Professional Documents

Culture Documents

Stoke Review - Sterilization

Uploaded by

Masrawana Mohd Masran0 ratings0% found this document useful (0 votes)

195 views8 pagesSterilization for Palm Oil Mill

Original Title

Stoke Review- Sterilization

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSterilization for Palm Oil Mill

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

195 views8 pagesStoke Review - Sterilization

Uploaded by

Masrawana Mohd MasranSterilization for Palm Oil Mill

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Polini Recicuw

ISSUED BY GEBR. STORK & Co’s APPARATENFABRIEK N.V, AMSTERDAM

Volume 1 No. 2

March 1960

Sterilization

seen

"Tha fet mechanical treatment the fruit of the oil alos is exposed to is sterieaton. The

prevent atcle will dea! with the purpose ofthis process, the requirements underlying it

and the time/temperature limits it iz subject to

1 will avo dhscust a fow aspects of cultivation technique, because the systein of harvesting

employed in the plantation has a marked influence upon the process results,

We propose to go into the practical problems connected with sterilization in a future article

Purpose

1.01 Ina

enzyme

ation of the oil-splitting

‘The circumstance that on the world market

the quality of palm oil is measured i.a, by

its free fatty acid content, makes it neces

sary to avoid as much as possible the forma-

tion of this acid prior to the recovery pro-

cess and an increase in acidity during

and/or through that process.

In the preceding number of this Review it

has been explained that the enzyme respon-

sible for the oil-splitting action in fresh

fruit ean be destroyed by a heat treatment,

Further, it has been shown that this en-

zyme is already rendered irreversibly inac-

tive at comparatively low temperatures and

short heating periods.

Ey:

1.02 Coagulation of the albuminous

substances

Most of the albuminous substances with which

we are here concerned, are of-the ‘globulin’ type

‘They will coagulate as a result of the

ment in the sterilizers and, consequ

cannot act as emulsifiers inthe further stages of

the process, also because the gel is irreversible.

However, not all the colloids present in the fruit

are irreversible, or rather irresoluble, so that if

they are contained in the extracted liquid they

may change back into the colloidal state by 2

dilution of the electrolyte (addition of water to

the crude). That is why these colloids which are

carried with the fruit to the digester and the press

(or extraction-centrifugal) in the form of gel,

should be retained in the pressed residue as far as

possible, so that they cannot be conveyed with

the extracted liquid (crude oil) to the clarification

plant and cause trouble there.

‘The effective coagulation of the albuminous mat-

ter requires a temperature of at least 100°C(212°F)

1.03 Hydrolysis of the

matter

eilaginous

‘The mucilage present in the form of colloids in

the protoplasm of the cells does not exert any os-

motic pressure on the cell walls, Now the hydrol-

ysis of this mucilaginous matter, which plays an

important part in the decomposition of carbo-

hydrates by water or steam, is strongly promoted

by sterilization.

Owing to the action of heat and moisture the

mucilage will partly hydrolyze and partly coag-

ulate, The dispersion balance will be upset, and the

insoluble carbo-hydrate molecules broken down into

soluble glucose molecules producing osmotic forces

which, supported by differences in pressure arising

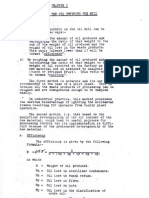

LOSS OF FRUIT IN EMPTY BUNCHES

80 90

STERIUZING TIME

100 min

with respect to the atmosphere, may bring about a

collapse of the cell wall. The process requires a

sterilization temperature of over 100° G, otherwise

the necessary period of reaction would become too

long.

1.04 Loosening the fruit in the bunch

In the sterilizer the harvested bunch is prepared

as it were, for the subsequent threshing or strip-

ping proces.

‘Through the sterilization namely, a certain hydvol-

ysis which occurs in nature as the fruit ripens, is

accelerated. This action can be compared with the

hydrolysis of poly-saccharides (starch-cellulose) and

their conversion into mono-saccharides. The place

of contact between the fruit and its stem is hydrol-

yzed by the steam and the reduction of the poly

saccharide molecules is attended with a better solu-

bility of the substances in this place of contact.

AAs a result the fruit is loosened in the bunch (as

with the natural ripening process) and can be

released,

To enable the hydrolysis to take place, the fruit

should be brought into contact with steam, The

higher the temperature and the longer the steril-

iuation period, the more readily the fruit ean be

stripped from’ its bunch afterwards

Figure 1 shows the relationship between the

loss of fruit in empty bunches, the sterilizing time

and the temperature, The conclusions

presented are based on large scale factory tests

which have covered a considerable period of time:

‘The scale for the ordinate has not been indicated,

so that no exact losses can be derived from the

graph which is only intended to give a general

idea of comparative values. For example, it dem=

onstrates that sterilization at 120° C for 80 minutes,

gives the same proportion of non-released fruit as

sterilization at 115°C: for 100 minutes

We now come to the question of bunch stripping

itself.

First of alll we would remark that in the bunch

stripper or thresher, varying quantities of bunch

trash containing calyx fragments are knocked out

along with the fruit,

Another point is that of inadequately stripped

bunches. Practice proves that in any batch of emp-

ty bunches there will always be several which con-

tain non-released fruit, As long as this is a matter

of one or two stray fruits the bunches may be said

to be empty for practical purposes, and the losses

of oil sustained in consequence will not exceed

1.04%, t0 0.05%, in well-run mills.

‘There may also be bunches however, which

though stripped, contain appreciably more than

just a couple of undetached fruits, and such

bunches should be considered the result of some

abnormality either in the process (faulty action

of the stripping machine, inadequate sterilizat

or in the bunch itsel

A. Faulty action of the stripper or

thresher

This may result from imperfections in the design

of the suipper and/or from incorrect operation

(uneven charging or overloading). The fruit left

in the stripped bunch is soft and will fall out

immediately the bunch is dropped or shaken.

B, Abnormal bunches

‘These are hard to deal with because they eannot

be treated very well mechanically. The fruit in

such bunches is reasonably soft but remains firmly

attached to the stem, In the stripping process the

Ihunches acquire a remarkably hairy and fibrous

appearance. Even after re-steriization it will as

‘often as not be impossible to detach the fruit in

the stripper and it has to be cut loose with a knife

if any oil is to be recovered from it

Although strictly speaking it is outside the com-

pass of this article to da so, we would dwell briefly

6n this interesting phenomenon.

Presumably a knot-head bunch or hard bunch, owes

its peculiarities to very immature spots caused by

some disease or stagnation in the flow of saps arrest-

ing the ripening process. We base our conjecture

‘on the following observations:

1. Among under-ripe bunches there is always an

appreciably higher percentage of knot-heads

than among ripe ones

2. A mieroscopie examination does not show any

‘anatomical difference between the tissue of fruit

from a knot-head bunch and that of fruit from

a normal one.

3. Every degree of ripeness from under-ripe to ripe

is represented in any one bunch. The vipe por

tion is at the top, where the fruit begins to drop

cout. As one approaches the stalk the fruit will

be found less ripe, the base of the bunch con-

taining a proportion of decidedly immature

and/or undeveloped fruit. It follows theoret-

ically, that any bunch whieh it has been found

10203045060 min

impossible to strip properly of its fruit

which, therefore, may be termed a knot-head

bunch’ should have no, or hardly any, fruit at

the top and a large portion of fruit at the base

This theory is in eflect bore out by practice.

Only if a buneh is reaped in a completely i

ture state will it become an all-out knot-head,

but of course this rarely occurs on a well-run

', Inadequate sterilization

Too low a sterilizing temperature may be respon-

sible for improper stripping. The factors by which

this ean be brought about are dealt with elsewhere

in the present number

1.05 Preparation of the fruit for

further treatment ia the

‘extraction plant

In the digester the pericarp must be loosened

completely trom the nuts, Through the steriliza-

tion the structure of the flesh of the palm fruit is

so far weakened that this separation can in effect

be brought about during digestion.

It is not fully known how long and at what tem-

perature the fruit should be sterilized in order to

produce the desired result. ‘These ave indications,

however, that the flesh loses its resistance already

after a short period of sterilization,

L., Kehren has described a number of tests carried

out to measure the force required to drive a pin

of a given diameter into the fruit. Those pressures

were recorded at which the pericarp could no

longer resist the penetration of the pin. Figure 2

pictures the results obtained.

It is generally known that bunches will. shrink

when subjected to sterilization, so that after the

process they are about 2/3 of their original size,

Figure 2 gives an indication that shrinkage is

well on its way to completion after a period of

approx. 10 minutes,

1.06 Preliminary treatment of the n

If the nuts are to be cracked properly, they must

be exposed to a given temperature for a given time

Owing to desiceation the kernel will detach itself

from the shell surrounding it

AAs the process involves the evaporation of moisture

from the inside of the kernel (diffusion-drying), it

is obvious that the period of drying should ‘be

considerable,

Teis recommended to use moderate temperatures,

otherwise there is the risk that the kernel will

discolos

is

Requirements

201 Sterilization and the quality of

palm oil

Next to a low FFA content a good bleachabil

is among the requirements high-grade palm oil is

expected to meet, In other words, the bleach-

ability of the oil may not be impaired by steil-

ization, ‘The state in which the harvested fruit

reaches the factory is of paramount importance

with regard to the bleaching properties of the oil,

Tt has been found that palm oil obtained from

fover-tipe (loose) fruit is comparatively hard to

bleach and that the presence of an excessive pro-

portion of over-ripe fruit may have a most adverse

influence upon the final product. (Of course this

is applicable to rotten fruit in even stronger

measure). That is why such fruit should be pr

vented from lying about on the floor or on a

platiorm in the sterilizing station or elsewhere for

a day or even a part of the day.

Furthermore, good bleachability necessitates a

proper air-release prior to sterilization, the shortest

posible sterilizing time and the lowest posible

process temperature.

If beside these requirements we take into account

those which were mentioned in the paragraphs

1.01 up to and including 1.06, we find many of

them to be contradictory, which implies that some

compromise must be established in practice.

Time and temperature limits of

the sterilization process

3.01

For want of anything better, the only criterion we

can apply to ascertain whether sterilization has

been carried out correctly is the proportion of

inadequately sterilized bunches. If the temperature

used has been too low and/or if the sterilizing time

hhas been too short, this proportion will rise con-

siderably. There are a couple of factors governi

the minimum time and temperature limit i

1. the size of the bunches

2. the degree of ripeness of the crop

3.01.01 The size of the bunches

The smaller the bunches the more rapidly they

will be sterilized, because they expose a relatively:

large surface to the action of the steam whilst the

hheat has only to travel a comparatively short

distance, This rule has been tested on bunches

from palms of varying ages, whereby the youngest

palmtrees were supposed to yield the smallest

bunches. The outcome was as follows:

Arca ance Pesshacik Smee

“e

Tyan s0min 2 29

Syeas 30min, 2 8

Syears 30min, 2 "

years 30min, 2 2

‘These figures are quite self-explanatory. The crop

from any plantation comprising bunches from

palms of several year-classes, the sterilizing eyele is

always based on the bunches from the oldest class.

3.01.02 The degree of ripeness of

the erop

If the bunches harvested are so ripe that much of

the fruit is already loose on its stem, the sterilizing

eyele can be relatively short, If the average

degree of ripeness is lower so that the bunches are

‘more compact, the sterilizing cycle should be pro-

longed a litte

In the preceding lines we have repeatedly used the

terms ripe, under-ripe, over-ripe, without attempt

ing to define them and we shall now proceed to

do s.

‘The time at which the bunches are harvested is

always the result of a financial-economic compro

mise made between the oil yield on the one hand

and the expenditure involved in the harvesting

procedure on the other

Although it is by no means our intention to expa-

tiate on matters of cultivation technique (

Review having quite a different purpose), we think

it useful to give a brief summary of the chief points

controlling the harvesting standards

a. In the paragraph dealing with knot-head

bunches (1.04. b), we have pointed to the cit-

cumstance that the fruits in a given bunch will

not ripen simultaneously.

Whereas at the apex ripe fruit may already

hegin to drop out, there will stil be a quantity

of under-ripe and even undeveloped fruit at the

base.

b. The fruit has its maximum oil content the

moment it will become loose in its bunch. By

“oose’ we understand the condition which

permits the fruit at the outside of the bunch

to be detached easily and by a slight pressure

of the thumb. Ifa bunch containing such fruit

is harvested, the mere faet of its falling to the

ground will release a large number of fruits

A few days before this moment arrives it will

be found possible already to break a few fruits

from the bunch with a little exertion, but in

this stage there can of course be no question

of any loose fruit.

Several research workers (H. M. Blommencaal,

L. Kehren, A. Dessasis) have published figures

relating to the oil content by weight of the

pericarp during the ripening process. As they

have based themselves on different test_mate-

Is and_have carried out their experiments

under different climatic conditions it is un-

derstandable that their conclusions are not

exactly identical, but making due allowance for

the minor variations resulting from the dif-

ferences alluded to we may draw from their

tests the general inference that the average oil

content by weight of the pericarp in freshly-

ripe fruit which is loose in its bunch, is 50%,

Five days before this moment is reached the

oil eontent is about 437, and ten days before it

is approx. 347,

. Asa general nile any increase in the percentage

of detached fruit will entail a rise of the FEA

content (please refer to Stork Palmoil Review

Nr. 1)

—

4.

&

An increased percentage of detached fruit is

likely to impair the bleaching properties of

palm oil.

Oil recovered from under-ripe fruit has a higher

meiting point than oil from Ireshly-ripe fruit

fad this is sometimes an advantage in the

processing of margarine.

‘The fruit that has fallen to the ground is con-

veyed to the mill with the harvested bunches,

so far as it can be found under the trees and so

far as the harvesters are prepared to collect it

‘There will always be a slight loss because a cer-

tain proportion of the detached fruit lies hidden

from view amid the foliage of the ground cover

in the plantation or is eaten by animals,

For reasons of economy, the harvester cannot

return every day to a given tree to see whether

a bunch has attained the correct degree of

ripeness. It may frequently happen that a har-

vvester comes across a bunch which is slightly

under-ripe but which may be over-ripe if left

till the next round.

‘This can hardly be ascertained from ground

level, especially when the tree is old and there-

fore tall, and it is quite understandable that the

harvester, once he has climbed the tree, will he

disinclined to leave alone a bunch which

though under-ripe — is not totally unsuitable

for harvesting, and to come down empty-hand-

ed. His keenness on including doubtful bunches

will be the more readily explainable when his

wages are based purely on quantity

‘This enumeration shows that here again a vati-

ety of conflicting considerations necessitates. a

balanced compromise on the basis of statistical

investigations and/or experience, established in

the form of a harvesting instruction and rules

concerning the harvesting intervals to be ob-

served.

Tt will be clear that in the crop arriving at the

mill every degree of ripeness between over-ripe

and under-ripe may be represented. Now, in a

well-organized palin oil mill it is common p

tice to keep a close check on the actual situation

by singling out part of the erop (ie, a few

Tories) and subjecting it to an analysis, the

bunches being sorted into different classes.

‘This is what such an analysis might look like:

(00 = no detached fruit 1%

= from 0 40 10% of detached fruit =

= from 10 10 25% of detached fruit

Chass 2 = from 25 t0 50% of detached fruit

lass 3 = from 50 40, 75% of detached fruit = €%

lass + = from 75 to 100% of detache fruit = 1%

ass 5. = part of intevior fruit also detached = 4%

Jetached fruit 1%

Totals 100%

Considering the circumstance that by the fall of

the bunches from the trees and as a result of

bunch transport to the mill a large quantity

of fruit will be released before arrival, the eat-

egories 00-0 and perhaps also category 1 may

be classed as under-ripe. The bunches from

class 5 are over-ripe, while class 4 is rather a

doubtful case

Which class should include the major part of

the erop is a matter to be decided by the man-

agement of the mill on the basis of the com-

promise adopted.

‘To harvest a crop that is on the unde!

implies a lower oil content by weight of the

pericarp, a lower FFA percentage, better bleach-

yy and a higher melting” point, whereas

with a largely over-ripe crop it is just the other

way round.

A harvest comprising bunches of all year-clases,

which for the most part come under the eat-

ripe side

Hortsontal sterilizers

Temperatures

eee ie Tre ee ee te ie oe

OOOOCOO0O

IOOOCOCOOCO

IOOOOCOOCO

lO

lO

egories 2 up to and including 4, can be sterilized

with little or no tisk of inadequate results, if

the process cycle is built up as follows:

de-aeration 5 min,

working up to full pressure : 20 min.

steril

ing 50-60 min.

3.02 Maximum limit

‘This is controlled by a tendency of the kernel to

discolour as a result of over-steriizing. The

diagram above, which is the outcome of thorough

full scale investigations made in one of the palm

oil mills in Sumatra, gives the approximate rela

tion between temperature, period and discoloura-

tion:

Explanation of symbols

© no visible discolouration

© slight discolouration

© marked discolouration

® kernel to turn brown

© kernel to turn dark brown

© ‘kernel to turn black

‘This table leads one to expect that the kernel can

be subjected to a temperature of 130°C for a

period of 1.5 hour without showing signs of dis

colouration. Yet experience proves that under

these circumstances the kernel tends to be slightly

off-coloured, which fact should be accounted for

as follows:

From the very beginning of the heat treatment,

certain changes will occur in the kernel which

later on, eg, after 2 hours, result in discolouration.

Tt is unlikely and even impossible that during the

first hours of the heat treatment nothing should

happen in the kernel at all, and that it should

nevertheless turn brown suddenly after the said

period of 2 hours,

‘The real situation is that although after say 1.5

hour at 130°C the kernel is still white, it_ will

be well on the way to discolouration, Additional

heating at a later stage of the recovery process (€.

in the digester) may make the kernel pass the

discolouration limit, the temperature of 130°C

having brought it very near this limit as the table

shows,

At 120°C the risk of discolouration at any stage

ff the process is much smaller, so that the kernel

may be expected to retain its original colour. It

will be observed from the table that the rate of

discolouration increases considerably at tempera-

tures above 130° C.

For the sake of good order we would mention

that to ascertain whether there has been any dis-

colouration one should take a kernel in its

final condition, ie. dried and ready for despatch,

cut it through and examine the section. This is

ecause no signs of discolouration will ever show

at the outside.

‘To complete the picture we give below a short

list of the types of kernel oil that are obtained

from palm Kernels in various conditions

1, Kemels from fruit that is sterilized for very

short period at normal temperature will yield

cil of a slightly yellow colour, although the

kernels themselves remain quite white

2, The oil recovered from normal kernels is of a

light yellow colour and is easy to bleach.

3. The oil recovered from kemels that have not

heen adequately dried is of a greyish-yellow

colour and is hard to bleach.

4, The oil recovered from light brown kemels is

again light yellow andl can generally be bleached

without trouble.

5, The oil recovered from kernels that have been

stored wet and/or are slightly rotten is dark

red and hard to bleach.

6. The oil recovered from dark brown kemels is

dark brown and cannot be bleached.

The effect of the sterilizing

temperature on the oil recove:

quo’

As is generally known, the use of a high steriizing

‘temperature will improve the oil recovery quotient,

ic. the oil losses in fibre will be lower. It is obvious

therefore, that there will always be a tendency

to increase the sterilizing temperature. ‘There is,

however, a certain maximum. limit which for

reasons explained in the preceding paragraph it

is essential to adhere to.

content

zation

to the high temperature the fruit is ex-

sterilization, part of the moisture

in it will evaporate spontaneously after the pres-

posed to durin

sur has been released, ‘This loss of moisture

amounting to 10%, of the weight of the fruit,

assists materially in the expression of the oil in

the press system.

Experiments, both on a laboratory seale

full factory seale, have demonstrated that the oil

recovery improves with a given moisture content

The optimum

moisture content has been found to be about

12%, + 2%. If the moisture content is less than

10%, or if it exceeds 147, the oil recovery quotient

will decrease

and on a

of the pericarp after sterilization,

To explain this phenomenon we should consider

The cell-

wall namely is made up of 2 parts, ie. a wall of

the structure of the cellular membrane

cellulose, which cellulose is almost invariably asso-

ciated with other substances (chiefly pectin, hemi-

cellulose, etc.) as well as a wall built up of fine

lipoid membranes confining the protoplasm. In

this stratified structure the moisture can be hound

in many ways and sometimes in large quantities

The chemical reaction taking place during steril~

ization (refer to 1,02 and 1.03) and the abstra

tion of moisture from the cell-wall weaken the

cells to such an extent that the oil can be easily

liberated from them afterwards,

The moisture content of the bunches handled in

the mill depends on the degree of ripeness they

have when harvested, the time elapsing between

harvesting and arrival at the mill and climatic

conditions

Whilst making due allowance for the same restric-

tions that were applicable to the oil content of the

pericarp (3.01.02 - b), we may state that the

pericarp of freshly-ripe fruit has a moisture con-

tent of about 337, this percentage having been

44 ten days previously and 38 five days previously

sneral rule that a normal

crop which has not been too long on its way to

the mill will be brought at the optimum moisture

content by normal sterilization with saturated

Tt can be laid down as a

Conelusi:

In the present number attention has been paid to

those factors which are of importance in the

mechanical sterilization of palm fruit and which

affect both the quantity and the quality of the oil

recovered,

In the next number of this Review we propose to

deal with subjects of a more practical nature

n consumption, the advan

as de-aeration, ste

and drawbacks of various types of sterilizers, ete

“Capcity 18

Some references

cone st Comytagn Toop

“ey * bunches

or

Anda

cen Go BE 3 |

es ‘| |

Tic Gon SERS Rito °

a ee :

Been 4,

Ciwtiam iene 0

re eo

eeleneesed Piao ; |

= ieageia ' |

So = ;

SCAM. Rep of Congo Leo 15

hans Gye ;

i = : |

ito Ree of Gabon 3

{864 Eranenia nh Angola 3

3 StF coe ERAS ct eae 3

Pa

EeRpilae Amerdan’ fee Pavan 3

ro Teg 4

so ode po Decne 1986

aah Sopa angie Gms | 0 on f EF pe hour i

1S as Induce 38 ho Maayan 3 noe cami);

461 foie prewes {17 fae

Boorstraat - Telephone 60591 - Postbox 3007 - Telex 12517 - Amsterdam (Holland)

1 70 sal sl automat)

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Asme SectionsDocument56 pagesAsme SectionsalperbogaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ISO 9001-2015 Checklist PDFDocument37 pagesISO 9001-2015 Checklist PDFHomero Januncio100% (1)

- NADOPODDocument27 pagesNADOPODsyoolove100% (1)

- RP2-ISO9001 2015 ADocument50 pagesRP2-ISO9001 2015 AMasrawana Mohd Masran100% (1)

- Understanding AlgebraDocument127 pagesUnderstanding Algebragr4ycloudNo ratings yet

- 2.pengreddan BTSDocument119 pages2.pengreddan BTSMasrawana Mohd Masran100% (5)

- WWW WWW WWW WWW: VU/VH SeriesDocument60 pagesWWW WWW WWW WWW: VU/VH SeriesMasrawana Mohd MasranNo ratings yet

- Waste MGMT & Env ControlDocument45 pagesWaste MGMT & Env ControlMasrawana Mohd Masran100% (1)

- Study of Characteristics & Quality of CPODocument22 pagesStudy of Characteristics & Quality of CPOMasrawana Mohd MasranNo ratings yet

- Clarification of Crude Palm OilDocument29 pagesClarification of Crude Palm OilMasrawana Mohd MasranNo ratings yet

- Monggana Volume 1 Chapter 1Document26 pagesMonggana Volume 1 Chapter 1Masrawana Mohd MasranNo ratings yet