Professional Documents

Culture Documents

Inter Office Correspondence

Uploaded by

isomerase0 ratings0% found this document useful (0 votes)

86 views2 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

86 views2 pagesInter Office Correspondence

Uploaded by

isomeraseCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

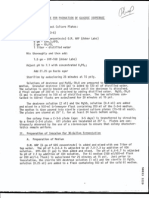

PENICK & FORD

LIMITED

INTER-OFFICE CORRESPONDENCE

D.5623

pave: February 6, 1970 copies To.

10: Dr. Phed:

H.A.Katz

row: oR. D. Harvey

Re: Glucose Isomerase

Pilot Plant study

In regard to your memo of January 26, 1970, we have a

column which is 14 inches x 10 feet. We are making plans to

have at our disposal substrate from any point in processing

i.e., filtration, carbon treatment, or deionization.

There are some factors which we feel will be important in

your investigations in the laboratory and in a pilot plant trial.

1) Use of Filtered syrup

It is suggested the use of filtered syrup be avoided.

After filtration, syrup contains a very fine precipitate which

tends to flocculate on aging. The content of this material is

inconsistent and dependent on several factors: syrup quality,

flow rate, type of filter media, and condition of filter cake.

Floccy material such as described above will tend to absorb on

the cellulose column and, undoubtedly, affect the system.

2) Use of Carbon Refined syrup

As syrup is processed, the ash content increases. Carbon

treatment significantly increases ash content. However, this

would be one point that could be examined as a substrate supply.

Do you have information indicating which metals have a poisoning

or inhibitory effect on the enzyme and what levels of such metals

are tolerable? It may be advisable for us to begin running assays,

for such metals, on our product stream.

D.5623 Page 2 February 6, 1970

3) Use of Deionized syrup

It appears that deionized syrup would be the ideal substrate.

The major objection here is the requirement of an additional

deionization.

4) Concentration of Substrate

Will there be any desire to concentrate the substrate? At

this D.E. and temperature, viscosity is not a significant problem.

With higher concentrations it may be possible to convert more

substrate (lbs. of Dry Substance) for a given bed volume in a

specified time period.

5) The 14" diameter column will be wrapped with a hot water hose

and insulated to maintain the temperature at 140°F. Please

supply us with the flow rate and the percent solids of the

proposed feed syrup. What refining steps are expected after

isomerization.

The Bendix Polarimeter has been sent to you for recalibration

and modification for higher fructose levels.

RDH/oe

ztpO EeBes

You might also like

- A Course in Probability Chapter 1 - WeissDocument433 pagesA Course in Probability Chapter 1 - Weissvidhu1911100% (1)

- Burton - Sonatina - Flute PartDocument9 pagesBurton - Sonatina - Flute PartNicolás Barrantes Carrasco0% (1)

- Alfred Korzybski: Olivet LecturesDocument250 pagesAlfred Korzybski: Olivet LecturesNava-yauvana Dās100% (3)

- Kufr - An Islamic Critique - by Shaykh Abdalqadir As-Sufi Ad-DarqawiDocument35 pagesKufr - An Islamic Critique - by Shaykh Abdalqadir As-Sufi Ad-DarqawiYusuf Denhollander100% (4)

- Frantz Fanon and The Psychology of Oppression Hussein Abdilahi BulhanDocument297 pagesFrantz Fanon and The Psychology of Oppression Hussein Abdilahi BulhanAbdi O. BoobeNo ratings yet

- Cherep Spiridovich - The SECRET WORLD GOVERNMENT or The HIDDEN HANDDocument206 pagesCherep Spiridovich - The SECRET WORLD GOVERNMENT or The HIDDEN HANDOnder-Koffer100% (3)

- Who Shall Survive J L Moreno 1978 879pgs PSY - SMLDocument879 pagesWho Shall Survive J L Moreno 1978 879pgs PSY - SMLMª AntoniaNo ratings yet

- Doka CatalogueDocument10 pagesDoka CatalogueurabiNo ratings yet

- Ferro Carril 1Document27 pagesFerro Carril 1Astelsa TecnologíaNo ratings yet

- Toward A Critical HRDDocument16 pagesToward A Critical HRDAyu DestiariniNo ratings yet

- Managing Individual Performance A Strategic PerspectiveDocument20 pagesManaging Individual Performance A Strategic PerspectiveMohammad KhaledNo ratings yet

- NAVMC 2795 - Users Guide To CounselingDocument59 pagesNAVMC 2795 - Users Guide To Counselingfurious manNo ratings yet

- Goulds - History - of Freemasonry - Throughout - The - World - V4-1936-Scribners-417pgs-SEC - SOC - SML PDFDocument417 pagesGoulds - History - of Freemasonry - Throughout - The - World - V4-1936-Scribners-417pgs-SEC - SOC - SML PDFAlejandro Sanchez GarciaNo ratings yet

- Bald or AlgebraDocument573 pagesBald or AlgebraShannon MooreNo ratings yet

- Who Shall Survive-J L Moreno-1978-879pgs-PSY - SML PDFDocument879 pagesWho Shall Survive-J L Moreno-1978-879pgs-PSY - SML PDFjeni_paraschivNo ratings yet

- Breakwater 2007Document1 pageBreakwater 2007api-256773601No ratings yet

- Research and Product DevelopmentDocument2 pagesResearch and Product DevelopmentisomeraseNo ratings yet

- Debate Feminista MaryDocument14 pagesDebate Feminista MaryVictoria Itzayana MartínezNo ratings yet

- 1996 MRR 10Document9 pages1996 MRR 10isomeraseNo ratings yet

- A Theory of Shakespeare CanadaDocument5 pagesA Theory of Shakespeare CanadamgterNo ratings yet

- World Thought Police Tomas Schuman 1986 68pgs SOV POL - SMLDocument68 pagesWorld Thought Police Tomas Schuman 1986 68pgs SOV POL - SMLAlberto Gómez CoronaNo ratings yet

- The Jewish Encyclopedia Vol X 1905Document326 pagesThe Jewish Encyclopedia Vol X 1905Peter James ClarkNo ratings yet

- Wittgenstein and General SemanticsDocument4 pagesWittgenstein and General SemanticsLuis Alexander Aponte RojasNo ratings yet

- Las Huellas de Mis Pasos: Pedro RiveraDocument138 pagesLas Huellas de Mis Pasos: Pedro RiveraJenny RodriguezNo ratings yet

- Holloway 1987 The Red Rose of NissanDocument23 pagesHolloway 1987 The Red Rose of NissanolsbolsNo ratings yet

- Theories and Etiology of Child Sexual Abuse by MalesDocument11 pagesTheories and Etiology of Child Sexual Abuse by MalesKiana TehraniNo ratings yet

- 1933 LawDocument4 pages1933 LawTiger Dimension-ElNo ratings yet

- Martin, F - Balada para Flauta y Piano - Flute PartDocument7 pagesMartin, F - Balada para Flauta y Piano - Flute PartNicolás Barrantes CarrascoNo ratings yet

- The Secret Societies of All Ages & Countries Vol.2Document382 pagesThe Secret Societies of All Ages & Countries Vol.2Onder-Koffer100% (1)

- M.Karr-Theory of Summation in Finite TermsDocument13 pagesM.Karr-Theory of Summation in Finite Termsalphamale173No ratings yet

- CSWIP 3 0 Fillet Welded JointDocument4 pagesCSWIP 3 0 Fillet Welded JointarianaseriNo ratings yet

- Invadir El Espacio Público Transformar El Espacio Privado : Jean FrancoDocument21 pagesInvadir El Espacio Público Transformar El Espacio Privado : Jean FrancoConstanza Burgos ContardoNo ratings yet

- A Review of Surface Tension Measuring Techniques, Surfactant, and Their Implication For Oxygen Transfer in Wastewater Treatment PlantsDocument69 pagesA Review of Surface Tension Measuring Techniques, Surfactant, and Their Implication For Oxygen Transfer in Wastewater Treatment PlantsEugene PaiNo ratings yet

- TIFL0067881 - 7885 - College - of - Knowledge - 1980Document5 pagesTIFL0067881 - 7885 - College - of - Knowledge - 1980Julia PurperaNo ratings yet

- 1-Public Law 86-346-Sept-22-1959Document4 pages1-Public Law 86-346-Sept-22-1959John BoyNo ratings yet

- 1 2 theNewOrderOfBarbarians PDFDocument24 pages1 2 theNewOrderOfBarbarians PDFgurudasaNo ratings yet

- Childcustody PDFDocument71 pagesChildcustody PDFAlejandro VidalNo ratings yet

- Disclosure Summary Page Ia C Dr-2: Ovj, J0Document3 pagesDisclosure Summary Page Ia C Dr-2: Ovj, J0Zach EdwardsNo ratings yet

- John G Lake-Spiritual Hunger The God-Men LakeDocument52 pagesJohn G Lake-Spiritual Hunger The God-Men Lakepajodream777100% (2)

- The Limits To GrowthDocument205 pagesThe Limits To GrowthAlec DursleyNo ratings yet

- World Thought PoliceDocument68 pagesWorld Thought PoliceMistah RoflcopterNo ratings yet

- Progress in Heterocyclic Chemistry: A Critical Review of the 1997 Literature Preceded by Two Chapters on Current Heterocyclic TopicsFrom EverandProgress in Heterocyclic Chemistry: A Critical Review of the 1997 Literature Preceded by Two Chapters on Current Heterocyclic TopicsNo ratings yet

- Frankenstein, or the Modern Prometheus: The 1818 TextFrom EverandFrankenstein, or the Modern Prometheus: The 1818 TextNo ratings yet

- Have You Heard a Kangaroo Buzz?: Learn About Animal SoundsFrom EverandHave You Heard a Kangaroo Buzz?: Learn About Animal SoundsNo ratings yet

- A Shred of Honour: A Markham of the Marines NovelFrom EverandA Shred of Honour: A Markham of the Marines NovelRating: 3 out of 5 stars3/5 (8)

- Would You Spread a Turtle on Toast?: Learn About NutritionFrom EverandWould You Spread a Turtle on Toast?: Learn About NutritionNo ratings yet

- A Song for Sung Li: A Story about the San Francisco EarthquakeFrom EverandA Song for Sung Li: A Story about the San Francisco EarthquakeRating: 4 out of 5 stars4/5 (1)

- Rules of Thumb for Mechanical EngineersFrom EverandRules of Thumb for Mechanical EngineersRating: 3.5 out of 5 stars3.5/5 (3)

- The Maddest Idea: An Isaac Biddlecomb NovelFrom EverandThe Maddest Idea: An Isaac Biddlecomb NovelRating: 3.5 out of 5 stars3.5/5 (9)

- Quarterly ReportDocument4 pagesQuarterly ReportisomeraseNo ratings yet

- 11 :45 - 12 :30Document4 pages11 :45 - 12 :30isomeraseNo ratings yet

- Iim11"1' D: - E - A - VassalloDocument12 pagesIim11"1' D: - E - A - VassalloisomeraseNo ratings yet

- ''Form 2422 Rev - 5/67Document2 pages''Form 2422 Rev - 5/67isomeraseNo ratings yet

- F@RM 2422 Rev - 5/67Document2 pagesF@RM 2422 Rev - 5/67isomeraseNo ratings yet

- Project InitiationDocument16 pagesProject InitiationisomeraseNo ratings yet

- Intef:-Offlce Corf :espondencDocument5 pagesIntef:-Offlce Corf :espondencisomeraseNo ratings yet

- R.J.reynolds Industries, Inc .Document1 pageR.J.reynolds Industries, Inc .isomeraseNo ratings yet

- Form 2422 Rev - Sj67Document1 pageForm 2422 Rev - Sj67isomeraseNo ratings yet

- Forld Z7e2 - ' Rey - s/67Document2 pagesForld Z7e2 - ' Rey - s/67isomeraseNo ratings yet

- April 21, 1970Document1 pageApril 21, 1970isomeraseNo ratings yet

- May 5, 1970 Dr. Murray SenkusDocument1 pageMay 5, 1970 Dr. Murray SenkusisomeraseNo ratings yet

- P 4 . 'II.t 2 ?.L Re yDocument1 pageP 4 . 'II.t 2 ?.L Re yisomeraseNo ratings yet

- Quarterly Report February 12, 1970Document1 pageQuarterly Report February 12, 1970isomeraseNo ratings yet

- Minutes of The Penlck & FordDocument9 pagesMinutes of The Penlck & FordisomeraseNo ratings yet

- Form 2422 Rev - 5/67Document2 pagesForm 2422 Rev - 5/67isomeraseNo ratings yet

- Procedure For Production of Glucose IsomeraseDocument4 pagesProcedure For Production of Glucose IsomeraseisomeraseNo ratings yet

- Xylose Production From Corn HullsDocument19 pagesXylose Production From Corn HullsisomeraseNo ratings yet

- Project Titles 19691110Document2 pagesProject Titles 19691110isomeraseNo ratings yet

- Minutes of January 21, 1969 MeetingDocument5 pagesMinutes of January 21, 1969 MeetingisomeraseNo ratings yet

- F CJ Z:M 2 4 t2 RevDocument1 pageF CJ Z:M 2 4 t2 RevisomeraseNo ratings yet

- Form 2a22 Rev 5167Document2 pagesForm 2a22 Rev 5167isomeraseNo ratings yet

- Inter Office MemorandumDocument2 pagesInter Office MemorandumisomeraseNo ratings yet

- Quarterly Report November 14, 1969 Jane PDocument1 pageQuarterly Report November 14, 1969 Jane PisomeraseNo ratings yet

- Inter-Office MemorandumDocument2 pagesInter-Office MemorandumisomeraseNo ratings yet

- For"t.1 2422 Rev - 5/67Document3 pagesFor"t.1 2422 Rev - 5/67isomeraseNo ratings yet

- Inter Office MemorandumDocument2 pagesInter Office MemorandumisomeraseNo ratings yet

- Inter-Office Memorandum: To: MR - E - A - VassalloDocument2 pagesInter-Office Memorandum: To: MR - E - A - VassalloisomeraseNo ratings yet

- Inter Qefice MemorandumDocument1 pageInter Qefice MemorandumisomeraseNo ratings yet