Professional Documents

Culture Documents

Api 598

Uploaded by

Nitin AggarwalOriginal Title

Copyright

Available Formats

Share this document

Read this document in other languages

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api 598

Uploaded by

Nitin AggarwalCopyright:

Available Formats

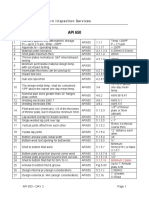

Pressure Testing

Test Requirements by Valve Type & Specification

API 598

API 6D

ANSI

Up to DN100 up to 1500LB

Up to DN100 above 1500LB

Resilient-seated

Lubricat'd.

B16.34 or

Over DN100 up to 600LB

Over DN100 above 600LB

Floating Trunnion

Plug

MSS SPBall

or B/fly

TEST TYPE

Gate

Globe

Check

Gate

Globe

Check

Valves

61

Shell Hydro

Required Required Required Required Required Required Required Required Required Required Required

Backseat Hydro*

Required Required

N/A

Required Required

N/A

N/A

N/A

N/A

Required

N/A

Seat(s) Hydro

Optional Required Required Required Required Required Optional Required^ Required Required

Note 1

Seat(s) LP (pneum.) Required Optional Optional Optional Optional Optional Required Optional^ Optional Optional

Note 1

(*Backseat test required for all valves that have backseat feature except bellows-sealed valves.)

(^For metal-seated ball & butterfly valves the LP closure test is required and the hydro closure test is optional.)

1) MSS SP-61 allows LP closure test on valves below 600LB for DN300 and smaller, and on all pressure classes for DN100 and smaller. ANSI B16.34 allows

an LP closure test on valves below 600LB for DN200 and smaller, and all pressure classes for DN100 and smaller.

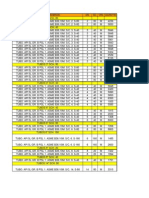

Class

150LB

300LB

600LB

800LB

900LB

1500LB

2500LB

Test

Shell Hydro

Seat(s) Hydro

Seat(s) LP

Shell Hydro

Seat(s) Hydro

Seat(s) LP

Shell Hydro

Seat(s) Hydro

Seat(s) LP

Shell Hydro

Seat(s) Hydro

Seat(s) LP

Shell Hydro

Seat(s) Hydro

Seat(s) LP

Shell Hydro

Seat(s) Hydro

Seat(s) LP

Shell Hydro

Seat(s) Hydro

Seat(s) LP

A105, WCB, LF2

450

psig

325

psig

60-100

psig

1125

psig

825

psig

60-100

psig

2225

psig

1630

psig

60-100

psig

3000

psig

2175

psig

60-100

psig

3350

psig

2450

psig

60-100

psig

5575

psig

4100

psig

60-100

psig

9275

psig

6800

psig

60-100

psig

Test Pressures by Material & Pressure Class

API 598

WC1, LC1, LCB

WC6, WC9, C5

CF3(M),CF8(M), F316 F304L, F316L, CN7M

400

psig

450

psig

425

psig

350

psig

300

psig

325

psig

325

psig

275

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

1050

psig

1125

psig

1100

psig

900

psig

775

psig

825

psig

800

psig

675

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

2100

psig

2250

psig

2175

psig

1800

psig

1550

psig

1650

psig

1600

psig

1325

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

psig

3000

psig

2900

psig

2400

psig

psig

2200

psig

2150

psig

1800

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

3150

psig

3375

psig

3250

psig

2700

psig

2300

psig

2475

psig

2400

psig

2000

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

5225

psig

5625

psig

5400

psig

4500

psig

3825

psig

4125

psig

3975

psig

3300

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

8700

psig

9375

psig

9000

psig

7500

psig

6375

psig

6875

psig

6600

psig

5500

psig

60-100

psig

60-100

psig

60-100

psig

60-100

psig

API 6D

425

300

80 +/-10

1100

800

80 +/-10

2175

1600

80 +/-10

80 +/-10

3250

2400

80 +/-10

5400

4000

80 +/-10

9000

6600

80 +/-10

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

psig

Minimum Test Duration

API 598

Shell Test

Check

Other

Valve Size

to DN50 1 min.

15 sec.

DN65-DN100 1 min.

1 min.

DN125 1 min.

1 min.

DN150 1 min.

1 min.

DN200 1 min.

2 min.

DN250 1 min.

2 min.

DN300 1 min.

2 min.

DN350-DN450 2 min.

5 min.

DN500 up 2 min.

5 min.

(*Applies to DN50 only)

Backseat

15 sec.

1 min.

1 min.

1 min.

1 min.

1 min.

1 min.

1 min.

1 min.

API 6D

Seat(s) Test

Check

Other

1 min.

15 sec.

1 min.

1 min.

1 min.

1 min.

1 min.

1 min.

1 min.

2 min.

1 min.

2 min.

1 min.

2 min.

2 min.

2 min.

2 min.

2 min.

Shell Test

Seat(s)

2 min*

2 min.

N/A

5 min.

5 min.

5 min.

15 min.

15 min.

30 min.

2 min*

2 min.

N/A

5 min.

5 min.

5 min.

5 min.

5 min.

5 min.

Maximum Allowable Leakage for Closure/Seat(s) Test

API 598

API 6D

Metal-Metal

Resilient

Liquid

Air/Gas

Liquid

Air/Gas

Liquid

Air/Gas

Valve Size

to DN50

0

0

0

0

DN65-DN100

12

12

0

0

DN125

12

12

0

0

No visible leakage at

DN150

12

12

0

0

applicable test

DN200

20

40

0

0

pressure for specified

DN250

20

40

0

0

test duration.

DN300

20

40

0

0

DN350-DN450

28

56

0

0

DN500 up

28

56

0

0

(Allowable leakage rates are drops/minute for liquid and bubbles/minute for air/gas.)

MSS SP-61 & ANSI

B16.34

Shell Test Seat(s)

15 sec.

1 min.

1 min.

1 min.

1 min.

3 min.

3 min.

3 min.

3 min.

15 sec.

30 sec.

30 sec.

30 sec.

30 sec.

1 min.

1 min.

1 min.

2 min.

You might also like

- Api 598Document13 pagesApi 598SurachaiAumongkolNo ratings yet

- Api-598-En-12266-1 Seat LeakDocument2 pagesApi-598-En-12266-1 Seat Leakelumalai24100% (10)

- Pressure Test Chart API 598Document1 pagePressure Test Chart API 598John0% (1)

- W-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FDocument6 pagesW-P-10-01 - Design Validation TestProcedure - BALL VALVE PR2 ANNEX FPalkesh TrivediNo ratings yet

- Api 602Document4 pagesApi 602kreyson77750% (2)

- API 598 Testing Procedure-20130720-032647Document2 pagesAPI 598 Testing Procedure-20130720-032647JOMAGUES100% (1)

- API 598 Valve Inspection and TestingDocument2 pagesAPI 598 Valve Inspection and TestingAmanda Ariesta Aprilia100% (1)

- API 598 Summary Tables Valve Testing Procedure PDFDocument10 pagesAPI 598 Summary Tables Valve Testing Procedure PDFzhangjie100% (2)

- Valves Test & Inspection Seminar - by H. Sinaei PourDocument67 pagesValves Test & Inspection Seminar - by H. Sinaei PournasiramzanNo ratings yet

- Testing Procedure of Ball ValveDocument2 pagesTesting Procedure of Ball Valverajesh100% (2)

- Grove API 6d Gate Valve IomDocument21 pagesGrove API 6d Gate Valve Iomanon_793851477No ratings yet

- API 570 FormulasDocument2 pagesAPI 570 FormulasArif Mokhtar89% (9)

- PNEUMATIC TESTDocument2 pagesPNEUMATIC TESTdyke_engg50% (2)

- Valve Inspection & TestingDocument6 pagesValve Inspection & TestingRavi Shankar M GNo ratings yet

- Torque Values RTJ (B16.5)Document3 pagesTorque Values RTJ (B16.5)Dave Donohue100% (9)

- Split TeeDocument80 pagesSplit TeeJohn Peter100% (1)

- API 600 Vs API 603Document9 pagesAPI 600 Vs API 603Farid A Ghani100% (1)

- R3215-005041 Appendix A 2.0 - Datasheet For Corrosion CouponDocument1 pageR3215-005041 Appendix A 2.0 - Datasheet For Corrosion Couponsaiful anwarNo ratings yet

- 510 E10 Addendum1Document1 page510 E10 Addendum1Gonzalo TelleríaNo ratings yet

- ABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesDocument69 pagesABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesBhaiJan59100% (4)

- API 650 PoıntsDocument4 pagesAPI 650 PoıntsSamet BelliNo ratings yet

- Piping Material Equivalent GradesDocument19 pagesPiping Material Equivalent GradesTejas DesaiNo ratings yet

- Presentation Dished Ends (Heads)Document24 pagesPresentation Dished Ends (Heads)Rahul Moottolikandy100% (1)

- API 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingDocument10 pagesAPI 6A Bolting, API 6ACRA Bolting, API 6A718 Bolting: Minimum Requirement of Closure BoltingQuality controller0% (1)

- Master Flo Choke Valve CatalogueDocument28 pagesMaster Flo Choke Valve Cataloguegladwyn_hallatu100% (2)

- Choke Valve Data SheetDocument1 pageChoke Valve Data SheetFabricio Vega Estrella100% (1)

- Velan Ball Valve 1 PDFDocument9 pagesVelan Ball Valve 1 PDFMilena Lemus FonsecaNo ratings yet

- Smith Gasket BrochureDocument29 pagesSmith Gasket BrochureJeesan MathewNo ratings yet

- Heat Treatment Requirement As Per ASME B31.3Document2 pagesHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- Piping Material SpecificationDocument108 pagesPiping Material SpecificationgeroldhemNo ratings yet

- Construction Instrument Tubing Pressure & Leak Test ProcedureDocument9 pagesConstruction Instrument Tubing Pressure & Leak Test Procedurezack zeeartNo ratings yet

- ASME PCC-1-2013 Bolt Torque Table for SA-105 Steel FlangesDocument1 pageASME PCC-1-2013 Bolt Torque Table for SA-105 Steel FlangeskhaireddinNo ratings yet

- Final Inspection Release NoteDocument2 pagesFinal Inspection Release NoteMark ThrelfallNo ratings yet

- Api 6aDocument23 pagesApi 6aumairahmedbaig75% (4)

- PMS-V32-Ball Valves - FlangedDocument2 pagesPMS-V32-Ball Valves - FlangedMB Azharudeen100% (1)

- Gate Valves For Fire - Protection ServiceDocument28 pagesGate Valves For Fire - Protection ServiceLesther ChavesNo ratings yet

- Pfi Es-5 2002Document2 pagesPfi Es-5 2002bayu212100% (1)

- Testing Procedure of Dual Plate Check ValveDocument2 pagesTesting Procedure of Dual Plate Check Valverajesh100% (2)

- 1 - Asme B31-3 (165 Q&a)Document33 pages1 - Asme B31-3 (165 Q&a)Mohammed Kadhim75% (12)

- Double Containment EDocument43 pagesDouble Containment EDavid FonsecaNo ratings yet

- API 570 - 01 API 570 and B31.3 PracticeDocument5 pagesAPI 570 - 01 API 570 and B31.3 PracticeMegan KirbyNo ratings yet

- Sa (Valves and Fittings Exam)Document6 pagesSa (Valves and Fittings Exam)rajaksekar100% (2)

- Pfi-Es-22 (1999)Document4 pagesPfi-Es-22 (1999)jothish100% (5)

- Tabla Api 598Document2 pagesTabla Api 598Sergio LazarteNo ratings yet

- Made in Italy - EuropeDocument8 pagesMade in Italy - EuropeenenickNo ratings yet

- SobrasDocument117 pagesSobrasEstratagema De Deus Etd Lotad ONo ratings yet

- Presstestreq PDFDocument3 pagesPresstestreq PDFMohammadreza AsheghNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- Ansul Wheeled RedLine 150lb F-2002046Document4 pagesAnsul Wheeled RedLine 150lb F-2002046German Duvan HernandezNo ratings yet

- Forged, High Pressure Valves ANSI 900-4500 1/2" - 4": Butt Weld EndsDocument2 pagesForged, High Pressure Valves ANSI 900-4500 1/2" - 4": Butt Weld Endstri_purwadiNo ratings yet

- Rei Vol IDocument297 pagesRei Vol IDineshNo ratings yet

- Red Line Wheeled Extinguisher MODELS 150-D, 350-D: Data/SpecificationsDocument4 pagesRed Line Wheeled Extinguisher MODELS 150-D, 350-D: Data/SpecificationsDnyaneshwarNo ratings yet

- DOT3 Tank SelectionDocument1 pageDOT3 Tank SelectiondjmauropicottoNo ratings yet

- Pumps+Valves4 MudGateValves 081129Document6 pagesPumps+Valves4 MudGateValves 081129isamelgqNo ratings yet

- HFD Catalog WPF PDFDocument16 pagesHFD Catalog WPF PDFPartsGopher.comNo ratings yet

- 3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2Document16 pages3 Way and 4 Way Plug Valves PTWPFW Technical 20-00-2zampacaanasNo ratings yet

- Series 800 Specification SheetDocument2 pagesSeries 800 Specification SheetFEBCONo ratings yet

- Faslt 0020 enDocument6 pagesFaslt 0020 enshashikanth79No ratings yet

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsFrom EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsNo ratings yet

- Millets and Grains - Glossary in English and Hindi My Weekend Kitchen 2Document1 pageMillets and Grains - Glossary in English and Hindi My Weekend Kitchen 2Nitin AggarwalNo ratings yet

- Belzona 1511 Product Flyer.Document2 pagesBelzona 1511 Product Flyer.Nitin AggarwalNo ratings yet

- Score Group System-V-Map G3 A3 Flyer (Rev 0)Document4 pagesScore Group System-V-Map G3 A3 Flyer (Rev 0)Nitin AggarwalNo ratings yet

- Dowel Pins and Extractable Dowels PDFDocument4 pagesDowel Pins and Extractable Dowels PDFtech81No ratings yet

- Dimensional Tolerance ChartDocument1 pageDimensional Tolerance Chartpushkar_k123No ratings yet

- Bind Second Valve OverviewDocument27 pagesBind Second Valve OverviewNitin AggarwalNo ratings yet

- Belzona 1511 Instruction For UseDocument2 pagesBelzona 1511 Instruction For UseNitin AggarwalNo ratings yet

- PSV Manual Rev 1 020708Document37 pagesPSV Manual Rev 1 020708Nitin AggarwalNo ratings yet

- BHEL Valves PDFDocument135 pagesBHEL Valves PDFNitin Aggarwal100% (1)

- Materials for Advanced Coal Power PlantsDocument23 pagesMaterials for Advanced Coal Power PlantsAnonymous lmCR3SkPrKNo ratings yet

- Pipe Dimensions Chart Rev Jan 2012Document1 pagePipe Dimensions Chart Rev Jan 2012snake13No ratings yet

- Galvanic Corrossion & The Prevention.Document27 pagesGalvanic Corrossion & The Prevention.Jayakrishnan RadhakrishnanNo ratings yet

- Carpenterguidetomachining PDFDocument170 pagesCarpenterguidetomachining PDFNitin AggarwalNo ratings yet

- Niton Data Transfer-V6 0 PDFDocument209 pagesNiton Data Transfer-V6 0 PDFNitin AggarwalNo ratings yet

- KXDX D H W U: 6.0 Impact LoadsDocument4 pagesKXDX D H W U: 6.0 Impact LoadsSuman SahaNo ratings yet

- 2600 Series Catalog R3Document96 pages2600 Series Catalog R3Mrr Afrasiabi100% (1)

- Guidelines For Hard Facing Onto SteelsDocument7 pagesGuidelines For Hard Facing Onto SteelsmohamedfirozNo ratings yet

- 3800series PRV Catalog 0810C R2 PDFDocument36 pages3800series PRV Catalog 0810C R2 PDFMrr Afrasiabi0% (1)

- Pressure Relief Valve Engineering HandbookDocument93 pagesPressure Relief Valve Engineering Handbookakrouti92% (12)

- Series4200 111 R2Document16 pagesSeries4200 111 R2Nitin AggarwalNo ratings yet

- Series6400&6600 111C R2Document20 pagesSeries6400&6600 111C R2Nitin AggarwalNo ratings yet

- Experimental Study of Cavitation Stellite-6Document9 pagesExperimental Study of Cavitation Stellite-6Nitin AggarwalNo ratings yet

- Heat Treatment of SteelsDocument18 pagesHeat Treatment of SteelsRajeev SaiNo ratings yet

- CW 2700catalog LowRes PDFDocument20 pagesCW 2700catalog LowRes PDFMrr AfrasiabiNo ratings yet

- Imperial Torque RatingDocument19 pagesImperial Torque RatingNitin AggarwalNo ratings yet

- Torque RatingsDocument22 pagesTorque RatingsNitin AggarwalNo ratings yet

- Human Factors For Valve DesignDocument249 pagesHuman Factors For Valve DesignNitin AggarwalNo ratings yet

- Nbstechnologicpapert362 PDFDocument35 pagesNbstechnologicpapert362 PDFNitin AggarwalNo ratings yet

- 25 Thick Cylinders Stresses Due To Internal and External PressuresDocument14 pages25 Thick Cylinders Stresses Due To Internal and External PressuresPRASAD326100% (4)

- Stellite 6 HardnessDocument28 pagesStellite 6 HardnessNitin AggarwalNo ratings yet

- Bipolar Stepper Motor..Document17 pagesBipolar Stepper Motor..Jaka Rusmana100% (1)

- Parts Catalogue: CD DeluxeDocument52 pagesParts Catalogue: CD DeluxeJonathan FiquitivaNo ratings yet

- DSE E400 Data Sheet Control US Size PDFDocument2 pagesDSE E400 Data Sheet Control US Size PDFEko SulistyoNo ratings yet

- Caterpillar Monitoring SystemDocument3 pagesCaterpillar Monitoring SystemFajarTaufiq100% (1)

- S1r9a9m9 Water CarDocument7 pagesS1r9a9m9 Water Carapi-372572650% (2)

- vh3372 EnglishDocument20 pagesvh3372 EnglishtonNo ratings yet

- Boltec 335hDocument4 pagesBoltec 335hErick AlarconNo ratings yet

- Belt Pulley & PTO System ExplainedDocument17 pagesBelt Pulley & PTO System ExplainedFoo He XuanNo ratings yet

- Covered Line Wire: Standards / Testing SpecificationsDocument5 pagesCovered Line Wire: Standards / Testing Specificationsjorge_moralesmNo ratings yet

- Tsu Minh Phát 2152231 CC01 09Document23 pagesTsu Minh Phát 2152231 CC01 09221003ddtNo ratings yet

- SJ-20140825101256-001-ZXDT02-PU (V2.5) Solar Power Unit User Manual - 585179Document29 pagesSJ-20140825101256-001-ZXDT02-PU (V2.5) Solar Power Unit User Manual - 585179rodrigo velasquezNo ratings yet

- Datavideo MCU-100PDocument22 pagesDatavideo MCU-100PTomas VeteveNo ratings yet

- Tru TracDocument8 pagesTru TracJavier SaavedraNo ratings yet

- Fire Alarm, Smoke Detector and Automated Sprinkler SystemDocument19 pagesFire Alarm, Smoke Detector and Automated Sprinkler SystemShakeel AhmedNo ratings yet

- AISnet Quick Start Guide V1 - 00 - EngDocument5 pagesAISnet Quick Start Guide V1 - 00 - EngDavor GiaconiNo ratings yet

- 3.4.1.7 Lab - Research A Hardware UpgradeDocument2 pages3.4.1.7 Lab - Research A Hardware UpgradeLinnaNo ratings yet

- Tuthill t850Document4 pagesTuthill t850orlincosNo ratings yet

- Jungheinrich II Etv Etm 214 216 Spec EnglishDocument4 pagesJungheinrich II Etv Etm 214 216 Spec EnglishEmreNo ratings yet

- Dinamic BrakeDocument18 pagesDinamic BrakeSam eagle goodNo ratings yet

- Power Bridge Rectifiers: FeaturesDocument3 pagesPower Bridge Rectifiers: FeaturesFatumaNo ratings yet

- Libherr CraneDocument157 pagesLibherr Craneali67% (3)

- 6 HeidolphDocument7 pages6 HeidolphCeleynes RTNo ratings yet

- 01-11-ECX1 Conn Box Cable-02Document6 pages01-11-ECX1 Conn Box Cable-02maverick11No ratings yet

- 2020 I30 G 1.4 Mpi-DiagramDocument1 page2020 I30 G 1.4 Mpi-DiagramcarsexpressNo ratings yet

- Hydraulic pump repair partsDocument5 pagesHydraulic pump repair partsalexis aguirre espejoNo ratings yet

- 2 11 PDFDocument19 pages2 11 PDFBOLFRANo ratings yet

- Jamec Air FittingsDocument18 pagesJamec Air Fittingsgoeez1No ratings yet

- Battery ChargingDocument7 pagesBattery Charging123olympiakosNo ratings yet

- Fire and Gas Alarm SystemDocument6 pagesFire and Gas Alarm SystemsswahyudiNo ratings yet

- Dynamic Braking Chapter 9Document28 pagesDynamic Braking Chapter 9pabloNo ratings yet