Professional Documents

Culture Documents

60CSTL H2S

Uploaded by

Vipin NairOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

60CSTL H2S

Uploaded by

Vipin NairCopyright:

Available Formats

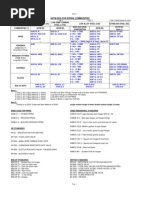

SPECIFICATION NUMBER: 60CSTL-H2S

SERVICE: ASME CLASS 600 HYDROGEN SULFIDE

MAXIMUM HARDNESS: 235 Bhn

STRESS RELIEF: NO (33)

MEETS CODE(S): ASME B31.3

COLOR:

DATE: 1/30/01

PHILTEX/RYTON COMPLEX PIPING SPECIFICATION

MINIMUM C/A: 1/16"

MIN NDE: 100%

PRESSURE/TEMPERATURE

LIMITATIONS:

SIZE

&

ASME CLASS 600

FLANGES

(35) (42)

ASME 600

A105 RF

SW PRF'D

WN - SCH 80

A105 RF

WN

SCH 80

FITTINGS

ELL, TEE,

RED, CAP

SW - A105 3000# PRF'D

SE - DO NOT USE - ALLOW

EXCEPTIONS FOR: EXISTING

EQUIPMENT, PSV'S W/SE, ETC.

BW - A234 WPB SCH 80

SW - A105 3000# PRF'D

SE - DO NOT USE - ALLOW

EXCEPTIONS FOR: EXISTING

EQUIPMENT, PSV'S W/SE, ETC

A234

WPB

SCH 80

CPLGSINLINE

(1)

BRANCH

CONNECT

PIPE

XXXX

10

12

HYDROSTATIC TESTING: YES

14

16

18

20-24

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

USE THE TABLE IN SECTION 3.6 OF THE APPPLICATION GUIDELINES

SEAMLESS UNLESS OTHERWISE SPECIFIED BY PHILLIPS DESIGN ENGINEERING -- COAT & WRAP BURIED PIPE

SIZE

&

NIPPLE

(17)

SMLS

XXXX

SE

BW / SW

A106 B

SW - SCH 80 / SE - SCH160(5)

XXXX

XXXX

10

12

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

XXXX

A106 B STD SMLS / A 53 B STD EFW

A105 SCH 80

BOLTING MATERIAL

WELDOLET & BW ELBOLET 3 IN 6 IN

A105 SCH 80

NUTS

SOCKOLET, THREDOLET, SE & SW

ELBOLET

A105 6000#

GASKETS

SWAGE NIPPLE FOR 2 IN PIPE

20-24

XXXX

WELDOLET & BW ELBOLET 2 IN

(5)

UNIONS

18

XXXX

A106 B

SCH 40

SMLS

BUSHINGS

16

XXXX

A106 B

SCH 80

SMLS

PLUGS, SOLID, ROUND HEAD

14

XXXX

A105 (6) (15)

A105 FOR INSTRUMENT USE ONLY

(16)

FLANGES PRF'D / A105 3000# SW

A234 WPBN SCH 160

TUBING (1/2 & SMALLER)

SWAGELOK TUBING FITTINGS

THREAD COMPOUND

(28)

THERMOWELL CONNECTION

1. A193 B7M WITH GREEN XYLON 1014 OR 1424

COATING PRF'D.

2. A193 B8M CLASS 11 STUD BOLTS

3. NEVER MIX B8M & B7M.

A194 2H HEAVY HEX NUTS WITH GREEN XYLON

1014 OR 1424 COATING, USE COATED ONLY WITH

COATED

BOLTS.316 SS PRF'D.

1.

GRAPHONIC

2. USE 14GA 3003 RING GASKETS ONLY WHERE

GRAPHONICS CAN NOT

BE UTILIZED, BUT

NEVER IN WET H2S SERVICE.

3.

USE316

GRAPHONICS

AT RYTON.

SMLS

STAINLESSWITH

STEELNICKLE

( .035"200

WALL)

316 STAINLESS STEEL

GLADIATOR PASTE PRF'D / RECTORSEAL / VIRGIN

TEFLON

FLANGED

316 THERMOWELL PRF'D

Philtex/Ryton Mechanical Design Engineering must approve any exceptions to these specifications for any job on a case-by-case basis.

60CSTL-H2S

REV: 0

SPECIFICATION NUMBER: 60CSTL-H2S

SERVICE: Error: Reference source not found

DATE: 1/30/01

PHILTEX/RYTON COMPLEX PIPING SPECIFICATION

Valves listed below are preferred Consult the Phillips Engineering Standards for the other acceptable alternatives.

Orbit valves are considered a specialty item consult engineering.

SIZE

GATE

OS&Y

CHECK

(14) (25)

-1

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

BONNET

CONSTRUCT

END CONNECTION

NOTES

BODY MATERIAL

TRIM MATERIAL

SPRING MATERIAL

END CONNECTION

NOTES

A105 (800#)

13% CHROME SS HF

GRAPHITE (23)

WELDED/BOLTED -B7M

W/2HM NUTS

FE PFR'D

(6)

A216 WCB

13% CHROME SS HF

GRAPHITE (23)

BOLTED- B7M W/2HM NUTS

A105 (800#)

13% CHROME SS HF

INCONEL X-750

FE PRF'D

A216 WCB

410 SS

INCONEL X-750

FE

SWING / WAFER

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

END CONNECTION

NOTES

XXXXX

BALL

FIRESAFE

API 607

API 608

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

SEAT MATERIAL

END CONNECTION

NOTES

A105

316 SS

GRAPHITE

SSTL

SE / FE PRF'D

(6)

A105

316 SS

GRAPHITE

SSTL

FE

PLUG

FIRESAFE

API 607

BODY MATERIAL

PLUG MATERIAL

SLEEVE MATERIAL

END CONNECTION

NOTES

XXXXX

XXXXX

GLOBE

BODY MATERIAL

TRIM MATERIAL

PACKING MATERIAL

BONNET

CONSTRUCT

A105 (800#)

13% CHROME SS HF

GRAPHITE (23)

BOLTED - B7M W/2HM

NUTS

FE PRF'D

A216 WCB

13% CHROME SS HF

GRAPHITE (23)

BOLTED B7M W/2HM NUTS

OS&Y

END CONNECTION

NOTES

8 12

FE

BUTTERFLY

FIRESAFE

API 607

API 609

(25)

XXXXX

FE

NOTES

(1)

Use socket weld fittings except in areas where welding is not permitted.

(5) All first take-off piping threaded nipples 1/2" to 1 1/2" to first block valve(s) shall be schedule 160 and stamped "160".

(6) Atmospheric vent and drain valves must be 1", have SE construction on the atmospheric end and must have a solid round plug threaded into it (1/2" on level gage bridles).

(14) Use only spring loaded check valves in vertical lines. Do not install any check valve with normal flow direction being down.

(15) No hexagonal head or hollowed out plugs allowed.

(16) Bushings to be a minimum of two size reductions.

(17) No all thread nipples allowed.

(23)

Valves shall have die formed graphoil rings with braided graphite wiper ring top & bottom, with corrosion inhibitor.

(25) Equipment installed between flanges, i.e., wafer butterfly and check valves and some control valves, requires fire insulation or shielding of the flanges bolts.

(33) Stress relief not required for carbon steel less than 0.750" wall.

(35) For slip-on flanges, leave a 1/4" gap on the back weld or drill an 1/8" hole from the backside to the bore for hydrogen gas to escape.

(42)

Slip-on flanges are to be used only on existing sulfur contaminated piping.

14 - 24

You might also like

- 15CSTL NaDocument3 pages15CSTL NaVipin NairNo ratings yet

- 30S316 H2SDocument2 pages30S316 H2SVipin NairNo ratings yet

- A2 1 16junDocument2 pagesA2 1 16junamitrai86No ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- Water SystemDocument9 pagesWater SystemArun GuptaNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- Internal Normalization Piping Project Specification for Weakly Corrosive HydrocarbonsDocument1 pageInternal Normalization Piping Project Specification for Weakly Corrosive Hydrocarbonsliviu_dovaNo ratings yet

- App B Piping Specifications PDFDocument4 pagesApp B Piping Specifications PDFirawan_epNo ratings yet

- A11Document1 pageA11liviu_dovaNo ratings yet

- 0 UltrastarDocument16 pages0 UltrastarGumersindo MelambesNo ratings yet

- Eaton HansenKingDocument80 pagesEaton HansenKingKING COMERCIAL LTDANo ratings yet

- Cd60 Low Leakage Control DamperDocument3 pagesCd60 Low Leakage Control Dampermorucha_chicleNo ratings yet

- Auto LPG Dispensing Station SpecificationDocument5 pagesAuto LPG Dispensing Station SpecificationShyBokxNo ratings yet

- Steam Line Mechanical DistributionDocument25 pagesSteam Line Mechanical DistributionNAYEEMNo ratings yet

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocument643 pages6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85No ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- BelGAS P627 2014 RegulatorDocument10 pagesBelGAS P627 2014 RegulatorkaviarasuNo ratings yet

- Horizontal Condensate Collection Manifold - FabricatedDocument2 pagesHorizontal Condensate Collection Manifold - Fabricatedkresimir.mikoc9765No ratings yet

- C 316SFeb2008Document2 pagesC 316SFeb2008Mano NegraNo ratings yet

- Engineering Considerations for Sour Gas TrapsDocument4 pagesEngineering Considerations for Sour Gas TrapsbloggerparthiNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Spirax Sarco Ball Float PDFDocument12 pagesSpirax Sarco Ball Float PDFchanayireNo ratings yet

- PCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Document6 pagesPCSE-100-ET-C-024:: Perú Camisea Second Expansion (Pcse)Moises Alvarez LeandroNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Valves & ControlsDocument16 pagesValves & ControlseborresonNo ratings yet

- Ep33411 b11Document9 pagesEp33411 b11salamrefighNo ratings yet

- Valve Trim Temperatur e Range °F Design Code Rev. #Corr. Allow. (In) Service Pressure Rating Material Piping Mat'l ClassDocument42 pagesValve Trim Temperatur e Range °F Design Code Rev. #Corr. Allow. (In) Service Pressure Rating Material Piping Mat'l ClassJuan Carlos ValderramaNo ratings yet

- 01SD0J01Document5 pages01SD0J01raobabar21No ratings yet

- Yanbu: Export Refinery ProjectDocument6 pagesYanbu: Export Refinery ProjectJanakiraman MalligaNo ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Series LF860 Specification SheetDocument2 pagesSeries LF860 Specification SheetFEBCONo ratings yet

- rc61180 b09Document9 pagesrc61180 b09eww08No ratings yet

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- A17Document1 pageA17liviu_dovaNo ratings yet

- Valve Spirax Sarco 25P Ti-3-015-UsDocument2 pagesValve Spirax Sarco 25P Ti-3-015-Ussugesus100% (2)

- 01SD1B02Document5 pages01SD1B02raobabar21No ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Top Guide Control ValveDocument32 pagesTop Guide Control Valveachari_swapnilNo ratings yet

- Flange Selection GuideDocument11 pagesFlange Selection GuidebandithaguruNo ratings yet

- D11Document1 pageD11liviu_dovaNo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Codeline, 150 PSI, Drawing - 80S15Document3 pagesCodeline, 150 PSI, Drawing - 80S15RamanNegiNo ratings yet

- CS310ADocument4 pagesCS310Arabacet2923No ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- Piping Shortage MaterialDocument12 pagesPiping Shortage MaterialAnonymous i3lI9MNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- 3., 4., & 9. RBXC Catalogue Local 2015Document16 pages3., 4., & 9. RBXC Catalogue Local 2015Nilesh RanadeviNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- Compact Block & Bleed ValveDocument20 pagesCompact Block & Bleed Valverawrr90No ratings yet

- Astm Nos For PipingDocument6 pagesAstm Nos For PipingJessica HerringNo ratings yet

- ROV Actuator DatasheetDocument5 pagesROV Actuator DatasheetNawfel ArafathNo ratings yet

- Class 61502 Carbon Steel Piping Design LimitsDocument10 pagesClass 61502 Carbon Steel Piping Design LimitsbalajivangaruNo ratings yet

- United Insulation DocumentsDocument168 pagesUnited Insulation Documentsjsherrer1No ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- 8311 Pressure Regulators Technical BulletinDocument16 pages8311 Pressure Regulators Technical BulletinEduardo RodriguesNo ratings yet

- 01CS1S02Document5 pages01CS1S02raobabar21No ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Input FileDocument10 pagesInput FileVipin NairNo ratings yet

- X-1-Estimating Tool - Rev 0Document10 pagesX-1-Estimating Tool - Rev 0Vipin NairNo ratings yet

- Blackjack Cheat Sheet PDF Color PDFDocument1 pageBlackjack Cheat Sheet PDF Color PDFVipin NairNo ratings yet

- Corsair 7 MIRs Feb 20 Feb 2717 NM 13 UsDocument1 pageCorsair 7 MIRs Feb 20 Feb 2717 NM 13 UsVipin NairNo ratings yet

- Steel Cals SimpleDocument53 pagesSteel Cals SimpleVashish RamrechaNo ratings yet

- Circuitization Project Workflow GuideDocument1 pageCircuitization Project Workflow GuideVipin NairNo ratings yet

- Stream Inspection Criteria FormDocument4 pagesStream Inspection Criteria FormVipin NairNo ratings yet

- DIY Cloth Face Covering Instructions PDFDocument3 pagesDIY Cloth Face Covering Instructions PDFnathanNo ratings yet

- 965 B10193 05,00Document1 page965 B10193 05,00Vipin NairNo ratings yet

- Texas MudHensDocument1 pageTexas MudHensVipin NairNo ratings yet

- Xref Lines Not in LCI DBDocument8 pagesXref Lines Not in LCI DBVipin NairNo ratings yet

- CUI Project ExchnagersDocument5 pagesCUI Project ExchnagersVipin NairNo ratings yet

- Static Head Calculation For B-31Document1 pageStatic Head Calculation For B-31Vipin NairNo ratings yet

- Terminal 3 Map2 - 2015 - R3 - tcm13-4102Document2 pagesTerminal 3 Map2 - 2015 - R3 - tcm13-4102Vipin NairNo ratings yet

- Management of Critical Process Equipment To Ensure It Is Designed and Installed Correctly, and That It Operates and Is Maintained ProperlyDocument2 pagesManagement of Critical Process Equipment To Ensure It Is Designed and Installed Correctly, and That It Operates and Is Maintained ProperlyVipin NairNo ratings yet

- Synthron Final Report1 PDFDocument17 pagesSynthron Final Report1 PDFVipin NairNo ratings yet

- Sphere MAWPDocument2 pagesSphere MAWPVipin NairNo ratings yet

- Vibration Related Failures of Small Bore AttachmentsDocument13 pagesVibration Related Failures of Small Bore AttachmentsJose PradoNo ratings yet

- LWN TablesDocument7 pagesLWN TablesVipin NairNo ratings yet

- Excel VBA For Dummies. BonusChapter02Document4 pagesExcel VBA For Dummies. BonusChapter02nick_giannNo ratings yet

- 05 Minor Moc SDR FormDocument23 pages05 Minor Moc SDR FormVipin NairNo ratings yet

- A-18 Top HeadDocument1 pageA-18 Top HeadVipin NairNo ratings yet

- PVElite Installation MethodDocument1 pagePVElite Installation MethodadnaniaziNo ratings yet

- Pressure Vessel MI Field TemplateDocument1 pagePressure Vessel MI Field TemplateVipin NairNo ratings yet

- Redlined DWGDocument1 pageRedlined DWGVipin NairNo ratings yet

- College Engineering Commencement TicketDocument1 pageCollege Engineering Commencement TicketVipin NairNo ratings yet

- E Battery TanksDocument8 pagesE Battery TanksVipin NairNo ratings yet

- How To Practice Self Care - WikiHowDocument7 pagesHow To Practice Self Care - WikiHowВасе АнѓелескиNo ratings yet

- The Impact of StressDocument3 pagesThe Impact of StressACabalIronedKryptonNo ratings yet

- Activity No 1 - Hydrocyanic AcidDocument4 pagesActivity No 1 - Hydrocyanic Acidpharmaebooks100% (2)

- Solcon Catalog WebDocument12 pagesSolcon Catalog Webquocviet612No ratings yet

- Carpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesDocument105 pagesCarpentry Shop: Building, Doors, Windows, Trusses, WorkbenchesVinod KumarNo ratings yet

- Arp0108 2018Document75 pagesArp0108 2018justin.kochNo ratings yet

- Chapter 3 - CT&VT - Part 1Document63 pagesChapter 3 - CT&VT - Part 1zhafran100% (1)

- FileDocument284 pagesFileJesse GarciaNo ratings yet

- Piping Material Classes GuideDocument98 pagesPiping Material Classes GuideLuis Pottozen VillanuevaNo ratings yet

- Retail Management PPT1Document14 pagesRetail Management PPT1Srilekha GubbalaNo ratings yet

- Reach Out and Read Georgia Selected For AJC Peachtree Road Race Charity Partner ProgramDocument2 pagesReach Out and Read Georgia Selected For AJC Peachtree Road Race Charity Partner ProgramPR.comNo ratings yet

- Request Baha Alert PPMPDocument3 pagesRequest Baha Alert PPMPLö Räine AñascoNo ratings yet

- HierbasDocument25 pagesHierbasrincón de la iohNo ratings yet

- TSS-TS-TATA 2.95 D: For Field Service OnlyDocument2 pagesTSS-TS-TATA 2.95 D: For Field Service OnlyBest Auto TechNo ratings yet

- MEDICO-LEGAL ASPECTS OF ASPHYXIADocument76 pagesMEDICO-LEGAL ASPECTS OF ASPHYXIAAl Giorgio SyNo ratings yet

- Theories of Motivation and Child Moral DevelopmentDocument5 pagesTheories of Motivation and Child Moral DevelopmentPamela mirandaNo ratings yet

- Tumors of The Central Nervous System - VOL 12Document412 pagesTumors of The Central Nervous System - VOL 12vitoNo ratings yet

- 4.5 Cargo DischargingDocument2 pages4.5 Cargo DischargingHasan Cosalev100% (1)

- 1 Colmac DX Ammonia Piping Handbook 4th EdDocument64 pages1 Colmac DX Ammonia Piping Handbook 4th EdAlbertoNo ratings yet

- Roadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostDocument4 pagesRoadblocks Overcome Cruise PurchaseTITLE Top 15 Cruise Hesitations Answered TITLE How to Convince People Cruises Worth CostJanel Castillo Balbiran33% (3)

- Position paper-MUNUCCLE 2022: Refugees) Des États !Document2 pagesPosition paper-MUNUCCLE 2022: Refugees) Des États !matNo ratings yet

- A. Kumar Aswamy Job Offer LetterDocument1 pageA. Kumar Aswamy Job Offer LetterHimanshu PatelNo ratings yet

- Antenna LecDocument31 pagesAntenna Lecjosesag518No ratings yet

- Abortion and UtilitarianismDocument4 pagesAbortion and UtilitarianismBrent Harvey Soriano JimenezNo ratings yet

- Critical Criminal Justice IssuesDocument132 pagesCritical Criminal Justice IssuesAnnamarella Amurao CardinezNo ratings yet

- Treatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Document5 pagesTreatment of Fruit Juice Concentrate Wastewater by Electrocoagulation - Optimization of COD Removal (#400881) - 455944Victoria LeahNo ratings yet

- Grab Go Porter S 5 ForcesDocument2 pagesGrab Go Porter S 5 ForcesUtkarsh SharmaNo ratings yet

- The Girls Center: 2023 Workout CalendarDocument17 pagesThe Girls Center: 2023 Workout Calendark4270621No ratings yet

- Soal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020Document5 pagesSoal UTS Bahasa Inggris SMP Semester Genap Tahun Ajaran 2020awan MustofaNo ratings yet

- New930e-4se Ceam031503 930e4se Omm A31937 Up PDFDocument273 pagesNew930e-4se Ceam031503 930e4se Omm A31937 Up PDFSergelen SakhyabazarNo ratings yet