Professional Documents

Culture Documents

Leaf Spring Catalogue

Uploaded by

RajaSekarsajja0 ratings0% found this document useful (0 votes)

990 views1 pageThis is a catalog of the various springs from the manufacturer.

Original Title

Leaf spring catalogue

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis is a catalog of the various springs from the manufacturer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

990 views1 pageLeaf Spring Catalogue

Uploaded by

RajaSekarsajjaThis is a catalog of the various springs from the manufacturer.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

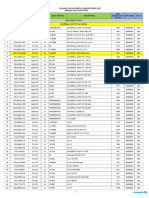

Parabolic Leaf Springs with progressive Characteristics

Drawing no.

item

5.120.26.10

5.120.26.11 E

5.120.26.8

with friction augmentation

with friction augmentation

with friction augmentation

device

device

device

225

225

225

14003

14003

14003

symbol

unit

Max. axle load

kN

Distance between spring eye centers

mm

Eye diameter

mm

36

36

36

Spring height, unloaded

H0

mm

232

240

251

H20

mm

- of the main spring

b x ho

mm

120 x 26

120 x 26

120 x 26

- of the helper spring

b x hu

mm

120 x 40

120 x 40

120 x 40

- of the main spring

no

pieces

- of the helper spring

no

pieces

- of the main spring

Ca1

mm/kN

1,44 7%

1,435 7%

1,43 7%

- of the complete spring

Ca2

mm/kN

0,59 7%

0,59 7%

0,585 7%

- of the main spring

Cz1

mm/kN

1,68 7%

1,74 7%

1,77 7%

- of the complete spring

Cz2

mm/kN

0,55 7%

0,57 7%

0,59 7%

Contact load of the helper spring (in RC)

FE,R

kN

41,2

41

42

Contact load of the helper spring (in LS)

FE,S

kN

38,8

37,6

38

mm

100

Height

mm

170

Length

mm

150

Weight

kg

119

119

119

Remarks

---

---

Replacement for 9

ESMA SJ

Standard GB spring

(in straight condition)

+1

+1

+1

Spring height under 20 kN load

(in roller carriage)

203

+3

-2

211

+3

-2

222

+3

-2

Cross section of spring leaves

Number of leaves

Flexibility (in roller carriage)

Flexibility (in link suspension)

Dimension of the mounted spring buckle:

Width

+4

-2

+3,5

-2

+3,5

-3,5

Leaf TS, 120 x 16

(never produced)

100

170

150

+4

-2

+3,5

-2

+3,5

-3,5

100

170

150

+4

-2

+3,5

-2

+3,5

-3,5

You might also like

- Leaf Spring Catalogue PartDocument20 pagesLeaf Spring Catalogue PartYi Chen0% (1)

- Master-Truck CatalogDocument166 pagesMaster-Truck CatalogVAHAGNNo ratings yet

- Steering System: (Non Tiltable)Document52 pagesSteering System: (Non Tiltable)SiddheshNo ratings yet

- Valmebrochureeng PDFDocument24 pagesValmebrochureeng PDFheri_prasetyadiNo ratings yet

- Runmax Catalog PDFDocument118 pagesRunmax Catalog PDFMijhaelNo ratings yet

- 112Document26 pages112jridi Mouhamed amine100% (1)

- MICO双路制动阀06 466 200 PDFDocument6 pagesMICO双路制动阀06 466 200 PDFKennyNgNo ratings yet

- Leaf Spring Catalogue PartDocument28 pagesLeaf Spring Catalogue PartYi ChenNo ratings yet

- KNOORDocument5 pagesKNOORAmit JainNo ratings yet

- LPT 1613C / LPT 1613C EX: Parts ListDocument394 pagesLPT 1613C / LPT 1613C EX: Parts ListAnkit KapoorNo ratings yet

- Lavjya Parts Catalogue-744fe - 742fe - 855fe-Sept 1713Document199 pagesLavjya Parts Catalogue-744fe - 742fe - 855fe-Sept 1713Nil PhadtareNo ratings yet

- CP - 1st Feb 22 - DS, Axle, Clutch Parts Price ListDocument27 pagesCP - 1st Feb 22 - DS, Axle, Clutch Parts Price ListAmit JainNo ratings yet

- TRF DrawingsDocument4 pagesTRF DrawingssivaNo ratings yet

- Maximum Retail Price List: Moving The Wheels of IndustryDocument22 pagesMaximum Retail Price List: Moving The Wheels of IndustryAlexander David Pino SalazarNo ratings yet

- Falcon BUS CatalogueDocument4 pagesFalcon BUS CatalogueVikky Mehta67% (3)

- Serial Number Range: From SN 4001 To 4550Document228 pagesSerial Number Range: From SN 4001 To 4550jayrreyes12No ratings yet

- Kardánkereszt 2012Document72 pagesKardánkereszt 2012georgeNo ratings yet

- FİLOEX.İVECO تجاريةDocument182 pagesFİLOEX.İVECO تجاريةShaher Al ShaarNo ratings yet

- Tata LPT 70921-30Document10 pagesTata LPT 70921-30Niten GuptaNo ratings yet

- Price List LuK TractorDocument6 pagesPrice List LuK TractorAmit Chopra AmitNo ratings yet

- SparesDocument369 pagesSparesD. Ravi Chander Kumar50% (2)

- OS PR Wheel HubDocument1 pageOS PR Wheel HubirfanNo ratings yet

- Tongyi Tensioner CatalogueDocument17 pagesTongyi Tensioner CataloguetrucktensionerNo ratings yet

- Boschkbx Price 2013 PDFDocument40 pagesBoschkbx Price 2013 PDFvivek0630No ratings yet

- Gs Kamani BushesDocument3 pagesGs Kamani BushesHemant Panpaliya100% (1)

- Khodiyar DSR MHCV Order PAD Q2 2022-23Document14 pagesKhodiyar DSR MHCV Order PAD Q2 2022-23Jayesh PatelNo ratings yet

- sc92f Exploded DrawingsDocument16 pagessc92f Exploded Drawingsapi-194218891No ratings yet

- Catalogo de Partes Xpulse 200 FiDocument100 pagesCatalogo de Partes Xpulse 200 FiRafael Angel Berdugo MuñozNo ratings yet

- Price List W.E.F. 01.08.2021: Authorised Distributor Unipatch Rubber LTDDocument22 pagesPrice List W.E.F. 01.08.2021: Authorised Distributor Unipatch Rubber LTDmanoj_doshi_1No ratings yet

- Leaf Spring Catalogue PartDocument27 pagesLeaf Spring Catalogue PartYi ChenNo ratings yet

- E-Catalog LEAF SPRINGS MERCEDES BENZ AESADocument20 pagesE-Catalog LEAF SPRINGS MERCEDES BENZ AESAMarcelo Furrier RosaNo ratings yet

- Descripition: Oem Part NoDocument60 pagesDescripition: Oem Part NoНурсултан ОразбаевNo ratings yet

- Toyota TGFL PDFDocument7 pagesToyota TGFL PDFluong khanhbanhNo ratings yet

- Clutch 430Document17 pagesClutch 430Shivam GuptaNo ratings yet

- York Trailer Axle Spare Parts ListingDocument12 pagesYork Trailer Axle Spare Parts Listingfahrie_manNo ratings yet

- Prabha Price ListDocument8 pagesPrabha Price ListKeyur PanchalNo ratings yet

- GBDocument36 pagesGBSatya Narayan ShuklaNo ratings yet

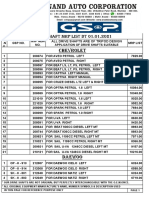

- Anand Sardar - GSP DRIVE SHAFT MRP LIST DT 01.01.2021Document10 pagesAnand Sardar - GSP DRIVE SHAFT MRP LIST DT 01.01.2021sssakol1981100% (1)

- Amw MRP 04.10.2013Document131 pagesAmw MRP 04.10.2013Niten Gupta33% (3)

- 04 CatalogueDocument320 pages04 CatalogueqqqNo ratings yet

- Scania Catalogue - SpringsDocument9 pagesScania Catalogue - SpringsFilipposNo ratings yet

- Bosch Spares Price List 1Document8 pagesBosch Spares Price List 1Venkat CmrlNo ratings yet

- Truck LightsDocument79 pagesTruck LightsarchychenNo ratings yet

- Tata Bearings Application Manual Brochure - 2Document12 pagesTata Bearings Application Manual Brochure - 2bhushan kalwa100% (1)

- Genuine Clutch Part 01.09.2018Document26 pagesGenuine Clutch Part 01.09.2018Venkatesh VNo ratings yet

- MetalcoDocument39 pagesMetalcokumaryoNo ratings yet

- Filter InformationDocument255 pagesFilter InformationHari NotoNo ratings yet

- Luk Price List Nepal 2080 Bageshwari Tractor 9848024782Document30 pagesLuk Price List Nepal 2080 Bageshwari Tractor 9848024782Sandeep SinghalNo ratings yet

- Jungheinrich DFG TFG 540s 545s 550s S50s PDFDocument8 pagesJungheinrich DFG TFG 540s 545s 550s S50s PDFPratik ShahuNo ratings yet

- FD70-100NH CatalogueDocument4 pagesFD70-100NH CatalogueLui DavidNo ratings yet

- Ace 14XW Part BookDocument243 pagesAce 14XW Part Bookasim ghoshNo ratings yet

- Denso Starter 200808Document21 pagesDenso Starter 200808kbron1962No ratings yet

- Dr. Trukk Price List W.E.F. 1st April, 2015. List No: 4Document20 pagesDr. Trukk Price List W.E.F. 1st April, 2015. List No: 4ananth ajithNo ratings yet

- Launch Notes BS6 Apr'22 CV SACDocument5 pagesLaunch Notes BS6 Apr'22 CV SACShambhu Kumar100% (1)

- Gajra Gears MRP W.E.F. 4th June, 2022Document9 pagesGajra Gears MRP W.E.F. 4th June, 2022Lalremruata Singson100% (1)

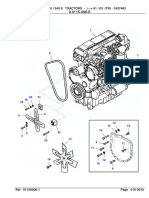

- Massey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)Document15 pagesMassey Ferguson 240 TRACTOR Service Parts Catalogue Manual (Part Number 1637463)zhuangfuqian31No ratings yet

- Parts MriDocument90 pagesParts MriManoj DoshiNo ratings yet

- Bomba de Lodos BH 800 PDFDocument36 pagesBomba de Lodos BH 800 PDFJose Barrero0% (1)

- Spur Gears Component Generator PDFDocument4 pagesSpur Gears Component Generator PDFElieser JúnioNo ratings yet

- Current & Voltage Transducer: Magnetic ComponentsDocument12 pagesCurrent & Voltage Transducer: Magnetic Componentskoral_golNo ratings yet

- Heavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticDocument7 pagesHeavy Vehicle Dynamics Comparison Between Leaf Spring HydropneumaticRajaSekarsajjaNo ratings yet

- Hydro Pneumatic DamperDocument6 pagesHydro Pneumatic DamperRajaSekarsajjaNo ratings yet

- Carbon It RidingDocument3 pagesCarbon It RidingRajaSekarsajjaNo ratings yet

- Nitro - CarburizingDocument9 pagesNitro - CarburizingRajaSekarsajjaNo ratings yet

- Hydro Pneumatic DamperDocument6 pagesHydro Pneumatic DamperRajaSekarsajjaNo ratings yet

- Hytrel Design GuideDocument37 pagesHytrel Design GuidecountzeroaslNo ratings yet

- HEF TreatmentDocument12 pagesHEF TreatmentRajaSekarsajjaNo ratings yet

- Raw 4x4 BrochureDocument1 pageRaw 4x4 BrochureRajaSekarsajjaNo ratings yet

- 021 025Document5 pages021 025marcglebNo ratings yet

- Damping Curves UpdateDocument9 pagesDamping Curves UpdateRajaSekarsajjaNo ratings yet

- Properties of Common Spring MaterialsDocument2 pagesProperties of Common Spring MaterialsArnaldo Morbid CruzNo ratings yet

- Evaluation of Coating PerformanceDocument14 pagesEvaluation of Coating PerformanceRajaSekarsajjaNo ratings yet

- Parabolic Leaf Spring OptimizationDocument8 pagesParabolic Leaf Spring OptimizationRajaSekarsajjaNo ratings yet

- WeldingDocument129 pagesWeldingAnilkumar Cm93% (15)

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaNo ratings yet

- Vehiclestandardscodeofpracticesection 2 Feb 2004Document100 pagesVehiclestandardscodeofpracticesection 2 Feb 2004Abhiyan Anala ArvindNo ratings yet

- Disc Spring SheetDocument2 pagesDisc Spring SheetRajaSekarsajjaNo ratings yet

- Software - Shock Absorber and Vehicle Dynamic SimulationDocument14 pagesSoftware - Shock Absorber and Vehicle Dynamic Simulationnbkate07No ratings yet

- An Introduction To Automotive Suspension SystemsDocument19 pagesAn Introduction To Automotive Suspension SystemsSahil ChouhanNo ratings yet

- Transient Characteristics of A Hydraulically Interconnected Suspension System PDFDocument12 pagesTransient Characteristics of A Hydraulically Interconnected Suspension System PDFmanteghNo ratings yet

- Tubular Piston RodsDocument1 pageTubular Piston RodsRajaSekarsajjaNo ratings yet

- PTFE Piston RingsDocument21 pagesPTFE Piston RingsRajaSekarsajjaNo ratings yet

- Silent Bloc Bushing PDFDocument1 pageSilent Bloc Bushing PDFRajaSekarsajjaNo ratings yet

- Shock Absorber Performance Test Rig: Ubique SystemsDocument1 pageShock Absorber Performance Test Rig: Ubique SystemsRajaSekarsajjaNo ratings yet

- Damper Control ValveDocument2 pagesDamper Control ValveRajaSekarsajjaNo ratings yet

- Dhuaa PDFDocument8 pagesDhuaa PDFAhmadMoaazNo ratings yet

- 3-D Measurements On PistonsDocument4 pages3-D Measurements On PistonsRajaSekarsajjaNo ratings yet

- Damping Force at Zero Velocity ExplainedDocument6 pagesDamping Force at Zero Velocity ExplainedRajaSekarsajjaNo ratings yet

- Where The Graphs Come FromDocument7 pagesWhere The Graphs Come FromRajaSekarsajjaNo ratings yet