Professional Documents

Culture Documents

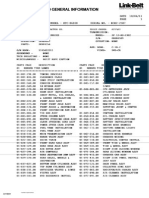

SM-751 - 67 To 88 PDF

Uploaded by

namduong368100%(1)100% found this document useful (1 vote)

106 views22 pagesOriginal Title

SM-751 - 67 to 88.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

100%(1)100% found this document useful (1 vote)

106 views22 pagesSM-751 - 67 To 88 PDF

Uploaded by

namduong368Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 22

CLARK

— Lubricate the fixing ring @2) using engine oil and

place it onthe ol filter (3).

= Manually stat he oil filter (3) on the beating union

(1) until counter-boring, further screw up the ail filter

@) by 34 um,

Place a new fixing ring on the block housing (6).

— Apply, (if aceded) new fixing ring onthe ol tempor-

ture/pressure sensor (4) and assemble itt the beating

(1) tightening the fixing serews tothe prescribed cou

ple,

NOTE

In some applications, the bearing of the

exchanger shall be assembled to a serew

threaded union connected tothe filter om the

‘opposite side of the engine, throughout two

pipelines (see picture 2).

NOTE

‘The shape and the dimensions of the alterna-

{or support vary according t0 the use of the

‘engine. Therefore the relevant pictures pro-

vide a general guideline of the procedures

that are to be carried out. However the pro-

cedures deserted are applicable.

~ Assemble the alternator bearing (1) ensuring thatthe

pins (3 and 4) are against the engine block,

= Tighten the serews (2) and lock them to the pre-

seribed coupe

Group 00, Engine(D-IVECO)

NOTE

Before assembly, always check that the

threads of the ports and of the serews have

no evidence of tear and wear nor dirt.

Connect te altemator (1) tthe support.

Tighten the serew without locking it)

“Place the gasket (1) over the block,

‘The choice of the gaskt's thickness shall be made in

consideration ofthe eylinder progusion measured with

respect ta the block's upper surface

NOTE

‘Verity that the engine block stand is clean.

Do not grease the gasket. It fs recommended

to keep the gasket inside packaging. until

assembly tothe cylinder head.

Gasket assembly shall be made following the

direction of wording printed on the gasket

‘Sw7st

right

Intended for CLARK dealers only

‘OO(DAVECOYS-24

‘Do not sel or dstibute

CLARK Group 00, Engine(D-IVECO)

itself so that this willbe readable as indicated MI2 180 nT No + 180 dog's

the picture.

20

Carry out the assembly of the rocker ams after previ

‘os check of the componens.

~Place he head (3) over the bloc and insert serews (1)

and @).

NOTE

If the valves have been removed from the

head, itis necessary to assemble them before

assembling the head itself on the engine

block

ROCKER ARM UNIT COMPONENTS:

1. Elastic ing - 2. Spacer- 3. Rocker ams-

4. Support

Check the coupling surfaces of bearing and shat: no evi-

dence of excessive wear shal be detected or damages

Replace if necessary.

eee

Qo

~Lutviate cylinder bed bolts and instal hea. A a

Bolts must be torqued using stitching pattern starting

‘with the centre bolts and moving out. Bolts to be B

‘orqud in stages all bots torqued to snug torque, then

90 degrees rotation forall bolts: Then a further 90

degrees for the M12 x 140 and M12 x 180,

fee

(ee

MI2x 70 0 Nm +90 dee's

MI2 140 vrs Nan + 180 dog's fees

‘SHAFT AND ROCKER ARM BASIC DATA

a Intended for CLARK dealers only (00(0-1VECO}3-25

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

1 unscrewed, check adjustment quota

Tighten the serew-threaded nut (1) o the 4 04 0.6 Nm

couple.

ROCKER ARM ADJUSTMENT SCREW

Before executing assembly, check the Rocker Arm driv=

ing rods: these shall not be deformed; the spherical ends in

contact with the Rocker Armadjustment screw and with

the tappet(arows) shall not present evidence of seizure

‘orwearin case of detection proceed replacing them.

‘Tho rods driving the intake and exhaust valves are ideni-

cal and therfore interchangeable,

loser the tappet driving rods and the Rocker Arm unit.

‘Before using the Fixing serews again,measre them

‘wice as indicated inthe pieture, checking D1 and D2

diameters

ifD1 -D2 < 0,1 mm the serew can be used again;

ifD1 -D2 > 0,1 mm the serew must be replaced;

pa ba

a

© d-— D

Tighten the screws (2) to the prescribed couple and

assemble water temperate sensor (1),

[Adjust the slack between rocker arms and valves using

socket wrench (1), point wrench (3) and feeler gauge (2).

Conect slack is

“suction valves 0.25 40.05 mam

exhaust valves 0.50 40.08 mm.

NOTE

In order carry out a quicker adjustment of

the working lack between roeker arms and

valves, proceed. as following: Rotate. the

engine drive shaft, balance the valves of cy:

Inder 1 and adjust the valves identified by

star symbol, as indicated in the following

table:

ylinder wo 2 [2 | 3 [4

NOTE

Rotate the engine drive shaft, balance the

valves of cylinder 4 and adjast the valves

‘Sw7st

she

Intended for CLARK dealers only

‘OO(DAVECOYS-26

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

Identiti by star symbol, as indicated in the

following table:

Qylinder Wo] [2 [3 [@

“Assemble injectors after having replaced the sealing

gasket (1). >

NOTE

During assembly of injectors,

injector sphere is corectly positioned on the

head housing. a

oo: Assemble exhaust manifold (1) providing new gaskets

©)

not matching your model. Anyhow,

described procedure i apy

a Hor i

5

a

Assemble eylinder covers (2) with the respective eas-

ets:

Fit the seal nods and tight the serews fixing them to

the prescribed couple

NOTE

Always replace the gaskets using new ones. s

‘Check the threads of the fixing screws: there

shall be no evidence of wear or dirt deposit.

Seal nods shall have no visible deformation,

Assemble thermostat unit (2) ineluding thermostat (5)

and gasket (4).

Sw75i

she

Intended for CLARK dealers only

‘OO(DIVECO}S-27

‘Do not sel or dstibute

CLARK Group 00, Engine(D-IVECO)

Tighten the serews tothe prescribed couple For applications with traditional bet stretcher

NOTE In order to comect the POLY-V belt eany out the

‘The serews (1) have been have been utilised ‘operations described on page & vice versa

tofix the bracket (3). NOTE

Disassemble the bracket and reassemble i

eee eee cae For belt stretching turn the alternator as

Cnsaeae Indicated in the figure, tighten serew (1) and

noe the bolt that fixes the alternator to the sup-

port.

NOTE

‘the old belt sto be reassembled examine it

carefully in order to see if there may be inel-

sons or evident sign of yielding.

Assemble the pulley fan bering tightening the serews

to the prescribed couple f

~ Assemble the alterator tensioning bracket

“Mount pulley (3) and secure it to support through \

screws (2).

Assemble the transmission pulley (1).

For applications with automatic belt tensioner

‘Assemble belt Po-V (4) oa the pulley (5) of the engine

shal, onthe jockey pulley (2), onthe water pump (6) and

fn the alternator (3), tighten (syn. tension) the belt by

means ofthe automatic belt tensioner

ae Intended for CLARK dealers only OO(DAVECOYS-28

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

Mount Poly-V belt (4) on pulley (7), engine shaft pul-

ley (5), guide pulleys (6), water pump 3) and altema

tor (2); stretch the belt by operating on automatic belt

tensioner (2).

Also assemble the brackets (1) fixing the fuel pipe

lines to the injectors: use the same screws (2) fixing

the manifold plate as shown inthe pictur

“Apply on the surface joining the suction manifold

plate (1) asuicent coat of Loctite 5999 and provide.

xing the serews tothe presribed couple

IF the pipe (6) of the scion manifold plate (1) as

bboen removed, reassemble it after having fit a new

gasket).

Tighten the serews (7 othe prescribed coupe

NOTE

For the versions provided with heater, also

assemble components (3) and (4).

Assemble priming pump (1) providing new gasket and

tighten the srews (2) 10 the presribed eouple

Also assemble feed pump (see specie procedure) and

the power take-off undemeath,

NOTE

Pump mounting requires specific procedure

contained inthis section.

Sw75i

right

Intended for CLARK dealers only

‘O0(DAVECO}3-29

‘Do not sel or dstibute

Group 00, Engine(D-IVECO)

1. Roar bracket fing sccow (on suction coletor plate) 2. Fuel recovery pipeline o pump 3. Rotary feed pump

‘4 Connection nut to pumping elements 5. Injectar 6. Bracke hing screw to jection pump side

7. Font brackel xing screw (on suction collector plat)

Assemble the pipes (1) and (2) proving fuel feed and

recovery between pump and injectors;

‘Serew up the locking nuts and tighten the screws fix-

ing the fuel recovery manifold; fix the pipes to the

injectors throughout the brackets previously assem-

the LDA pipeline (1) tothe engine head and to the

feed pump.

~ Assemble the fuel fer bearing (4) t the bracket

fixed tothe engine head.

Connect the fel pipelines (2 and 3) respectively

from priming pump to filter bearing an rom this ast,

one to fed pump.

— Using 99360076 equipment assemble ful filter (1).

‘Sw7st

right

Intended for CLARK dealers only

‘OO(DAVECO}S-30

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

NOTE

‘The filter shall be priory filled with fuel to

facilitate feed system bleed operations.

NOTE

‘To connect fuel pipelines (2 and 3, Figure 96)

{in low pressure from the relating connection

‘unions iis necessary to pres the locking fas-

tener (1) as showa in picture B.

After having connected the pipeline, reset the

fastener (1) into block position as shown in

ure A.

Wie [ GE

=Ohia!

For urbocompressed versions

proceed assembling the turbocharger:

— Hold the turbocharger and place it on the exhaust

‘manifold ater having interposed the gasket

—- Serew up the fing nuts ofthe turbocharger to the

exhaust manifold tightening them to the prescribed

couple,

— Tighten the lubrication pipe fixing ring. Operate in

the same way on the other end ofthe pipe. Connect it

to the upper part ofthe heat exchanger.

‘To complet engine assembly it is necessary to remove it

fiom the turing stand

Using rocker arm 99360595 hold the engine and

loosen the screws fixing the brackets to the turing

stand 99322208,

Disassemble the brackets fom the engine after hav

ing property putt on wooden bearing.

Completion of the engine

(On the right hand side:

reassemble the pipes (1) from the union (2) 40 the

lubrication oil filter (placed on the opposite sid):

tighten the pipe rings (1) and conneet them to the

NOTE

‘In some cases, the oll fer (3) 6 directly

placed om the heat exchanger: in this case it

shall he assembled using too! 99360076.

Sw75i

she

Intended for CLARK dealers only

0(D-VECO}3-31

‘Do not sel or dstibute

CLARK Group 00, Engine(D-IVECO)

For turbocompressed versions (On the left hand side:

Reassemble the lubrication oil exhaust pipeline (1) Assemble ol fier (1) together with bracket (fr the

fiom the turbocharger: from underneath the turbo- versions with engine ol fier not directly assembled

charger tighten the two serews (2) tighten the screw to the exchanger: tighten the screws 3) assembling

(@) fixing the pipetinew the Block thoughout the the bracket (4) including fier bearing (3).

ing collar (4 to the Bock; finally tighten the union (5) Using tool 99360076 screw up oil iter,

to the Block, Assemble oil level rod togetherwith ide pipe (2) Fill

CE up engine ol

Insall the engine on the machine (for installation

=< ‘operations please apply to specific issue.

—Reassemble the state properly hold the starter (1)

and tighten the fing crews tothe prescribed couple.

ae Intended for CLARK dealers only OO(DAVECOYS-32

‘Do not sel or dstibute

CLARK Group 00, Engine(D-IVECO)

Rotary feed pump disassembly and assembly Ti following procedure analyses this second hypothesis

7 since it is the more complex.

procedure

NOTE

"This procedure preseribes th

= The fuel pipelines (from pumping ele-

‘ments to Injectors, bleeding recovery

pipes from injectors to pump, LDA pipe-

line and feed provided by priming pump)

shall ll be disassembled.

Electrical connection to feed pump shall

be disconnected.

~ Accelerator eabl shal be disconnected.

Engine versions wit tot (99360330) ‘

Disassemble the starter fromthe ywhel box and use root ad

99360330 2) 1 rotate the flywheel

Find the top dead centre with the toot (99398097) -

False injector

Remove the rocker covers ofthe Luceylinder; remove the

‘scinjector and place the tool (1) tose the Ist cylinder top

dead centre position (end-of-compression phase). Pre

oad the gauge.

The searched condition is obtained by rotating the engine

shaft properly until you find the maximum value on the

Comparator and then checking thatthe intake and exhaust

valves ar both closed.

‘Once PMS has been obtained, lock the My wheel by means

of tol 99360339 Figure 104),

Engine versions with tol (99360339)

Disassemble the starter from the flywheel box (1) and use

‘99360339 (2) to rotate the flywheel

Incase feed pump replacement is necessary, this shall be

supplied pre-set aleady as spare par

(On the other hand, in cas the pump shall be disassembled

snd reassembled later on without being repaired wil be

necessary to pre-set it while itis sil assembled 10 the

engine and disasemble i only afterwards,

Unscrew the side stew that locks the pump shat pat=

tilly (1) and remove spacer (2). This must be kept on

a Intended for CLARK dealers only 00(D-VECOYS-83

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

4 side (we recommend to fix it on the pump with a

wie ora clip),

Tighten the lateral serew (1) blocking rotation of the

ump sh.

9

From timing side, remove the cover (2) loosening the

sorews (1) inorder to have access to the union fixing

‘nut G) tothe pump driving gear.

Loosen the fixing nut (3) and remove the relating

washer

a ph ,-@

~Prom the pump sie, loosen the fixing nuts (1) without

removing them in order to enable moving the pump

‘backward using 99340035 extractor,

Assemble the 99340035 extractor throughout the two

threaded ports (4, Figure 107) and withdraw the gear

fiom the pump shat

Property hol! the feed pump and loosen completely

the fixing nuts,

Withdraw the pump from the studs, together with the

ssket

‘When the supply pump i 1 be assembled on the engine

the PAMLS. conditions at compression end stage eylinder

No. | must be cared! ot

NOTE

Hold the pump driving gear to avoid inter-

ference or crawling during timing gear rota-

tion

“Assemble the pump pre-set in its housing on the

engine ting the shat into the gear port (not provided

with wreneh)

Tighten the fixing nuts (1) looking the pump flange in

the slot centre

NOTE

‘The gasket removed during pump disassem-

biy shall not be utilised again.

Always use original spare parts.

‘Sw7st

she

Intended for CLARK dealers only

O/DAVECOYS-34

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

~On th timing side, throughout the specially appointed

por, fi the washer and serew up the fixing mt (3) to

‘he pump shaft. Lock the nut othe 90.98 Ne couple.

and insert spacer (2). Tighten screw (I)so tat it locks

spacer (2) inthis way the supply pur shaft will be

bl orotate Feely.

Assemble the cover (2, Figure 110) including gasket

fad tighten the screws (1, Figure 110).

Disassemble the flywheel rotationlocking toot

‘99360339 of 99360330; arrange the starting motor in

Connect all pipeines (from pumping elements to

injectors, bleeding recovery pipes from injectors t0

pump, LDA pipeline and feed provided by priming

With the injection pump inserted in relating seat and

securing screws loosened, mount comparator

99395613 (2) and 99395100 gauge tool (1), preloading

the rod by 2.5 mm,

Rotate the engine drive shaft to shift fom the cond

tion ofthe frst eylinder to TDC end of compression

phase. Reset the dial gauges and rotate the engine

tive shaft condition of the Ist cylinder to TDC in

phase of compression (ste Figure 105).

From this position on the comparator applied on the

[pump it must be posible to read the value listed onthe

‘pumping clement pre-lif table. Section 4

Rotate the pump in anti-clockwise direction if the

stroke is shorter or in lockwise direction if he stoke

is longer, until obtaining the stoke prescribed.

Checking these conltions, lock the pump by tighten

ing the relevant nist the prescribed! pir

EEE co-neren)

mm, * = oy em

Connect electrical comections to clectr-magnets on

the hydraulic head and on KSB.

NOTE

In case pump removal has been carried out

while the engine was assembled, connect

acceleration cable,

[Ignition pump control and timing

Sw751 Intended for CLARK dealers only 0(D-VECO}3-35

‘Do not sel or dstibute

CLARK

Group 00, Engine(D-IVECO)

Feed system bleed procedure

‘Version with A type fue iter

In case any operation has been exccuted on the compo-

nents ofthe feed circuit, itis necessary to execute bled-

ing of air within the system.

Loosen the bleedar vent seew (3) on the fuel fer (1)

and keep working oa the bled lever of the priming

pump @),

Continue executing this operation until when fuel

You might also like

- Energies 10 00666 PDFDocument46 pagesEnergies 10 00666 PDFnamduong368No ratings yet

- ZF - 3HP12 For BMW Workshop ManualDocument36 pagesZF - 3HP12 For BMW Workshop Manualnamduong368100% (1)

- TEREX AC1000 - Load Chart PDFDocument116 pagesTEREX AC1000 - Load Chart PDFduongpnNo ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- AutoCAD 2013Document264 pagesAutoCAD 2013panosscribd100% (1)

- AutoCAD 3D Course ManualDocument166 pagesAutoCAD 3D Course ManualJed Tedor98% (47)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- AutoCAD 2014 Tutorial 3DDocument26 pagesAutoCAD 2014 Tutorial 3DseleneletoNo ratings yet

- CBD&CBG 25manual PDFDocument120 pagesCBD&CBG 25manual PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- Link Belt HTC86100 Parts Manual PDFDocument423 pagesLink Belt HTC86100 Parts Manual PDFnamduong368No ratings yet

- Manitowoc Parts ManualDocument1,040 pagesManitowoc Parts Manualnamduong368100% (2)

- CBE 25, MN PDFDocument95 pagesCBE 25, MN PDFnamduong368No ratings yet

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- 3 - Electrical System PDFDocument39 pages3 - Electrical System PDFnamduong3680% (1)

- Manitowoc 8500-1 Parts Manual PDFDocument1,046 pagesManitowoc 8500-1 Parts Manual PDFnamduong368100% (1)

- Workshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Document140 pagesWorkshop Manual Technical Data TAD530 531 532GE TAD730 731 732 733GE Group 20 26Courtney French91% (23)

- Link Belt RTC80130 Parts Manual PDFDocument453 pagesLink Belt RTC80130 Parts Manual PDFnamduong368100% (1)

- SM-751 - 1 To 22 PDFDocument22 pagesSM-751 - 1 To 22 PDFnamduong368No ratings yet

- Manitowoc 4600 S4 Parts Manual PDFDocument108 pagesManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- Manitowoc 4600 S4 Lubrication Guide PDFDocument40 pagesManitowoc 4600 S4 Lubrication Guide PDFnamduong368100% (1)

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- Manitowoc 4600 S4 Parts Manual PDFDocument108 pagesManitowoc 4600 S4 Parts Manual PDFnamduong36850% (2)

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- Manitowoc SC70 Lubrication Guide PDFDocument32 pagesManitowoc SC70 Lubrication Guide PDFnamduong368No ratings yet

- LTM 1130-5.1 - PN - Technical Specification PDFDocument18 pagesLTM 1130-5.1 - PN - Technical Specification PDFnamduong368No ratings yet

- Hypac C766C, C778B - Om PDFDocument122 pagesHypac C766C, C778B - Om PDFnamduong368100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)