Professional Documents

Culture Documents

BeamSplice DESIGN

Uploaded by

cecastaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BeamSplice DESIGN

Uploaded by

cecastaCopyright:

Available Formats

PROJECT :

CLIENT :

JOB NO. :

PAGE :

DESIGN BY :

REVIEW BY :

DATE :

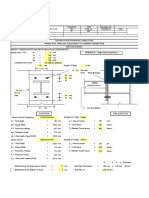

Beam Bolted Splice Design Based on AISC Manual 14th Edition (AISC 360-10)

INPUT DATA & DESIGN SUMMARY

WF BEAM SECTION

WF STEEL YIELD STRESS

(Flange Plate 5.71 in x 19.5 in x 1 in)

= > W21X48

Fy =

50

ksi

PLATE STEEL YIELD STRESS

F yp =

36

ksi

FLANGE PLATE THICKNESS

t fp =

in

t wp =

0.75

in

WEB PLATE THICKNESS

BEAM AXIAL LOAD, ASD

T =

70

kips, ( 20% WF's Pn / Wt)

VERTICAL SHEAR FORCE, ASD

V =

100

kips, ( 69% WF's Vn / Wv)

MOMENT AT SPLICE, ASD

M =

80

ft-k, ( 30% WF's Mn / Wb)

BOLT DIAMETER

f =

1

BOLT MATERIAL (A307, A325, A490)

HOLE TYPE (STD, NSL, OVS, SSL, LSL)

STD =

NSL =

OVS =

SSL =

LSL =

in ( 1 in)

ASTM =

=>

Standard round holes ( d + 1/16 " )

Long or short-slotted hole normal to load direction

Oversize round holes

Short-slotted holes

Long-slotted holes

CONNECTION TYPE (SC, N, X)

SC

N

X

A325

STD

=>

(Web Plate 9.5 in x 13.5 in x 0.75 in)

N

THE DESIGN IS ADEQUATE.

= Slip critical connection

= Bearing-type connection with threads included in the shear plane

= Bearing-type connection with threads excluded from the shear plane

FLANGE BOLTS

WEB BOLTS

2

2

rows

vert rows

3

3

ANALYSIS

SECTION PROPERTIES (AISC 14th Table 1)

d

tw

tf

k

20.6

0.35

0.43

0.93

bolts on each row (total 6 bolts at each end)

bolts on each row (total 6 bolts at each end)

bf

8.14

A

14.1

=

=

=

3.00

1.75

5.71

in, (Tab J3.3)

in, (Tab J3.4)

in

<

Bolt spacing used

=

Edge spacing used

=

bf

[Satisfactory]

L fp

D

L wp

=

=

=

19.5

9.5

13.5

in

in

in

d - 2k

Allowable shear capacity

R n / Wv

Flange bolt shear

v = T / AT + M / S =

DETERMINE PLATE DIMENSIONS

Bolt spacing required

Edge spacing required

Flange Plate

Web Plate

Zx

107

<

3.00

1.75

in

in

[Satisfactory]

[Satisfactory]

[Satisfactory]

CHECK CAPACITY OF BOLTS (AISC 360-10 J3)

18.8

kips / bolt, (AISC 14th Table 7)

2 0.5

v = [(T / A T ) + (V / A V ) ]

Web bolt shear

AT =

S=

AV =

where

11.7

kips / bolt

17.1

<

R n / Wv [Satisfactory]

k / bolt

<

R n / Wv [Satisfactory]

18

bolts, (total one end bolts)

123.6 in-bolts, (flange bolts only)

6

bolts, (one end web bolts only)

CHECK WEB PLATE FOR SHEAR CAPACITY (AISC 360-10 G2)

V / (D t wp ) =

14.0

ksi < 0.6 F yp C v / W v = 0.6 F yp 1.0 / 1.5 =

CHECK FLANGE PLATE FOR TENSION CAPACITY (AISC 360-10 D)

T / (2 B t fp + D t wp ) + M / (d B t fp ) =

11.9

ksi

<

14.4

F yp / W t = F yp / 1.67 =

CHECK FLANGE NET TENSION FRACTURE (AISC 360-10 J4.1)

F up

=

58

ksi ( for plate, AISC Manual 14th Edition, page. 2-39)

0.5 T + M / d =

81.60

kips

<

F up / W [ B - n (d s + 1/8 ) ] t fp =

ksi

[Satisfactory]

21.56 ksi

100

kips

CHECK FLANGE NET SHEAR FRACTURE (AISC 360-10 J4.2)

Fu

=

65

ksi ( for WF, AISC Manual 14th Edition, page. 2-39)

0.5 T + M / d =

81.60

kips

<

0.6 Min( F u t f , F up t fp ) / W ( S shear length) =

[Satisfactory]

[Satisfactory]

82.80

kips

[Satisfactory]

CHECK WEB PLATE BLOCK SHEAR (AISC 360-10 J4)

lh

=

4.9

in

lv

V =

=

100.00

1.2

kips

in

<

0.6 A v F up / W + A t F up / W = (0.3 l v + 0.5 l h ) t wp F up =

122.89 kips

[Satisfactory]

You might also like

- ISMB 600: AssumptionsDocument5 pagesISMB 600: AssumptionsRajasekar MeghanadhNo ratings yet

- HSS Flange Plate Moment Connection - Temporary SteelDocument9 pagesHSS Flange Plate Moment Connection - Temporary SteelrajedmaglinteNo ratings yet

- Base Plate and Blot Design-UploadDocument6 pagesBase Plate and Blot Design-UploadygguptaNo ratings yet

- Portal FrameDocument42 pagesPortal Framesurendra_pangaNo ratings yet

- BP1 Bolt Connection CapacityDocument22 pagesBP1 Bolt Connection CapacityballisnothingNo ratings yet

- Bracing Connection RefDocument5 pagesBracing Connection Refsukarma acharyaNo ratings yet

- Rafter Splice DesignDocument2 pagesRafter Splice DesignkalpanaadhiNo ratings yet

- Brace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Document44 pagesBrace Compression and Tension Capacity Design Charts As Per CSA S16 09 Rev1.5Antonio LópezNo ratings yet

- Moment ConnectionDocument39 pagesMoment ConnectionRitwick MishraNo ratings yet

- Weld StrengthDocument9 pagesWeld StrengthRUDHRA DHANASEKAR50% (2)

- CorbelDocument5 pagesCorbelBharathi ThadigotlaNo ratings yet

- Design of CHQRD PlateDocument20 pagesDesign of CHQRD PlateRagavanNo ratings yet

- Here: Mat Foundation Design Spreadsheet PDFDocument2 pagesHere: Mat Foundation Design Spreadsheet PDFbiniamNo ratings yet

- Base Plate Design Per EURO CODEDocument14 pagesBase Plate Design Per EURO CODEbutca1No ratings yet

- RAM Connection Input With CommentsDocument6 pagesRAM Connection Input With CommentsAhmed Saeed OokaNo ratings yet

- Simple Bracing ConnectionDocument33 pagesSimple Bracing ConnectionRohit SinghNo ratings yet

- MM Met D19084 RP 012Document96 pagesMM Met D19084 RP 012Dass DassNo ratings yet

- Double Angle ConnectionDocument8 pagesDouble Angle ConnectionrunkirNo ratings yet

- 12-7 Column Web Moment ConnectionDocument1 page12-7 Column Web Moment ConnectionsuperpiojooNo ratings yet

- Bolt Design (Blodget)Document4 pagesBolt Design (Blodget)Mayuresh KudveNo ratings yet

- Wind Load Calculations On VesselsDocument3 pagesWind Load Calculations On VesselssudhakarebvnNo ratings yet

- Beam Shear Connection Working 2Document41 pagesBeam Shear Connection Working 2rammohan100% (2)

- b2b SpliceDocument21 pagesb2b SplicePrasad Dayalamoorthy DNo ratings yet

- FinPlate Type Cleat ConnectionDocument81 pagesFinPlate Type Cleat ConnectionRajveer SinghNo ratings yet

- Beam Column Web ConnectionsDocument9 pagesBeam Column Web Connectionsmsiddiq1No ratings yet

- Connections I V2.1.0.a1Document49 pagesConnections I V2.1.0.a1gissel vicencioNo ratings yet

- Truss DRGDocument1 pageTruss DRGkvamshi_1971No ratings yet

- Beam SpliceDocument17 pagesBeam SpliceBoddu Ramakrishna100% (1)

- Base Plate & BoltsDocument3 pagesBase Plate & BoltsarvnndNo ratings yet

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Document3 pagesHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariNo ratings yet

- Macro For Concrete Plate Element DesignDocument8 pagesMacro For Concrete Plate Element DesignArivoli JayaramanNo ratings yet

- Bare Frame (Mbma-02)Document2 pagesBare Frame (Mbma-02)ansgcekNo ratings yet

- Design of Shear KeyDocument13 pagesDesign of Shear KeyRonnie SmithNo ratings yet

- He800b PDFDocument5 pagesHe800b PDFUday UdmaleNo ratings yet

- Beam Pin Connection, Bsa, BSC (Single Shear Gusset Plate Type)Document6 pagesBeam Pin Connection, Bsa, BSC (Single Shear Gusset Plate Type)vijaystructuralNo ratings yet

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 pagesFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerNo ratings yet

- Anchor Bolt (CSA) Rev1.1Document10 pagesAnchor Bolt (CSA) Rev1.1coolkaisyNo ratings yet

- Design Basis For Steel Connection of Standard Drawing - Rev Ad PDFDocument5 pagesDesign Basis For Steel Connection of Standard Drawing - Rev Ad PDFvijaystructuralNo ratings yet

- Is 800 2007Document12 pagesIs 800 2007Ragavan100% (1)

- Moment Connection Beam Column IS BS SECTION FOR IS800Document27 pagesMoment Connection Beam Column IS BS SECTION FOR IS800JANMESHNo ratings yet

- S T S T: Larsen & Toubro LimitedDocument4 pagesS T S T: Larsen & Toubro LimitedNitesh SinghNo ratings yet

- Typical Beam To Beam Connection Design Calcultion - Fin PLTDocument122 pagesTypical Beam To Beam Connection Design Calcultion - Fin PLTAsaru DeenNo ratings yet

- 4 stiffened-WH500X400X12X25-WH500X400X12X25Document7 pages4 stiffened-WH500X400X12X25-WH500X400X12X25phanikrishnabNo ratings yet

- BOLTGRP13Document33 pagesBOLTGRP13NEONo ratings yet

- Anchor Bolt Design Per IS LSMDocument6 pagesAnchor Bolt Design Per IS LSMdebjyoti_das_6No ratings yet

- Raft FoundationsDocument19 pagesRaft Foundationsvijaycool889No ratings yet

- Project: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionDocument4 pagesProject: 34M Stadium Mast - Philips India Limited Description: D-28/SM/TLL Pile Cap Design For CompressionEr Ravi VishwakarmaNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Moment Connection DesignDocument52 pagesMoment Connection DesignKakaNo ratings yet

- Bolted Connection Angle Brace TensionDocument2 pagesBolted Connection Angle Brace TensionRajib MaharjanNo ratings yet

- Design of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Document10 pagesDesign of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Rajib MaharjanNo ratings yet

- Design Load Basis Report Tensile Canopy - Vedvan - Noida - R0Document27 pagesDesign Load Basis Report Tensile Canopy - Vedvan - Noida - R0Neeraj KumarNo ratings yet

- Design of Connection (Rb2 With Column)Document14 pagesDesign of Connection (Rb2 With Column)adil_khan648No ratings yet

- Beam Column Cleat Angle ConnectionDocument4 pagesBeam Column Cleat Angle ConnectionsatyaNo ratings yet

- Beam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 pageBeam Bolted Splice Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña Velasquez100% (1)

- Beam Connection of Conventional Configuration Based On AISC 360-10Document4 pagesBeam Connection of Conventional Configuration Based On AISC 360-10sushilkumarNo ratings yet

- Beam SpliceDocument2 pagesBeam SplicePaoloEduardoCarusid'EmpaireNo ratings yet

- Ocbf IbcDocument3 pagesOcbf IbcNikki RobertsNo ratings yet

- Bracing ConnectionDocument15 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Bracing ConnectionDocument10 pagesBracing ConnectionrajedmaglinteNo ratings yet

- Sustainable ArchitectureDocument8 pagesSustainable ArchitectureDeen SharpNo ratings yet

- Led Expo 2010Document6 pagesLed Expo 2010Swati SinghNo ratings yet

- Kebutuhan Mep Estimasi Harga No. Uraian Type Vol. SatDocument8 pagesKebutuhan Mep Estimasi Harga No. Uraian Type Vol. SatKoplak MakmurNo ratings yet

- Thermal Properties of PolymersDocument18 pagesThermal Properties of PolymersPrabhuPalanichamy67% (3)

- 23 - PCA MethodDocument64 pages23 - PCA MethodPrashant GargNo ratings yet

- Piping Codes and StandardsDocument21 pagesPiping Codes and StandardsZa Yon100% (1)

- A Study On Estimation and Costing of A Seven Storied Residential Building in Dhaka CityDocument9 pagesA Study On Estimation and Costing of A Seven Storied Residential Building in Dhaka CityPallavi PatilNo ratings yet

- Architectural Acoustics Jp2Document68 pagesArchitectural Acoustics Jp2Anand KunkulolNo ratings yet

- Properties of Metals and AlloysDocument19 pagesProperties of Metals and AlloysIlhamsidiqNo ratings yet

- MCHW Vol 1 1000 - Web PDFDocument51 pagesMCHW Vol 1 1000 - Web PDFalejandraoy9No ratings yet

- Refrigeration System: ComponentsDocument31 pagesRefrigeration System: ComponentsMae CaspeNo ratings yet

- Technical Manual Hdpe Pipes PDFDocument64 pagesTechnical Manual Hdpe Pipes PDFM.Sreeram Sanjay100% (1)

- DW 30L278Document4 pagesDW 30L278DeniRahayuYuniartoNo ratings yet

- The Use of Post Tensioning in Marine StructuresDocument39 pagesThe Use of Post Tensioning in Marine StructuresmonkeyDivanNo ratings yet

- Oberflächenbehandlungsangaben: PG Norm/StandardDocument11 pagesOberflächenbehandlungsangaben: PG Norm/Standardsafat parNo ratings yet

- STI User Guide 2007 EditionDocument20 pagesSTI User Guide 2007 Editionmk779900mkNo ratings yet

- Boiling (For ESE) - ExergicDocument5 pagesBoiling (For ESE) - ExergicSOUMEN KOLENo ratings yet

- Electrical and Equipment SafetyDocument82 pagesElectrical and Equipment SafetybkannurbsNo ratings yet

- Ashiana Mulberry Presentation PDFDocument23 pagesAshiana Mulberry Presentation PDFBharat ChatrathNo ratings yet

- Centrifugal Pump, Shipboard Use: Standard Specification ForDocument15 pagesCentrifugal Pump, Shipboard Use: Standard Specification ForDarwin DarmawanNo ratings yet

- Sni 03-1727-1989 (Pembebanan)Document31 pagesSni 03-1727-1989 (Pembebanan)Nugraha Bintang50% (4)

- Iron Ore Tailing As Replacement of Fine AggregateDocument48 pagesIron Ore Tailing As Replacement of Fine AggregateAvinash DNo ratings yet

- Building A Combiner BoxDocument5 pagesBuilding A Combiner BoxELECTROSTATIC SPRAYERS GREECENo ratings yet

- MSE Report DONE 1 Composites PDFDocument21 pagesMSE Report DONE 1 Composites PDFBaltazar MharkNo ratings yet

- Plate Heat Exchanger Gaskets WEBSITEDocument2 pagesPlate Heat Exchanger Gaskets WEBSITESHAKEEL ISMAIL LAMBAYNo ratings yet

- Tack Coat Guidelines: State of California Department of Transportation Division of Construction April 2009Document38 pagesTack Coat Guidelines: State of California Department of Transportation Division of Construction April 2009Nuno AntonioNo ratings yet

- Rate AnalysisDocument14 pagesRate AnalysisStephen Raj0% (1)

- KLOCKE - Abrasive Machining of Advanced Aerospace Alloys and CompositesDocument24 pagesKLOCKE - Abrasive Machining of Advanced Aerospace Alloys and CompositesLuis Fillipe Lopes TorresNo ratings yet

- FDA Guidance Document For Testing Orthopedic Implants - Porous CoatingsDocument10 pagesFDA Guidance Document For Testing Orthopedic Implants - Porous Coatingsmaven3No ratings yet

- Lubricants and LubricationDocument57 pagesLubricants and LubricationJako MishyNo ratings yet