Professional Documents

Culture Documents

3900W 175 PDF

Uploaded by

namduong3680 ratings0% found this document useful (0 votes)

23 views2 pagesOriginal Title

3900W_175.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pages3900W 175 PDF

Uploaded by

namduong368Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 2

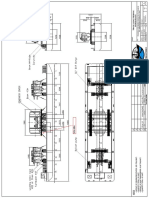

3900W TOWER LIFTCRANE

TOWER AND BOOM

SPECIFICATIONS

‘The No. 9 Towor in 114° length (from tower hinge to boom

hinge) and the No, 18 Boom In 100" length are standard for

the Model 3500 Tower Liftcrane. See. chart with TOWER

RANGE DIAGRAM for other possible combinations of tow

and. boom lengths, Tower constructed of Inverted angle

‘chord members with tubular lacing; box section 74” wide x

72" deep at the pin connected Joints. Boom constructed of

tubular chord members and lacing: box section 5314” wide

x 48%" deep at the pin connected joints,

TOWER COMPONENTS: 30/ butt section; 19%" backstay

Ingort; two 30" inserts (one, with equalizer attachment lugs,

must be placed 30’ above backstay insert; one 20’ insert

(with rubber bumpers for tower cap boom carrier}; and

tower cap.

‘Tower insert sections in 10', 20’, and 40" lengths are optional,

for 1247, 134, 144" 154, and 168" lengths

BOOM COMPONENTS: 17’ butt section; two 20" Insert, and

23! top section with one 27” diameter antifrction beating

sheave (Gwo sheaves optional,

Boom insort sections in 10’, 20', and 30" ngths are optional

for 110%, 120, 130%, 140," and “160! lengths. Intarmediate

boom suspension is required for boom lengths of 120, 140",

or 180".

TOWER BACKSTAY: 28" 1” long (to pin centors). Consists of

two box section struts, pinned to the backstay insert, and

supported al a predetoimined angle fo the butt section

TOWER CAP: Provides hinge point for boom cartier and

struls and is pinned to top of tower. Antifietion bearing

sheave provides for load lino passage over cap. Attached

boom stop pendant limits boom angle

BOOM CARRIER: Becomes part of the tower cap when as-

sembied, Function Is to center the boom hinge pin on the

tower cap in @ lock arrangement, when boom reaches Working

position, for even distribution of oad to tower.

One 8” diameter x 1956” wide, bushed, wire rope roller guide

is provided in the boom carrier to prevent fouling of the holst

line when boom is folded to front of tower

STRUTS: A group of three struts is used with the tower cap

ta hold boom in working position. Boom struts are 19° 1%",

20'0", and 170" Tong,

TOWER PENDANT RIGGING: Between equalizer and struts,

Sot of to 115". Inserts matched with correct langth pendants,

EQUALIZER: Equalizer ascombly for 10-part boom hoist roev-

ing, with antirition bearing sheaves,

GANTRY: Retractable gantry with telescopic link-type back

hiteh straps pinned to up position for raising or lowering

tower, and intermediate position for operation. Antiotion

bearings in vertical back hitch sheaves,

‘TOWER HOLD BACK ASSEMBLY: A machanizm which, along

with boom holst, controls raising and lowering of tower. This

device consists of wire rope running from a drum to a sheave

‘mounted forward of the rotating bed and attached to the

tower, so force may be applied to forward side of tower during,

raising and lowering.

TOWER BOOM LATCH: A spring engaged, manvally released

latch, which supports boom on the Iront of tower, for erection

‘or lowering of tower.

Form Mo, 1S

NO. 9 TOWER — NO. 18 BOOM

INGE DIAGRAM

The ral shown ae

Pea

Bee

NO. 9 TOWER — No. 18 BOOM

‘COMBINATIONS:

(Lined unset

iudoagu oe gurl t corer

oe [0 fe | oe |e [rr

HEC ee

TE heldahisla iT Tr

a

© notation

You might also like

- ZF - 3HP12 For BMW Workshop ManualDocument36 pagesZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- CDP&CGP Manual de Taller PDFDocument178 pagesCDP&CGP Manual de Taller PDFnamduong3680% (1)

- Na ZF Tab GBDocument34 pagesNa ZF Tab GBEdevaldo SantanaNo ratings yet

- Energies 10 00666 PDFDocument46 pagesEnergies 10 00666 PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- TEREX AC1000 - Ucm02 - 030345Document2 pagesTEREX AC1000 - Ucm02 - 030345namduong368No ratings yet

- 1.2generatorstator+auxtransformer1 Comment 3Document1 page1.2generatorstator+auxtransformer1 Comment 3namduong368No ratings yet

- Qua Khuc Cua Tai Cau Khe VanDocument1 pageQua Khuc Cua Tai Cau Khe Vannamduong368No ratings yet

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- TEREX AC1000 - Ucm02 - 047720 PDFDocument114 pagesTEREX AC1000 - Ucm02 - 047720 PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- TEREX AC1000 - Ucm02 - 040854 PDFDocument104 pagesTEREX AC1000 - Ucm02 - 040854 PDFnamduong368No ratings yet

- TEREX AC1000 - Load Chart PDFDocument116 pagesTEREX AC1000 - Load Chart PDFduongpnNo ratings yet

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- CBD&CBG 25manual PDFDocument120 pagesCBD&CBG 25manual PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CDP&CGP 25manual PDFDocument244 pagesCDP&CGP 25manual PDFnamduong368100% (1)

- Em&Cem 20-35 PDFDocument186 pagesEm&Cem 20-35 PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CDP&CGP Manual de Taller PDFDocument178 pagesCDP&CGP Manual de Taller PDFnamduong3680% (1)

- SM-751 - 67 To 88 PDFDocument22 pagesSM-751 - 67 To 88 PDFnamduong368100% (1)

- 3900W 175 PDFDocument2 pages3900W 175 PDFnamduong368No ratings yet

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- 3950D 6007 PDFDocument6 pages3950D 6007 PDFnamduong368No ratings yet

- 3900T 6597 PDFDocument8 pages3900T 6597 PDFnamduong368No ratings yet

- 3900vicon 6001 PDFDocument7 pages3900vicon 6001 PDFnamduong368No ratings yet

- 60 FT Ringe7702 PDFDocument6 pages60 FT Ringe7702 PDFnamduong368No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)