Professional Documents

Culture Documents

Scope: (B) Tank Strapping Includes The Following Measurements

Uploaded by

EIWAAOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Scope: (B) Tank Strapping Includes The Following Measurements

Uploaded by

EIWAACopyright:

Available Formats

Scope

1. This standard describes the procedures for calibrating upright cylindrical tanks larger than a

barrel or drum.

Definitions

2. (a) Tank strapping is the term commonly applied to the procedure for the measurement of

tanks to provide the dimensions necessary for the computation of gage tables. These tables will

show the quantity of oil in a tank at any given depth.

(b) Tank strapping includes the following measurements:

(1) Depth.4heli height, oil height, ring height, equalizer line height, and gaging height.

(2) Thickness of Tank Walls.-Stave thickness and metal thickness.

(3) Circumferences of Tank at Specified Locations.

(4) Deadwood.-Any object within the tank, including a floating roof, which displaces liquid and

reduces the capacity of the tank; also any permanent appurtenances on the outside of the tank,

such as cleanout boxes or manholes, which increase the capacity of the tank.

Significance

Accurate tank calibration are a most important factor in liquid volume determinations, for the

reason that an incorrect dimension results in an erroneous gage table, which might be in use over

an extended period of time before the error is discovered. In most cases, the person who

computes the gage tables is not the one making the actual field measurements and has no direct

means of checking such measurements; therefore, this person must depend upon the tank

strapper for accurate measurements. Errors in gage tables cause the accounting of tank contents

to be inaccurate; therefore, payments are subject to question. Settlements involving such errors

are very difficult, and sometimes impossible, to adjust without loss to one of the parties involved.

As the procedure for taking measurements and the achievement of accuracy in tank strapping are

so important, ail such measurements should be witnessed by all parties interested in the

subsequent measurement of quantities in the tanks being strapped. It is hoped that the foregoing

will provide an adequate idea of the extreme importance of correctness in this particular detail.

Calibration Process Parameters

You might also like

- Standards Update Notice (Sun) ISSUED: July 8, 2020: Standard InformationDocument3 pagesStandards Update Notice (Sun) ISSUED: July 8, 2020: Standard InformationvpjagannaathNo ratings yet

- Magnetic Particle Process Guide: Nonfluorescent/Visible Color FluorescentDocument1 pageMagnetic Particle Process Guide: Nonfluorescent/Visible Color FluorescentLion A-jNo ratings yet

- Electric Hoists PDFDocument18 pagesElectric Hoists PDFedark2009No ratings yet

- Valve Testing & Seat Leakage Comparism PDFDocument6 pagesValve Testing & Seat Leakage Comparism PDFAnupmaNo ratings yet

- PDVSA 0602.1.472 Dikes For Storage Tanks 6pDocument6 pagesPDVSA 0602.1.472 Dikes For Storage Tanks 6pIsmar AdrianNo ratings yet

- Technical Brief Sphere Leg Inspection PDFDocument1 pageTechnical Brief Sphere Leg Inspection PDFThiru RajaNo ratings yet

- 13.api 570 Open BookDocument60 pages13.api 570 Open BookAMAL VISHNUNo ratings yet

- Field inspection report for aggregate sieve analysisDocument1 pageField inspection report for aggregate sieve analysisMOST PASONNo ratings yet

- PDF Material Handling SafetyDocument40 pagesPDF Material Handling SafetyAtif RazaNo ratings yet

- ULTRASONIDODocument248 pagesULTRASONIDOJorge Vera Alvarado0% (1)

- Installation and Maintenance of Inline Flame ArrestorsDocument3 pagesInstallation and Maintenance of Inline Flame Arrestorshk168No ratings yet

- List of Equipment Used For Tank CalibrationDocument1 pageList of Equipment Used For Tank CalibrationAmit HasanNo ratings yet

- PPSC - Product Data Sheet Fusion Bonded EpoxyDocument1 pagePPSC - Product Data Sheet Fusion Bonded EpoxyjulianpirahNo ratings yet

- Garlock gasket M & Y values for flange designDocument3 pagesGarlock gasket M & Y values for flange designGanesh.MahendraNo ratings yet

- Volume in Tank Using PressureDocument2 pagesVolume in Tank Using PressureJacques J PienaarNo ratings yet

- Consequences and Standards From Using CP Systems To Prevent CorrosionDocument7 pagesConsequences and Standards From Using CP Systems To Prevent CorrosionAdnan RanaNo ratings yet

- Cadweld Soldadura Exotermica PDFDocument34 pagesCadweld Soldadura Exotermica PDFMercedes Dueñas LlanosNo ratings yet

- Storage Tank Inspection and Calibration Using Laser Scanning and Trimble RealworksDocument42 pagesStorage Tank Inspection and Calibration Using Laser Scanning and Trimble RealworksMahmoud GaberNo ratings yet

- Tank SettlementDocument6 pagesTank SettlementkorichiNo ratings yet

- Timesheet Form Name of Employee: Name of Project Employee Register: Calender Month and Year: Jul-17Document12 pagesTimesheet Form Name of Employee: Name of Project Employee Register: Calender Month and Year: Jul-17Agus FerdianNo ratings yet

- Pressure Vessel Dimension InspectionDocument3 pagesPressure Vessel Dimension InspectionAnas Sarkiah0% (1)

- Ipc2012 90450Document7 pagesIpc2012 90450Marcelo Varejão CasarinNo ratings yet

- API 570 Exam Prep TrainingDocument3 pagesAPI 570 Exam Prep Trainingalouis100% (1)

- Price List For CAREDocument2 pagesPrice List For CARESaurabh SrivastavaNo ratings yet

- API 653 Certification Data Sheets DimensionsDocument12 pagesAPI 653 Certification Data Sheets DimensionsBrian CaseNo ratings yet

- Effect Analysis of An Arc-strike-Induced Defect On The Failure of A Post-Tensioned ThreadbarDocument9 pagesEffect Analysis of An Arc-strike-Induced Defect On The Failure of A Post-Tensioned ThreadbarnaderbahramiNo ratings yet

- Article 4 Metodo UltrasonidoDocument24 pagesArticle 4 Metodo UltrasonidoLessly Lorena Apala RamirezNo ratings yet

- API 1104 Reading ChecklistDocument2 pagesAPI 1104 Reading Checklistbacabacabaca100% (2)

- Cathodic Protection 2015Document21 pagesCathodic Protection 2015ainunNo ratings yet

- Cyclohexane Storage Tank (T-102) : Technological Institute of The PhilippinesDocument18 pagesCyclohexane Storage Tank (T-102) : Technological Institute of The PhilippinesEUNICE ANGELA LASCONIANo ratings yet

- API-653 ASTI In-service Exam TrainingDocument2 pagesAPI-653 ASTI In-service Exam TrainingalgoreNo ratings yet

- BLADDER TANK PROPORTIONING SYSTEMDocument12 pagesBLADDER TANK PROPORTIONING SYSTEMakshay MahajanNo ratings yet

- CO Dept of Labor AST Inspection RequirementsDocument6 pagesCO Dept of Labor AST Inspection RequirementsalgoreNo ratings yet

- Rstreng PDFDocument5 pagesRstreng PDFwellyNo ratings yet

- Arc StrikeDocument9 pagesArc StrikeBulut YildizNo ratings yet

- Attachment 06 - API 18LCM Report Out Aug 2015Document10 pagesAttachment 06 - API 18LCM Report Out Aug 2015Erika MaraNo ratings yet

- ch4 - API 574 PDFDocument6 pagesch4 - API 574 PDFRAMADOSSNo ratings yet

- AD250 Wireless Datasheet WebDocument12 pagesAD250 Wireless Datasheet WebArumugam RajendranNo ratings yet

- Tank ModelDocument26 pagesTank Modelnippo123No ratings yet

- Manual of Petroleum Measurement StandardsDocument20 pagesManual of Petroleum Measurement StandardsPedro Pablo Nuñez LeonNo ratings yet

- (MFL) Arkaline IranDocument12 pages(MFL) Arkaline IranFrank MosesNo ratings yet

- The New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsDocument3 pagesThe New 3rd Edition of The ALPEMA Plate-Fin Heat Exchanger StandardsvheshaghianNo ratings yet

- 1st April 2021 653 PaperDocument7 pages1st April 2021 653 Papermohamed haMEEM100% (1)

- QW 423.1 InterpretationDocument1 pageQW 423.1 InterpretationZaheed ManooNo ratings yet

- API 510 Data Sheet - AnswersDocument6 pagesAPI 510 Data Sheet - Answersjithinjose86No ratings yet

- Case Study 4Document2 pagesCase Study 4Ahmed shabanNo ratings yet

- Mechanical Assembly ProcedureDocument9 pagesMechanical Assembly ProcedurenrqmNo ratings yet

- Haward Technology Middle East Point Enginee Technology Middle East 77 Pe120Document203 pagesHaward Technology Middle East Point Enginee Technology Middle East 77 Pe120alexverde3No ratings yet

- Api 653 Daily Points To Recall (Day 3)Document2 pagesApi 653 Daily Points To Recall (Day 3)Naveed Ahmed100% (1)

- API 510 Data Sheet Study GuideDocument1 pageAPI 510 Data Sheet Study Guideads_1203No ratings yet

- Mechanical Damage Workshop & Study Phase 1 Workshop Executive SumDocument17 pagesMechanical Damage Workshop & Study Phase 1 Workshop Executive SumLilyShiNo ratings yet

- Uphill Versus Downhill Welding PDFDocument4 pagesUphill Versus Downhill Welding PDFPatrick DominguezNo ratings yet

- 3D Laser Scanning Tank Inspection and CalibrationDocument7 pages3D Laser Scanning Tank Inspection and CalibrationOkayNo ratings yet

- Konet PresentationDocument28 pagesKonet PresentationKrishna MoorthyNo ratings yet

- API-650 Peaking & BandingDocument4 pagesAPI-650 Peaking & BandingSamet BelliNo ratings yet

- (GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Document3 pages(GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Said ArjonaNo ratings yet

- API 653 Daily PointsDocument4 pagesAPI 653 Daily Pointsraobabar21No ratings yet

- Infrared ThermographyDocument21 pagesInfrared Thermographyudita_shah1989No ratings yet

- TSM Strapping (Tank Calibration)Document2 pagesTSM Strapping (Tank Calibration)skthen72No ratings yet

- Measurement Accuracy and Sources of Error in Tank Gauging 2270Document6 pagesMeasurement Accuracy and Sources of Error in Tank Gauging 2270CRT ServicesNo ratings yet

- General Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingDocument59 pagesGeneral Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingashishpearlNo ratings yet

- A020a020m PDFDocument31 pagesA020a020m PDFDaniel LodiNo ratings yet

- A020a020m PDFDocument31 pagesA020a020m PDFDaniel LodiNo ratings yet

- Fin Glass 6Document4 pagesFin Glass 6EIWAANo ratings yet

- A020a020m PDFDocument31 pagesA020a020m PDFDaniel LodiNo ratings yet

- General Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingDocument59 pagesGeneral Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingashishpearlNo ratings yet

- General Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingDocument59 pagesGeneral Requirements For Rolled Structural Steel Bars, Plates, Shapes, and Sheet PilingashishpearlNo ratings yet

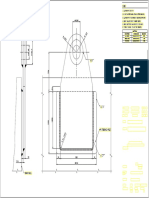

- Pad Eye New-ModelDocument1 pagePad Eye New-ModelEIWAANo ratings yet

- 1 Analysis For ForkliftDocument12 pages1 Analysis For ForkliftEIWAANo ratings yet

- Table 4 - Factor SB For Standard MethodDocument1 pageTable 4 - Factor SB For Standard MethodEIWAANo ratings yet

- Fin Glass 6 PDFDocument6 pagesFin Glass 6 PDFEIWAA100% (1)

- Fin Glass 6Document6 pagesFin Glass 6EIWAA100% (1)

- Pad Eye AnalysisDocument1 pagePad Eye AnalysisEIWAANo ratings yet

- Pad Eye TesterDocument1 pagePad Eye TesterEIWAANo ratings yet

- Hydrotest ReportDocument1 pageHydrotest ReportEIWAA100% (1)

- Analysis StructureDocument3 pagesAnalysis StructureEIWAANo ratings yet

- SSSSSSSS: TTTTT TTTTTTT T TTTDocument8 pagesSSSSSSSS: TTTTT TTTTTTT T TTTEIWAANo ratings yet

- AspectDocument2 pagesAspectEIWAANo ratings yet

- Pad EyeDocument1 pagePad EyeEIWAANo ratings yet

- Glass PanelDocument2 pagesGlass PanelEIWAA50% (2)

- ConnectionDocument2 pagesConnectionEIWAANo ratings yet

- NDT Report FormsDocument1 pageNDT Report FormsEIWAA100% (2)

- Wind AnalysisDocument3 pagesWind AnalysisEIWAANo ratings yet

- ConnectionDocument2 pagesConnectionEIWAANo ratings yet

- Strctural Calculations CWDocument5 pagesStrctural Calculations CWEIWAANo ratings yet

- 1analysis For Curtain Wall GlassDocument2 pages1analysis For Curtain Wall GlassEIWAANo ratings yet

- Bracing NewDocument1 pageBracing NewEIWAANo ratings yet

- ActivityDocument1 pageActivityEIWAANo ratings yet

- Design CommentsDocument1 pageDesign CommentsEIWAANo ratings yet

- DocumentDocument1 pageDocumentEIWAANo ratings yet