Professional Documents

Culture Documents

3900T 6597 PDF

Uploaded by

namduong3680 ratings0% found this document useful (0 votes)

41 views8 pagesOriginal Title

3900T_6597.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

41 views8 pages3900T 6597 PDF

Uploaded by

namduong368Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

MANITOWOC

SPECIFICATIONS 5

© MANITOWOC 1976

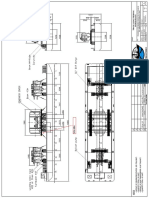

TAILSWING OVER LUGS WITH:

NoGw | 171014" (@.620m)

‘One Cw. _| 19° 8” 165m)

Two Outs. | 1673%" (4.972m)

Three Gms. | 1773!" (6.266)

cat |

J Ee

[ies a [ees ee

acitted ais bat a Leeann

189 77Tel © One brs

FW (520m

e740 fos 02 |e

rouNos Pounos

complete with 9 No. 8A Hamer

need 0m, ganty and backnneh, bom ret ee

Moning and pendants hes wie’ rope Done BOOM BUTT: (lens wire rope and pendant)

Mi8oNe coporwors package eounterwegha and HANMERHEAD BOOM TOP: (eaupped oa

Complete Ca nn aaser0 i a

compile wih baste machinery, boom pom, teaver and wna

eluding drune, Sut not eudng. gan and Rar unparboom pol 39

eas, “ont oh ‘acon’ oF counter Tota ase

See et atew oom wens:

Insert" th pendants) oxo

wih contr ost and rly path, Joe Ineo — 10" fn benaens) 138

bumper countorslgh Os00 pound) an ent pa wn paneer ue

nd Yur cutrigoreoveies 6925 pou Inert 40 fh boners) ie

80

Inner

Midge

Outer Weigh are approximate

(component arson,

WEIGHT DISTRIBUTION FOR TRAVELING CHART ON PAGE 7.

CRANE POWER PLANTS

ope cyt | wore | stoke | _piapincamont | Mfatywhoa™

Basic Cumming LTAA0-0325 6 | ser | sae #0 '310@ 2000

‘OPTIONAL Detroit Dose BV-71N @ | 425 | S000" 568 276 @ 2000

‘Ar Compressor: 182 elm Fuel Tank Gspacty: 75 gallons.

‘Tandem compressors (145 clm each) required in place of sing

‘han boom hoist, om stop and drum elutch controls.

ir compressor on all non-VICON models with any ar contols other

UPPER MACHINERY

ROTATING BED: one-piece, heavy reinforced steel fabrt-

‘cation with integral machinery side frames. Provides rigid deck

for power plant, house rollers, rotating machinery, A-frame and

‘boom hinge. Houses swing lock and swing gear.

HOUSE ROLLERS: 4

2 Front, antifriction besring-mounted,

2 Rear, antifetion boaring-mounted.

HOOK ROLLERS:

Justment.

2 Front antiriction bearing-mounted.

4 Rear antiriction bearing-mounted

6 Mounted on eccentrie shaft for 0c

A-FRAME: Supports gantry, independent boom hoist, and

counterweight, Fabricated steel roof supports and vertical

Center lags; heavy bar front and roar logs. All Joints bolt and

pin-connected.

POWER TRANSMISSION, NON-VICON: Engin

mounted. S-stage torque converter transmits power through

chain drive to horizontal swing crive shaft — tho beginning

ower source for hoist, swing and independent boom hoist.

Chain drives fully enclosed and run in oil Speed and power

‘output requirements vary with engine APM which is controlled

by hand and/or foot throttle. Consult factory for appropriate

chain sprocket ratios.

POWER TRANSMISSION, VICON®: The VICON (Vari-

able Independent CONtto! — Patented) system provides step-

toss variable control power transmission for various machine

functions. Engine power is divided at transmission caso and

tranamited to two controled torque converters. Through chain

‘ives, ear converter powers horizon swing dive sha (which

ts beginning power source for independent boom host) wh

font converter supplies holst power. Controls arranged 10

engage clutches wile litle or no toraue fs transmitted from

power eource, vinually eliminating clutch slippage and wear

hain erves fully enclosed and run in oll. Since speed and

ower requirements vary, consult factory for appropriste tans-

mission and chain sprocket ratios.

HORIZONTAL SWING DRIVE SHAFT: Alloy set shat,

antifsction besring-mounted. Swing oluiches mounted on cast

steel hub splined to shaft. Integral clutch spiders and bevel

pinion, ball besring-mounted. evel pinions, totally enclosed

fand oll spray lubricated, drive the inlormeciate vertical swing

shall. Sprockst on shalt provides drive for independent boom

holst. Forced.air cooling provided for non-VICON machines

with clam combination.

SWING CLUTCHES: single-aisc clutches, splined to hor'-

zontal swing drive shaft, ae manvally applied by axiakpressure

‘cam levers whien apply cluteh pressure evenly over entire

friction area, providing very smooth swing action. Cam faces

separated by antifietion roller bearings which take axial thrust

to minimize friction. Clutch disc assombly caslly removed for

replacement of clutch facing

INTERMEDIATE VERTICAL SWING SHAFT: Alloy

see, antirition bearing mounted. Bevel goar splined to upper

fond driven by horizontal swing drive shaft bevel pinions. Spur

pinion, splined on lower end, engages swing gear and drives

vertical swing shatt

VERTICAL SWING SHAFT: alloy steel, antitiction bear-

Jing mounted shaft. Swing gear on top driven by spur pinio

‘of intermesiate vertical swing shaft. Pinion on bottom engage

ring gear intogral with roller path.

SWING BRAKE: External contracting, manual brake. Drum

Is splined to upper end of forged alloy steel shaft which is

bushing mounted in the rolaling bod slightly behind, above

‘and to one side of the vertical ewing shaft. Integral spur

inion on lower end of Drake shaft engages swing goar. Foot

pedal control latches for parking,

SWING LOCK: Heavy goar segment, manually controlled,

‘engages swing gear, Operates independent of intermediate ver-

tical swing shat. High-tension spring link cushions engagement.

(Upper Machinery Continued on page 4)

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Na ZF Tab GBDocument34 pagesNa ZF Tab GBEdevaldo SantanaNo ratings yet

- Energies 10 00666 PDFDocument46 pagesEnergies 10 00666 PDFnamduong368No ratings yet

- TEREX AC1000 - Ucm02 - 047720 PDFDocument114 pagesTEREX AC1000 - Ucm02 - 047720 PDFnamduong368No ratings yet

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- 1.2generatorstator+auxtransformer1 Comment 3Document1 page1.2generatorstator+auxtransformer1 Comment 3namduong368No ratings yet

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- TEREX AC1000 - Ucm02 - 030345Document2 pagesTEREX AC1000 - Ucm02 - 030345namduong368No ratings yet

- ZF - 3HP12 For BMW Workshop ManualDocument36 pagesZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- Qua Khuc Cua Tai Cau Khe VanDocument1 pageQua Khuc Cua Tai Cau Khe Vannamduong368No ratings yet

- TEREX AC1000 - Ucm02 - 040854 PDFDocument104 pagesTEREX AC1000 - Ucm02 - 040854 PDFnamduong368No ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- TEREX AC1000 - Load Chart PDFDocument116 pagesTEREX AC1000 - Load Chart PDFduongpnNo ratings yet

- CDP&CGP 25manual PDFDocument244 pagesCDP&CGP 25manual PDFnamduong368100% (1)

- CBD&CBG 25manual PDFDocument120 pagesCBD&CBG 25manual PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CDP&CGP Manual de Taller PDFDocument178 pagesCDP&CGP Manual de Taller PDFnamduong3680% (1)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CDP&CGP Manual de Taller PDFDocument178 pagesCDP&CGP Manual de Taller PDFnamduong3680% (1)

- SM-751 - 67 To 88 PDFDocument22 pagesSM-751 - 67 To 88 PDFnamduong368100% (1)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- 3900W 175 PDFDocument2 pages3900W 175 PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- 60 FT Ringe7702 PDFDocument6 pages60 FT Ringe7702 PDFnamduong368No ratings yet

- Em&Cem 20-35 PDFDocument186 pagesEm&Cem 20-35 PDFnamduong368No ratings yet

- 3950D 6007 PDFDocument6 pages3950D 6007 PDFnamduong368No ratings yet

- 3900vicon 6001 PDFDocument7 pages3900vicon 6001 PDFnamduong368No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)