Professional Documents

Culture Documents

36ft Ringer 7701 PDF

Uploaded by

namduong3680 ratings0% found this document useful (0 votes)

44 views6 pagesOriginal Title

36ft_ringer_7701.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views6 pages36ft Ringer 7701 PDF

Uploaded by

namduong368Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

MANITOWOC

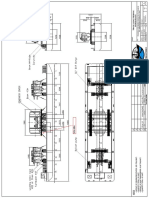

30-Foot Diameter

PLATFORM -RINGIER

SPECIFICATIONS

—s

MANITOWOC

36-Foot

Hydraulic Boom Hoist

Diameter

PLATFORM -RINGER’

(Operator's Module

OUTLINE

DIMENSIONS

9

arin

3 LI

2 J

& O

i

Ez 36° Diameter Ring-

=

1a ast

| bs 2'(5.233m)

Counterweight —}-| [leon Heer

\ rows (isin,

| Romer 15 ain

Hoist Unt

:

5 er]

| + |

5 ‘Tap of Je

" odesn

| _ fmeecnte

€ ROTATION rn

amass (toute gly

fa ne ian mtr

7 7° (2th

WEIGHTS

POUNDS*

36' DIAMETER RING, 4 segments with wear

plates: 38,610

FRONT ROLLER CARRIER, with 4 house

rollers, 2 hook rollers and mast support 22,000

ROTATING PLATFORM, with 2-drum 390

Hoist and hydraulic boom hoist 112,720

RINGER-SWINGER ATTACHMENTS,

2 with positioners (each 1,500) 3,000

REMOVABLE COUNTERWEIGHT (13-PC)

Rear (7 boxes, each 46,000) 322,000,

Front Left (8 boxes, each 38,000). 114,000

Front Right (3 boxes, each 38,000) 114,000,

Total 550,000

TELESCOPIC BOOM STOPS 825

POUNDS"

MAST AND BACKHITCH, 130' No. 22A mast

with pendant backhitch 31,170

OPERATOR'S MODULE, complete with all

‘operating controls and mounting bracket 2,050

BOOM NO. 27

BOOM BUTT: (less wire rope and pendants)... 8,485

BOOM TOP: (equipped with six sheave lower

‘boom point) 9,720

‘Add for upper boom point and sheave... 1,255

Total 10,975

BOOM INSERTS:

Insert—20" (with pendants & wire rope guide). 3,860

Insert—40" (with pendants & wire rope guides) 6,650

36-FOOT DIAMETER RING ASSEMBLY

RING SEGMENTS: Fabricated, reinforced I-beam con-

struction. Four ring segments (front, rear and two sides) are

bolt-connected for fast installation and removal.

WEAR PLATES: Sixicon 3("alloy steel plates cut to fit on

ROTATING

ROTATING PLATFORM: Fabricated deep box section

side rails with lattice-type supports form a mounting plat-

form for machinery components. Catwalks and railings pro-

vided along both sides of platform. Platform can be

‘mounted on fixed or transporter base. Base or transporter

must be equipped with king pin to provide concentricity,

‘between rotating platform and 36" diameter ring

KING PIN: Cast steel, Bolted to support structure with

high strength bolts. Provides pivot for rotating platform.

‘Takes horizontal load only, no uplift. Grease fittings provide

lubrication to bronze bearingsin platform. Support structure

supplied by customer, except with transporter mounting,

FRONT ROLLER CARRIER: Fabricated box section

construction with 4 house rollers and 2 hook rollers, all

antifriction bearing mounted. Provides lugs for boom hinge

pins and mast support. Pin-connected to front end of ro-

tating platform.

OPERATOR'S MODULE: Stee! construction, indepen-

dently mounted on boom carrier, fully enclosed and in-

sulated. Includes operating controls for load hoist, boom

hoist and swing; safety glass windows, cab heater, wind-

top of ring segments to protect them from wear. Attached

to ring by retainer plates designed to clear hook roller

hanger assembly.

RING GEAR: Sixteen segments bolt-connected to ring,

STRUCTURE

shield wiper, horn and defogging fan.

COUNTERWEIGHT TRAY: Rotating platform extends

beyond 36' diameter ring to form center section of counter-

weight tray. Two side wings pin-connected to center sec-

tion complete rear counterweight tray which supports 322,

000 pounds of counterweight. Two additional side wings,

pin-connected to rotating platform on either side of boom

hoist, each support 114,000 pounds of counterweight.

COUNTERWEIGHT ROLLERS: Two sets of dual

equalized support rollers and two hook rollers mounted

under center section of rear counterweight tray are antifric-

tion bearing mounted

RINGER COUNTERWEIGHTS: 550,000 pounds. Op-

tional interlocking steel boxes filled with scraperete (con-

sisting of 7 boxes weighing 46,000 pounds each and 6

boxes weighing 38,000 pounds each), Note: counterweight,

can be supplied at job site in most readily available

form such as cast concrete, stee! plate or billets. Certifica-

tion of weights is recommended to assure accuracy

of counterweight.

MACHINERY COMPONENTS

LOAD HOIST: VICON® (Variable Independent CONtrol)

controlled 390 Hoist with power plant for load and whip

lines. Available in either 2 or 3 drum models for versatility

in meeting specific application requirements. Hoist

includes VICON power load lowering, radiator, en-

gine shroud, fully enclosed gears and drive chains, anti-

friction bearing drum journals, electric starting, instrument

panel and air controls in operator's module. Drums 19" in

diameter x37" wide, equipped with ratchet and paw. Op-

tional grooved laggings available. Dual, air actuated drum

brakes are spring set, air released, air applied. Single, air

actuated drum clutches,

INDEPENDENT BOOM HOIST: Dual drums with

‘grooved laggings driven by bronze worm and gear through

Planetary gear reduction. All rotating shafts antifrction

bearing mounted. Boom hoist powered by variable displace-

ment hydraulic motor providing full range speed control

Boom hoist brake, external contracting band-type. spring

applied, air released. Auxiliary brake, external contracting

band-type, manually applied from operator's module.

Ratchet mounted to worm gear, pawl gravity engaged, air

released. Ratchet and paw! mounted inside gear housing.

‘Boom hoist mounted on rear of rotating platform,

POWER PLANTS: See page 5

THE RINGER-SWINGER®

The swing function for the 36° diameter PLATFORM-

RINGER is performed by Manitowoc's exclusive, patented

RINGER-SWINGER system. This fully modulated, hydrau-

lically powered system provides swing acceleration or de-

celeration in either direction. Operation is controlled by a

single lever and full, free-float exists when lever is in neu-

tral position.

‘The system utilizes two RINGER-SWINGER units,

‘one mounted on either side of the front roller carrier. A

hydraulic motor powers a direct drive pinion which is held

in constant contact against an internal ring gear by hydrau-

lic and spring positioners. A drive pinion flange and gear

‘segment skirt maintains pitch control between pinion and

ring gear.

Hydraulic

Positioner

Drive Pinion Flange.

‘The number of RINGER-SWINGER assemblies required

for a project, such as barge-mounting, depends upon spe-

sific lifting and swinging requirements. Two RINGER-

‘SWINGERS are standard equipment on each 36" diameter

PLATFORM-RINGER and additional RINGER-SWINGERS,

are optional. Consult factory for specific information,

Front Roller Carrer

POWER PLANT OPTIONS _

] ~ Cubic Inch

cyinder | Bore | stoke | pesaceront

Cummins KT-115 480 @ 2.000

Caterpillar 8408 460 @ 2.000

—ceteriter o5a6 | 355 6 2000

GM. 2V-73N 410 @ 2,000

- Fuel Tank Capacity: 200 Gallon:

Model 380 Hoist

Drum | Wire Rope ‘Spooling Capacity ]

0 orm | oiometer | wan | “SEG? | — Fi Layers | Wax

2-DRUM HOIST }

LIETCRANE

ovat Fron | sgor | gras | ay" 161 ql 1.505 |

ie Roar | Teor | 873s | i 181 i 1388

OPTIONAL 5-DRUM HOIST

CIETORANE |

oat zeront | igor | g72s" 181 7 soo!

vino teat | 186" | 8738 181 ; 7808

FRONT END EQUIPMENT

NO. 27 BOOM: 40 boom butt, 40" open throat top, 20!

and 40" inserts. All welded construction. Rectangular boom

with inverted angle chords and tubular lacings, Chords are

100,000 PSI yield steel. Lower boom point equipped with

six 32" OD antifriction bearing mounted sheaves. Basic

boom length 140'; maximum boom length 340"

FIXED MAST: Consists of 130" No. 22 boom with open

throat top. Mast is pin-connected to mast support on front

roller carrier

BACKSTAY STRUT: Two-piece, box section construc-

tion. Supports mast when boom hoist lines are slack

MAST BACKSTAY PENDANTS: Four 2" swaged struc-

tural strand pendants.

BOOM RIGGING: Eiaht-par line reeved betwoen fixed

mast and boom equalizer Controls boom angle by single

line continuously reeved from dual boom hoist drums which

ower boom up and down. Two pair of 13,” pendants con-

ect equalizer to boom point

EQUALIZER: Steel fabrication

antifriction bearing mounted,

WIRE ROPE GUIDE: Mounted on top side of boom,

Two sheaves bronze bearing mounted.

WIRE ROPE ROLLER GUIDE: Mounted on top side

fof boom, Induction hardened tubing. Antifriction bear-

Jing mounted.

Four vertical sheaves

UPPER BOOM POINT: Optional. Pin-connected toopen

throat top. Single or double 36" OD sheaves available, both

antifriction bearing mounted,

4% OFFSET BOOM TOP: Optional. Permits greater

clearance between load and boom, Standard No. 27 boom

converted by adapter links at upper boom joint

FOR CAPACITY CHARTS AND INFORMATION,

CONSULT FACTORY.

NO. 122A JIB: Optional. 28-ton maximum capacity 40°

length extendible 10 50' with 10' insert Jib angie adjustable

t0 8, 10, and 20 degrees. To section eauioned with 32

roller bearing sheave, wire rope guide and anchor for two-

part line. Jib attaches to lower boom point

CONSULT JIB LIFTING CAPACITY CHARTS FOR

SPECIFIC CAPACITY WHEN USED ON VARIOUS

BOOM LENGTHS.

NO. 123 JIB: Optional. 20-ton capacity. 30° length ex-

tendible 10 60' with 10' inserts. Jib angle adjustable to

0, 10, and 20 degrees. Top section equipped with 24" roller

Dearing sheave, wire rope guide and anchor for two-part line.

vib adapter required to mount No. 128 jib on No. 27 boom.

CONSULT JIB LIFTING CAPACITY CHARTS FOR

SPECIFIC CAPACITY WHEN USED ON VARIOUS

BOOM LENGTHS.

FIXED MOUNT

Manitowoe’s 36" diameter PLATFORM-RINGER is adapi-

able to provide high capacity lifting capability for barge,

Pedestal or gantry applications. The fixed mount eliminates

the need for ring side beams Only a king pin support

is requires.

‘BARGE MOUNT

The 86" diameter ring can be directly mounted to top of its

support structure and secured by a clamp arrangement, The

ring can also be supported on blocking or steel vedestals,

located on 4" centers under the ring perimeter and at its

four segment joints.

GANTRY MOUNT

MOBILE MOUNT

For even greater versatility, Manitowoc’s 36’ diameter

PLATFORM-RINGER can be crawler-transporter mounted

to provide the mobility needed to move the PLATFORM-

RINGER from lift to lift. The crailer-transporter can then

be removed and ulilized as a high capacity load transporter

while the PLATFORM-RINGER remains available for if work

CRAWLER-TRANSPORTER

‘This method of mounting requites two side beams and a

king pin assembly which are bolt-connected to the trans-

porter carbody. The ring is supported in a conven-

tional manner using blocking or Manitowoc’s Serew-Jack

support system.

Because of program of continuing improvements, Manitowoc Engineering Co. reserves he right to change this description at any time, without notes.

MANITOWOC ENGINEERING CO.

(A division of The Menitowoe Company ne.)

Manitowos, Wisconsin 54220

MorsM—Line in USA,

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Energies 10 00666 PDFDocument46 pagesEnergies 10 00666 PDFnamduong368No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 1.2generatorstator+auxtransformer1 Comment 3Document1 page1.2generatorstator+auxtransformer1 Comment 3namduong368No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- TEREX AC1000 - Ucm02 - 040854 PDFDocument104 pagesTEREX AC1000 - Ucm02 - 040854 PDFnamduong368No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Qua Khuc Cua Tai Cau Khe VanDocument1 pageQua Khuc Cua Tai Cau Khe Vannamduong368No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- TEREX AC1000 - Ucm02 - 030345Document2 pagesTEREX AC1000 - Ucm02 - 030345namduong368No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- ZF - 3HP12 For BMW Workshop ManualDocument36 pagesZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Na ZF Tab GBDocument34 pagesNa ZF Tab GBEdevaldo SantanaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- TEREX AC1000 - Ucm02 - 047720 PDFDocument114 pagesTEREX AC1000 - Ucm02 - 047720 PDFnamduong368No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- CBD&CBG 25manual PDFDocument120 pagesCBD&CBG 25manual PDFnamduong368No ratings yet

- TEREX AC1000 - Load Chart PDFDocument116 pagesTEREX AC1000 - Load Chart PDFduongpnNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- CDP&CGP Manual de Taller PDFDocument178 pagesCDP&CGP Manual de Taller PDFnamduong3680% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- CDP&CGP 25manual PDFDocument244 pagesCDP&CGP 25manual PDFnamduong368100% (1)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- SM-751 - 67 To 88 PDFDocument22 pagesSM-751 - 67 To 88 PDFnamduong368100% (1)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CDP&CGP Manual de Taller PDFDocument178 pagesCDP&CGP Manual de Taller PDFnamduong3680% (1)

- Em&Cem 20-35 PDFDocument186 pagesEm&Cem 20-35 PDFnamduong368No ratings yet

- 3950D 6007 PDFDocument6 pages3950D 6007 PDFnamduong368No ratings yet

- 3900T 6597 PDFDocument8 pages3900T 6597 PDFnamduong368No ratings yet

- 3900W 175 PDFDocument2 pages3900W 175 PDFnamduong368No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- 3900vicon 6001 PDFDocument7 pages3900vicon 6001 PDFnamduong368No ratings yet

- 60 FT Ringe7702 PDFDocument6 pages60 FT Ringe7702 PDFnamduong368No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)