Professional Documents

Culture Documents

Method Statement PVC Conduit Installation

Uploaded by

Azree Mohd Noor67%(3)67% found this document useful (3 votes)

4K views8 pagesA work method statement

Original Title

method statement PVC Conduit Installation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA work method statement

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

67%(3)67% found this document useful (3 votes)

4K views8 pagesMethod Statement PVC Conduit Installation

Uploaded by

Azree Mohd NoorA work method statement

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 8

TABLE OF CONTENT

ITEM NO. TITLE PAGE

- TABLE OF CONTENT

1.0 OBJECTIVE 3

2.0 SCOPE 3

3.0 HANDLING AND STORAGE 3

4.0 WORK METHODOLOGY 3-4

5.0 RESPONSIBILITY 6

6.0 EQUIPMENT 7

7.0 TYPICAL INSTALLATION ARRANGEMENT LAYOUT 8

8.0 SAFETY, HEALTH, SECURITY AND ENVIRONMENT 9

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 2 of 9

Reference :

1.0 OBJECTIVE

This method statement explains the detailed requirements and procedures for the

installation of PVC Conduits and accessories in the concrete slabs, columns, block works

and concrete walls.

2.0 SCOPE

This procedure applies to project site which requires installation of electric PVC conduits

and its accessories inside and outside the building.

2.0 HANDLING AND STORAGE

2.1 Deliver components parts and material to site, completely identified in accordance

with approved brand and supplier and also comply with certified drawings

prepared for this work.

2.2 Store in accordance with the manufacturers instructions, above ground, properly

protected from the weather and construction activities.

3.0 WORK METHODOLOGY

3.1 Material: Material used will be as approved by the engineer. The sizes and routes

routing will be as per the approved shop drawing.

3.2 Installation

1. During the course of the installation of the conduit system, procedures for

working and dressing the installation as recommended shall be employed.

2. All bends and sets shall be in accordance with IEE regulation 522-08

formed with the aid of a helical spring fitted internally, with if necessary,

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 3 of 9

Reference :

3. Conduit system shall be installed so as to ensure compliance with the

requirements of Specified Standard and Regulation.

4. Joints between PVC conduit + fittings shall be made with suitable

adhesive, but expansion couplings shall be installed where any length of

conduit, inclusive of draw in boxes etc, exceeds five meters in length.

5. The minimum and maximum sizes of conduit to be employed shall be

inch and 1 inch respectively, unless otherwise stated in subsequent

sections of the specification.

6. Conduits in floors shall be routed and installed so as to avoid the fixings of

floor standing equipment to be installed on the floor.

3.3 Fixing of Conduits

1. When conduits are run on shuttering, prior to the laying of concrete in-situ,

additional security must be provided near to every box and at intervals of not

more than 1.2 meters by binding short lengths of steel wire, of not less than

2mm diameter twisted around the conduit and reinforcing steel. The conduits

shall be adequately fixed to prevent excessive movement and damage during

the pouring and setting of concrete and shall be protected from mechanical

damage. Check there is no damage before screed / concrete is poured. Unless

otherwise indicated to cast in conduits shall not be less than 30mm.cores to

plastered over conduits shall not be less than 5mm.

2. Where conduits are left "open ended" prior to wiring they shall be protected

by caps or plugs to prevent the ingress of building material.

3. All conduits runs must be designed to permit wiring to be readily installed

after the complete erection of the conduits through the available draw-in,

accessory and luminary suspension boxes.

4. Where surface mounted equipment (other than luminaries) is specified, all

concealed conduits shall be terminated and an adaptable box installed recessed

into the wall at every surface mounted equipment position.

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 4 of 9

Reference :

5. Where conduits pass through an external wall/roof the conduit box shall be

fitted on the side and after wiring filled with an inert, permanently plastic

compound having a high insulation value.

6. Make provision in conduit and trunking, installation where building expansion

joints are crossed or settlement is likely.

7. Ensure conduits are not concealed until works has been inspected and

approved. Ensure that conduit and fittings buried in concrete or behind plaster

are protected against corrosion or electrolytic action prior to rendering.

4.0 RESPONSIBILITY

Project Manager:

o To ensure that all the preparation and application works are carried out according to

the Contract Specification and with the approved drawings.

o To ensure that the progressing of work is carried out according to the planned program

and as per the approved method of statement.

o To ensure that all the equipment and materials required executing the work are

available according to the planned construction program.

o To co ordinate with the Main contractor, MEP Coordinator and Safety Officer, for a

safe and proper execution of the works.

Site Engineer:

o To ensure that the works are carried out according to the Contract Specifications,

approved method statement and the shop drawings.

o To provide all necessary information and distribute responsibilities to his construction

team.

o To monitor the progress of work in relation with the work program and to report to the

Project Manager.

o To co-ordinate with the safety officer and to ensure that the works are carried out in

safe practicing methods.

Foreman:

o The foreman will carry out his duties by maintaining continuous coordination with the

site engineer on daily basis, and ensure proper distribution of the workforce in the

required and planned locations.

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 5 of 9

Reference :

o To ensure that his assistant foreman/ charge hand are aware of the job requirements

and they have enough information to carry out their duties properly.

o To ensure in consultation with the site engineer that the manpower involved in the

works are moving as agreed and planned for the work.

o To ensure that the daily work is progressing as planned and advice the site engineer of

any requirement for additional resources.

o To control disposal of waste materials according to the instructions received from the

site engineer.

o To ensure full coordination with the safety officer to maintain safe working and proper

housekeeping of the site, following the approved safety measures and further ensure

that all his working team are aware of the same to prevent accident and losses.

o To inform the site engineer and of the areas ready for inspection.

o Distribution and the control of material shall be monitored by foreman and store

keeper.

5.0 EQUIPMENT

The requirements that will be engaged for PVC conduiting works will be as follows:

1. Hack saw

2. Measuring tape

3. Cutting plier

4. Knipex (End cutter)

5. Bending spring

6. Drilling Machine

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 6 of 9

Reference :

6.0 TYPICAL INSTALLATION ARRANGEMENT LAYOUT

Method Statement for Installation Of Electrical PVC Conduits And Accessories In The Concrete Slabs, Columns,

Block Works And Concrete Walls

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 7 of 9

Reference :

7.0 QUALITY ASSURANCE PLAN

ITP

Clause

No.

Inspection

Description

Type of

Inspection

Reference

Document

Testing

Requirement/

Acceptance

Criteria

Verifying /

Control

Data Forms

1

Design and

Drawings

Review of

Documents

Design

Drawings

All the

Drawings

Design

Drawings,

Authorities

Departments

Requirements

2

Material

Approval

Review of

Documents

Approved

Drawing,

Specification

Should be as

per the

approved

drawing and

Specification

Documents

Submittals

3

Check

installation

of PVC

Conduits

Visual

Approved

Method

Statement

Proper bends

correct height

and Location,

material

should have

minimum

status on No

Objection

with

comments (2)

Approved

Drawing

Method

Statement

4

Raise

inspection

request

Visual

Measurement

instrument

Approved

Drawings

NO

obstructions

height, Proper

position

Approved

Drawings

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 8 of 9

Reference :

8.0 SAFETY, HEALTH, SECURITY AND ENVIRONMENT

Strictly follow as per the manufacturers Health and Safety recommendations for handling and

used of the materials. Ensure all involved personnel shall be aware of the same.

A special safety inspector is assigned; all personnel involved in this work shall use

the mandatory P.P.E as follows.

a. Safety Helmet

b. Safety Shoes/Boots

c. Safety glasses.

d. All other PPE as required by the risk assessment.

All work will be undertaken by qualified competent persons with experience of the type of work

described above, and in all cases in full accordance with safety procedures specified in the

company's health and safety Policy.

METHOD STATEMENT

Title : Method Statement For Installation Of

Electric PVC Conduits And Accessories

Page : 9 of 9

Reference :

You might also like

- 00 - MS - MV Cable Pulling and InstallationDocument9 pages00 - MS - MV Cable Pulling and Installationanon_534254691100% (1)

- Method Statement-Conduiting WorkDocument10 pagesMethod Statement-Conduiting WorkEesha ThakreNo ratings yet

- 00 - MS - Wires and Cables InstallationDocument9 pages00 - MS - Wires and Cables InstallationEslam TahaNo ratings yet

- Cable Tray Method StatementDocument8 pagesCable Tray Method StatementNidhin Mohan0% (1)

- Installation of Electric Conduits Method StatementDocument8 pagesInstallation of Electric Conduits Method Statementanon_534254691No ratings yet

- Rev - 03 - Ms - Installation of Cable Tray or Trunking SystemDocument7 pagesRev - 03 - Ms - Installation of Cable Tray or Trunking Systemanon_534254691No ratings yet

- MS - Audio Visual System InstallationDocument9 pagesMS - Audio Visual System InstallationDuel TimeNo ratings yet

- Method Statement For PVC Conduits InstallationDocument9 pagesMethod Statement For PVC Conduits InstallationAnandu AshokanNo ratings yet

- Method Statement For Electrical Surface Conduit InstallationDocument14 pagesMethod Statement For Electrical Surface Conduit Installationshareyhou100% (1)

- Install and Fix Electrical PVC ConduitsDocument6 pagesInstall and Fix Electrical PVC Conduitsmidhun murali100% (1)

- Method of Statement For Electrical WorkDocument9 pagesMethod of Statement For Electrical WorkKg Chit Zaw100% (1)

- Method Statement For Installation of Low Voltage CablesDocument7 pagesMethod Statement For Installation of Low Voltage Cablestsraj1071% (7)

- Method Statement For Light FixturesDocument14 pagesMethod Statement For Light Fixturesshareyhou100% (3)

- METHOD OF STATEMENT FOR ELECTRICAL WORK at KALBE PROJECTDocument9 pagesMETHOD OF STATEMENT FOR ELECTRICAL WORK at KALBE PROJECTKg Chit Zaw100% (2)

- Method Statement For LV Cables, Wiring For Lighting and Power InstallationDocument11 pagesMethod Statement For LV Cables, Wiring For Lighting and Power InstallationAnandu Ashokan50% (2)

- Rev - 10 - Ms - Installation of Lighting Control PanelDocument8 pagesRev - 10 - Ms - Installation of Lighting Control Panelanon_534254691No ratings yet

- Method of Statement For MV&LV SwitchgearsDocument12 pagesMethod of Statement For MV&LV SwitchgearsUtku Can Kılıç100% (1)

- Method Statement Transformer InstallationDocument2 pagesMethod Statement Transformer Installationphilipyong92% (13)

- Method Statement For Installation of Cables, Wires & Termination - Rev02.Document27 pagesMethod Statement For Installation of Cables, Wires & Termination - Rev02.RaulSaavedra88% (8)

- Method Statement For Cable Pulling and ConnectionsDocument7 pagesMethod Statement For Cable Pulling and Connectionskamil100% (1)

- Method-Statement For Electrical InstallationDocument31 pagesMethod-Statement For Electrical Installationmozartjr22100% (3)

- MV Cable Pulling and Installation Method StatementDocument9 pagesMV Cable Pulling and Installation Method StatementMark Tristan Vallesteros100% (6)

- Method of Statement ElectricalDocument30 pagesMethod of Statement ElectricalNaveed70% (10)

- 00 - MS - Lighting Fixtures InstallationDocument9 pages00 - MS - Lighting Fixtures InstallationDuel TimeNo ratings yet

- Method Statement For Conduit Installation Including Accessories PVC & GIDocument17 pagesMethod Statement For Conduit Installation Including Accessories PVC & GIgangadharan000100% (1)

- Method Statement For Installation of Cable TraysDocument6 pagesMethod Statement For Installation of Cable TraysjokanovNo ratings yet

- Installation of Electrical PanelsDocument6 pagesInstallation of Electrical PanelsNidhin MohanNo ratings yet

- Method of Statement For Installation of Wires and CablesDocument6 pagesMethod of Statement For Installation of Wires and Cablesgangadharan000100% (3)

- 00 - MS - LV Switchgear and Motor Control Center InstallationDocument8 pages00 - MS - LV Switchgear and Motor Control Center Installationanon_534254691No ratings yet

- 00 - MS - Electrical PanelBoards InstallationDocument8 pages00 - MS - Electrical PanelBoards Installationanon_534254691No ratings yet

- Method Statement For Cable Conduit & Tray Installation PDFDocument5 pagesMethod Statement For Cable Conduit & Tray Installation PDFUtku Can Kılıç100% (1)

- Method Statement - Earthing & Lightning ProtectionDocument6 pagesMethod Statement - Earthing & Lightning ProtectionKhaled Badawy0% (1)

- Installation of Surface Conduits and Cable TrayDocument12 pagesInstallation of Surface Conduits and Cable TrayWalidNo ratings yet

- Cable Installation Method StatementDocument9 pagesCable Installation Method Statementpandan27100% (2)

- Method Statement - Embedded ConduitsDocument3 pagesMethod Statement - Embedded ConduitsSimeon James Defeo Villacrusis100% (1)

- 4.47-MS For Electrical Installation WorksDocument6 pages4.47-MS For Electrical Installation WorksChijioke ObiNo ratings yet

- Busway Method of StatementDocument18 pagesBusway Method of StatementmahmoudNo ratings yet

- HVAC Installation MethodologyDocument4 pagesHVAC Installation MethodologyParasNo ratings yet

- Ms-Cable Tray InstallationDocument7 pagesMs-Cable Tray InstallationVane DG100% (1)

- Method Statement HT Switch GearDocument2 pagesMethod Statement HT Switch GearNasrul Syahmi100% (2)

- Method of Statement For Installation of Wires and CablesDocument6 pagesMethod of Statement For Installation of Wires and CablesArshad Akhtar KhanNo ratings yet

- Method Statement For Installation of PVC PipesDocument13 pagesMethod Statement For Installation of PVC PipesChathura Dharmasena100% (3)

- Rev - 15 - Ms - Installation of Earthing SystemDocument7 pagesRev - 15 - Ms - Installation of Earthing Systemanon_534254691No ratings yet

- Methof of Statement For Electrical PanelsDocument10 pagesMethof of Statement For Electrical PanelsWaleed SalihNo ratings yet

- 001 MEP - Method Floor&Wall PenetrationDocument7 pages001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- Installation of MV LV Switchgear & Panels - Method StatementDocument3 pagesInstallation of MV LV Switchgear & Panels - Method Statementfathonix100% (2)

- TRANSFORMER INSTALLATIONDocument20 pagesTRANSFORMER INSTALLATIONGodwin Arigbonu83% (6)

- Install Access Control System Method StatementDocument9 pagesInstall Access Control System Method StatementDuel Time100% (1)

- Method Statement SwitchgearsDocument6 pagesMethod Statement Switchgearskamil100% (1)

- Rev - 13 - Ms - Installation of GeneratorsDocument7 pagesRev - 13 - Ms - Installation of Generatorsanon_534254691No ratings yet

- Rev - 05 - MS - Installation of Electric PVC ConduitsDocument7 pagesRev - 05 - MS - Installation of Electric PVC Conduitsanon_534254691100% (1)

- Method of Statement for First Fixed Electrical WorkDocument8 pagesMethod of Statement for First Fixed Electrical WorkHytham El-NoubyNo ratings yet

- 00 - MS - Electrical Galvanized Conduits InstallationDocument9 pages00 - MS - Electrical Galvanized Conduits Installationwalid khamaesah100% (1)

- Pipe Laying HDPEDocument6 pagesPipe Laying HDPEFun TonNo ratings yet

- Ms - Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMs - Installation of Electric PVC Conduits and AccessoriesDuel TimeNo ratings yet

- Rev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBDocument5 pagesRev Description Prepared by Approved by Date Method Statement For Cold Water Services PJSBToyEn MEgatNo ratings yet

- Method Statement For Installation of Emt Conduit-OldDocument13 pagesMethod Statement For Installation of Emt Conduit-OldSalman SaifuddinNo ratings yet

- Method Statement For GI Conduits InstallationDocument9 pagesMethod Statement For GI Conduits InstallationAnandu AshokanNo ratings yet

- Method Statement For Cable Tray and Truncking InstallationDocument9 pagesMethod Statement For Cable Tray and Truncking InstallationAnandu AshokanNo ratings yet

- Method Statement For Wiring Accessories InstallationDocument9 pagesMethod Statement For Wiring Accessories InstallationAnandu AshokanNo ratings yet

- RFP Attachment-A Submission-RequirementsDocument57 pagesRFP Attachment-A Submission-RequirementsAzree Mohd NoorNo ratings yet

- RFP1 Electricity Imports v1.4 1jul2022Document46 pagesRFP1 Electricity Imports v1.4 1jul2022Azree Mohd NoorNo ratings yet

- RFP1 Electricity Imports v1.4 1jul2022Document46 pagesRFP1 Electricity Imports v1.4 1jul2022Azree Mohd NoorNo ratings yet

- Floating Solar BOM ModelDocument1 pageFloating Solar BOM ModelAzree Mohd NoorNo ratings yet

- RFP Submission RegisterDocument10 pagesRFP Submission RegisterAzree Mohd NoorNo ratings yet

- RFP Template A111Document9 pagesRFP Template A111Azree Mohd NoorNo ratings yet

- RFP Templates A222 A311 A334 A412 A521 A621 A622Document61 pagesRFP Templates A222 A311 A334 A412 A521 A621 A622Azree Mohd NoorNo ratings yet

- Floating Solar Market ReportDocument131 pagesFloating Solar Market ReportGustavo Iannacone100% (1)

- Chapter 9 DisinfectionDocument18 pagesChapter 9 DisinfectionMaqsood HassanNo ratings yet

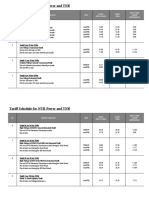

- TNB and NUR Tariff DifferencesDocument2 pagesTNB and NUR Tariff DifferencesAzree Mohd NoorNo ratings yet

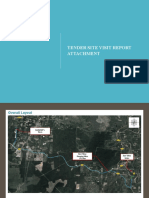

- Tender Site VisitDocument5 pagesTender Site VisitAzree Mohd NoorNo ratings yet

- Small Cafe DesignDocument4 pagesSmall Cafe DesignAzree Mohd NoorNo ratings yet

- Pump ControlDocument5 pagesPump ControlAzree Mohd NoorNo ratings yet

- Floating Solar Market Report Executive SummaryDocument24 pagesFloating Solar Market Report Executive Summaryvarun pradhanNo ratings yet

- Chapter 7 Rules Relating To Wells and BoringsDocument6 pagesChapter 7 Rules Relating To Wells and BoringsAzree Mohd NoorNo ratings yet

- Chapter 3 RegulationsDocument54 pagesChapter 3 RegulationsAzree Mohd NoorNo ratings yet

- Indonesia: Solar Energy ProfileDocument22 pagesIndonesia: Solar Energy ProfileAzree Mohd NoorNo ratings yet

- Method Statement For The Installation of 11kv HV SwitchgearDocument3 pagesMethod Statement For The Installation of 11kv HV Switchgearamg007100% (7)

- Chapter 1 Water ResourcesDocument8 pagesChapter 1 Water ResourcesAzree Mohd NoorNo ratings yet

- Water Treatment Design CriteriaDocument23 pagesWater Treatment Design CriteriaAzree Mohd NoorNo ratings yet

- SPP If Single Line DrawingDocument1 pageSPP If Single Line DrawingAzree Mohd NoorNo ratings yet

- Page 1Document1 pagePage 1Azree Mohd NoorNo ratings yet

- MOS - Cable InstallationDocument7 pagesMOS - Cable InstallationAzree Mohd NoorNo ratings yet

- Chapter 4 Emerging ContaminantsDocument4 pagesChapter 4 Emerging ContaminantsAzree Mohd NoorNo ratings yet

- WTP Design and CalculationDocument22 pagesWTP Design and CalculationAzree Mohd Noor100% (2)

- Azree - QuotationDocument1 pageAzree - QuotationAzree Mohd NoorNo ratings yet

- Method Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQDocument13 pagesMethod Statement For Switchgear Installation of MV LV HV Switchgear Panels - Method Statement HQAzree Mohd Noor100% (1)

- Utility InterfaceDocument1 pageUtility InterfaceAzree Mohd NoorNo ratings yet

- Itracker-Wl: Catching All The SunDocument6 pagesItracker-Wl: Catching All The SunAzree Mohd NoorNo ratings yet

- Css Sahara 02 04 InstructionsDocument12 pagesCss Sahara 02 04 Instructionsstelios_yuhas4576No ratings yet

- Cells in The Urine SedimentDocument3 pagesCells in The Urine SedimentTaufan LutfiNo ratings yet

- Obiafatimajane Chapter 3 Lesson 7Document17 pagesObiafatimajane Chapter 3 Lesson 7Ayela Kim PiliNo ratings yet

- Desert Power India 2050Document231 pagesDesert Power India 2050suraj jhaNo ratings yet

- CL 5313 17021-1 Requirements Matrix-1458-5Document6 pagesCL 5313 17021-1 Requirements Matrix-1458-5Ana AnaNo ratings yet

- Individual Assignment ScribdDocument4 pagesIndividual Assignment ScribdDharna KachrooNo ratings yet

- Failure Analysis Case Study PDFDocument2 pagesFailure Analysis Case Study PDFScott50% (2)

- IELTS Vocabulary ExpectationDocument3 pagesIELTS Vocabulary ExpectationPham Ba DatNo ratings yet

- Condy LatorDocument11 pagesCondy LatorrekabiNo ratings yet

- Boiler Check ListDocument4 pagesBoiler Check ListFrancis VinoNo ratings yet

- The Changing Face of War - Into The Fourth GenerationDocument5 pagesThe Changing Face of War - Into The Fourth GenerationLuis Enrique Toledo MuñozNo ratings yet

- Control SystemsDocument269 pagesControl SystemsAntonis SiderisNo ratings yet

- Advantages and Disadvantages of The DronesDocument43 pagesAdvantages and Disadvantages of The DronesVysual ScapeNo ratings yet

- WhatsoldDocument141 pagesWhatsoldLuciana KarajalloNo ratings yet

- Installation Instruction XALM IndoorDocument37 pagesInstallation Instruction XALM IndoorVanek505No ratings yet

- Injection Timing (5L) : InspectionDocument2 pagesInjection Timing (5L) : InspectionaliNo ratings yet

- IP68 Rating ExplainedDocument12 pagesIP68 Rating ExplainedAdhi ErlanggaNo ratings yet

- Testbanks ch24Document12 pagesTestbanks ch24Hassan ArafatNo ratings yet

- Scharlau Chemie: Material Safety Data Sheet - MsdsDocument4 pagesScharlau Chemie: Material Safety Data Sheet - MsdsTapioriusNo ratings yet

- PharmacologyAnesthesiology RevalidaDocument166 pagesPharmacologyAnesthesiology RevalidaKENT DANIEL SEGUBIENSE100% (1)

- Unit 1 Writing. Exercise 1Document316 pagesUnit 1 Writing. Exercise 1Hoài Thương NguyễnNo ratings yet

- BMS Technical ManualDocument266 pagesBMS Technical Manualiago manziNo ratings yet

- ME6404 Thermal EngineeringDocument18 pagesME6404 Thermal EngineeringAnonymous mRBbdopMKfNo ratings yet

- EnerSys Global Leader in Industrial BatteriesDocument32 pagesEnerSys Global Leader in Industrial BatteriesAshredNo ratings yet

- Application D2 WS2023Document11 pagesApplication D2 WS2023María Camila AlvaradoNo ratings yet

- Clogging in Permeable (A Review)Document13 pagesClogging in Permeable (A Review)Chong Ting ShengNo ratings yet

- Reservoir Rock TypingDocument56 pagesReservoir Rock TypingAffan HasanNo ratings yet

- Employee Engagement A Case Study at IVRCL-1Document7 pagesEmployee Engagement A Case Study at IVRCL-1Anonymous dozzql7znKNo ratings yet

- Symmetry (Planes Of)Document37 pagesSymmetry (Planes Of)carolinethami13No ratings yet

- 5505 SW 138th CT, Miami, FL 33175 ZillowDocument1 page5505 SW 138th CT, Miami, FL 33175 Zillowlisalinda29398378No ratings yet

- Quiz-Travel - Beginner (A1)Document4 pagesQuiz-Travel - Beginner (A1)Carlos Alberto Rodriguez LazoNo ratings yet