Professional Documents

Culture Documents

3060 Wps 2

Uploaded by

api-2807256860 ratings0% found this document useful (0 votes)

21 views4 pagesKELBY SAYER I.D. #: 36 Date: 12 / 2 / 2013 Code / Year: AWS D1. / 2004 JOINT DESIGN Pre-Qualified Yes No X Joint Configuration: BUTT JOINT Backing Yes X No Groove Angle: 900 Back Gouging Yes No BASE METAL Mat. : ASTM A36 Thickness: 3 / 8" Diameter (pipe): N / A FILLER metal A

Original Description:

Original Title

3060 wps 2

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentKELBY SAYER I.D. #: 36 Date: 12 / 2 / 2013 Code / Year: AWS D1. / 2004 JOINT DESIGN Pre-Qualified Yes No X Joint Configuration: BUTT JOINT Backing Yes X No Groove Angle: 900 Back Gouging Yes No BASE METAL Mat. : ASTM A36 Thickness: 3 / 8" Diameter (pipe): N / A FILLER metal A

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views4 pages3060 Wps 2

Uploaded by

api-280725686KELBY SAYER I.D. #: 36 Date: 12 / 2 / 2013 Code / Year: AWS D1. / 2004 JOINT DESIGN Pre-Qualified Yes No X Joint Configuration: BUTT JOINT Backing Yes X No Groove Angle: 900 Back Gouging Yes No BASE METAL Mat. : ASTM A36 Thickness: 3 / 8" Diameter (pipe): N / A FILLER metal A

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

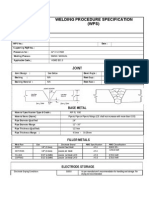

S&S Fabrication

Welding Procedure Specification

Name: KELBY SAYER

I.D. #:

36

Date:

12/2/2013

Code/Year: AWS D1.1/2004

JOINT DESIGN

Pre-Qualified

Yes

No X

Joint Configuration:

BUTT JOINT

Backing

Yes X

No

Root Opening:

3/32"

Root Face Dimension:

0

Groove Angle:

90

Back Gouging

Yes

No

BASE METAL

Mat. Spec. :

ASTM A36

Thickness:

3/8"

Diameter (pipe):

N/A

FILLER METAL

AWS Spec. :

AWS A5.18

AWS Class. :

ER70S-2

SHIELDING GAS

Gas:

ARGON

Composition:

100%

Flow Rate:

20 CFH

PREHEAT

Min. Preheat Temp. :

* 32F

Min. Interpass Temp. :

32F

Max. Interpass Temp. :

N/A

POSTION

Groove:

Fillet:

Vertical Progression

ELECTRICAL CHARACTERISTICS

Transfer Mode (GMAW)

Current

Power Source

Other:

Tungsten Electrode (GTAW)

TECHNIQUE

Contact to Work Distance:

Interpass Cleaning Method:

POSTWELD HEAT TREATMENT

*If base metal is below 32F, Min. Preheat must be @ 70F

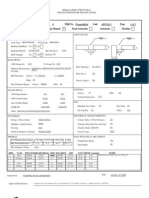

Welding Procedure

Number of Weld Passes:

8

Process:

GTAW

Filler metal Diameter:

3/32"

Amps or Wired Feed Speed:

150-250 A

Volts or Arc Length:

16.5-27.5 V

Travel Speed:

3-5 IPM

Weld Size:

3/8"

Authorized by:

WPS #

Reference PQR #

3

2G

N/A

Up

Down

L CHARACTERISTICS

e (GMAW)

Short-Circuiting

Globular

Spray

AC

DCEP

DCEN X

Pulsed

CC X

CV

ctrode (GTAW)

Size 1/8"

Type 2% THO

Stringer Bead X

Weave Bead X

Number of Passes:

8

Contact to Work Distance: 3/32"

aning Method:

WIRE BRUSH

HEAT TREATMENT

Temp. : N/A

Time: N/A

KELBY SAYER

You might also like

- 3060 Guess WpsDocument4 pages3060 Guess Wpsapi-280725686No ratings yet

- 3060 Wps 1Document4 pages3060 Wps 1api-280725686No ratings yet

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingaamirtec301100% (2)

- Manual Overlay WeldingDocument8 pagesManual Overlay Weldingcarlmac6183% (6)

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (2)

- WPS FormatDocument1 pageWPS FormatAbdullah AnsariNo ratings yet

- Welding Procedure Specification For 24'' PipeDocument2 pagesWelding Procedure Specification For 24'' Pipeenels77100% (1)

- Welding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002Document2 pagesWelding Procedure Specification (WPS) : Code: API Std. 1104 and ASME B31.4/B31.8 M.P.C.C 002shervinyNo ratings yet

- WPS 856110.016 Rev 3Document1 pageWPS 856110.016 Rev 3laz_kNo ratings yet

- WPSDocument1 pageWPSNidhinkorothNo ratings yet

- Approved Structural Steel-Welding Procedures - Armor Angle Field SpliceDocument3 pagesApproved Structural Steel-Welding Procedures - Armor Angle Field Spliceans44155No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Manual Structural WeldingDocument12 pagesManual Structural WeldingwalitedisonNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Attached WpsDocument6 pagesAttached WpsnourfarmajidNo ratings yet

- WPS - D1.1 - Prequalified Procedures QSSLDocument26 pagesWPS - D1.1 - Prequalified Procedures QSSLfazeel mohammedNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- MPCC 20 WPS12Document3 pagesMPCC 20 WPS12hekayat71No ratings yet

- WPS PDFDocument1 pageWPS PDFSarah DeanNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Metrode WPS SuperduplexDocument4 pagesMetrode WPS SuperduplexClaudia Mms100% (3)

- Sample8 DrawingDocument1 pageSample8 DrawingRam Kumar NNo ratings yet

- Approved Structural Steel-Welding Procedures - Stud WeldingDocument3 pagesApproved Structural Steel-Welding Procedures - Stud Weldingans44155100% (2)

- WPS-021, 09.07.07, Page-1Document2 pagesWPS-021, 09.07.07, Page-1nidhinchandranvsNo ratings yet

- WPS GTAW Stainless SteelDocument4 pagesWPS GTAW Stainless SteelAnand NarayananNo ratings yet

- WPS SiloDocument1 pageWPS SiloNidhinkorothNo ratings yet

- Approved Welding Procedures-Rebar Indirect Butt Joint With Splice AngleDocument8 pagesApproved Welding Procedures-Rebar Indirect Butt Joint With Splice Anglecipele12No ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- API Welding ProcedureDocument2 pagesAPI Welding ProcedureSamarakoon BandaNo ratings yet

- WPS 316 LDocument4 pagesWPS 316 Llaz_k100% (2)

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationFranklin londono0% (1)

- P91 WPSDocument6 pagesP91 WPSPepe SagitarioNo ratings yet

- WPS P91Document6 pagesWPS P91JoseAlbertoNeyraNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsManzar KhanNo ratings yet

- Welding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectDocument4 pagesWelding Procedure Specification Joint Venture: Azzawiya Control System Modernization ProjectwentropremNo ratings yet

- Alum 6xxx PwpsDocument1 pageAlum 6xxx PwpsAbu Zahid100% (1)

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- How to prepare Welding Procedures for Oil & Gas PipelinesFrom EverandHow to prepare Welding Procedures for Oil & Gas PipelinesRating: 5 out of 5 stars5/5 (1)

- Pipeline and Energy Plant Piping: Design and TechnologyFrom EverandPipeline and Energy Plant Piping: Design and TechnologyRating: 5 out of 5 stars5/5 (2)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileFrom EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNo ratings yet

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Mfet 3060 Gtaw Test PlanDocument3 pagesMfet 3060 Gtaw Test Planapi-280725686No ratings yet

- Mfet 3060 WPQRDocument3 pagesMfet 3060 WPQRapi-280725686No ratings yet

- Mfet 3060 Break Test and Macroetch ProcedureDocument2 pagesMfet 3060 Break Test and Macroetch Procedureapi-280725686No ratings yet

- Metallurgy Lab 8Document6 pagesMetallurgy Lab 8api-280725686No ratings yet

- Metallurgy Lab 4Document4 pagesMetallurgy Lab 4api-280725686No ratings yet

- Metallurgy Lab 7Document3 pagesMetallurgy Lab 7api-280725686No ratings yet

- Metallurgy Lab 6Document3 pagesMetallurgy Lab 6api-280725686No ratings yet

- Metallurgy Lab 3Document4 pagesMetallurgy Lab 3api-280725686No ratings yet

- Metallurgy Lab 2Document5 pagesMetallurgy Lab 2api-280725686No ratings yet

- Metallurgy Lab 1Document5 pagesMetallurgy Lab 1api-280725686No ratings yet