Professional Documents

Culture Documents

AISI - Anchor Chair Design

Uploaded by

JoséSebastiánCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

AISI - Anchor Chair Design

Uploaded by

JoséSebastiánCopyright:

Available Formats

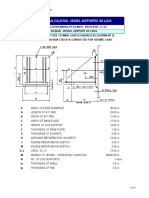

Part VII

Anchor Bolt Chairs

hen anchor bolts are required at supports

for a shell, chairs are necessary to

.

distribute the load to the shell. Small

tubular columns (less than 4 ft in diameler) may be

an exception if the base plate is adequate to resist

bending. Otherwise, chairs are always needed to

minimize secondary bending in the shell.

For flat-bottom tanks, choose a bolt circle to just

barely clear the bottom without notching It. For other

structures, follow the minimum clearances shown in

Fig. 7 1a. The designer must evaluate anchor bolt

location for interference wilh base or bottom plate.

= top-plate width, in., along shell

top-plate length, in., In radial direction

= top-plate thickn ess, in.

d

e

= anchor-bolt diameter, in.

= anchor-bolt eccentricity, in.

= 0.886d + 0.572, based on a heavy hex nut

em1n

= total load on weld, kips per lin. in. of weld

Top Plate

Critical stress in the top plate occurs between the

hole and the free edge of the plate. For convenience

we can consider this portion of the top plate as a

beam with partially fixed ends, with a portion of the

total anchor bolt load distrib uted along part of the

span. See Fig. 72.

s - tcz

...e.. (0.375g

- 0.22d)

(7 1)

. or

clearing shell by 1/2 in. See Table 7-1

= weld size (leg dimension), in.

WH = horizontal load , kips per lin. in. of weld

Wv = vertical load, kips per lin. in. of weld

0

= cone angle, degrees, measured lrom axis of

cone

Z

= reduction factor

Notation

distance, in.. from outside of top plate to

edge of hole

C a

(Q.375g - 0.22d) ] l/2

(72)

fmrn = d/2 + 1/8

= distance, in., between vertical plates

(preferred g = d + 1) (Additional distance may

be required for maintenance.]

chair height, in.

j

k

= vertical-plate thickness, in.

= vertical-plate width, in. (average width for

tapered plates)

= column

Top plate may project radially beyond vertical plates

as in Fig. 7 1d, but no more than 1/2" .

Chair Height

Chair must be high enough to distribute anchor bolt

load to shell or column without overstressing it. If the

anchor bolt were in line with the shell the problem

would be simple - the difficulty lies in the bending

caused by eccentricity of the anchor bolt with respect

to the shell. Except for the case where a continuous

ring is used at the top of chairs, maximum stress

occurs in the vertical direction and is a combination

of bending plus direct stress. Formulas which follow

are approximations, based on the work of Bjilaard.

length, in.

= bottom or base plate thickness, In.

design load, kips; or maximum allowable

anchor-bolt load or 1.5 times actual bolt load,

whichever is less

= least radius of gyration, in.

= nominal shell radius, in., either to inside or

centerline of plate (radius normal to cone at

bottom end for conical shells)

= stress at point, ksi

= shell or column thickness, in.

1.32

+ .031 ] (73)

= Pe [

12

1.43 ah2 + (4ah2).333

1'Rf

Rt

49

Table 7-1. Top-Plate Dimensions

Based on anchor-bolt stresses up to 12 ksi for 1 'hin.-dia.

bolls and 15 ksl for bolls 1 ~ in. in diameter or larger;

higher anchor boll stresses may be used subject to

designer's decision.

T op

p late

...,

"l

,,.

,k

Bolt Load, kips

p

19.4

32.7

43.1

56.6

'

"'

<

and where earthquake or winds over 100 mph

must be considered.

Maximum recommended chair height h = 3a.

(b) Vertical Column

or Skirt

(a) Typical Plan &

Outside Views

t

-.

}]

Top Plate Dimensions, in.

d

f d + 1 a e . c

1'h

4'h 1.87 0.734

2'h

1% 1

4~ 2.09 ".919

2'1'&

2

11,4

3

5

2.30 1.025

3y,

5y,

2.52 1.145

214 114

...

...!.

tI

..

If chair height calculated is excessive, reduce

eccentricity e. If possible, or use more anchor bolts

of a smaller diameter. Another solution is to use a

continuous ring at top of chairs.

If continuous ring is used, check for maximum

stress in circumferential direction. considering the

ring as though it were loaded with equally spaced

concentrated loads equal to Pe/h. Portion of shell

with in 16t either side of the attachment may be

counted as part ol the ring. (Refer to Fig. 7-3)

Note that the base plate or bottom Is also

subjected to this same horizontal force, except

inward instead of outward. This is true even if a

continuous ring is not used around the top of the

chairs - but it should never cause any very high

stresses in the base , so we do not normally check it.

However. it is a good thing to keep In mind in case

you have a very light base ring .

,

-

(d) Conical Skirt

(c) Flat Bottom Tank

Figure 7 1. Anchor-Bolt Chairs.

Vertical Side Plates

Be sure top plate does not overhang side plate (as in

Fig. 71d) by more than 112" radially.

Vertical-plate thickness should be at least

im1n = 1/2" or 0.04 (h - c), whichever Is greater.

Another requirement is jk > P/'25, where k is the

average width if plate is tapered.

These limits assure a maximum Ur of 86.6 and a

maximum average stress in the side plates of.12.5

Figure 7-2. Assumed Top-Plate Beam.

Where: Z =

1.0

am (

flit

.177

7) +

2

(7-4)

1.0

Maximum recommended stress is 25 ksi. This is a

local stress occurring just above the top of the chair.

Since it diminishes rapidly away from the chair, a

higher than normal stress is justified but an increase

for temporary loads, such as earthquake or wind is

not recommended . The following general guidelines

are recommended.

Minimum chair height h 6" , except use h 12"

when base plate or bottom plate is 3/8" or thinner

Figure 73. Chair with Continuous Ring at Top.

50

ksi , even assuming no load was transmitted into the

shell through the welds.

Assembly of Chair

For field erected structures, ship either the top plate

or the entire chair loose for installation after the

structure is sitting over the anchor bolts.

Where base plate is welded to skirt or column in

shop, attach side plates in the shop and ship top

plate loose for field assembly. See Fig. 7-4.

Where base or bottom plate is not welded to shell

in the shop, as for flat-bottom tanks and single.

pedestal tanks,. shop attach side plate.s to top plates

and then ship the assembly for field installation.

When you do this, weld both sides at top of side

plates- so shrinkage will not pull side plate out of

square. See Fig. 7-5.

Welds between chair and shell must be strong

enough to transmit load to shell. V" minimum fillet

welds as shown in Figs. 7-4 and 7-5 are nearly

always adequate, but you should check them If you

have a large anchor bolt with a low chair height.

Seal welding may be desired for application In

corrosive environments.

Assume a stress distribution as shown In Fig. 7-6

as though there were a hinge at bottom of chair. For

the purpose of figuring weld size, the base or bottom

plate is assumed to take horizontal thrust only, not

moment.

Note that loads are in terms of kips per inch of

weld length, not in terms of kips per square inch

stress. Critical stress occurs across the top of the

chair. The total load per inch on the weld is the

resultant of the vertical and horizontal loads.

..

Figure 7-6. Loads on Welds.

Formulas may also be used for cones , although

this underrates the vertical welds some.

Wv ~ _ _P_

(75)

a+ 2h

WH = _ _....P~e_ _

ah + 0.667h2

(76)

{7-7)

For an allowable stress of 13.6 ksi on a fillet weld,

the allowable load per lin. in. is 13.6 x 0.707 = 9.6

kips per in. of weld size. For weld size w, in., the

allowable load therefore is

9.6w ~

(78)

Design References

H. Bednar, "Pressure Vessel Design Handbook" ,

1981, pp. 72-93.

M.S. Troitsky, " Tubular Steel Structures" , 1982, pp.

5-10 - 5-16.

P.P. Bjilaard, " Stresses From Local Loadings In

Cylindrical Pressure Vessels," ASME

Transactions, Vol. 77, No. 6, 1955.

P. Buthod, "Pressure Vessel Handbook," 7th

Edition, pp. 75-82.

Figure 74. Typical Weld ing,

Base Plate Shop Attached .

~

16

Figure 75. Typical Welding ,

Base or Bottom Field Attached.

51

You might also like

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- WIND MOMENT (Per API-650 SECTION 5.11)Document9 pagesWIND MOMENT (Per API-650 SECTION 5.11)ramu karri100% (1)

- Calculation API 650Document78 pagesCalculation API 650isonwas 1966No ratings yet

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckManish542No ratings yet

- Aisi T 192 Steel Plate Engineering Vol 1 Vol 2Document132 pagesAisi T 192 Steel Plate Engineering Vol 1 Vol 2Ali MkawarNo ratings yet

- Anchor Bolt Chairs - CalculationDocument8 pagesAnchor Bolt Chairs - Calculationchicaiza123No ratings yet

- Anchor Chair Design FinalDocument26 pagesAnchor Chair Design FinalLe Bacha Bacha100% (4)

- Lug Support DesignDocument11 pagesLug Support Designimrancenakk100% (6)

- AISI Steel Plate Engineering Data-Volume 2-1992Document94 pagesAISI Steel Plate Engineering Data-Volume 2-1992jcarbajal2013No ratings yet

- Seismic Design Rules For Flat Bottom Cylindrical Liquid Storage Tanks PDFDocument35 pagesSeismic Design Rules For Flat Bottom Cylindrical Liquid Storage Tanks PDFJose Felix AcevedoNo ratings yet

- Sloshing Loads in Liquid-Storage Tanks With InsuffDocument9 pagesSloshing Loads in Liquid-Storage Tanks With Insuffjchavesz6100% (1)

- Anchor Chair Design - Version 1Document3 pagesAnchor Chair Design - Version 1Rey Fiedacan100% (2)

- Design of Tail Lug & Basering Reinforcement-FLUORDocument34 pagesDesign of Tail Lug & Basering Reinforcement-FLUORALONSO GOMEZ100% (1)

- Base Ring and SkirtDocument8 pagesBase Ring and Skirtduazo2009No ratings yet

- Design of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992Document76 pagesDesign of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992bhargavramudu 2019No ratings yet

- Welded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007Document20 pagesWelded Steel Water Tanks: Steel Plated Structures (Lecture Notes) Fourth Year Civil 2006-2007MazenMowafyNo ratings yet

- Prying ActionDocument8 pagesPrying ActionjoseherreramogollonNo ratings yet

- Book Review - Design of Steel Bins For Storage of Bulk Solids (Gaylord & Gaylord, Prentice-Hall, 1984)Document1 pageBook Review - Design of Steel Bins For Storage of Bulk Solids (Gaylord & Gaylord, Prentice-Hall, 1984)gdwvcdNo ratings yet

- Bednar - Pressure Vessel Design HandbookDocument230 pagesBednar - Pressure Vessel Design HandbookceballosingNo ratings yet

- 7203-6311-MDC-030KL TankDocument34 pages7203-6311-MDC-030KL TankDarshJhaNo ratings yet

- CICIND Model Code For Steel ChimneysDocument38 pagesCICIND Model Code For Steel ChimneysNikola BozovicNo ratings yet

- WRC 107Document2 pagesWRC 107mit1111chinNo ratings yet

- Agitator Support DesignDocument3 pagesAgitator Support DesignSabir Nasim100% (2)

- FIRE WATER TANK-API-650-Calculation-Report - RVDDocument42 pagesFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNo ratings yet

- 7-12-0006 Rev6 (Angle Leg Support)Document2 pages7-12-0006 Rev6 (Angle Leg Support)sumit kumarNo ratings yet

- Bolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryDocument1 pageBolt Connection Design Based On AISC 360-10/16: Input Data & Design SummaryKaren Esther Acuña VelasquezNo ratings yet

- Skirt Support Analysis TransportDocument5 pagesSkirt Support Analysis TransportHunnymijie NorNo ratings yet

- For Buildings and Other Structures For Wind LoadsDocument28 pagesFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- Project Name DOC. No.: Tank Name Rev No.: Item No.Document4 pagesProject Name DOC. No.: Tank Name Rev No.: Item No.AnggaNo ratings yet

- Support Lug CalculationsDocument26 pagesSupport Lug CalculationsDinesh ChouguleNo ratings yet

- Vessel Design RefDocument56 pagesVessel Design Refrogel_gana80% (10)

- Ibc 16Document114 pagesIbc 16Luis Fernando BaqueNo ratings yet

- Process Industry Practices Structural: PIP STC01015 Structural Design CriteriaDocument16 pagesProcess Industry Practices Structural: PIP STC01015 Structural Design CriteriaHarjasa AdhiNo ratings yet

- Saddle LoadsDocument11 pagesSaddle LoadsAnthony Dudley0% (1)

- Design Calculation For Anchor Chair API 650Document1 pageDesign Calculation For Anchor Chair API 650Mohammed Faizal Nv100% (2)

- Skirt Support DesignDocument8 pagesSkirt Support Designimrancenakk100% (2)

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- 100cub API 650 STEEL SiloDocument19 pages100cub API 650 STEEL SiloUDayNo ratings yet

- Silo Design Powdered Activated CarbonDocument187 pagesSilo Design Powdered Activated Carbonprasanth bhadranNo ratings yet

- "Lifting - Lug" - Lifting Lug Analysis: Program DescriptionDocument3 pages"Lifting - Lug" - Lifting Lug Analysis: Program Descriptionnamasral100% (3)

- Anchor Chair Design CheckDocument5 pagesAnchor Chair Design CheckHomer SilvaNo ratings yet

- Structural Analysis and Design of Process EquipmentDocument12 pagesStructural Analysis and Design of Process EquipmentPeja Jusoh50% (4)

- E.4 Leg Support CalculationDocument2 pagesE.4 Leg Support Calculationnaim100% (1)

- PV Elite Saddle AnalysisDocument4 pagesPV Elite Saddle AnalysismrosNo ratings yet

- Stiffened Plates PDFDocument16 pagesStiffened Plates PDFfarhadmrt6923No ratings yet

- 9178 2 PDFDocument39 pages9178 2 PDFvivekNo ratings yet

- Static Resistance Bolted Circular Flange JointsDocument9 pagesStatic Resistance Bolted Circular Flange JointsBálint Vaszilievits-SömjénNo ratings yet

- Silletas - Tanques API Metodo AISCDocument5 pagesSilletas - Tanques API Metodo AISCHEINER_PNo ratings yet

- Design of Colum Bases 12Document5 pagesDesign of Colum Bases 12radhe soniNo ratings yet

- Design of Circular DomesDocument8 pagesDesign of Circular Domesrshyams100% (1)

- Design of Pile Caps FinalDocument50 pagesDesign of Pile Caps FinalImam Shakil100% (2)

- RCC Design TipsDocument9 pagesRCC Design Tipssatoni12No ratings yet

- ENG List of Entry Point ProjectsDocument11 pagesENG List of Entry Point ProjectsKhoonShihHsienNo ratings yet

- Structural TipsDocument7 pagesStructural Tipsbalacr3No ratings yet

- Stepped Crane ColumnDocument14 pagesStepped Crane ColumnFrontlinerEagleNo ratings yet

- Structural Tips / Thumb RulesDocument7 pagesStructural Tips / Thumb Ruleswindspace3No ratings yet

- Pressure Vessel SupportDocument36 pagesPressure Vessel SupportAndreea Luca80% (5)

- Vessel Saddle SupportsDocument5 pagesVessel Saddle SupportsAzwa Onexox75% (4)

- 02 STLTIM Timber Design Students HandoutDocument36 pages02 STLTIM Timber Design Students Handoutdenmar balbonaNo ratings yet

- RCC Member Design TipsDocument8 pagesRCC Member Design TipsAbhishek ChaudhariNo ratings yet

- Design of Square Footing F1Document13 pagesDesign of Square Footing F1Abdullah KhanNo ratings yet

- Guidelinesfor Enhancing Building Securityin Singapore Jul 2010Document138 pagesGuidelinesfor Enhancing Building Securityin Singapore Jul 2010hutuguoNo ratings yet

- Ludwig Mies Van Der Rohe: Fransworth HouseDocument27 pagesLudwig Mies Van Der Rohe: Fransworth HouseTousif ShaikhNo ratings yet

- Technological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityDocument140 pagesTechnological Institute of The Philippines: 938 Aurora Boulevard, Cubao, Quezon CityKaty Perry100% (1)

- Grade of Concrete Permissible Stress in Compression Bending DirectDocument37 pagesGrade of Concrete Permissible Stress in Compression Bending DirectKasiNo ratings yet

- Review On Punching Shear Strength of Sla PDFDocument25 pagesReview On Punching Shear Strength of Sla PDFmahmoud IbrahemNo ratings yet

- Lecture 6 Composite ColumnsDocument66 pagesLecture 6 Composite Columnsabdelrahman emad100% (1)

- Ce 2352 - Design of Steel StructuresDocument3 pagesCe 2352 - Design of Steel StructuresVijay RajNo ratings yet

- SJ January 2023 V. 120 No. 1 PDFDocument346 pagesSJ January 2023 V. 120 No. 1 PDFlflorest2005100% (1)

- Column Base Plate: There Are Three Type of Column Base Plate Divided Inti The Load Condition AppliedDocument9 pagesColumn Base Plate: There Are Three Type of Column Base Plate Divided Inti The Load Condition AppliedHtet Wai LinNo ratings yet

- An Iconic Building and A Successful Stadium: Prof. Nichols St. Nooshin Ahmadi Yasaman Bagheri Farzad GolestaniradDocument29 pagesAn Iconic Building and A Successful Stadium: Prof. Nichols St. Nooshin Ahmadi Yasaman Bagheri Farzad Golestaniraddev dubeyNo ratings yet

- 2-Types of Foundations and Their SelectionDocument6 pages2-Types of Foundations and Their SelectionSamson Yonas0% (1)

- ParthenonDocument6 pagesParthenonRadyan JanuardyNo ratings yet

- Pier Luigi Nervi, Bridge DesignerDocument8 pagesPier Luigi Nervi, Bridge DesignerPLN_ProjectNo ratings yet

- Pipe Rack Design Philosophy (Continuous Pipe Racks)Document17 pagesPipe Rack Design Philosophy (Continuous Pipe Racks)Umer AleemNo ratings yet

- Anvil Strut Only CatalougeDocument148 pagesAnvil Strut Only CatalougericardoNo ratings yet

- Column Design - at Design OfficeDocument56 pagesColumn Design - at Design OfficeShamen AmarasekaraNo ratings yet

- Rules of ThumbDocument10 pagesRules of ThumbYazuraPoyoNo ratings yet

- Forensic Investigations of Collapse of Industrial Sheds at Thuvakudy, Tamil Nadu, India C. Natarajan and A. RajaramanDocument10 pagesForensic Investigations of Collapse of Industrial Sheds at Thuvakudy, Tamil Nadu, India C. Natarajan and A. RajaramanMaricel Parra OsorioNo ratings yet

- Civil Earthquake Resistent Building Construction ReportDocument25 pagesCivil Earthquake Resistent Building Construction ReportAjay WaswaniNo ratings yet

- 343r 95Document158 pages343r 95INGIMFBNo ratings yet

- UD AMS - Harini - UNIT 1Document83 pagesUD AMS - Harini - UNIT 1Divya PurushothamanNo ratings yet

- E3 Shelter (Eco-Friendly, Economical, Energy Efficient Shelter) - Civil Engineering Project TopicsDocument5 pagesE3 Shelter (Eco-Friendly, Economical, Energy Efficient Shelter) - Civil Engineering Project TopicsMohammad Imad Shahid KhanNo ratings yet

- Portal Frame Structures: Sem 9 - B.Tech Assignment 2Document25 pagesPortal Frame Structures: Sem 9 - B.Tech Assignment 2Pravah KhandekarNo ratings yet

- BOQ OLYMPIC InitialDocument322 pagesBOQ OLYMPIC InitialKEYSTONE INFRA PVT LTD0% (1)

- Ancient Greek ArchitectureDocument8 pagesAncient Greek ArchitectureFrancis Reese Benette DianasasNo ratings yet

- Steel Tips Committee of California Parte 1Document329 pagesSteel Tips Committee of California Parte 1RigobertoGuerraNo ratings yet

- Ring FoundationDocument22 pagesRing FoundationVarad Sonawadekar100% (1)

- Special SlabsDocument5 pagesSpecial SlabsMarielle G. CastilloNo ratings yet

- Deflections PortalsDocument9 pagesDeflections PortalsJim SpsNo ratings yet