucie Millrudye kardunNo ratings yet

- Ultratech, AP Cement WorksDocument29 pagesUltratech, AP Cement WorksSanjeev PmNo ratings yet

- Daily Power Generation Report: Fuel ReceivedDocument10 pagesDaily Power Generation Report: Fuel ReceivedJacky KaruppaiahNo ratings yet

- Flow Process Cement PlantDocument10 pagesFlow Process Cement PlantAgung BinantoroNo ratings yet

- Energy Efficient Turbo BlowersDocument11 pagesEnergy Efficient Turbo BlowersnishanandNo ratings yet

- Bag Filter Vs EP InformationDocument8 pagesBag Filter Vs EP InformationDaniel RicartNo ratings yet

- 02 PCRA NitendraDewanganDocument127 pages02 PCRA NitendraDewanganGovind RaoNo ratings yet

- RPM Kiln Vs FDDocument2 pagesRPM Kiln Vs FDTIRIANTONo ratings yet

- 15th NCB Technical PaperDocument10 pages15th NCB Technical PaperSalah RomdaniNo ratings yet

- Rm-1 1st Chamber Liners ReplacementDocument1 pageRm-1 1st Chamber Liners Replacementsivareddy143No ratings yet

- Performance of Fans After at Various Plants: RetrofittingDocument19 pagesPerformance of Fans After at Various Plants: RetrofittingmkpqNo ratings yet

- Low Grade Flue Gas Waste Heat Utilization For Air Conditioning in Coal Based Power PlantDocument30 pagesLow Grade Flue Gas Waste Heat Utilization For Air Conditioning in Coal Based Power PlantSymron AngelNo ratings yet

- CM - 2 Heat BalanceDocument2 pagesCM - 2 Heat BalanceThaigroup CementNo ratings yet

- Crash Stop Sample Raw MillDocument14 pagesCrash Stop Sample Raw MillAbhishekNo ratings yet

- Materials Weight SG (SSD) Volume, FDocument2 pagesMaterials Weight SG (SSD) Volume, FBùi Hắc HảiNo ratings yet

- Industrialtraining Report NTPC SingrauliDocument49 pagesIndustrialtraining Report NTPC Singraulirupesh kumar67% (3)

- Raw Mill Area-HamzaDocument21 pagesRaw Mill Area-HamzaAdnan rasoolNo ratings yet

- Regular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsDocument23 pagesRegular Paper 2 - Set A: Section - Ii: Short Descriptive QuestionsYogaAnandNo ratings yet

- PAT SchemeDocument42 pagesPAT SchemeamitNo ratings yet

- Fuel & Energy Comparison Between B/E & Air LiftDocument1 pageFuel & Energy Comparison Between B/E & Air LiftAbul Qasim QasimNo ratings yet

- Pyro Heat Balance 8000TPD @23.03.2023Document2 pagesPyro Heat Balance 8000TPD @23.03.2023harikrushnaNo ratings yet

- Performance Driven Maintenance Feb 52013Document25 pagesPerformance Driven Maintenance Feb 52013recaiNo ratings yet

- Coriolis Part1Document20 pagesCoriolis Part1Krishna Bhanu SinghNo ratings yet

- Atox Gear PresentationDocument27 pagesAtox Gear PresentationMujahid BalochNo ratings yet

- Shree Project FinalDocument20 pagesShree Project FinalMostafa KordyNo ratings yet

- Kiln Float and Hydraulic Thrust DeviceDocument21 pagesKiln Float and Hydraulic Thrust DevicehaiderNo ratings yet

- APCW TadipatriDocument25 pagesAPCW TadipatriChanna BasavaNo ratings yet

- SP Line III GenerationDocument5 pagesSP Line III Generationhmaza shakeelNo ratings yet

- Process - Operation - Optimization of The ETA Cooler - MugherDocument138 pagesProcess - Operation - Optimization of The ETA Cooler - Mugherzewdu dechasaNo ratings yet

- Forward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HDocument2 pagesForward Side Backward Side Forward Side Backward Side 1 1 2 2 3 3 4 4 5 5 6 6 7 7 8 8 B H B H B H B HMahmoud HanafyNo ratings yet

- Calciner Op Ex CalculationDocument9 pagesCalciner Op Ex CalculationNair YadukrishnanNo ratings yet

- Pyro System - Control Loops V0.0Document2 pagesPyro System - Control Loops V0.0Junaid MazharNo ratings yet

- Energy Savings of Pump Applications - General IndustryDocument13 pagesEnergy Savings of Pump Applications - General IndustryDave DuasoNo ratings yet

- Electrical Energy Module Final Draft 20Document161 pagesElectrical Energy Module Final Draft 20Safrin SangiaNo ratings yet

- ATOX Raw Mill. Weekly ReportDocument7 pagesATOX Raw Mill. Weekly ReportDilnesa EjiguNo ratings yet

- VRM Fan ..Document2 pagesVRM Fan ..harikrushnaNo ratings yet

- New Hardware Grinding Aid - ECOFORDocument5 pagesNew Hardware Grinding Aid - ECOFORlovjnxNo ratings yet

- I-P-1.01-W-3 (Kiln Feed Flowmeter)Document2 pagesI-P-1.01-W-3 (Kiln Feed Flowmeter)JCSNo ratings yet

- CoolerDocument10 pagesCoolerbudiNo ratings yet

- 2012 - Design, Fabrication and Commissioning of RDF PDFDocument72 pages2012 - Design, Fabrication and Commissioning of RDF PDFHilmi Gazali TvkNo ratings yet

- Dimension Tolerance (Coal Mill)Document4 pagesDimension Tolerance (Coal Mill)nishant361No ratings yet

- Cooler Air Flow Vs Kiln FeedDocument2 pagesCooler Air Flow Vs Kiln FeedBùi Hắc HảiNo ratings yet

- Operation Manual: HRM1700M Vertical Roller Coal MillDocument30 pagesOperation Manual: HRM1700M Vertical Roller Coal MillAhmed ElhusseinyNo ratings yet

- BoilerOpt Presentation - PJBDocument21 pagesBoilerOpt Presentation - PJBenjineringNo ratings yet

- Kiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DDocument1 pageKiln Audit Heat Balance Tool - Data Entry Sheet 1: Clinker T/DMohamed SelimNo ratings yet

- Coal FeedDocument8 pagesCoal FeedaakashtrivediNo ratings yet

- VRM Daily Stoppage DetailsDocument7 pagesVRM Daily Stoppage DetailsValipireddy NagarjunNo ratings yet

- Proposal For Reducing Emissions of SOx in Cement Plants PDFDocument4 pagesProposal For Reducing Emissions of SOx in Cement Plants PDFharrazyNo ratings yet

- Ball Mill PulveriserDocument67 pagesBall Mill PulveriserMURALIGOCAM_29070605100% (1)

- Mill - Fire ProtectionDocument3 pagesMill - Fire ProtectionANAND PANDEYNo ratings yet

- Loss in Weight TrainingDocument22 pagesLoss in Weight TrainingSantrupta PandaNo ratings yet

- APTI413 PP Ch9Document56 pagesAPTI413 PP Ch9Stefanos DiamantisNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Coal Mill Heat BalanceDocument3 pagesCoal Mill Heat BalancevvijaybhanNo ratings yet

- Digital Thermostat T1 700Document58 pagesDigital Thermostat T1 700IBJSC.comNo ratings yet

- 301 Controller ManualDocument24 pages301 Controller ManualHoàng Việt PhươngNo ratings yet

- Nu 5100 5100eg HalfDocument19 pagesNu 5100 5100eg HalfCristian AedoNo ratings yet

- 03 - Confined Space EntryDocument18 pages03 - Confined Space Entryrashm006ranjanNo ratings yet

- New Book Launch Schedule 36 Days: Planning Complete!Document1 pageNew Book Launch Schedule 36 Days: Planning Complete!rashm006ranjanNo ratings yet

- 3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom ListDocument2 pages3rd Floor Service Bldg. Intercom List 2nd Floor Service Bldg. Intercom Listrashm006ranjanNo ratings yet

- Earned Value Management (EVM)Document8 pagesEarned Value Management (EVM)rashm006ranjanNo ratings yet

- NCQC 2016 RaipurDocument8 pagesNCQC 2016 Raipurrashm006ranjanNo ratings yet

- Machinery Lubrication I IIDocument12 pagesMachinery Lubrication I IIrashm006ranjan50% (2)

- Turbine Cooling TemperaturesDocument12 pagesTurbine Cooling Temperaturesrashm006ranjan0% (1)

- Energy Audit For Electric MotorDocument4 pagesEnergy Audit For Electric Motorrashm006ranjanNo ratings yet

- Simple FormattingDocument1 pageSimple Formattingrashm006ranjanNo ratings yet

- Annemometer and ThermometerDocument1 pageAnnemometer and Thermometerrashm006ranjanNo ratings yet

- HyperGraph3D TutorialsDocument41 pagesHyperGraph3D Tutorialsrashm006ranjanNo ratings yet

- SKF Dry Lubricated Bearings 11358 3 enDocument28 pagesSKF Dry Lubricated Bearings 11358 3 enrashm006ranjan100% (1)

- 790Document5 pages790rashm006ranjanNo ratings yet

- Coal Mill Heat BalanceDocument2 pagesCoal Mill Heat Balancerashm006ranjanNo ratings yet

- Bevel & Hypoid Gears:: Measuring BacklashDocument3 pagesBevel & Hypoid Gears:: Measuring Backlashrashm006ranjan100% (1)

- Steam Ejector CalculationsDocument11 pagesSteam Ejector Calculationsrashm006ranjanNo ratings yet

- Compressor and Compressed Air SystemDocument34 pagesCompressor and Compressed Air Systemrashm006ranjanNo ratings yet

- The Condenser Performance Test and Thermal Performance Analysis of Variable Conditions in TQNPCDocument4 pagesThe Condenser Performance Test and Thermal Performance Analysis of Variable Conditions in TQNPCrashm006ranjanNo ratings yet

- Loss Optimisation in BoilersDocument50 pagesLoss Optimisation in Boilersrashm006ranjanNo ratings yet

- Paper 2 - Set B Solutions: General InstructionsDocument14 pagesPaper 2 - Set B Solutions: General Instructionsrashm006ranjanNo ratings yet

- National Institute of Technology CalicutDocument14 pagesNational Institute of Technology Calicutrashm006ranjanNo ratings yet