Professional Documents

Culture Documents

Film Artifacts RFI

Uploaded by

NDTInstructor0 ratings0% found this document useful (0 votes)

46 views5 pagesfilm artifacts

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentfilm artifacts

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

46 views5 pagesFilm Artifacts RFI

Uploaded by

NDTInstructorfilm artifacts

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

Part 5. Radiographic Artifacts

Indication Description

Because most nenrdevant indications can

be readily related to their actual causes,

this category of indications is

comparatively easy to interpret. False and

actual discontinuity indications will be

presented here to provide guidance for

the radiographic film interpreter.

The interpretation of radiographs is not

a procise science. As mentioned earlier in

this chapter, even those qualified film

interpreters with years of experience will

often disagree on the nature of

discontinuities and their disposition. The

descriptions and illustrations"? contained

in this chapter may be used as a general

guideline to help identify similar

indications encountered during the

interpretation process.

False Indications (Film

Artifacts)

The radiographic process is very intolerant

of dirt and careless handling of the

recording media. Violations of good

darkroom practice in film loading

Unloading and processing will result in

artifacts that must be recognized for what

they are, not what they may appear to be.

Erroneous interpretations may be made

as the result of not recognizing artifacts.

Emulsion scratches are a common cause

of such misinterpretation. These and

‘many other artifacts are quickly

recognizable by viewing both surfaces of

the film with reflected light.

The double film technique is one of

the most effective steps in recognizing

artifacts, by simply comparing the area of

interest on both films. If the indication is

fon one film and not the other, is not in

the same place or has changed in

appearance, itis an artifact.

‘There are many different types of

artifacts, some of which can be confused

with actual discontinuities. It is extremely

important to identify these false

indications and to note their presence in

the film interpreters report. In some cases

the existence of artifacts in the area of

interest may require reradiography. Itis

therefore important to take every

reasonable step to minimize artifacts.

202 Radiographic Testing

Artifacts Caused before

Processing

ilm Scratches

Radiographic film emulsion is quite

sensitive and scratches can be caused by

most abrasive materials; fingernails and

rough handling during loading or

unloading are examples. Film seratches

can be identified by reflecting light at an

langle to the film surface.

Crimp Marks

(Crimp marks are caused by bending the

film abruptly, usually when loading and

unloading the film Rolder. Ifthe film is

crimped before exposure, it will produce a

‘erescent shaped indication that is lighter

in density than the adjacent film density

(Fig 14). Iferimped after exposure, the

film will produce an indication that is

darker than the adjacent film density.

Ficune 14. Crimp marks resulting from poor handling of

individual sheet of fim: (2) before exposure; (b) aftr

exposure.

@ Oo)

Pressure Marks

Pressure marks are caused by severe

localized applications of pressure to the

film. For example, a part may be dropped

fon the film holder during setup. This wil

produce an artifact. on the processed film

Fig 19).

Static Marks

‘Static charges may develop when the

radiographic film is handled roughly or

moved rapidly during loading or

Unloading the film holder. It may also be

caused by rapid removal of the paper

wrapper used as an interleaf. The

‘appearance of static marks will range from

branchlike, jagged dark lines to irregular,

abrupt dark spots.

Screen Marks

Scratches and other blemishes in a lead

screen will become intensified and can

create significant indications on the film

image. This may be especially noticeable

when the film older containing the lead

screens is bent to accommodate part

configuration. Dirt on fluorescent screens

‘will interfere with light transmission to

the film and a light area will result after

the film is processed. Dirt on lead screens

interferes with electron bombardment of

the film and also produces a light area in

the image (Fig. 16). Screens should have a

unique serial number inscribed in a corner

to identify these problems and to make it

‘easier to locate the faulty screen.

‘Small bits of foreign material (such as

lint, tobacco, paper or dandruff) between

the film and fluorescent or lead screens

will cause light spots in the processed

film. To minimize false indications from

Ficure 18. Pressure mark caused before

‘exposure, visible as low density.

screens, itis imperative that they be

absolutely clean, smooth, free of

imperfections and foreign matter.

‘A word of caution: manufacturers of

screens often apply a thin plastic coating

to protect the sereen from scratches,

during processing. This coating must be

removed before using a new screen as it

will absorb much of the emissions that

would otherwise provide the desired

intensification.

Fog

Fogis an overall, small density increase

caused when unexposed film is exposed

to some chemicals, low levels of radiation,

high humidity, small darkroom light leaks

for an inadequate safelight. Information

regarding safe light intensity limits can be

obtained from the film manufacturer.

Light Leaks

Exposure to light usually results in

noticeable local film blackening (Fig. 17).

Ficure 16, Words front and back scratched in

the surface of front and back lead foi

screens before radiography of a 25 mm

(1.0 in.) welded steol plate. Hairs placed

‘between respective screens and film are

visible as light marks preceding inscribed

words,

Figure 17. Light leaks.

_—a. | ~«S

Radiographic interpretation 203,

Film holders should be examined

rogularly to eliminate the problem.

Finger Marks

‘Marks such as fingerprints are normally

easy to recognize. They may be darker or

lighter images on the film.

Artifacts Caused during

Processing

Chemical Streaks

During manual processing, streaks on the

film may result if cher

processing are not adequ:

from the hanger clips Fig. 18). Overall

film streaking may also result when th

film is placed directly into a water rinse

without first placing!t into the stop bath

solution. Developer carryover into the

fixer may cause an overall streaking

condition. A further cause of streaking is

insufficient agitation of the film hanger

during development.

Spotting

If fixer solution comes in contact with the

film before development, light areas or

spots will result (Fig. 19). If drops of

developer or water inadvertently reach the

film before placing it into the developer,

dark spots can result (Fig. 20).

Ficure 18. Streaking caused by inadequately

cleaned film hangers.

204 Radiographic Testing

Ficure 19, Light spots caused before

‘development: (a) by stop bath splashed on

film; (B) by fixer splashed on film.

@

Ficure 20. Dark spots caused before

development: (a) by water splashed on film;

(©) by developer splashed on fim.

@

©)

Another spotting condition may occur

from water droplets on the film surface.

During the drying process, these droplets,

take longer to dry and leave a distinet

circular pattern on the film surface. Water

spots can be reduced by using a wetting

‘agent before drying,

Delay Streaks

‘Those are uneven streaks in the direction

of film movement through an automatic

[processor. A delay in feeding successive

films may result in the drying of solutions

‘on the processor rollers. Cleaning the

‘exposed rollers with a damp cloth should

eliminate delay streaks.

ir Bells

Air balls are caused by air bubbles clinging

to the surface of the film when it is

immersed in the developer. An air bell

[prevents developer from reaching the film

surface, thus causing light spots on the

film image. If the film hanger is tapped

abruptly against the side of the tank then

properly agtated, the air bubbles should

‘become dislodged.

Dirt

If dirt or other contaminants accumulate

‘on the surface of the developer or fixer, a

hoticaably dirty pattor will probably

‘appear on the film. Ifthe rinse water is

‘Rot adequately replenished, it can also

cause a similar problom, especially ifthe

jwater coming into the wash tank Ts dirty

and filtration is not used (Fig. 21). This

Condition ean be verified by observing the

surface of the film in reflected light.

a

Ficure 21. Surface deposits caused by

contaminated wash water in automatic

Pi Lines

These lines run across the film,

perpendicular to the direction of rolling

When an automatic processor is used,

They occur at regularly spaced intervals,

3.14 times the roller diameter. This

Condition is apparently caused by a slight

it of chemicals on the rollers by the

leading edge of the film (Fig. 22).

Pressure Marks

Pressure marks may be caused by a buildup

of foreign matter On rollers in an

automatic processor or by inadequate

clearances betweon rollers. Rollers should

be thoroughly cleaned and properly

adjusted to minimize this condition

ig. 23).

Kissing

Film that comes in contact with other

film, especially in the developer during

‘manual processing, will result in a severe

blotch in the area of contact.

Ficure 22. Pi lines. Two oF more lines recur

at interval of x x roller diameter.

Ficure 23, Pressure marks caused by foreign

‘matter on rollers oF improper roller

clearance.

Radiographic Interpretation 205

Artifacts Caused after

Processing

Scratches

Scratches result from rough handling.

Even after processing, the emulsion is

sensitive to all types of abrasion and care

should be taken to minimize damage to

the emulsion.

Fingerprints

These occur when improperly handling

the film, as can happen during

interpretation. Film should be handled

with care by the edges or comers

Whenever possible. To prevent

fingerprints, radiographs should be

handled with cotton or nylon gloves.

Radioscopic Artifacts

Radioscopic artifacts are also operator

dependent and must be recognized. They

are caused primarily by electronic noise

{generated in video systems and can be

Corrected by filtering, Dust on the lens

surface is another common cause of real

time artifacts. When using image

enhancement techniques on radiographs,

a very careful examination of the film

should be made to identify all artifacts

before enhancement. Otherwise, the

artifacts will also be enhanced and could

possibly be difficult to identity in

Subsequent evaluations, This is also true

when radiographs are duplicated or

microfilmed.

206 Radiographic Testing

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Color Vision TestDocument1 pageColor Vision TestNDTInstructorNo ratings yet

- PAUT Vs RadiographyDocument1 pagePAUT Vs RadiographyNDTInstructorNo ratings yet

- TunisiaDocument4 pagesTunisiaNDTInstructorNo ratings yet

- Color Vision TestDocument1 pageColor Vision TestNDTInstructorNo ratings yet

- NigieriaDocument12 pagesNigieriaNDTInstructorNo ratings yet

- Forging DefectsDocument1 pageForging DefectsNDTInstructor0% (1)

- A309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2Document1 pageA309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2NDTInstructorNo ratings yet

- Piping 4Document1 pagePiping 4NDTInstructorNo ratings yet

- Job Description NDTDocument4 pagesJob Description NDTNDTInstructorNo ratings yet

- Piping 3Document1 pagePiping 3NDTInstructorNo ratings yet

- Piping 4Document1 pagePiping 4NDTInstructorNo ratings yet

- Inspections and Audits For Boilers and Pressure VesselsDocument2 pagesInspections and Audits For Boilers and Pressure VesselsNDTInstructorNo ratings yet

- H300 Introduction (Si Units) : Para. 304.3.3Document2 pagesH300 Introduction (Si Units) : Para. 304.3.3NDTInstructorNo ratings yet

- (A) Elastic Behavior. The Assumption That DisplaceDocument1 page(A) Elastic Behavior. The Assumption That DisplaceNDTInstructorNo ratings yet

- Eddify Lyft Presentation DocumentDocument4 pagesEddify Lyft Presentation DocumentBernardo FariasNo ratings yet

- MTDocument1 pageMTNDTInstructorNo ratings yet

- 344.2 Visual Examination: Para. 344.7Document1 page344.2 Visual Examination: Para. 344.7NDTInstructorNo ratings yet

- General TankDocument2 pagesGeneral TankNDTInstructorNo ratings yet

- Tank Inspection SolutionDocument7 pagesTank Inspection SolutionNDTInstructorNo ratings yet

- Shell Settlement EvaluationDocument1 pageShell Settlement EvaluationNDTInstructorNo ratings yet

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Olympus Multiscan Ms 5800 Er1uDocument2 pagesOlympus Multiscan Ms 5800 Er1uNDTInstructorNo ratings yet

- Procedure CFVDocument13 pagesProcedure CFVNDTInstructorNo ratings yet

- Api 580Document1 pageApi 580NDTInstructorNo ratings yet

- Optimized Performance For Wall Thickness and LiftoffDocument1 pageOptimized Performance For Wall Thickness and LiftoffNDTInstructorNo ratings yet

- Job Hazard AnalysisDocument5 pagesJob Hazard AnalysisNDTInstructorNo ratings yet

- Solutionstainlesssteelweldinspection 170124181624Document13 pagesSolutionstainlesssteelweldinspection 170124181624NDTInstructorNo ratings yet

- Vision CertificateDocument1 pageVision CertificateNDTInstructorNo ratings yet

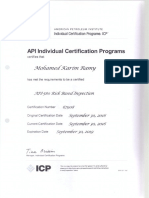

- API Individual Certification Programs: Mohamed Karim RamyDocument1 pageAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNo ratings yet

- API Individual Certification Programs: Mohamed Karim RamyDocument1 pageAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)