Professional Documents

Culture Documents

Data Sheet For Polymerization Agitator (AR-301) : Project: Epdm Terpolymer Pilot Plant

Uploaded by

Christopher LloydOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Data Sheet For Polymerization Agitator (AR-301) : Project: Epdm Terpolymer Pilot Plant

Uploaded by

Christopher LloydCopyright:

Available Formats

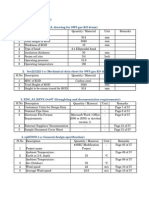

PROJECT: EPDM TERPOLYMER Pilot Plant

TITLE: Datasheet For Agitator (AR-301)

Data Sheet for Polymerization Agitator (AR-301)

Rev.: 1

Document No.: EPDM-300-DAS-A4-RE-0001

Page: A

PROJECT: EPDM TERPOLYMER Pilot Plant

TITLE: Datasheet For Agitator (AR-301)

1

A

4

3

2

1

0

14/5/2012

AA.SHOKRI

L.BAYANDORI

AA.SHOKRI

IFA

Revision

Date

Prepared By

Checked By

Approved By

Status

Document revision

Rev.: 1

Document No.: EPDM-300-DAS-A4-RE-0001

Page: B

PROJECT: EPDM TERPOLYMER Pilot Plant

Document No. : EPDM-300-DAS-A4-RE-0001

Rev.: 1

Datasheet For Agitator (AR-301)

Title:

01

ITEM NO.:

AR-301

02

QUANTITY:

03

DESCRIPTION:

04

MODE OF OPERATION:

05

SITE & UTILITY DATA:

06

LOCATION:

07

08

Page: 1

VESSEL NO.:

Polymerization Agitator

MAUNFACTURER:

continuous

INDOOR

UNDER ROOF

HEATED

MODEL:

61

DEGREE OF AGITATION:

OUTDOOR

62

PARTIAL SIDES

63

UNHEATED

64

LOW AGITATION WILL DETERMINE PARTICLES SETTLING

65

FOAMING TENDENCY:

09

10

ELECTRICAL AREA CLASSIFICATION:

CL.:

11

12

66

GR.:

WINTERIZATION REQ'D:

DIV.:

TROPICALIZATION REQ'D

44

-28

(C)

15

16

RELATIVE HUMIDITY:

Max.

86%

17

18

68

69

AMBIENT TEMP. (MAX / MIN):

VIOLENT

NONE

MEDIUM

MILD

MILD

FULLY

67

13

14

R-301

P&ID NO.:

MIXING CYCLE:

CONTINUOUS MIXING

BATCH MIXING

70

71

FLOW RATE AT CONTINUOUS MIXING:

72

TIME OF COMPLETE MIXING:

250

(h)

kg/hr

25

(min.)

73

ALTITUDE:

(m)

74

19

75

20

BAROMETRIC PRESSURE:

(mbara)

21

MIN.

818

802

/ MAX.

VESSEL WILL FILL OR EMPTY WHILE MIXING:

YES

NO

76

/ AVG.

810

22

77

POSITION OF AGITATOR:

78

AGITATOR SHAPE:

Anchor Agitator

Central

23

OTHER CONDITIONS:

79

AGITATOR DIAMETER:

By Vendor

(mm)

24

PLEASE ALSO SEE SPECIFICATION NO.

80

SHAFT DIAMETER:

By Vendor

(mm)

25

81

CLEARANCE (WALL TO IMPELLER):

26

82

27

UTILITY CONDITIONS:

83

28

PLEASE SEE SPECIFICATION FOR SITE & UTILITY DATA,

84

29

DOC. NO.

85

30

(mm)

DIRECTION OF ROTATION (FROM DRIVER):

CLOCKWISE

86

SPEED:

87

CRITICAL SPEED:

COUNTER-CLOCKWISE

0-100

(rpm)

31

MEDIUM DATA

32

PROCESS FLUID:

33

COMPOSITION:

( Note 1 )

34

DENSITY SLURRY:

630

35

DENSITY LIQUID:

36

BULK DENSITY OF SOLID:

37

DYNAMIC VISCOSITY:

38

pH Value:

39

SOLID CONTENT:

(kg/m3)

95

MOTOR DATA

40

PARTICLE SIZE:

(m)

96

MAUFACTURER:

97

TAG NO.:

98

SERVICE FACTOR:

SOLID

99

TYPE:

TOXIC

100

FRAME:

101

COUPLING TYPE:

(C)

102

POWER:

(kW)

(barg)

103

RATED SPEED:

(RPM)

104

(MOTOR DATA CONTINUED ON NEXT PAGE)

NOTES

Polymer Solution

880-890

0.3

89

SHAFT TORQUE:

(kg/m3)

90

WHILE IN OPERATION:

(kg/m3)

91

DURING START-UP:

(kg/m3)

92

(cP)

93

43

44

MEDIUM PROPERTIES:

GASEOUS

COMBUSTIBLE

LIQUID

EXPLODABLE

45

46

OPERATING TEMPERATURE:

47

OPERATING PRESSURE:

25-35

3.4

48

49

DESIGN DATA

105

50

DESIGN TEMPERATURE: (C)

106

MIN.:

51

52

54

-28

MAX.:

100

MIN.:

-1

ALLOWABLE SPL@1m:

MAX.:

85

AGITATION

57

TYPE OF AGITATION:

59

60

109

(dB)

110

111

56

BLEND

DISSOLVE

DISPERSE

REQUIRED SHAFT POWER:

By Vendor

(kW)

112

113

EMULSIFY

114

SUSPEND SOLIDS

115

HEAT TRANSFER

116

( BY VENDOR )

1 - Hexane: 80%wt, EPDM: 6%wt, Propylene: 13%wt.

108

55

58

107

DESIGN PRESSURE:(barg)

53

(Nm)

94

41

42

(rpm)

88

2 -

PROJECT: EPDM TERPOLYMER Pilot Plant

Document No. : EPDM-300-DAS-A4-RE-0001

Rev.: 1

Datasheet For Agitator (AR-301)

Title:

Page: 2

01

MOTOR DATA

61

AGITATOR DATA

02

DRIVE BY:

( BY VENDOR )

62

IMPELLER TYPE:

03

CONTROL LOCATION:

63

NO. IMPELLER:

04

PROTECTION CLASS:

64

BLADE:

05

TEMPREATURE CLASS:

65

IMPELLER DIAMETER:

06

FULL LOAD AMPS:

66

IMPELLER WIDTH:

07

LOCKED ROTOR AMPS:

67

HELICAL FLIGHTS PITCH

08

EXPLOSION PROTECTION:

68

SCREW WIDTH:

(Continued from Page 1)

09

MATERIAL DATA

11

PROCESS SIDE:

SS 316

71

12

SHAFT / STIRRER:

SS 316

72

13

BOLTS (OUTSIDE / INSIDE):

73

14

NUTS (OUTSIDE / INSIDE):

74

15

SHAFT SEALS:

75

SHAFT SEAL

18

TYPE:

By Vendor

19

RING MATERIAL:

By Vendor

20

SEALING LIQUID:

By Vendor

21

SEALING PRESSURE:

22

SEAL MANUFACTURER:

79

80

(barg)

81

82

83

AUXILIARY EQUIPMENT

( BY VENDOR )

THERMOSYPHON

REFILL UNIT

MEASURING SYSTEM

84

SPACED TYPE

85

CIRCULATION UNIT

86

OTHERS

87

88

29

VESSEL DATA

30

NUMBER OF BAFFLES:

31

BAFFLES DIMENSION:

32

DIAMETER:

33

89

90

(m)

91

1000

(mm)

92

LENGTH CYL.:

890

(mm)

93

34

NOMINAL VOLUME:

0.8

(m3)

94

35

OPERATION VOLUME:

MAX.:

(m3)

0.7

95

MIN.:

96

37

38

39

Supplier.

2- Approved vendor list by oil ministry.

78

28

36

1 - Agitator to reactor connection has to be checked with

77

(2)

23

27

NOTES

76

17

26

mm

mm

mm

mm

70

16

25

1

See Drawing

69

10

24

Anchor

97

OPERATION FILLING LEVEL:

MAX.:

800

(mm)

/

98

MIN.:

100

99

40

100

CONNECTION LIST

41

( NOTE 1 )

42

43

NO.

DESCRIPTION

DN

44

P1

Agitator Connection

6"

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

PN

FACING

LF

STANDARD

NOZZLE LENGTH

COMMENTS

PROJECT: EPDM TERPOLYMER Pilot Plant

Document No. : EPDM-300-DAS-A4-RE-0001

Title:

Datasheet For Agitator (AR-301)

These Data Should Be Verified By Vendor

Rev.: 1

Page: 3

You might also like

- 130403-23 73 10-Air Handling Unit DX Coil Rev-01Document4 pages130403-23 73 10-Air Handling Unit DX Coil Rev-01Adil ShahNo ratings yet

- Anex 1Document59 pagesAnex 1rotatic_engineerNo ratings yet

- Model: BSQ-300-50: Belt Drive Centrifugal Inline FanDocument6 pagesModel: BSQ-300-50: Belt Drive Centrifugal Inline FanErnesto GarzaNo ratings yet

- Condesator Axial CiprianDocument1 pageCondesator Axial CiprianAlex RotaruNo ratings yet

- 315 Me DS 083 D3Document6 pages315 Me DS 083 D3mihailspiridonNo ratings yet

- Cooling Tower Data Sheet REV-00Document12 pagesCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1No ratings yet

- Engine Room Ventilation - Calculation PDFDocument2 pagesEngine Room Ventilation - Calculation PDFSarawut Jae100% (1)

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- Essar Pump Data 208810Document9 pagesEssar Pump Data 208810Rakhee SinhaNo ratings yet

- Data Sheet N834.3 E038 011Document5 pagesData Sheet N834.3 E038 011VipinVijayNo ratings yet

- Heat Exchanger Mechanical Design Calculations Per ASME & TEMA - by Abdel Halim GalalaDocument136 pagesHeat Exchanger Mechanical Design Calculations Per ASME & TEMA - by Abdel Halim Galalagutmont100% (3)

- Wind Turbine Technology Low Wind Speed Zones Wirachai Roynarin Wind Water Solar Research Rmutt ThailandDocument15 pagesWind Turbine Technology Low Wind Speed Zones Wirachai Roynarin Wind Water Solar Research Rmutt ThailandRendra WijayaNo ratings yet

- XOMOXXRPActuatorsEMEA TechnicalDataDocument29 pagesXOMOXXRPActuatorsEMEA TechnicalDataSergio VargasNo ratings yet

- Inputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)Document3 pagesInputs From Client: 1. bfp132401 1 0 (G.A. Drawing For SWS Gas KO Drum)SIVANo ratings yet

- Reaction Tank Design For WWTPDocument9 pagesReaction Tank Design For WWTPDavid LambertNo ratings yet

- 2.1 GeneralDocument248 pages2.1 GeneralHugo Alfredo Calderon TapiaNo ratings yet

- B4 GEGuarantee LM6000 PFDocument7 pagesB4 GEGuarantee LM6000 PFJulian JairNo ratings yet

- Bomba de Engranajes Kracht KP5 - GB - 09-08Document12 pagesBomba de Engranajes Kracht KP5 - GB - 09-08Mauricio Ariel H. OrellanaNo ratings yet

- Sop of TG & AuxilliariesDocument29 pagesSop of TG & Auxilliarieschcrr67% (3)

- B 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerDocument11 pagesB 84567 SB MM2 DSR ST 60 0013 2 AOC Seal Gas Filter CoalescerpragatheeskNo ratings yet

- XR15 Performance DataDocument16 pagesXR15 Performance Databarber bobNo ratings yet

- Water-Cooled Series R (TM) RTHD Product ReportDocument2 pagesWater-Cooled Series R (TM) RTHD Product ReporttrangocvuNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- GDS134Document4 pagesGDS134Saurabh VermaNo ratings yet

- HVAC TBA With AttachmentDocument48 pagesHVAC TBA With AttachmentumeshNo ratings yet

- Seleccion Chiller 100 Ton FeserDocument7 pagesSeleccion Chiller 100 Ton FeserWilliamUrcuhuarangaJesusNo ratings yet

- L028 Me Dat 01 00122 001 00Document8 pagesL028 Me Dat 01 00122 001 00sivasan10006098No ratings yet

- FO14-104 Vacuum Deaerator Datasheet - Rev ADocument3 pagesFO14-104 Vacuum Deaerator Datasheet - Rev AHuzefa Calcuttawala100% (2)

- Technical Data FauDocument3 pagesTechnical Data FauĐặng HoàngNo ratings yet

- AHU CLCP Dimension DrawingsDocument92 pagesAHU CLCP Dimension DrawingsPhạm ĐạtNo ratings yet

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Burner CalculationDocument11 pagesBurner CalculationBùi Hắc HảiNo ratings yet

- VaporizersDocument21 pagesVaporizersAditya MahajanNo ratings yet

- Coalescers ZM E25Document2 pagesCoalescers ZM E25abaskmNo ratings yet

- Digital Zone 2 Technical Comparison: Air Cooled Chilled Water Package-280 TR - (Normal Operation)Document4 pagesDigital Zone 2 Technical Comparison: Air Cooled Chilled Water Package-280 TR - (Normal Operation)thinkpad x1No ratings yet

- Utr - PLN Suar PDFDocument86 pagesUtr - PLN Suar PDFJaka Sembung Golok100% (1)

- Attachment-6 TBE ANSI Pump BCUDocument31 pagesAttachment-6 TBE ANSI Pump BCURanu Januar100% (1)

- 5380T3TCAMech74.2 85IPUDocument4 pages5380T3TCAMech74.2 85IPUVincen LimNo ratings yet

- SVSW 004110 G16 0001 Rev.a Datasheet For PumpDocument6 pagesSVSW 004110 G16 0001 Rev.a Datasheet For Pumpnguyenquoc1988No ratings yet

- KWP Non-Clogging Centrifugal Pump: Automation Products AvailableDocument16 pagesKWP Non-Clogging Centrifugal Pump: Automation Products Availablefedeparamos5030100% (1)

- Technical Data Sheets - TurbineDocument19 pagesTechnical Data Sheets - Turbinepavankumar001No ratings yet

- 950 3-3 P5ZR 30 Pag 650-100Document8 pages950 3-3 P5ZR 30 Pag 650-100jeyaselvanmNo ratings yet

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralNo ratings yet

- Condensadora TTB TraneDocument24 pagesCondensadora TTB TraneRoberto Reyes Lara100% (1)

- 418-250-D00-Q2-001 (Calculation For Compressed Air Package - Rev.01)Document9 pages418-250-D00-Q2-001 (Calculation For Compressed Air Package - Rev.01)mehdi227No ratings yet

- 4560 E 2 TCM 12-73081 PDFDocument78 pages4560 E 2 TCM 12-73081 PDFVanessa Pajares LanciatoNo ratings yet

- Waste Heat Recovery UnitDocument15 pagesWaste Heat Recovery UnitEDUARDONo ratings yet

- Air Hammer DrillingDocument24 pagesAir Hammer DrillingDaljeet SinghNo ratings yet

- Garden Namkeen TestDocument12 pagesGarden Namkeen Testramakrishna.goliNo ratings yet

- AHU Eurovent ISKID Part 1Document27 pagesAHU Eurovent ISKID Part 1Joaquim MonteiroNo ratings yet

- Cubic Unit Cooler: SKB Semi-Industrial RangeDocument8 pagesCubic Unit Cooler: SKB Semi-Industrial RangeMohammad AmerNo ratings yet

- Sprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFDocument3 pagesSprezarka Embraco Aspera NJ9238GK Karta-Produktu PDFsergirojasNo ratings yet

- Mitsubishi Service ManualDocument48 pagesMitsubishi Service Manualrxp2007No ratings yet

- RDS-005 1st 1994 Centrifugal CompressorDocument15 pagesRDS-005 1st 1994 Centrifugal CompressorDesaiNo ratings yet

- 1124 RA12 Pages BrochureDocument16 pages1124 RA12 Pages BrochureGoanengineerNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- زندگی پنهان مادر ترزاDocument10 pagesزندگی پنهان مادر ترزاChristopher LloydNo ratings yet

- Comparison of Jet Aeration Systems vs. Diffused Aeration SystemsDocument8 pagesComparison of Jet Aeration Systems vs. Diffused Aeration SystemsChristopher LloydNo ratings yet

- WO2017037540A1Document29 pagesWO2017037540A1Christopher LloydNo ratings yet

- Experimental Evaluation of Ball Bar Standard ThermDocument12 pagesExperimental Evaluation of Ball Bar Standard ThermChristopher LloydNo ratings yet

- Venturi Scrubber ProjectDocument1 pageVenturi Scrubber ProjectChristopher LloydNo ratings yet

- EVE 402 Air Pollution Generation and Control: Wet CollectorsDocument8 pagesEVE 402 Air Pollution Generation and Control: Wet CollectorsChristopher LloydNo ratings yet

- Modelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsDocument10 pagesModelling of The Pressure Drop in Tangential Inlet Cyclone SeparatorsChristopher LloydNo ratings yet

- Energy and Exergy of Electric Arc Furnace PDFDocument26 pagesEnergy and Exergy of Electric Arc Furnace PDFChristopher LloydNo ratings yet

- Water Mist Systems in Tunnels: Some Unanswered QuestionsDocument10 pagesWater Mist Systems in Tunnels: Some Unanswered QuestionsChristopher LloydNo ratings yet

- Description of Thermal Oxidizers PDFDocument5 pagesDescription of Thermal Oxidizers PDFChristopher LloydNo ratings yet

- Fire Safety Enginering For An Auditorium Analysis: M. Filimon D. Diaconu-Șotropa C. P. OlariuDocument8 pagesFire Safety Enginering For An Auditorium Analysis: M. Filimon D. Diaconu-Șotropa C. P. OlariuChristopher LloydNo ratings yet

- Normal To Real Flow Rate and FAD Flow RateDocument25 pagesNormal To Real Flow Rate and FAD Flow RateChristopher LloydNo ratings yet

- TBS Case Study Train LoadoutDocument1 pageTBS Case Study Train LoadoutChristopher LloydNo ratings yet

- Normal Conditions at 100% Barometer Amb Temp,°C Inlet Capacity: Ist StageDocument1 pageNormal Conditions at 100% Barometer Amb Temp,°C Inlet Capacity: Ist StageChristopher LloydNo ratings yet

- Notes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelDocument7 pagesNotes On Sizing of Horizontal Ceiling Vents With Traditional Flow ModelChristopher LloydNo ratings yet

- Sound Pressure LevelDocument38 pagesSound Pressure LevelChristopher Lloyd100% (1)

- Combustion. Adiabatic Flame Temperature - Jeff MunicDocument56 pagesCombustion. Adiabatic Flame Temperature - Jeff MunicChristopher LloydNo ratings yet

- Spherical Particle Drag CoefficientDocument8 pagesSpherical Particle Drag CoefficientChristopher LloydNo ratings yet

- Mechanical Ventilation For Individual Pen Calf Barn CalculatorDocument3 pagesMechanical Ventilation For Individual Pen Calf Barn CalculatorChristopher LloydNo ratings yet

- Ps BallDocument5 pagesPs BallChristopher LloydNo ratings yet

- Wes Jackson PM PMP OhioDocument10 pagesWes Jackson PM PMP Ohioraj jdsNo ratings yet

- Kebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IDocument5 pagesKebersihan, Fungsi Sanitasi Dan Drainase - BAHASA INGGRIS - VII - Semester IRiska AyuNo ratings yet

- Global Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirDocument24 pagesGlobal Warmin G and Green House Effect: Submit Ted To:-Mr - Kaush Ik SirinderpreetNo ratings yet

- How To Create Your Cosmetic Product Information FileDocument12 pagesHow To Create Your Cosmetic Product Information Filewill100% (3)

- 2017 LT4 Wiring DiagramDocument10 pages2017 LT4 Wiring DiagramThomasNo ratings yet

- Qi Gong & Meditation - Shaolin Temple UKDocument5 pagesQi Gong & Meditation - Shaolin Temple UKBhuvnesh TenguriaNo ratings yet

- Umur Ekonomis Mesin RevDocument3 pagesUmur Ekonomis Mesin Revrazali akhmadNo ratings yet

- Grain Silo Storage SizesDocument8 pagesGrain Silo Storage SizesTyler HallNo ratings yet

- Factory OverheadDocument2 pagesFactory OverheadKeanna Denise GonzalesNo ratings yet

- FNCP Improper Waste DisposalDocument2 pagesFNCP Improper Waste DisposalKathleen Daban RagudoNo ratings yet

- German Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Document26 pagesGerman Specification BGR181 (English Version) - Acceptance Criteria For Floorings R Rating As Per DIN 51130Ankur Singh ANULAB100% (2)

- Ammonium Chloride: Product InformationDocument2 pagesAmmonium Chloride: Product InformationusamaNo ratings yet

- High CarbonDocument2 pagesHigh CarbonKarisoNo ratings yet

- Senographe Crystal: The Choice Is Crystal ClearDocument7 pagesSenographe Crystal: The Choice Is Crystal ClearmuhammadyassirNo ratings yet

- ME-317 Internal Combustion Engines - TurbochargingDocument21 pagesME-317 Internal Combustion Engines - TurbochargingHamzaJavedNo ratings yet

- Existensive Happiness by AristotleDocument2 pagesExistensive Happiness by AristotleIan Robert Roa NovalNo ratings yet

- Gintex DSDocument1 pageGintex DSRaihanulKabirNo ratings yet

- Basic Electrical Engineering Mcqs Unit 1Document13 pagesBasic Electrical Engineering Mcqs Unit 1shubha christopherNo ratings yet

- DELIGHT Official e BookDocument418 pagesDELIGHT Official e BookIsis Jade100% (3)

- Pentacam Four Maps RefractiveDocument4 pagesPentacam Four Maps RefractiveSoma AlshokriNo ratings yet

- Revised List of Maharashtra HospitalsDocument16 pagesRevised List of Maharashtra Hospitalsdummy data100% (1)

- Kern County Sues Governor Gavin NewsomDocument3 pagesKern County Sues Governor Gavin NewsomAnthony Wright100% (1)

- The Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayDocument356 pagesThe Ego and Analysis of Defense-Jason Aronson, Inc. (2005) Paul GrayClinica MonserratNo ratings yet

- Assignment 2: Loan Submission For Equipment FinanceDocument6 pagesAssignment 2: Loan Submission For Equipment FinanceIT'S SIMPLENo ratings yet

- Hasil Pemeriksaan Laboratorium: Laboratory Test ResultDocument1 pageHasil Pemeriksaan Laboratorium: Laboratory Test ResultsandraNo ratings yet

- Espiritualidad AFPP - 2018 PDFDocument5 pagesEspiritualidad AFPP - 2018 PDFEsteban OrellanaNo ratings yet

- Drug AbuseDocument33 pagesDrug AbuseharshulnmimsNo ratings yet

- Indiana Administrative CodeDocument176 pagesIndiana Administrative CodeMd Mamunur RashidNo ratings yet

- Gmail - RedBus Ticket - TN7R20093672Document2 pagesGmail - RedBus Ticket - TN7R20093672Bappa RoyNo ratings yet

- Manual Gavita Pro 600e SE EU V15-51 HRDocument8 pagesManual Gavita Pro 600e SE EU V15-51 HRwhazzup6367No ratings yet