Professional Documents

Culture Documents

3060 Guess Wps

Uploaded by

api-2807256860 ratings0% found this document useful (0 votes)

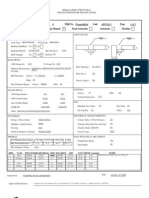

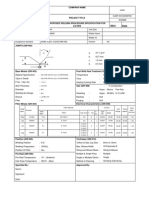

24 views4 pagesS&S Fabrication Welding Procedure Specification Name: Kelby Sayer I.D. #: 36 Date: 11 / 20 / 2013 Code / Year: AWS D1. / 2004 JOINT DESIGN Pre-Qualified Yes No X Root Opening: 1 / 32"-1 / 16" Groove Angle: 600 Back Gouging Yes No X BASE METAL Mat. : ASTM A36 Thickness: 3 / 8" Diameter (pipe):

Original Description:

Original Title

3060 guess wps

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentS&S Fabrication Welding Procedure Specification Name: Kelby Sayer I.D. #: 36 Date: 11 / 20 / 2013 Code / Year: AWS D1. / 2004 JOINT DESIGN Pre-Qualified Yes No X Root Opening: 1 / 32"-1 / 16" Groove Angle: 600 Back Gouging Yes No X BASE METAL Mat. : ASTM A36 Thickness: 3 / 8" Diameter (pipe):

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

24 views4 pages3060 Guess Wps

Uploaded by

api-280725686S&S Fabrication Welding Procedure Specification Name: Kelby Sayer I.D. #: 36 Date: 11 / 20 / 2013 Code / Year: AWS D1. / 2004 JOINT DESIGN Pre-Qualified Yes No X Root Opening: 1 / 32"-1 / 16" Groove Angle: 600 Back Gouging Yes No X BASE METAL Mat. : ASTM A36 Thickness: 3 / 8" Diameter (pipe):

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

S&S Fabrication

Welding Procedure Specification

Name:

Kelby Sayer

I.D. #:

36

Date:

11/20/2013

Code/Year: AWS D1.1/2004

JOINT DESIGN

Pre-Qualified

Yes

No X

Joint Configuration:

Backing

Yes

No X

Root Opening:

1/32"-1/16"

Root Face Dimension:

1/32"-1/16"

Groove Angle:

60

Back Gouging

Yes

No X

BASE METAL

Mat. Spec. :

ASTM A36

Thickness:

3/8"

Diameter (pipe):

N/A

FILLER METAL

AWS Spec. :

AWS A5. 18

AWS Class. :

ER70S-6

SHIELDING GAS

Gas:

Argon

Composition:

100% Ar

Flow Rate:

15 CFH

PREHEAT

Min. Preheat Temp. :

* 32F

Min. Interpass Temp. :

32F

Max. Interpass Temp. :

N/A

POSTION

Groove:

Fillet:

Vertical Progression

ELECTRICAL CHARACTERISTICS

Transfer Mode (GMAW)

Current

Power Source

Other:

Dyansty 350

Tungsten Electrode (GTAW)

TECHNIQUE

Contact to Work Distance:

Interpass Cleaning Method:

POSTWELD HEAT TREATMENT

*If base metal is below 32F, Min. Preheat must be @ 70F

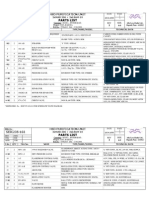

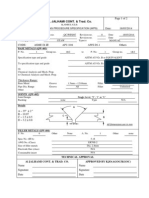

Welding Procedure

Number of Weld Passes:

3

Process:

GTAW

Filler metal Diameter:

3/16"

Amps or Wired Feed Speed:

214-350 AMPS

Volts or Arc Length:

26-32 VOLTS

Travel Speed:

2.5-7.5 IPM

Weld Size:

3/8"

Authorized by:

WPS # Guess

2G

N/A

Up

Down

L CHARACTERISTICS

e (GMAW)

Short-Circuiting

Globular

Spray

AC

DCEP

DCEN X

Pulsed

CC

CV X

yansty 350

ctrode (GTAW)

Size 1/8"

Type 2% Thor

Stringer Bead X

Weave Bead

Number of Passes: 3

Contact to Work Distance: 3/32"

aning Method:

N/A

HEAT TREATMENT

Temp. : N/A

Time: N/A

Kelby Sayer

You might also like

- 3060 Wps 1Document4 pages3060 Wps 1api-280725686No ratings yet

- 3060 Wps 2Document4 pages3060 Wps 2api-280725686No ratings yet

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- PREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONSDocument12 pagesPREQUALIFIED STRUCTURAL WELDING PROCEDURE SPECIFICATIONSwalitedisonNo ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (1)

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- NORTH CAROLINA DEPARTMENT OF TRANSPORTATION ARMOR ANGLE FIELD SPLICE WELDING PROCEDURE SPECIFICATIONDocument3 pagesNORTH CAROLINA DEPARTMENT OF TRANSPORTATION ARMOR ANGLE FIELD SPLICE WELDING PROCEDURE SPECIFICATIONans44155No ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Attached WpsDocument6 pagesAttached WpsnourfarmajidNo ratings yet

- WPS SiloDocument1 pageWPS SiloNidhinkorothNo ratings yet

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- WPS, PQR 041Document21 pagesWPS, PQR 041swamykommula100% (1)

- Approved Structural Steel-Welding Procedures - Stud WeldingDocument3 pagesApproved Structural Steel-Welding Procedures - Stud Weldingans44155100% (2)

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12No ratings yet

- MPCC 20 WPS12Document3 pagesMPCC 20 WPS12hekayat71No ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS PDFDocument1 pageWPS PDFSarah DeanNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS PQRDocument51 pagesWPS PQRLuis Muñoz100% (1)

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- DNO Piping SpecificationDocument2 pagesDNO Piping SpecificationDurgesh GuptaNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Welding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchDocument4 pagesWelding Procedure Specifications (WPS) : Groove Design, Root Spacing As Per The Enclosed SketchaNo ratings yet

- CGC Welding Procedure SpecificationDocument2 pagesCGC Welding Procedure SpecificationErick HoganNo ratings yet

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- SEJC235-102 Parts List: HSD Purification UnitDocument3 pagesSEJC235-102 Parts List: HSD Purification UnitidigitiNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- PQR-WPS-WPQR XXX Rev 0Document6 pagesPQR-WPS-WPQR XXX Rev 0Brett Gosselin100% (1)

- Fermi Lab Orbital Welding ProcedureDocument2 pagesFermi Lab Orbital Welding ProcedurePramod Athiyarathu100% (1)

- Superduplex Welding Procedure Specification (WPSDocument4 pagesSuperduplex Welding Procedure Specification (WPSClaudia Mms100% (3)

- Casting MaterialsDocument42 pagesCasting MaterialsTirta BudiawanNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Scientific American, Vol. XXXIX.—No. 24. [New Series.], December 14, 1878 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesFrom EverandScientific American, Vol. XXXIX.—No. 24. [New Series.], December 14, 1878 A Weekly Journal Of Practical Information, Art, Science, Mechanics, Chemistry, And ManufacturesNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Mfet 3060 Break Test and Macroetch ProcedureDocument2 pagesMfet 3060 Break Test and Macroetch Procedureapi-280725686No ratings yet

- Mfet 3060 WPQRDocument3 pagesMfet 3060 WPQRapi-280725686No ratings yet

- Mfet 3060 Gtaw Test PlanDocument3 pagesMfet 3060 Gtaw Test Planapi-280725686No ratings yet

- Metallurgy Lab 6Document3 pagesMetallurgy Lab 6api-280725686No ratings yet

- Metallurgy Lab 8Document6 pagesMetallurgy Lab 8api-280725686No ratings yet

- Metallurgy Lab 7Document3 pagesMetallurgy Lab 7api-280725686No ratings yet

- Metallurgy Lab 2Document5 pagesMetallurgy Lab 2api-280725686No ratings yet

- Metallurgy Lab 4Document4 pagesMetallurgy Lab 4api-280725686No ratings yet

- Metallurgy Lab 3Document4 pagesMetallurgy Lab 3api-280725686No ratings yet

- Metallurgy Lab 1Document5 pagesMetallurgy Lab 1api-280725686No ratings yet

![Scientific American, Vol. XXXIX.—No. 24. [New Series.], December 14, 1878

A Weekly Journal Of Practical Information, Art, Science,

Mechanics, Chemistry, And Manufactures](https://imgv2-2-f.scribdassets.com/img/word_document/187374175/149x198/94bb94db93/1579716754?v=1)