Professional Documents

Culture Documents

Bunkering Procedure

Uploaded by

stabinmathewOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bunkering Procedure

Uploaded by

stabinmathewCopyright:

Available Formats

BUNKERING

BUNKERING IN PROGRESS

TAKING SAMPLE, WHILE BUNKERING IN PROGRESS, AT

THE BUNKER MANIFOLD

BUNKER SAMPLER CONTRAINER

BUNKER OIL SAMPLE

BOTTLE

FO TANKS QUICK CLOSING

VALVE

PERSONNEL AND THEIR DUTIES

CHIEF ENGINEER:

PLANS THE BUNKERS

INFORMS MASTER.

ALLOCATES DUTIES.

ENGINEER IN CHARGE:

TAKES SOUNDINGS.

CARRIES OUT CHECK LIST.

ASSISTANT IN CHARGE:

FITTER / MOTORMAN, TO ASSIST THE ENGINEER

CHIEF OFFICER:

MOBILISES ANTI POLLUTION TEAM.

DUTY OFFICER:

1. BRINGING BARGE ALONGSIDE.

2. TENDING MOORINGS.

3. CHECK DRAFTS.

BOSUN OR AB OR OS:

ASSISTS DUTY OFFICER.

BEFORE STARTING BUNKERS

1. WRITTEN PROCEDURES OF BUNKERING POSTED:

2. DUTY LIST, RESPONSIBLE ENGINEER / FITTER

POSTED.

3. INSTRUCTIONS TO PERSONNEL INVOLVED,

GIVEN.

4. COMMUNICATION : SHIP & BARGE / TERMINAL

ESTABLISHED.

5. COMMUNICATION, LOADING PROCEDURE AND

EMERGENCY STOP PROCEDURE WITH BARGE /

TERMINAL AGREED.

6. ANTI POLLUTION MATERIAL / FIRE FIGHTING

EQUIPMENT IS READY AT BUNKER STATION.

7. BUNKER MANIFOLD CONNECTION, NOT IN USE IS

BLANKED OFF.

8. ALL DECK SCUPPERS ON DECK ARE CLOSED.

9. BUNKERING FLAG OR LIGHT IS POSTED.

10. BUNKERING HOSE IS PROPERLY CONNECTED &

SECURED.

11. BUNKERING LINE VALVES ARE SET CORRECTLY.

12. INITIAL SOUNDINGS OF ALL BUNKER TANKS

CHECKED & RECORDED.

13. ALL SPILL TRAYS ARE EMPTY & DRAIN PLUGS ARE

IN PLACE.

14. JACOB LADDER IS READY FOR GOING DOWN TO

BARGE.

15. BARGE TANK SOUNDINGS CHECKED & RECPRDED.

16. NO OIL SPILLAGE IN THE VICINITY OF THE SHIP

ITEMS DISPLAYED PROMINENTLY NEAR

THE MANIFOLD

1. OIL TRANSFER PROCEDURE.

2. SHIPS BUNKER PIPELINE DIAGRAM.

3. OIL TANK LAYOUT WITH VENT PIPING.

4. PLACARD NO SMOKING.

DURING BUNKERING

1. TIME OF COMMENCEMENT OF OPERATION NOTED.

2. NO LEAKAGE OF OIL FROM FLANGES & PIPE

LINES.

3. OIL IS PROPERLY LED INTO THE RIGHT TANK.

4. NO BRANCHED FLOW TO THE OTHER TANKS.

5. CHECK SOUNDING OF THE RECEVING TANK AT

REGULAR INTERVALS.

6. MONITOR CLOSELY SHIPS HEEL & TRIM.

7. BUNKER MANIFOLD IS MANNED ALWAYS.

8. TAKE THREE BOTTLES OF SAMPLES BY DRIP

METHOD.

STOP BUNKERS

1. OIL SPILL.

2. LIGHTNING.

3. FIRE IN VICINITY.

4. SPARKS FROM FUNNEL.

5. VESSEL SURGING.

ON COMPLETION

1. AIR PURGE HAS BEEN CARRIED OUT.

2. ALL THE VALVES ARE CLOSED.

3. HOSE DISCONNECTED & MANIFOLD BLANKED

OFF.

4. TIME OF COMPLETION OF OPERATION NOTED.

5. ANTI POLLUTION MATERIAL / FIRE FIGHTING

EQUIPMENT, ARE STORED IN ORIGINAL PLACES.

6. SOUND ALL TANKS & CALCULATE QUANTITY

RECEIVED.

7. INFORM DUTY OFFICER.

8. ENTRIES MADE IN THE OIL RECORD BOOK.

BUNKER QUANTITY CALCULATIONS.

SPECIFICATION OF FUEL:

SP.GRAVITY : 0.9834 @ 15*C

FUEL PUMPING TEMPERATURE: 50*C

SO THE TEMPERATURE OF OIL = 50 15 = 35*C

CONSTANT : 0.00065 (IF NOT, IT HAS TO BE CORRECTED

FROM THE TABLES).

(50 15)0.00065 = 0.02275

SP.GRAVITY AT PUMPING: 0.9834 0.02275=0.96065.

IF WE BUNKER 2000M3 OF FUEL,AND

IF WE TAKE SP.GRAVITY AS 0.9834

QUANTITY RECEIVED = 2000 X 0.9834 = 1966.8MT.

IF WE TAKE SP.GRAVITYAS 0.96065 (WHILE PUMPING)

QUANTITY RECEIVED = 2000 X 0.96065 = 1921.3MT.

SO THE DIFFERENCE IN RECEIVING QUANTITY =1966.8

1921.3 = 45.5MT

PREPARED BY:

C.P.RAYEN, B.E.

PROFFESSOR,

AMET UNIVERSITY

Chennai

You might also like

- Basic Training For Oil and Chemical Tankers CargoDocument140 pagesBasic Training For Oil and Chemical Tankers CargoCamilla Alba100% (8)

- VIQ 7 - Knowlwdge Based Questions For Officers - Oil Tankers PDFDocument4 pagesVIQ 7 - Knowlwdge Based Questions For Officers - Oil Tankers PDFFaisal Karim Shazib100% (2)

- Errors in Oil Record Book Part I EntriesDocument3 pagesErrors in Oil Record Book Part I EntriesAbdul Anis100% (1)

- Bunkering Code of Practice PDFDocument62 pagesBunkering Code of Practice PDFsijuwolaoluranti100% (3)

- Loading ProcedureDocument77 pagesLoading ProcedureAnkit Vyas100% (2)

- Bunker Fraud MitigationDocument7 pagesBunker Fraud MitigationKolavennu ChandNo ratings yet

- Total VettingDocument11 pagesTotal VettingTruong's83% (6)

- BunkerDocument31 pagesBunkerAnonymous S9ObmiLKV100% (3)

- IOPP FORM B - Vessel Preparation ChecklistDocument4 pagesIOPP FORM B - Vessel Preparation ChecklistvagGS1150No ratings yet

- Oil PollutionDocument12 pagesOil PollutionGaurish SalgaocarNo ratings yet

- TDBFPDocument3 pagesTDBFPAnoop Kumar Allanki100% (1)

- BunkeringDocument29 pagesBunkeringChirag Gupta100% (2)

- Tricks of Bunker SupplyDocument5 pagesTricks of Bunker SupplyrubinoestelaNo ratings yet

- Bunkering Is Dangerous: Procedure For Bunkering Operation On A ShipDocument3 pagesBunkering Is Dangerous: Procedure For Bunkering Operation On A ShipSurajitSarkar100% (1)

- MALPRACTICES in Bunkering OperationsDocument21 pagesMALPRACTICES in Bunkering OperationsJuncheng100% (2)

- All About BunkeringDocument55 pagesAll About Bunkeringkamaldscl100% (1)

- ISM-Code MaintenanceDocument3 pagesISM-Code MaintenanceghwertpNo ratings yet

- Oil Record Book FillingDocument7 pagesOil Record Book Fillingmaninder_khasria100% (3)

- Marine FuelDocument17 pagesMarine FuelviviwulanNo ratings yet

- Disposal For Spilled Oil and Prevention For Secondary DisasterDocument4 pagesDisposal For Spilled Oil and Prevention For Secondary DisasterIonescu EdaNo ratings yet

- BUNKERING ChecklistDocument2 pagesBUNKERING ChecklistleotvrdeNo ratings yet

- Petroleum Calculation Series: DefinitionDocument6 pagesPetroleum Calculation Series: Definitionrubinoestela100% (1)

- Oil Record BookDocument9 pagesOil Record BookAmit PandeyNo ratings yet

- Oil Record Book Cum Se Completeaza Corect 15.10.2018Document29 pagesOil Record Book Cum Se Completeaza Corect 15.10.2018Popa VasileNo ratings yet

- Tanker MGT& Self AssessmentDocument5 pagesTanker MGT& Self AssessmentKnobb MuridnakalNo ratings yet

- Marpol Annex 2Document6 pagesMarpol Annex 2secrets1003100% (1)

- Bunkering ProcedureDocument4 pagesBunkering ProcedureVinay Gupta100% (2)

- Tier III SCR For Large 2-Stroke MAN B&W Diesel EnginesDocument6 pagesTier III SCR For Large 2-Stroke MAN B&W Diesel EnginesWon-young SeoNo ratings yet

- DNV BQS - tcm4-482822Document8 pagesDNV BQS - tcm4-482822captkcNo ratings yet

- Fire OnboardDocument98 pagesFire OnboardAji HandokoNo ratings yet

- Basic Handling of Molasses For ShipsDocument1 pageBasic Handling of Molasses For ShipsPrabhakaran RamanathanNo ratings yet

- What Is The Ism CodeDocument13 pagesWhat Is The Ism CodeRizal IsmailNo ratings yet

- Oral-Preparation-Guide (Rifat Azad-Bma 49) PDFDocument105 pagesOral-Preparation-Guide (Rifat Azad-Bma 49) PDFTarek Aziz100% (2)

- Marine Emergency Procedures 2019Document20 pagesMarine Emergency Procedures 2019Jasonll100% (1)

- Safe Bunkering PracticesDocument2 pagesSafe Bunkering Practiceskabirsharma76No ratings yet

- Marpol SECADocument3 pagesMarpol SECAAnonymous XtvvG80zuNo ratings yet

- ORB HOW-TO Ver 1 8Document13 pagesORB HOW-TO Ver 1 8kojet90100% (1)

- Training Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFDocument37 pagesTraining Material 126 Company Guidance For Recording Operations in The Oil Record Book PDFkurupath100% (1)

- Notes On Marine EngineeringDocument19 pagesNotes On Marine Engineeringavm4343100% (2)

- Inert Gas SystemDocument13 pagesInert Gas SystemBisrat100% (1)

- DrydockDocument8 pagesDrydockRavindar AnandanNo ratings yet

- Supervision of Crude Oil Washing (COW) OperationsDocument6 pagesSupervision of Crude Oil Washing (COW) Operationstony100% (1)

- Oil Record BookDocument12 pagesOil Record BookNorman Sasongko100% (2)

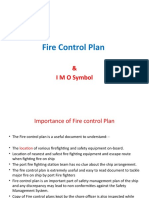

- Fire Control Plan IMO SymbolDocument13 pagesFire Control Plan IMO SymbolAkshay A KumarNo ratings yet

- Check List 84 - BALLASTING, DeballastingDocument1 pageCheck List 84 - BALLASTING, Deballastingprakash7kNo ratings yet

- 00 h23 EngineRoomResourceManagement English PDFDocument36 pages00 h23 EngineRoomResourceManagement English PDFsocrates19582405100% (1)

- Crude Oil WashingDocument2 pagesCrude Oil WashingBharatiyulam100% (1)

- Oral Question and AnswerDocument179 pagesOral Question and AnswerMariyath Muraleedharan KiranNo ratings yet

- How To Prepare For Vetting Inspection in The Engine Room?Document4 pagesHow To Prepare For Vetting Inspection in The Engine Room?saket007iNo ratings yet

- Crude Oil Washing and Heating PolicyDocument6 pagesCrude Oil Washing and Heating PolicyGuss Kontarakis100% (1)

- CDI-T Operating Manual Section 4.0 Terminal Inspection ProceduresDocument6 pagesCDI-T Operating Manual Section 4.0 Terminal Inspection ProceduresTh NattapongNo ratings yet

- Vetting Obs ListDocument30 pagesVetting Obs ListBrian Dsilva60% (5)

- Partnership Towards A Safe and Better Marine Future: MISC Maritime Services (MMS) Shipowner and Charterer ForumDocument22 pagesPartnership Towards A Safe and Better Marine Future: MISC Maritime Services (MMS) Shipowner and Charterer Forumclaudio santellanesNo ratings yet

- Bunkering ProcedureDocument21 pagesBunkering ProceduresinthustonNo ratings yet

- Bunker Plan - 07.12.16Document1 pageBunker Plan - 07.12.16Farman AliNo ratings yet

- CS6431-Thermal Engineering Lab - I: Laboratory ManualDocument21 pagesCS6431-Thermal Engineering Lab - I: Laboratory ManualVivek AnandanNo ratings yet

- What Is Cappuccino Bunker Effect On ShipsDocument7 pagesWhat Is Cappuccino Bunker Effect On ShipsshubhamNo ratings yet

- Gas Turbine Operation, Maintenance & InspectionDocument57 pagesGas Turbine Operation, Maintenance & Inspectionromadhinho100% (3)

- ME6412 Thermal Engineering Lab I 2013 RegulationDocument21 pagesME6412 Thermal Engineering Lab I 2013 RegulationSumit Chandra VermaNo ratings yet

- Food Poisoning: © Food - A Fact of Life 2009Document14 pagesFood Poisoning: © Food - A Fact of Life 2009stabinmathewNo ratings yet

- All Types PumpsDocument61 pagesAll Types PumpsstabinmathewNo ratings yet

- NO Compliance Under The No Sip Call and Section 126 RulesDocument9 pagesNO Compliance Under The No Sip Call and Section 126 RulesstabinmathewNo ratings yet

- Refrigeration Cycle TheoryDocument8 pagesRefrigeration Cycle TheorystabinmathewNo ratings yet

- The General List of Questions and AnswersDocument17 pagesThe General List of Questions and AnswersstabinmathewNo ratings yet

- Shell & Tube Installation, Operation & Maintenance ManualDocument14 pagesShell & Tube Installation, Operation & Maintenance Manualnidhul07No ratings yet

- Dimethylformamide - Nugentec Ghs MsdsDocument8 pagesDimethylformamide - Nugentec Ghs MsdsstabinmathewNo ratings yet

- DG Annex 111Document58 pagesDG Annex 111stabinmathewNo ratings yet

- Annex VDocument42 pagesAnnex Vstabinmathew100% (3)

- Techniques of DC Circuit AnalysisDocument33 pagesTechniques of DC Circuit AnalysisstabinmathewNo ratings yet

- History of MarpolDocument41 pagesHistory of MarpolstabinmathewNo ratings yet

- Annex Iii: Harmful Substances in Packaged FormDocument10 pagesAnnex Iii: Harmful Substances in Packaged FormstabinmathewNo ratings yet

- Marpol 73 78 Annex IIDocument32 pagesMarpol 73 78 Annex IIstabinmathew100% (2)

- Marpol 73 78 Anex IIDocument32 pagesMarpol 73 78 Anex IIstabinmathewNo ratings yet

- Annex IDocument68 pagesAnnex IstabinmathewNo ratings yet

- Westermo MRD 330-3xx & GreenBow IPSec VPN Client Software ConfigurationDocument12 pagesWestermo MRD 330-3xx & GreenBow IPSec VPN Client Software ConfigurationgreenbowNo ratings yet

- Santa Letters 2013Document16 pagesSanta Letters 2013Lebanon_PublishingNo ratings yet

- Piping Tie in Procedure Rev A PDFDocument15 pagesPiping Tie in Procedure Rev A PDFMohammed Sibghatulla100% (1)

- IBM Tivoli Monitoring Implementation and Performance Optimization For Large Scale Environments Sg247443Document526 pagesIBM Tivoli Monitoring Implementation and Performance Optimization For Large Scale Environments Sg247443bupbechanhNo ratings yet

- Brick Bonding AssignmentDocument4 pagesBrick Bonding AssignmentNija AsifNo ratings yet

- Guide To Manually Importing/Transferring Your Livery For FH4/FM7/FH3 PCDocument12 pagesGuide To Manually Importing/Transferring Your Livery For FH4/FM7/FH3 PCLennike SantosNo ratings yet

- Computing The Maximum Volume Inscribed Ellipsoid of A Polytopic ProjectionDocument28 pagesComputing The Maximum Volume Inscribed Ellipsoid of A Polytopic ProjectiondezevuNo ratings yet

- ADMS 2510 Week 13 SolutionsDocument20 pagesADMS 2510 Week 13 Solutionsadms examzNo ratings yet

- Auto Setting DataDocument6 pagesAuto Setting Datahalo91No ratings yet

- Lesson Worksheet: 6.1A MeanDocument7 pagesLesson Worksheet: 6.1A Meanwaiman fuNo ratings yet

- RRB NTPC Previous Year Paper 20: WWW - Careerpower.inDocument16 pagesRRB NTPC Previous Year Paper 20: WWW - Careerpower.inSudarshan MaliNo ratings yet

- 2.1 Article On Reasonable Compensation Job Aid 4-15-2015Document3 pages2.1 Article On Reasonable Compensation Job Aid 4-15-2015Michael GregoryNo ratings yet

- Muscovy DucksDocument27 pagesMuscovy DucksStephenNo ratings yet

- FIN323 Project 2021-2022Document6 pagesFIN323 Project 2021-2022saleem razaNo ratings yet

- Food Safety and StandardsDocument8 pagesFood Safety and StandardsArifSheriffNo ratings yet

- Product Sold by APPLE AustraliaDocument1 pageProduct Sold by APPLE AustraliaImran KhanNo ratings yet

- IEC947-5-1 Contactor Relay Utilization CategoryDocument1 pageIEC947-5-1 Contactor Relay Utilization CategoryipitwowoNo ratings yet

- United States Court of Appeals, Third CircuitDocument18 pagesUnited States Court of Appeals, Third CircuitScribd Government DocsNo ratings yet

- 2 Days Meat Processing Training Program (Kalayaan Laguna)Document2 pages2 Days Meat Processing Training Program (Kalayaan Laguna)Jals SaripadaNo ratings yet

- The US Navy - Fact File - MQ-8C Fire ScoutDocument2 pagesThe US Navy - Fact File - MQ-8C Fire ScoutAleksei KarpaevNo ratings yet

- BrochureDocument8 pagesBrochurevacmanilaNo ratings yet

- Regulator With NRVDocument2 pagesRegulator With NRVBiswanath LenkaNo ratings yet

- EU MDR FlyerDocument12 pagesEU MDR FlyermrudhulrajNo ratings yet

- L - HRF22B0301 - Hose & Pulley Block (ZM, METRIC)Document5 pagesL - HRF22B0301 - Hose & Pulley Block (ZM, METRIC)Gustavo RodriguezNo ratings yet

- Mid Semester Question Paper Programming in CDocument8 pagesMid Semester Question Paper Programming in CbakaNo ratings yet

- The Lafayette Driller: President's Message By: Lindsay LongmanDocument7 pagesThe Lafayette Driller: President's Message By: Lindsay LongmanLoganBohannonNo ratings yet

- Manaloto V Veloso IIIDocument4 pagesManaloto V Veloso IIIJan AquinoNo ratings yet

- Invoice SummaryDocument2 pagesInvoice SummarymuNo ratings yet

- Bp344 RampDocument29 pagesBp344 RampmaeNo ratings yet

- Management Thoughts Pramod Batra PDFDocument5 pagesManagement Thoughts Pramod Batra PDFRam33% (3)