Professional Documents

Culture Documents

Ghee Plant Process

Uploaded by

Engr Faiq ChauhdaryCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ghee Plant Process

Uploaded by

Engr Faiq ChauhdaryCopyright:

Available Formats

Encon Consulting Engineers

GHEE PLANT

INSTALLATION, OPERATION

AND

MAINTENANCE MANUAL

DESIGN & ENGINEERING BY

Head Office: Regional Office:

Encon Engineers Deekay Consult

M-28, 7th Floor, Mrigold, P. O. Box 49577

Krishnakeval Township, Nairobi, Kenya

Kondhwa Khurd, Pune 411048-INDIA Tel / Fax : + 254 733767539 / 2 582973

Tel / Fax : + 91 20 26831210 / +91 9422002758

Email : encon@vsnl.com / enconindia@hotmail.com Email : saj_de_sai@yahoo.com

Encon Consulting Engineers

INDEX

1. GHEE MAKING PROCESS

2. EQUIPMENT SPECIFICATIONS & DESCRIPTION

3. GHEE PUMP MANUFACTURER'S MANUAL

4. GHEE CLARIFIER MANUFACTURER'S MANUAL

5. FLOOR PLAN LAYOUT DRAWING NO. Ghee 01 R1

6. GHEE FLOW DIAGRAM DRAWING NO. Ghee R0

7. G A OF GHEE KETTLE DRAWING NO. Royal 01 R0

8. G A OF GHEE SIEVE TANK DRAWING NO. Royal 02 R0

9. G A OF GHEE BALANCE TANK DRAWING NO. Royal 03 R0

10. G A OF GHEE STORAGE TANK DRAWING NO. Royal 04 R0

Encon Consulting Engineers

GHEE MAKING PROCESS

Ghee is animal fat normally produced from Milk. Following are the step taken during

ghee making process.

1. During pasteurization process milk cream is separated in the cream separator

with 50 70 % fat content. (These equipments are not in our scope of supply.)

2. This cream is then churned in butter churn. This makes butter of 84 % fat. The

whey is drained in whey tank, which is used as by product. (These equipments

are not in our scope of supply.)

3. Butter from the butter churn is taken in the butter trolley. (These equipments

are not in our scope of supply.)

4. This butter either can be stored in the cold room, till sufficient butter is

available for further processing. (These equipments are not in our scope of

supply.)

5. Once sufficient butter is available, it is taken in the Ghee Kettle.

6. Open the condensate drain valve and remove all the condensate from the

steam jacket.

7. Steam valve in the ghee kettle is opened slowly and start supplying steam (1.5

bar G.). This is to heat the butter and melt it.

8. Close the drain valve and open steam trap and let condensate pass through it.

9. Once enough butter is melted, start the agitator of the ghee kettle.

10. Continue supplying steam to the kettle.

11. The butter oil will start boiling and water from the butter will evaporate.

12. Let all the water evaporate.

13. Close slowly the steam supply valve and open vent valve on the jacket.

14. Let all condensate from the steam jacket get drained.

15. Let ghee to cool down.

16. Continue agitating ghee with the help of agitator.

17. After ghee temperature has come down to around 70 Deg C, drain this in the

ghee filter tank.

18. With the help of SS strainer, most of burned protein from the butter is filtered

out.

19. Once all ghee is filtered, start the ghee pump.

20. The ghee should be fed to ghee clarifier, where ghee will be clarified.

21. The clarified ghee is collected in the balance tank.

22. Ghee from the balance tank, with the help of another ghee pump is transferred

to jacketed ghee storage tank.

23. This storage tank has water jacket with electric heater. In case of very cold

weather, switch on the electric heater. This is to keep ghee in free flowing

condition.

24. This is final product. Pack ghee in consumer packing. (These equipments are

not in our scope of supply.)

25. Clean the complete plant from inside and outside with warm detergent

followed with water and wipe out all traces of butter / ghee.

26. Clean all pipes / valves.

Encon Consulting Engineers

EQUIPMENT SPECIFICATIONS AND DESCRIPTIONS

A. Ghee Kettle.

A.1 Description

This is three jacket, fabricated from SS 304 material. The inner jacket is

closed, by hemispherical dish from the bottom and top is covered. The plate

thickness is selected to suit pressure. The volume of the vessel is 500 ltr.

The outer jacket is steam jacket. This is fabricated from SS material. This

jacket has, steam inlet, condensate outlet, and safety valve connection. The

steam is distributed in the jacket with the help of pipe.

The kettle is then insulated by glass wool insulation and finally cladded with

SS sheet.

The following attachment and accessories are included,

Scrapper type ghee agitator.

Plug type ghee outlet valve.

Ghee temperature indicator.

Steam inlet valve and pressure indicator.

Steam trap with isolation and by pass valve.

Steam jacket safety valve.

Legs support.

Top cover.

A.2 Installation

See attached layout plan. The height of the roof under this must be 4 mtrs.

The place should be well ventilated to remove water vapors, which is

generated during ghee making process. The front should be clear. The butter

loading is done from the front of the kettle.

A.3 Routine Maintenance.

1. After using kettle, drain completely the steam jacket.

2. Keep vent valve open, when system is not in use.

3. Clean the kettle with detergent from inside and outside.

4. Check agitator and remove any dirt on the shaft.

5. Check all valves for any leakage and stop it.

B. Ghee Sieve Tank.

B.1 Description

This is tank fabricated from SS 304 material. This has SS strainer at the top to

filter ghee. The following attachment and accessories are included,

SS strainer

Plug type ghee outlet valve.

Legs support.

Top cover.

B.2 Installation

See attached layout plan. It should be kept near the ghee kettle. The pipe with

valve is provided along-with the ghee kettle.

B.3 Routine Maintenance

1. After using tank, drain completely.

2. Clean the tank with detergent from inside and outside.

3. Check all valves for any leakage and stop it.

Encon Consulting Engineers

C. Ghee Pump

C.1 Description

This is hygiene design centrifugal pump, manufactured from SS 304 material.

Please refer attached manufacturer manual.

C.2 Installation

See attached layout plan. It should be kept near the ghee kettle.

C.3 Routine Maintenance

Refer attached manual.

D. Ghee Clarifier

D.1 Description

This is high speed centrifuge, used to clarify ghee. This will remove all material

from the ghee and clarified ghee will be dispensed in the balance tank. Please

refer attached manufacturer manual.

D.2 Installation

See attached layout plan. This must be anchored with the help of foundation

bolts. Refer manufacturer manual for proper installation of the clarifier.

D.3 Routine Maintenance

Refer attached manual.

E. Ghee Balance Tank

E.1 Description

This is fabricated from SS 304 material and have following accessories.

Ball feet legs

Outlet Valve

Cover

E.2 Installation

See attached layout plan.

E.3 Routine Maintenance

Clean the tank from inside & outside with warm detergent solution.

F. Ghee Storage Tank

F.1 Description

This is fabricated tank having water jacket. The jacket has electric heater with

thermostat. The tank is fabricated from SS 304 material.

F.2 Installation

See attached layout plan.

F.3 Routine Maintenance

1. Drain water once in a week.

2. Fill only soft water.

3. Check electric heater and thermostat.

4. Clean the tank from inside and outside after usage.

You might also like

- Boiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewFrom EverandBoiler Operation Engineer Exam, Interview Q&A, Terminology, and Boiler OverviewNo ratings yet

- Bomba MixerDocument2 pagesBomba MixerBinelli79No ratings yet

- Tender For Ghee Plant ModificationDocument161 pagesTender For Ghee Plant ModificationJagdish ParmarNo ratings yet

- DENWEL Carboblender v16bDocument2 pagesDENWEL Carboblender v16bAndor MolitoriszNo ratings yet

- en 3706Document22 pagesen 3706Thanh XuanNo ratings yet

- A. LavalDocument96 pagesA. LavalCleto TundumulaNo ratings yet

- Instruction Manual Alfa Laval Agitator Alt Altb Ese03504enDocument112 pagesInstruction Manual Alfa Laval Agitator Alt Altb Ese03504ennqh2009No ratings yet

- DIA Glass Lined Reactor PIDDocument1 pageDIA Glass Lined Reactor PIDSandiip JogdankarNo ratings yet

- Rotary ValvesDocument6 pagesRotary ValvesGelorawan AditNo ratings yet

- Yeast nutrient and ethanol production processDocument1 pageYeast nutrient and ethanol production processMubashar RehmatNo ratings yet

- Mass Transfer TechnologyDocument32 pagesMass Transfer TechnologyVasu DevanNo ratings yet

- Static Pressure Calculator r3 Rev1610 27Document1 pageStatic Pressure Calculator r3 Rev1610 27Wrya SaeedNo ratings yet

- Process Applications: Calcium Chloride-Based Heat Transfer FluidsDocument3 pagesProcess Applications: Calcium Chloride-Based Heat Transfer FluidszhyhhNo ratings yet

- GEA Fil382 ATpicco UK DH-DriftDocument56 pagesGEA Fil382 ATpicco UK DH-DriftFlorin RaduNo ratings yet

- 10-Drying of Milk Dairy and Food EngineeringDocument7 pages10-Drying of Milk Dairy and Food Engineeringariyani yantoNo ratings yet

- Product Datasheet - Sheffcoat™ White PVA 03Document4 pagesProduct Datasheet - Sheffcoat™ White PVA 03Random2319No ratings yet

- Iso 15874 2 2013 en PDFDocument11 pagesIso 15874 2 2013 en PDFAlde IbrahimNo ratings yet

- Practice Workbook: Modeling Pumps, Tanks, and PrvsDocument21 pagesPractice Workbook: Modeling Pumps, Tanks, and PrvsMidwardFranciscoQuispeLivisiNo ratings yet

- Tornado Lobe Pump BrochureDocument20 pagesTornado Lobe Pump BrochureAnonymous T7zEN6iLHNo ratings yet

- Improved Method For CO2 MeasurementsDocument4 pagesImproved Method For CO2 MeasurementsgangsNo ratings yet

- Brosjyre ChemineerDocument14 pagesBrosjyre ChemineerRaul DiazNo ratings yet

- Swagelok Magnehelic Gauge InstructionsDocument4 pagesSwagelok Magnehelic Gauge InstructionsAnonymous vF4wgBTdSbNo ratings yet

- Aultons Pharmaceuticals Drying PDFDocument18 pagesAultons Pharmaceuticals Drying PDFAdrián L ValladaresNo ratings yet

- GheeDocument11 pagesGheeLakshmi Kanthan BharathiNo ratings yet

- Niro Sanitary Code For Components DesignDocument10 pagesNiro Sanitary Code For Components DesignJignesh PandyaNo ratings yet

- Vpsa O2 Systems Brochure ML IND0032Document8 pagesVpsa O2 Systems Brochure ML IND0032kalaiNo ratings yet

- CPG Pressure Vessel DivisionDocument18 pagesCPG Pressure Vessel DivisionNikhil VermaNo ratings yet

- Evaporative Condenser in Stainless SteelDocument11 pagesEvaporative Condenser in Stainless Steeljose luisNo ratings yet

- SPX Heavy Duty Side Entry MixersDocument12 pagesSPX Heavy Duty Side Entry MixersaquilesanchezNo ratings yet

- Pressure Vacuum Relief Valve Flame Arrester 102Document3 pagesPressure Vacuum Relief Valve Flame Arrester 102vikramNo ratings yet

- Ventilation and Air Conditioning of Sterile Spaces in HospitalsDocument28 pagesVentilation and Air Conditioning of Sterile Spaces in HospitalsJonathan Herrera JaraNo ratings yet

- Metering Pumps User's ManualDocument56 pagesMetering Pumps User's ManualZelminha StNo ratings yet

- DD Katalog PDFDocument110 pagesDD Katalog PDFAnand GuptaNo ratings yet

- RotothermDocument2 pagesRotothermLee HaagNo ratings yet

- Clariant SDS Synergen GU Argentina EnglishDocument18 pagesClariant SDS Synergen GU Argentina EnglishMaximiliano MackeviciusNo ratings yet

- CO2 Recovery System Boosts Performance with New DesignDocument14 pagesCO2 Recovery System Boosts Performance with New DesignstopbotheringmeNo ratings yet

- ChillPAC With SABCube Screw CompressorDocument2 pagesChillPAC With SABCube Screw Compressorlist16947100% (1)

- Clarke 100e Mig WelderDocument18 pagesClarke 100e Mig WelderplainmanNo ratings yet

- Aeromatic Ltd. Fluid Bed DryerDocument13 pagesAeromatic Ltd. Fluid Bed DryerDitha ParamitaNo ratings yet

- BOQ From (HVAC)Document26 pagesBOQ From (HVAC)Neeta Samir Munj ParkarNo ratings yet

- Hydroheater Auto Manual VersionDocument45 pagesHydroheater Auto Manual VersionVishal Nawalgaria100% (3)

- Scientific Glass EquipmentDocument28 pagesScientific Glass EquipmentJuan P RuizNo ratings yet

- Vertical Ribbon Mixer DesignDocument12 pagesVertical Ribbon Mixer DesignHamza Al MahanaNo ratings yet

- Sulphur MelterDocument9 pagesSulphur MelterabderrahimnNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- Guide To Steam Tracing and Condensate CollectionDocument34 pagesGuide To Steam Tracing and Condensate CollectionRAMNo ratings yet

- HeatPipe WrapAroundDocument2 pagesHeatPipe WrapAroundJohnson ChuaNo ratings yet

- Spraying Systems CatalogueDocument116 pagesSpraying Systems Catalogueniknenad50% (2)

- Ahlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentDocument28 pagesAhlstar End-Suction Single-Stage Centrifugal Pumps: Flow EquipmentARYAN_FATHONI_AMRINo ratings yet

- Service Manual VD (E1) 12-05 - enDocument45 pagesService Manual VD (E1) 12-05 - enPhong LeNo ratings yet

- Dorner 3200 Vacuum ConveyorDocument8 pagesDorner 3200 Vacuum ConveyorBobKatNo ratings yet

- Pressure Temperature Chart According To ASME B16.34 ASME B PV CodeDocument5 pagesPressure Temperature Chart According To ASME B16.34 ASME B PV CodeDwayne YiiNo ratings yet

- Balston Coalescing Compressed Air and Gas FiltersDocument70 pagesBalston Coalescing Compressed Air and Gas FilterspraveenNo ratings yet

- uPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeDocument35 pagesuPVC & PVC Pipes Catalogue uPVC & PVC Pipes Catalogue: High Standard PipeFerryTimothyNo ratings yet

- Flexible ConnectionsDocument118 pagesFlexible ConnectionsMuzaffarNo ratings yet

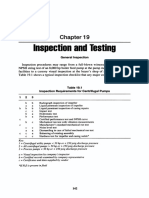

- Pump inspection and testing proceduresDocument4 pagesPump inspection and testing proceduresAmal KaNo ratings yet

- Brochure Belt Drive MDDK enDocument2 pagesBrochure Belt Drive MDDK enmuhamad.badar9285100% (1)

- Roller Bearing Shop GuideDocument7 pagesRoller Bearing Shop GuideBidyut kalitaNo ratings yet

- YXY-25A User ManualDocument7 pagesYXY-25A User ManualEdwin ThieroffNo ratings yet

- Manual Item 2Document13 pagesManual Item 2ricardoNo ratings yet

- Total HardnessDocument1 pageTotal HardnessEngr Faiq ChauhdaryNo ratings yet

- PSQCA Banaspati Anisidine ValueDocument21 pagesPSQCA Banaspati Anisidine ValueHemendra_Sango_7630% (1)

- Faiq Ilyas ParticularsDocument2 pagesFaiq Ilyas ParticularsEngr Faiq ChauhdaryNo ratings yet

- Designing of Steam Reformer& Heat Recovery Unit in Direct Reduced Iron Production (DRI)Document71 pagesDesigning of Steam Reformer& Heat Recovery Unit in Direct Reduced Iron Production (DRI)Engr Faiq Chauhdary100% (2)

- Plant CalculationsDocument22 pagesPlant CalculationsEngr Faiq ChauhdaryNo ratings yet

- Feasibility Report On The Production of Direct Reduced IronDocument5 pagesFeasibility Report On The Production of Direct Reduced IronEngr Faiq ChauhdaryNo ratings yet

- Heat Balance On FurnaceDocument7 pagesHeat Balance On FurnaceEngr Faiq ChauhdaryNo ratings yet

- Dust CleanerDocument38 pagesDust CleanerEngr Faiq ChauhdaryNo ratings yet

- Chapter 31. Current and Resistance Chapter 31. Current and Resistance Current and ResistanceDocument11 pagesChapter 31. Current and Resistance Chapter 31. Current and Resistance Current and ResistanceArwaa AlmaghrabiNo ratings yet

- WHO Blocks Nanosilver Shipments to Treat Ebola in AfricaDocument2 pagesWHO Blocks Nanosilver Shipments to Treat Ebola in AfricaTamas ZefferNo ratings yet

- Lea 2 PDFDocument21 pagesLea 2 PDFKY Renz100% (1)

- Chem Tech South 2013 - ConferenceDocument5 pagesChem Tech South 2013 - ConferenceAbirami PriyadharsiniNo ratings yet

- Fundamentals of SwimmingDocument7 pagesFundamentals of SwimmingSheila Mae Lira100% (1)

- EBARA FS513CT-R0E pump manualDocument6 pagesEBARA FS513CT-R0E pump manualApriliyanto Rahadi PradanaNo ratings yet

- Tenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionDocument4 pagesTenofovir Disoproxil Fumarate: Riefing - Nfrared BsorptionMostofa RubalNo ratings yet

- Manual de Uso Ecografo GE Logiq e PDFDocument192 pagesManual de Uso Ecografo GE Logiq e PDFDaniel CortesNo ratings yet

- On The Problem of The External World in The Ch'Eng Wei Shih LunDocument64 pagesOn The Problem of The External World in The Ch'Eng Wei Shih LunGuhyaprajñāmitra3100% (1)

- JKF8 Intelligent Reactive Power Compensation ControllerDocument4 pagesJKF8 Intelligent Reactive Power Compensation ControllerGuillermo Morales HerreraNo ratings yet

- Colistimethate Sodium 1 Million I.U. Powder For Solution For Injection - Colistin - (Emc)Document8 pagesColistimethate Sodium 1 Million I.U. Powder For Solution For Injection - Colistin - (Emc)hakim shaikhNo ratings yet

- Electronics Meet Animal BrainsDocument44 pagesElectronics Meet Animal BrainssherrysherryNo ratings yet

- Aac Block Adhesive: Product DescriptionDocument2 pagesAac Block Adhesive: Product DescriptionmaznahNo ratings yet

- 25f8e d64fDocument6 pages25f8e d64fapi-233604231No ratings yet

- Project Cash FlowsDocument2 pagesProject Cash FlowsAdarsh Chhajed20% (5)

- This Is Your Presentation TitleDocument28 pagesThis Is Your Presentation TitleStephanie AcarapiNo ratings yet

- Sharp LC 50le440u ProspectoDocument2 pagesSharp LC 50le440u ProspectovwcxlNo ratings yet

- Research PaperDocument13 pagesResearch PaperHamid ElmyNo ratings yet

- Vectors FoundationDocument8 pagesVectors FoundationNaning RarasNo ratings yet

- Dr. Carlos S. Lanting College: College of Maritime EducationDocument14 pagesDr. Carlos S. Lanting College: College of Maritime EducationJeynard Moler J. TanNo ratings yet

- 3-Ph Induction MotorDocument246 pages3-Ph Induction MotorAn00pgadzillaNo ratings yet

- Improving Students' Science Process SkillsDocument9 pagesImproving Students' Science Process SkillsNovia RahmawatiNo ratings yet

- TRUKE C20-33(35)L CLARK ENGINE PARTS LISTDocument2 pagesTRUKE C20-33(35)L CLARK ENGINE PARTS LISTРоман ПетровNo ratings yet

- CSO Skull SeriesDocument2 pagesCSO Skull SeriesWilchanNo ratings yet

- 32776Document6 pages32776Muqtar KhanNo ratings yet

- Matlab For SolidworksDocument18 pagesMatlab For SolidworksAle' AmoudiNo ratings yet

- ECC Report: Mobile Coverage ObligationsDocument77 pagesECC Report: Mobile Coverage ObligationsRedamichael JemberuNo ratings yet

- Présentation Transportation ManagementDocument14 pagesPrésentation Transportation ManagementHiba Hmito100% (1)

- ArduinoDocument15 pagesArduinoAlvarez TomasNo ratings yet

- SPECIFIC GRAVITY - DENSITY OF HYDRAULIC CEMENT (IS - 4031-Part 11-1988)Document6 pagesSPECIFIC GRAVITY - DENSITY OF HYDRAULIC CEMENT (IS - 4031-Part 11-1988)Pritha DasNo ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessFrom EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessNo ratings yet

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tFrom EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tRating: 4.5 out of 5 stars4.5/5 (27)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesFrom EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesNo ratings yet