Professional Documents

Culture Documents

Sol Stov

Uploaded by

Rakesh0 ratings0% found this document useful (0 votes)

4 views11 pagesstove

Original Title

sol-stov

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentstove

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views11 pagesSol Stov

Uploaded by

Rakeshstove

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

'US 2006028900141

cu») United States

2) Patent Application Publication co) Pub. No.: US 2006/0289001 A1

6

6)

en

@

Hopewell

SOLAR STOVE

Inventor:

[Byron Hopewell, Alexandria, VA (US)

Comespondence Address:

OLIFF & BERRIDGE, PLC

P.O. BOX 19928

ALENANDRIA, VA 22320 (US)

Appl. No.

Filed:

11/165,049

Jun, 24, 2005

(43) Pub. Date: Dec. 28, 2006

Publication Classification

(1) Intec.

2s 202 (2006.01)

(32) US.c1 126681

on ABSTRACT

A solar stove may include a cabinet with a heating area. A

follow reflector including # large opening. and small

‘opening may he positioned below the heating area. A rellec-

tor assembly refets solar energy toward the large opening

The cabinet may also allow solar enengy to heat an onter

surface of the hollow reflector. A cooking vessel used with

the solar stave may’ ince a convex bottom that extends

through the small opening and into an interior ofthe hollow

reflector.

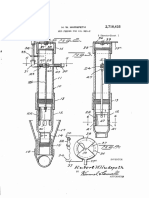

Patent Application Publication Dec. 28, 2006 Sheet 1 of 6 US 2006/0289001 AI

12 10

0

br —212

Tp — 162

FIG. 1

Patent Application Publication Dec. 28, 2006 Sheet 2 of 6 US 2006/0289001 AI

a2

222

FIG, 2

Patent Application Publication Dec. 28, 2006 Sheet 3 of 6 US 2006/0289001 A1

Patent Application Publication Dec. 28, 2006 Sheet 4 of 6 US 2006/0289001 AI

FIG. 6

Patent Application Publication Dec. 28, 2006 Sheet 5 of 6 US 2006/0289001 AI

106

FIG. 7

FIG. 8

US 2006/0289001 AI

Patent Application Publication Dec. 28, 2006 Sheet 6 of 6

‘Old

6 Old

US 2006/0289001 AI

SOLAR STOVE

BACKGROUND

[0001] This invention relates to apparatus for collecting

‘and focusing solae energy. The apparatus may be used for

‘cooking or any other desired purpose.

SUMMARY,

[0002] A solar stove gcoording 10 this invention may

‘include # cabinet including a heating area, and a hollow

reflector including a large opening and a small opening. The

hollow reflector may be positioned below the heating area

such thatthe large opening faces downvsard in use of the

solar stove.

[0003] A reflector assembly that includes at least one

reflector may be provided to reflect solar energy toward the

Jarge opening. An adjustment mechanism may be provided

1o adjust position of the reflector assembly.

[0004] The solar stove may include casters that facilitate

fotation of the solar stove about a vertical axis, for easy

Positioning of the solar stove to optimize solar collection,

[0005] The cabinet andor hood connected to the cabinet

‘ay’ inchide one or more theanally insulated panels, and

may also or alternatively include one or more themally

transmissive panels n us, the thermally transmissive pan

‘els may he positioned facing the su, to allow absomption of

solar energy. The insulated panels restrict heat loss

[0006] A cooking vessel that includes a convex bottom,

‘ay be used withthe solar stove. The convex bottom may

‘extend through the small opening and ino an interior ofthe

hollow reflector. ARematively,a thermally conductive inser

may be provided that includes convex bottom that extends

through the small opening and into aa interior ofthe hollow

reflector: The insert may have a flat top surface (© accom-

rmodate a Ma-boliomed cooking vessel

[0007] The solar stove may conduct solar energy to both

inner and outer surfices of the hollow reflector, For

‘example, a reflector assembly may condet solar energy 10

the inner surface, and a transparent window may conduet

solar energy to the outer surface.

[0008] These and other objects, advantages andlor Features

are deseribed in or apparent from the following description

‘of exemplary embodiments

BRIEF DESCRIPTION OF THE DRAWINGS

[0009] Exemplary embodiments of the invention will be

‘described in detail below with reference to the drawing

figures, in whieh:

[0010] FIG. 1 isa front elevation view of a solar stove;

[0011] FIG. 2 illustrates an exemplary embodiment of 2

feflector support bracket used in the solar stove of FIG

[0012] FIG. 3 itluseates an exemplary embodiment of

father reflector support bricket used inthe solar stove of

4 ilostrtes a detail ofa reflector adjustment

mechanism Used i the solar stove of FIG. 1;

Dee. 28, 2006

[0014] FIG. 5 is a perspective view of an exemplary

hollow reflector used inthe solar stove of FIG. 1;

[0015] FIG. 6 sa perspective view of another exemplary

hollow reflector usod inthe solar stove of FIG. 1;

[0016] FIG. 7ilusirates « cross section along lines 7-7 of

FIG. 5

[0017] FIG. 8 ilustntes a detail of « connection between

separate parts ofthe reflector shown in FIG. 5:

[0018] | FIG, 9 ilustrates an exemplary pot usable wit the

solar stove of FIG. 1:

[0019] FIG, 10 illustrates another exemplary pot usable

‘with the solar stove of FIG, I: and

[0020] FIG, 1 illustrates an exemplary pan usable with

the solar sive of FIG. I.

DETAILED DESCRIPTION OF EMBODIMENTS

[0021] FIG. 1 itlastrates an exemplary solar stove 10

‘cording to this invention. As depicted the soar stove may

Jnclude a hood 12, a cabinet 14, ond legs 16 and 18, The

hood 12 is preferably attached tothe cabinet 14 via a hinge

(oot depicted), The hood 12 preferably includes a handle 128

‘0 facilitate opening and closing of the hood 12.

[0022] In FIG. 1, a front panel 142 of the cabinet 14 is

shown partially cut away so that interior components 100

and 146, described below, can be viewed in erss-section.

[0023] In this embodiment, the eahinet 14 includes a op

‘panel 146 supported by supports 147 tht are atc to legs

W6 and 18 ort panels ofthe cabinet 14, The top panel 146

includes an opening 148. A high-heat area exists at the

‘pening 148, anda lower-eat area exists at other locations

of the top panel 146. In use, for example, one cooking

vessel, such asa pot or pan, may’ Be placed af the high-heat

farea for cooking, and then moved to the wersheat are for

‘warning.

[0024] A hollow reflector 100 having a large opening at

fone end and a small opening at the other end is situated

below the top panel 146, with the small opening of the

hollow reflector 100 being positioned to match the opening

148 of the panel 146, The hollow reflector 100 may be held

in place by any stitable support mechanism. In some

embodiments, the ratio ofthe area ofthe large opening to the

area ofthe small opening is about 6:1

[0025] ‘The cabinet 14 is preferably enclosed om all sides

so that it can retain heat, but some embodiments may omit

fone or more panels such that the eabinet 14s not fully

fenelosed, A bottom panel (aot show), when present, has aa

‘opening conesponding 10 the large opening of the hollow

reflector 100, so that sunlight can pass into the hollow

reflector 100, If desired, the large opening of the hollow

reflector 100 can be covered by glass or another transparent

‘material that allows sunlight to pass through.

[0026] _Appanol 144 of the eabinet 1 is preferably made of

lass or other transparent material, Sunlight an pass

through and heat an outer surface of the hollow reflector

100, providing heat in addition to that provided by the

sunlight passing inside the hollow reflector 100. The outer

Strfage of the hollow reflgtor 100 may be blackened to

better absorb the solar energy that passes through the pancl

144

US 2006/0289001 AI

[0027] Preferably at least some panels of the hood 12

‘and/or some panels ofthe cabinet 14 are made of or covered

by thermally insulating material, to better retain heat pen-

‘erated within the solar stove 10, Preferably the hood 12,

‘and/or the cabinet 14 includes at lest one thermally con-

‘ductive panel that absorbs heat from the sun an transmits it

‘o an interior of the hood 12 andr the cabinet 14. For

‘example, in this embodiment, panels 122 and 124 of the

hood 12 are thermally insoatve, and panel 126 of the hood

12s thermally condictive, The thermally conductive panel

126 may be made of, for example, blackened copper or the

like.

[0028] The embodiment shown in FIG. 1 is designed to be

positioned with the sunlight coming fom the side (upper let

tn FIG. 1), ith the operator standing infront of the sol

stove 10, This configuration is advantageous beeause, with

the sunlight coming from the side, instead of from behind

the solar stove 10, the sunlight does not shine in the eyes of

the operator when the operator is facing the solar stove. IP

the sola stove 10 were designed so thatthe front side faces

the sun, the operator would block the sunlight when standing

in front of the solar stove 10, which would clearly be

undesirable

[0029] ‘The solar stove 10 includes a lower reflector

‘assembly, hereafier refered os Nat eflector assembly 200,

that inchudes at least one, and preferably at least (0,

reflectors. The flat elector assembly 200 of this embadi-

rent includes flat reflectors 210, 220 and 230. Although

‘depicted in the drawings and described hereafter as flat

reflectors the reflectors 210, 220 andlor 280 may instead be

‘curved in one of more dimensions to enhance focusing

power. Atleast one of the Hat selectors 210, 220 and 230 is

‘adjustable so tat it can be positioned optimally to reflect

sunlight into the hollow reflector 100, Preferably, at last

two of the flat effectors 210, 220 and 230 are adjustable In

this embodiment, ll tree ofthe flat reflectors 240, 220 and

230 are adjustable. An exemplary adjustment mechanism

‘vill be described below, but st will be appreciated that

Various ether adjustment mechanisms are possible and are

‘within the scope ofthis invention,

[0030] ‘The flat reNector 210 is attached to a reflector

support 212 via a pin 214. FIG. 2 illustrates the reflector

support 212 in detail Tabs 2122 ofthe reflector support 242

are preferably sized to slide over the legs 16

[0031] The pin 214 may extend through a slot 162 formed

‘in each leg 16 (only the font leg 16 and the front leg 18 are

shown in FIG. 1. The pin 214 may’be threaded at both ends,

and adjustment Knobs 260 with mating threads may be

attache to each end ofthe pin 214 and tightened aginst the

Jes 16 lock the pin 214 in positon, Of course, other knob

‘configurations are possible, such as configuration in whieh

the knobs 260 are attached t9 a bolt passing through the

reflector support 212, instead of to the pin 214

[0032] The opposite end of the Ma reflector 210 may be

attaehed fo the reflector 220 by a hinge 242, as shown,

[0033] The fat reflector 220 may be attached to the Mat

fefleetor 230 by a hinge connection ata reflector support

244. The reflector support 244, shown in more detail in FIG.

3. may he sized and shaped tobe able to slide along support

members 20 connected to the legs 16 aod 18,

Dee. 28, 2006

[0034] The Hat reflectors 210, 220 aad 230 may’ be con.

ventional mirrors made of silvered plas, or may be made of

reflective metal, or any other desiod reilective material

[0035] Adjustment rods 250 are attached to the flat reflec-

for 220 and the fat reflector 280 by a pin connection, and

the cabinet 14 by rod locking devices 252. In this embod

meat, two adjustment reds 280 are provided, but some

‘embodiments may inlude only a single adjustment rod 280,

for more than (wo adjustment rods 250, The adjustment rods

2 may be used to adjust and hold the angular position of

the flat reflectors 210, 220 andior 230,

[0036] Casters 30 may be attached tothe legs 16 and 18.

The casters 30 facilitate transport and positioning of the

solar stove 10, Preferably, at least Wo of the casters 30 are

swiveltype casters to foclitate positioning of the solar stove

10 about a vertical axis of the solar stove 10, Using

swiveltype casters forall ofthe casters 30 makes postion:

ing of the solar stove 30 even easier

[0037] FIG. 4 illustrates details of an exemplary sod

locking deviee 252. As dopicted, the rod locking device 252

inthis embodiment includes a U-shaped member with holes

ormed therein to allow passage ofthe adjustment rod 20

[ent-out tabs of the rod locking device 252 engage a hole

284 formed in the panel 142 of the eabinet 14. The rod

locking device 252 is resilient, so that it presses outward

toward opposing edge portions of the hole 284. The holes

formed in the rod locking deviee 282 are sized to be just

barely larger than the diameter of the adjustment rod 250 s0

that, when the rod locking device 282 is in the position

shown in FIG, 4, the edges of the holes formed in the rod

Jocking device 252 bind ayainst the adjustment rod 280. To

perform an adjustment, an operator may squeeze the oppos-

ing sides of the tod locking device towards each other to

release the bind on the rod 260, and then the adjustment rod

260 may be std to a desired position. The operator then

‘leases the rod locking device 252, which deflets outward,

binding the adjustment rod 250 in the desieed position

[0038] 1 will be appreciated, ofcourse, that various other

rd locking devices are possible,

[0039] The hollow reflector 100 preferably bas a parabolic

shape, but may’ have any other shape designed to transmit

Sunlight toward the small opening of the hollow reflector

100. Some embodiments of the hollow rellestor 100

described below have curved surfaces, but some embodi-

:ments may include only fat surfaces. For example, a hollow

reflector 100 having the shape of a frustum of 8 pyramid

‘would have only flat surfaces. A curved-surface reflector is

generally preferable in tems of collection and reflection

ficiency. Roland Winston has deseribed various shapes that

‘are effective in solr collectors, some of which are known ia

the art as Winston cusp collectors. US. Pat. No. 3,923,381

to Winston, incorporated herein by reference in its enti,

discloses some collector shapes that may be useful for the

hollow reflector 100

[0040] FIG. 5 illustrates an embodiment of the hollow

reflector 100 in which the lange and small openings are

round, FIG. 6illustates an embodiment in which the large

And small openings are rectangular or square. The embod

‘meat shown in FIG. 8 is optically more efficient, but the

cembodinien shown in FIG. 6 may offer some advantages in

cease of manufacturing because it ean be formed by bending

US 2006/0289001 AI

sheet metal, The embodiment shown in FIG, § may be

‘manufactured by any suitable method. One suitable method

js metal spinning, in whieh a flat sheet of metal is pressed

‘aguinst a rotating body, and gradually assumes the shape of

the rotating body. n other embodiments the hollow reflector

100 may be made of fat sheets of metal that are, for

‘example, hinged together at their edges t form a reflector

100 having the general shape ofthe hollow reflcctor 100 of

FIG. 5, but with angular openings in the shape of, for

‘example, an octagon or hexagon.

[0041] FIG.7 shows cross section along ine 7-7 of FIG.

5. In this embodiment, the hollow reflector 100 is made in

‘wo sections 102 and 104, FIG, 8 shows an exemplary detail

‘ofa connection between the sections 102 and 104. In this

‘embodiment, the section 102 overlaps the section 104. The

sections 102 and 104 may be fasened together atthe overlap

section 1022 by welding, adhesive, serews, rivets or the like

[0042] An advantage of forming the hollow reflector 100,

Jn to oF more sections is that, when metal spinning is

‘employed, its easier to form shorter sections than longer

sections. Another alvantage is thatthe two sections 102 and

4104 may be packaged in a more compact manner during

shipping

[0043] FIG. 9 illustrates an exemplary cooking pot 302

‘sable with the solar stove 10, Preferably the pot 302 has 2

‘convex bottom 3022 that extends slightly into an interior

snace ofthe hollow eeflector 100, The convex bottom 3022

js preferably shaped so that it reaches a point of maximum

concentration of sunlight within the hollow reflector 100,

‘This configuration improves heating efficiency of the pot

302, The pot 302 may be insulated on its side surfaces and

top to better retain heat.

[0044] FIG. 10 shows another exemplary pot 304 wsable

‘withthe solar stove 10. Like the pot 302 of FIG. 9, the pot

304 has # conver bottom 3042, The pot 304 also has legs

144 that extend atleast as far asthe convex bottom 3042.

‘The legs 3044 allow the pot 308 tobe placed on a at surlace

without rolling. Like the pot 302, the pot 304 may have

insulated sides anor lid. Additionally as depicted in FIG.

10, the top panel 146 of the solar stove 19 may be shaped

‘accommodate the legs 304.

[0045] FIG. 11 illustrates a pan 306 that may be use ith

the solar stove 10. The pan 306 hss lt bottom, and may

be placed on top of an insert 400 thats placed in the opening

‘of the panel 146. The insert 400 is preferably mado of

‘conductive metal such as copper, and preferably has

‘convex bottom as depicted. The convex bottom of the insert

1400, Tike the convex botiom of the pots 302 and 304,

increases heating efficiency. Like the pots 302 and 304, the

pan 306 may have insulated sides andor to.

[0046] In some embodiments of the solar stove 10, the

‘insert 400 maybe permanently attached to the panel 146, oF

to the hollow reflector 100, The permanent attachment may

be accomplished by, for example, integrally molding the

pane] 146 othe hollow reflector 100 with a portion that ats

8s the insert 400, or by forming the parts separately and then

‘attaching them together by welding, adhesive, serews, rivets

‘or the like. In some embodiments, the pane! 146 may be 3

solid panel without an opening, and may absorb solar energy

fiom the hollow reflector 100 and transit the energy a the

‘cooking surface by thermal conduction

Dee. 28, 2006

[0047] Any of the cooking vessels shown in FIGS. 9-11

say be pressure vessels. Specifically, a mechanism may be

provided to hold he lid against the pot or pan so that, during

heating, higher pressure is developed withia the pot or pa

as compared tothe ambient atmospheric pressure. This ean

increase heating elliency, The mechanism that holds the id

‘against the pot may include interlocking tabs provided

‘espoctively onthe lid and on the vessel, as ina conventional

pressure-cooking vessel, or any other known or laterdevel-

‘oped mechani,

[0048] In some embodiments, the solar stove 10 may be

fonstnicted in such # manner that few or no tools andlor

hardware are quired to assemble the solar stove 10, For

‘example, the panels ofthe eabinet 14 may be made of shoot

‘material and include portions that are bent into shapes that

‘mate with the other panels andor the legs.

[0049] In addition to cooking, the solar stove 10 may be

used for other purposes, suchas drying erops or other items,

stilling water, sterilizing medical insruments, generating

electricity, and so forth

[0050] While the invention has been deseribed with ref

ference to specific embodiments, these embodiments are

illistative and not limiting. Various changes, substitutes,

‘improvements or the like may be made without departing

{rom the spirit and senpe of the invention

‘What i claimed is

1A solar stove, comprising:

a cabinet including a heating area; and

‘eng, the hollow reflector being positioned below the

Ineating area such that the large opening faces down-

ward in use

2. The solar stove of claim 1, further comprising &

reflector assembly that includes atleast one reflector that

reflects solar enemgy toward the large opening.

3. The solar stove of claim 2, further comprising an

adjustment mechanism that adjusts a position ofthe reflector

assembly.

4. The solar stove of claim 1, further comprising. 3

plurality of casters, atleast two of the casters being swivel

asters that facilitate rotation of the solar stove about a

vertical axis.

'. The solar stove of claim 1, further comprising a hood

that covers the heating area

6. The solar stove of claim 5, wherein the eabinet andor

the hood comprises at least one thermally insulated panel,

And at lest one thermally transmissive pane

7. The solar stove of claim 1, wherein the hollow reflector

includes atleast one curved strfiee

'8. The solar stove of claim 7, wierein the curved surface

isa parabolic surface.

9. The solar stove of claim 1, wherein the heating area

includes a high-heat area and a lower-heat area

10, 4 combination, comprising:

the solar stove of claim 1, wherein the small end of the

hollow reflctor has a small opening, and a cooking

vessel that inchides convex bottom that extends

through the small opening and into an interior of the

hollow reflector,

US 2006/0289001 AI

11, A combination, compri

the solar stove of elaim 1, wherein the small end of the

hollow reflector has a small opening, and

4 thermally conductive insert that ineludes a convex:

‘tom tha extends through the small opening and into

fan interior of the hollow eeflecor.

12. The combination of claim 8, wherein a top surface of

the inser js Nat

13. A solar stove, comprising:

‘hollow reflector ineluding an inner surface and an outer

surface;

4 first device that conducts solar energy to the inaer

surface; and

Dee. 28, 2006

«second device that conduets solar enengy 10 the outer

surfice.

14, The solar stove of claim 13, wherein the fist device

comprises a reflector assembly

18, Thesolar stove of claim 13, wherein the second device

‘comprises a transparent window

16. A solar stove, comprising:

‘hollow reflector including a lage opening and a small

end, and

a relector assembly that includes atleast one reflector that

reflects solar energy towanl the large opeaing.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Sept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LDocument4 pagesSept. 20, 1955 H. W. Hudspeth 2,718,435: Filed July 22, 1952 2 Sheets-Sheet LRakeshNo ratings yet

- Vernier DesignDocument9 pagesVernier DesignRakeshNo ratings yet

- Process For Surface Sizing PaperDocument7 pagesProcess For Surface Sizing PaperRakeshNo ratings yet

- Hybrid Topcoat Formulations For PaperDocument11 pagesHybrid Topcoat Formulations For PaperRakeshNo ratings yet

- Llo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterDocument3 pagesLlo. 715,3l5. P Atsntad Dec. 9, I902.: Cigar CutterRakeshNo ratings yet

- Interconnected Solar CellsDocument13 pagesInterconnected Solar CellsRakeshNo ratings yet

- Err-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695Document3 pagesErr-Easels - / ' Ma. Ma @&?7hii?%: March 3, 1936. G, Gimera Et Al 2,032,695RakeshNo ratings yet

- F PenDocument3 pagesF PenRakeshNo ratings yet

- Load BalancingDocument16 pagesLoad BalancingRakeshNo ratings yet

- Multipurpous KeyDocument12 pagesMultipurpous KeyRakeshNo ratings yet

- Sri LankaDocument2 pagesSri LankaRakeshNo ratings yet

- Sri Lanka BuddhismDocument2 pagesSri Lanka BuddhismRakeshNo ratings yet

- Electro Magnetic MotorDocument9 pagesElectro Magnetic MotorRakeshNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)