Professional Documents

Culture Documents

Fundamental Principles Reservoir Eng 14-Anexos y Prob

Uploaded by

Yesi Matos0 ratings0% found this document useful (0 votes)

18 views52 pagescuarta parte de los fundamentos del comportamiento de un pozo

Original Title

Fundamental Principles Reservoir Eng 14-Anexos y Prob - Copia

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentcuarta parte de los fundamentos del comportamiento de un pozo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views52 pagesFundamental Principles Reservoir Eng 14-Anexos y Prob

Uploaded by

Yesi Matoscuarta parte de los fundamentos del comportamiento de un pozo

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 52

Chapter 14

Decline-Curve Analysis

14.1 Introduction

Decline-curve analysis hasbeen the most widely used method

‘of forecasting future production from oil and gas fields since

‘Amps! formalized the technique in 1945, The technique has

few fundamental theoretical foundations, but the simplicity

and success of its forecasts are responsible for its general ac-

ceptance and use. There are three decline-curve types: expo-

nential, harmonic, and hyperbolic. In actuality, exponential

and harmonic decline curves are particular subsets of hyper-

bolic decline; therefore, there really is only one general de

cline-curve type with three parameters [qd and 1 (or h)]

that have tobe determined from measured data, When n = 0

(or h = &), the decline is exponential: and when n = 1 (or

‘i= 1s the decline is harmonic. While n usually is between

O and 1, cases where n > 1 have been reported. Values of

1n < O have not been reported: however, there is no reason

this could not happen. We have observed negative exponents,

which we show in one example in this chapter and explain, A

Yalue of n > 1 usually i attributed to tight ga, fractured, or

very heterogeneous reservoirs.

‘Simple graphical techniques exist for determining the de

cline-curve parameters g, and din the special cases of expo-

nential and harmonic decline. The exponential parameters

can be determined froma log ate, 4, VS. time, plot o from

44,8. cumulative-production, Q,, plot (on a linear scale),

‘The harmonic parameters can be determined from a log 4, vs.

Q, plot ora linear plot of 1/4, s.. The parameters are deter~

‘mined from the slopes, mand intercepts, b, ofthe plots, and

these estimates can be made more accurateif linear regression

is used in their determination, Three parameters are needed

forhyperbolic declines, and various techniques (which are al-

ways iterative in nature) have been proposed to determine

them, Sec, 14.2 reviews the mostimportant methods, Howey

er, the techniques that have been proposed and are used most

widely lack accuracy; therefore, we discuss more rigorous

techniques for determining hyperbolic parameters accurately.

We propose two complementary techniques for hyperbolic:

Parameter estimation and use iterative linear regression ofthe

‘methods to ensure accuracy. Then, we show use of nonlinear-

v0

regression techniques to solve for the three parameters. The

methods are simple to apply and do not rely on the skill orex-

perience of the user, and the results obtained are repeatable

and independent of the user.

14.2 Historical Review

Amold and Anderson? gave the firstand most obvious mathe-

matical approach to decline curves. Cutler’ later proposed

‘that a straight line could be obtained on log-log paper for hy-

perbolic decline by shifting the curve slightly horizontally

For exponential and hyperbolic declines, Larkey! used the

‘method of least squares or statistical approach to extrapolate

the decline curves. Pison derived the loss-ratio method and

determined rate/ime relationships for production decline

curves having a constant loss ratio. Arps! classified the de-

cline curves on the basis of the loss-ratio method and later

_gave the simplified rate/time and rate/eumulative-production

{equations for three basi types of declines ®

Three decline methods were derived from the differential

equation for the normalized decline rate

Ka" aaa)

‘where two hyperbolic-dectine exponents, and h, are shown

(note that n = 1/h) and K = proportionality constant Inthe

following three decline equations, d, = initial dectine rate.

1. Exponential decline, n = or h = =

42)

and Q, = (143)

2. Hyperbolic decline, all motherthan n = Oand n = 1 or

allh <1

4 (44)

[re(amyf (rma

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

-_

and Oy = Gaga ~ a)

ait

gla = a) cas)

3.Hamoie detine, n= Toe h = 1

046)

can

Example 14.1—Forecasting Future Production With De-

‘Curves. A well hasan intial rate of $50 STB/D and an

initial decline rate, d,, of 2%/month. Determine the rate and

cumulative production after 3 years for the following cases:

(1) exponential dectine (n = 0), (2) hyperbolic decline with

n= 0.6, and (3) harmonic decline (n = 1).

Solution. Two conversion factors are used here to convert

time: 30.4167 days = I month and 12 months = 1 year.

Case I

get

= 550exp(~ 0.02 x 3 x 12)

= 267.7 STBID

and Q, =

a

= (550 ~ 267.7/(0.02/30.41667)

= 429,310 STB.

Case 2

a + ma)

= (550)/(1 + 0.6 x 0.02 x 36)'"*

= 3023 STB/D

‘nd Fea gt

= Gaga - a

= [(550°* x 30.41667)/(0.4 x 0.02)]

x (550 302.3)

= 445,204 STB.

Case 3.

_4

[+a

= (550)/(1 + 0.02 x 36)

= 319.8 sTB/D

«

wo,

‘= (550 x 30.41667/0.02) In(550/319.8)

DECLINE-CURVE ANALYSIS

14.3 Parameter Estimation for Exponential Decline

If-m = 0, the dectine is exponential. Ths isthe most widely

used of the three methods, primarily because itis easy to de-

termine the parameters and gives a more conservative est

mate of future reserves for given parameters. Example 6.5,

Fig 6.6, showed that the decline in a well producing at

constant wellbore flowing pressure ina finite-acting homoge-

neous cylindrical reservoir is approximately exponential

Fetkovich etal.” show that stronger hyperbolic results are ob-

tained if the infinite-acting production is not excluded from

the decline-curve analysis. Even ifthe decline is strongly hy-

perbolic, an exponential curve can easly be fitted tothe last

few points and future production can then be projected with

the exponential fit. While itis true that this gives a conserva-

tive estimate of reserves, hyperbolic decline is more realistic

and should be used when appropriate. If n = 0 is assumed,

only two parameters, q,and d, need to be determined. Taking

‘the natural log of both sides ofthe exponential rate/time rela-

tionship (Eq. 14.2, ~ d,loge) gives

Ing, = Ing, ~ dt. (14.8)

‘Therefore, a plot of Ing, vs. F gives a straight Line with

m = ~ d, and b = Ing, If it is more convenient to plot

log qivs.1,then m = — d)loge and b = logq.

14.4 Parameter Estimation for Harmonic De

If'n = 1, the decline is harmonic. This isa less common, but

rn less simple, decline method. It can be used if the log qs.

, plotis linear. This comes from Eq, 14.7, which can be rear-

ranged to give

Ing, = Ing, ~ d,Q,/a,

Therefore, a plot of Ing, vs. Q, gives a straight line of

m= ~diq,and b = Ing,.If it's more convenient to plot

Toga. v8. Op then m =~ d/qloge and = Ing, Har-

‘monic decline is also linear on a plot ofthe inverse of rate vs

time. This comes from Eq, 14.6, which can be rearranged 2s

Va. = Wa, + (d,/4,)

Here, a plot 1/4, vs. gives a straight line of m = d./q,and

b= Va,

Note that just asit usually is possible tofitthe latest produc-

tion values with an exponential decline, it also usually is pos-

sible to fit the latest points with a harmonic decline because

a few points will be linear on a log, vs. Q, plot. However,

this is also erroneous and usually leads to more optimistic re-

serves ifthe true mis less than 1

49)

(14.10)

14.5 Production Plots

In the previous section, we discussed four types of plots for

analyzing and diagnosing production declines. If any ofthese

plots are linear, the slope. m, and intercept, b, can be used as

described previously to determine d, and q,. This section

ssurmmarizes the plots and discusses their relative merits.

1. A plotof log q,vs.ris linear ifthe decline is exponential

and concave upward if the decline is hyperbolic (n > 0) or

harmonic (1 = 1).

2. A plot log q,vs. Q, is linear ifthe dectine is exponen-

tial and concave upward ifthe decline is hyperbolic (n > 0)

or harmonic (n = 1),

3. Aplot of log qs. Q, is linearif the decline is harmonic,

concave downward ifthe decline is hyperbolic(n < )orex-

m

pponential (n= 0), and concave upward ifthe decline is hy-

perbolic with n >" 1.

4. plot of 1/g, vs. ris linear if the dectine is harmonic,

concave upward ifthe decline is hyperbolic (n < I)orexpo-

nential, and concave downward if the decline is hyperbolic

with n> 1

Plots 1 and 3 are the more common methods of presenting

production data, and Plots 2 and 4 can be used to confirm

trends observed there. Once again, these plots often can be

‘made to appear linear if to0 few points are used; therefore, at

the least, Plots 1 and 3 should be used to avoid confusion.

14.6 Hyperbolic Decline

All real wells actually have hyperbolic decline. Exponential

and harmonic decline are simply particular cases of hyperbol-

ic decline that have to be treated separately because inegra-

tion of Eq, 14.1 does not give Eq, 14.4 when n = O and in-

tegration of Eq. 14.4 doesnot give Eg. 14.5 when = 1, Tn

addition, these subsets are simpler to use because only iwopa-

rameters need tobe determined. In our opinion, however, al

three parameters should be determined forall wells if sufi

cient decline data are available because this shows that almost,

‘no wells have declines where nm =O or | exactly. While de-

termining the three parameters(,d,,andn)ismore dificult,

the techniques discussed next show how to doit simply and

consistently. The literature provides several approaches to

calculation ofthe parameters based on wial-and-error meth:

ods, type-curve overlays, graphical methods, and mathemati

calor statistical analysis

‘Slider and Fetkovich® both developed type-curve-overlay

methods to determine the parameters, Slider suggested that

several curves be plotted on transparent paper for diferent

values of mand d,.4,¥s.ris plotted on semilog paper fom the

production history ofthe wel; then, values of mand dean be

obtained by overlapping the set of curves. Fetkovich re-

viewed Slider's method and suggested that a log-log type-

curve-matching procedure could be developed to analyze de-

cline-curve data, He used some particular dimensionless

variables and found that exponential decline is common to

both empirical (given by Arps!) and analytical data. He also

1, a further example of fractured reservoirs having

Regression Coeicient

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

au MST

‘gee MSTBYmonth

Fig. 145—Log q vs. tplot for Bore field Muddy

in > 1, However, Cases 4 through 6 are individual wells in

the same reservoir, each with n < 1. A negative decline ex-

ponent was obtained for Case 4; consequently, the graph of

log q,vs. 1 + nd,t hada positive slope. The ine inthe graph

of log q,vs. also curved down, which is symptomatic of the

negative exponent for the well. In this case, the meaning of a

negative exponent, particularly when total field n is greater

than I probably means that the well has mechanical problems.

Fordecline-curve analysis tobe valid, all wellbore conditions

‘must remain constant, particularly the bottomhole pressure.

Ifmechanical problems (such as scale buildup or pump ineffi-

ciency) develop, the rate may fall more quickly than usual,

causing 1 to decrease and possibly become negative in ex

treme cases. In fact, because the overall field had n > 1, an

‘n-< 1 inall three wells in the field could indicate varying de-

grees of mechanical problems.

Results ofall six cases showed some discrepancy between

the methods, and we noticed that the discrepancy increased

i

Regression Costiciont

a

Ande

Fig. 18.56—Decline-curve plot for Borie field, Method 1.

as the data became more scattered. The discrepancy in re-

sults for Cases 2, 3, , and 6 can be explained adequately as

errors in measurement of rate and cumulative production. A

good method of selecting the most accurate technique is not

yet available. One proposal is touse the technique that gives

the highest maximum regression coefficient. The last col-

‘umn of Table 14.1 gives the maximum regression coefficient

for each case. According to this criterion, Method 1 should

be used for Cases 2 and 3 and Method 2 should be used for

Cases I and 4 through 6.

14.9 Hyperbolic-Decline-Curve Anal

Nonlinear Regression on a Spreadsheet

‘Towler and Bansal!8 proposed the two methods for decline-

‘curve analysis that are based on linear regression discussed in

the previous section. A potential problem with these methods

is that linear regression is performed on logs of variables that

impose more weight on smaller values of production rates.

ng

Fig. 14.7—-Regression-coetticient plot for Borie field, Method 1.

DECLINE-CURVE ANALYSIS

Production, Q,, STB

Fig. 14.8—-Decline-curve plot for Borie field, Method 2.

us

Regression Costfcient

Fig. 14.9—-Regression-costficient plot for Borie eld, Method 2.

Another problem is that the two methods do not produce

equivalent results. A method is needed that isnot tedious, can

produce repeatable results, and that weights the production

rates equally during curve-fitting.

‘This led to development of a nonlinear-regression tech:

nique done with a computer spreadsheet equipped with a

solver that would satisfy these criteria. The solver works by

‘optimizing A? with noniinear-equation solvers while varying

conly the three parameters in the equation. In addition, the

technique is simplified because many production databases

exist in spreadsheet format and it can be generalized to any

nonlinear curve-fitting application

Here, we present the technique so thatthe reader can use it

immediately. We develop the method in steps as would be

typed into a spreadsheet, apply the steps in an example, and

provide a sample spreadsheet that relates to both the method

and the example. We do not present development ofthe com

puter method as 2 tutorial of the software. The reader should

refer o a user's manual of the particular software to answer

specific questions that arise. However, the spreadsheet is built

ina stepwise fashion with specific reference to initialization

of variables and specific formulas in cells and columns. The

‘method is developed in Steps | through 12, then applied to-an

‘example case in the same stepwise fashion. Results for eight

‘cases that illustrate the efficacy of the method are discussed,

14.9.1 Nonlinear-Regression Method. Spreadsheets, such

8s Quattro Pro, Excel, or Lotus 123, canbe used indeveloping

the method. The following steps are designed to be generic

‘enough for application to all spreadsheet packages. For clari-

fication, refer to Table 14.2 while reading through the steps.

|. From experimental data, create a spreadsheet with a col-

‘umn of oil-production rate, g,, anda column of production time.

2. Create a new column for fitting ¢, that begins at the point

inthe finite-acting time period when the remaining oil-produc-

tion rates decline steadily. It is sometimes helpful to plot the

data in Step 1 for determining this high point, especially for a

large dataset. The time when the well or reservoir becomes fi-

nite acting can be determined with Eqs. 6.21 and 6.22. All fur-

ther steps depend on the q, values from this column,

3. Place the column of times, f, next to 4,

116

4. Setup cells forthe hyperbolic exponent inital decline

rate, d. and intial oil-production rate, q. We recommend

filling these cells with an intial guess of 0.5 form; d can be

estimated with Eq, 14.1 and q, from the highest value of q,

5. Set up a cello calculate average oi-production rat,

from 4,

6.Set up a column, containing the hyperbolic-dectine

curve equation to fit the production, q

7. Set up a column to calculate the errors squared from

a— 45)

8. Setupacell that calculates the sum ofthe errors squared,

Sey from Step 7

9° Setupa column to calculate the total erors squared from

aa

10. Setup cell that calculates the sum of the total errors

Squared, Sy, from Step 9.

11. Setup acell tocalculate the square ofthe regression co

clfcien, from R= 1 ~ Sy /Soy.

12. Initialize the solver to optimize the contents ofthe cells

contain nd and g, by maximizing the cel that contains

Towler and Bansal!® recommend thatthe solver be run

‘more than once to ensure that R® has been maximized,

‘The following example applies this method and shows a

sample spreadsheet with the results (Table 14.2). Note that an

alternative to maximizing R° is to minimize the sum ofthe

squares of the residuals, Se, which gives the same result

Example 14.2—Hyperbolic-Decline-Curve Analysis Us-

ing Nonlinear Regression on a Spreadsheet. Determine the

hyperbolic-decline-curve parameters forthe production data

shown in Table 14,2 using the nonlinear-regression technique

discussed

Solution. Table 14.2 is a working copy ofthe spreadsheet.

‘The top and left borders ofthe table are the spreadsheet col-

‘umn (alpha) and row (numeric) cell references, respectively.

1. Cells A8 through A3I and B8 through B31 contain the

production times and rates, respectively.

2. Cells D10through D31 contain the production rates tobe

curve fit,

3. Cells C10 through C31 contain times of the production

rates to be curve fit,

4. Cells AS, BS,andCS initially contained estimated values

for, dand q,0f0.5,0.5, and 1,520, respectively. The values

shown in these cells are the results after optimization

5. Cell ES contains the average of the data in Cells DIO

through D3]

6. The hyperbolic-decline-curve equation is entered into

Cells E10 through E31 on the basis of the values in Cells AS,

BS, and C5 and the values in the corresponding Cells C10

through C31

7. Values in Cells F10 through 31 are the differences ines-

rors squared from the values in the corresponding cells of

Cols. D and E.

8. Cell GS contains the sum of the errors squared from

Step 7.

9. Values in Cells G10 through G31 are the differences in

the total errors squared from the values in the corresponding

cells of Col. D and Cell ES.

10. Cell HS shows the sum of the total errors squared

from Step 9

1, Cell DS contains the formula for calculating the square

Of the regression coefficient.

12. The solver is called and initiated to optimize the con-

tents in Cells A5, BS, and C3 by maximizing the contents of

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

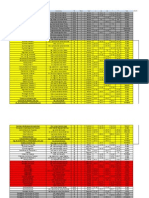

TABLE 142 EXAMPLE SPREADSHEET FOR FITTING PRODUCTION DATA WITH

JAHYPERBOLIC-DECLINE-CURVE EQUATION

x 3 co. © Fs

1 wos

2 Ded Cuve Analy

3

4 n 4g #3 ese

5 sooees—“ojesea 150051 096ee00 ess | rare Lots

6

a

7 Monty (ston ae:

8 Decemberi990at9

8 caruny 19811039,

10 Fetnryss61 152001500 net eat zeae

i Morn 1901 148311891409 ate 217459

12 Apa toe 2s 1205185012060

13 May 19% tae 3 takes ee

14 June 191 torr 40780528887

15 yay 1001 tot 5 nosh nome ae 8.88

13 August 10010571087 tse 10s

17 Septonberise1 9737 Shotts

18 Osobert991 862m

19° Noverber 1991 sot wth sass gd

zo December i991 53185] 2888

21 Jarvary199 ook

ze Feonayisie edt]

23 March 1080 ee

24 August 1992 soe 14 messmo

25° May 1002 ee ee rs

28° dno 862 www

27 ay 1992 mo 817 eHow .83 IB

20 August 082 er eer

29° Soniemberione 785i] 788_ BCT

50 Ociocers962 7532073 TBSSTB «a7

31 November 1902763278755 8——50.004

cell DS. In Quattro Pro, this is under TOOLS OPTIMIZER:

in Excel, itis under TOOLS SOLVER. The solver is runagain,

until the contents in Cell DS are maximized and do not change

between runs.

Note that these steps are not hard and fast. The reader is en-

couraged to experiment with such things asthe arrangement

ofcellsand columns tosuit specific applications. The remain-

ing seven cases were analyzed in the same manner. The next

section discusses the results forall eight cases.

14.10 Other Applications

The nonlinea-regression spreadsheet method (Method 3) was

tested wit eight different sets of production data. Table 14.3,

shows the results forthe eight sets; the table contains the case

ame; the hyperbolic-decline-curve parameters, n.d, and 4;

andthe square of the regression coefficient. The eight cases are

(1) Sliders! example, a dataset he used as an example of de-

clin-curves; (2) Borie field in Wyoming (total monthly pro-

duction); (3) Wel 1; (4) Well 2; (5) Well3; (6) Well 4 (7) Well

Siand (8) Well 6. Wells I through 6 are from an unnamed Field

in Wyoming’s Powder River basin. Details ofthe parameters

and curve fit are discussed individually forthe Slide example

DECLINE-CURVE ANALYSIS

and the Borie field and collectively for Wells | through 6. Figs.

14.10 through 14.17 graphically represent curve fitting of the

actual data for Cases 1 through 8, respectively.

‘The Slider and Borie data sets were selected for compatison

purposes because the results (showing the square of the re-

gression coefficient) for these two cases were discussed in

Sec. 14.8 and by Towler and Bansal.'® The square of the re-

‘gression coefficient is used as the measure of comparison be-

tween Method 3 and Methods 1 and 2 of Ref. 18.

Slider's data are used as a base case to test two methods

with linear regression. Comparison of the square of the re

sression coefficients shows 0.999842 (Method 3) compared

with 0.997916 (Method 1) and 0.998759 (Method 2). The

‘comparison reveals that Method 2 achieved the fit closest to

1. Fig. 14.1 shows curve fitting of actual data by linear-re-

‘gression Method 1

‘Towler and Bansal also used Borie field data to test the two

methods, Comparison of the regression coefficients shows,

(0.984216 (Method 3) compared with 0.9664694 (Method 1)

and 0.9641359 (Method 2). The comparison reveals that

Method 3 achieved the fit closest to 1. Fig. 14.1] shows curve

fitting of actual data by the Method 3,

i”

‘TABLE 14.3—HYPERBOLIC-DECLINE-CURVE PARAMETERS

USING NONLINEAR REGRESSION

Hyperbole Decine-Curve Parameters Regression Goefciont,

case a 4 a ___

Sider example 05241 0.00159 69273 0.990842

Borie field ogee = 0.05951 90,191.73 0.984216

Wetlt 3.73920 0.47052—1,838.05 o.ses098

Wetl2 308071 0.46400 1,63.99, 0.968656

wets 140244 0.68698. 4.579.77 0.975136

weld 4azts2 0.21596 664.63 0.986547

Wells 02684 0.1256 1500.81, 0.960890

wells 263868 0.16823 3,018.10 0.973083

| :

i :

a é

‘ . sas ee ee

Date Yoar

Fig. 14.10—Hyperbolic-curve fit, Slider’s example

Fig. 14.12—Hyperbolie-curve ft, Well 1.

Six unnamed wells from the Powder River basin were cho-

sento test Method 3 further. Regression coefficients for Wells

| through 6, respectively, are 0,948098, 0.968656, 0.975136,

0.956547, 0.969890, 0.973983,

In Table 14.3, note thatthe hyperbolic exponent, nis great-

certhan I for Wells | through 6. Towler and Bansal'® offer the

following explanation for this. Fetkovich? postulated that

usually falls between 0 and 1. Other researchers have given

reasons why n cannot be greater than 1 or less than 0. They

‘base this on analysis that assumes single-phase flow in homo-

‘geneous simple geometrical reservoirs. However, experience

18

Fig. 14.11—Hyperbolic-curve fit, Bort field.

Monin

Fig. 14.13—Hyperbolic-curve fit, Well2.

shows that numerous field cases exist where this is not so. In

the case for n greater than 1, Towler and Bansal!8 suggested

thatcases of n > 1 could be caused by fractured or heteroge-

‘nous reservoirs and that cases of n < I could result fromme-

‘chanical problems.

‘The nonlinear-regression technique of this section may not

always be the most accurate method of fitting the data It de-

pends somewhat on the source of the errors which cause the

scatter in the data. Ifthe errors are relative errors (relative to

the value of the production rate) then a technique, which re-

_gresses on the logs ofthe variables, may be more accurate. If

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Rate, STB/mostn

Fig. 14.14—Hyperbollecurve fit, Wall 3.

Month

Fig. 14.16—Hyperbolic-curve fit, Well 5.

the errors are more absolute (not dependent on the value of

production rate) then the regression used here, which re~

gresses on the absolute value of the variables, may be more

accurate. In certain circumstances, a weighted regression

‘may be more appropriate.

‘Once the decline parameters have been determined from the

production history, Eqs. 14.2 through 14.7 can be used to fore

cast future production rates and total cumulative production

froma well or field, Sometimes, however, itis useful to adapt

the formulas to special situations. Eqs. 14.2 to 14,7 can caleu-

late the rate ata given time or total cumulative production at

that ime, To determine the annual production for future fore~

‘asts, for example, the pitfall of calculating the rate at some

point then multiplying by 36S to get the annual production

should be avoided. This is wrong because the rate changes,

throughout the year. One could calculate the cumulative pro-

duction atthe beginning ofthe year and again tthe end ofthe

year and subiract the two to get the annual production. How-

ever, this can be done in one step by deriving the following

‘equations to give the cumulative production between two

time periods, and 1)

For hyperbolic decline,

Op = On = Tang l i” (14.14)

DECLINE CURVE ANALYSIS

Fate, STBimonn

Month

Fig. 1.17—Hyperbolic-curve fit, Well 6.

forexponenta decline,

Op ~ On = BF (iaas)

and for harmonic dectne

dag (22

On = On = fin( $4) + (416)

Another useful set of formulas calculates the time to reach

‘certain production rate once the decline parameters are de~

termined. The following are the time formulas.

For exponential decline (n= 0),

v= du(@): asin

for hype dete

[ley -

2(() ‘} ass

and forharmonc elie (=

a1} (4)-

-afe)-] ca)

Itis also important to be able to calculate the decline rate

at any Time #, This can be used to convert wells that started

production at different times to the same time basis. The for-

179

‘mula also can be used to calculate the decline rate every day,

every month, orevery year. From Ea, 14.1, the decline rate at

any Time ris given by

,

(#)

ee

decline rate remains constant when = 0, while the decline

rate decreases with time for n > 0.

4,

(1420)

Problems

14.1 A well with an exponential decline of 19/month cur-

rently produces at 150 STB/D.

1. What will its production rate be in 2 years?

2. What will its cumulative production be in those 2 years?

3. What will its decline rate be in 2 years?

4, How long will it take to reach a rate of 10 STB/D?

'5. What will otal cumulative production be from the end of

‘Year 24 10 the end of Year 25?

142A well with a current harmonic decline of 1%/month

currently produces at 150 STB/D.

1, What will its production rate be in 2 years?

2, What will its cumulative production be in those 2 years?

3 What will its decline rate be in 2 years?

4, How long will it take to reach a rate of 10 STB/D?

5. What will otal cumulative production be from the end of

Year 2410 the end of Year 25?

14.3 A well with a current hyperbolic decline of 15:/month

and = 0.6 currently produces at 150 STB/D.

1. What will its production rate be in 2 years?

2. What will its cumulative production be in those 2 years?

3. What will its decline rate be in 2 years?

4, How long will it take to reach a rate of 10 STB/D?

5. What will total cumulative production be from the end of|

Year 24 to the end of Year 25?

1444 A well has production data given in Table 14.4.

1. Make the following plots

a. Log 4, vs. 1

‘TABLE 14.¢—PRODUCTION HISTORY FOR PROBLEM 14.4

Time Fate

(ernie) _1sTa0)

os 80

15 596

25 579

35 523

45 531

55 at

65 410

15 410

85 456

95 382

105 405

ns 384

125 264

135 388

145 223

b. avs. Oy

Log 4.5. Q,.

a. 1/51

2. Determine whether the decline is exponential hyper

bolic, of harmonic.

3. Use hyperbolic-decline-curve analysis with nonlinear

repression ona spreadsheet to determine the exponent: ini-

tial dectine rate, d and apparent initial rate, 4,

4. Use these 1 estimate the expected rate and expected eu-

mulative production in (a) the 240th month and (b) the 480th

month,

'. What isthe remaining life of the well ifthe economic

limit is 6 STB/D?

14,5 Table 14.5 shows a well’s production history

1, What type of decline is this and why?

2. Estimate the production rate at r = 0,

Estimate d, and n

intercept on y axis,

general decline rate, L'/t, RB/D

decline rate, L'/t, RB/D

hhyperbotie-dectine exponent =

integration constant

slope of best-fit Hine

hyperbotic-dectine exponent = 1/h

initial oiF- production rate, L'/t, RB/D

production rate at Time r, L'/t, RB/D

‘cumulative production at Time tL, STB

regression coefficient

sum of squares of errors in measured data

= total sum of squares of measured data

time,

independent variable

dependent variable

/n

Superseript

average

‘TABLE 14.5—PRODUCTION HISTORY FOR PROBLEM 145 |

Time Rate

(months) _ _(sTB1)

° 350

1 345

2 30

3 395

4 330

5 325

6 320

7 315

8 310 |

8 306 |

10 301

" 27

2 22

13 208

“ 284

180

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING.

-_

References

1. Apps, JJ"Analysis of Decline Curves," Trans,, AIME (1945)

160, 228

2. Amold, R. and Anderson, R.: Preliminary Report on Coalinga

Oil Distic." U.S. Geological Survey Bull. (1908) 387, 79.

3. Cutler, W.W. Je: “Estimation of Underground Oil Reserves

by Well Production Curves,” U.S. Bureau of Mines Bull.

(1924) 228,

4, Larkey, CS: "Mathematical Determination of Production De-

cline Curves,” Trans., AIME (1925) 71, 1322

5 Pirson, SJ: “Production Decline Curve of Oil Wells May Be

Extropolated by Loss Ratio Method,” Oil & Gas J. (1935) 34,

No. 46,34

6. Arps, JJ: “Estimation of Primary Oil Reserves,” Trans.,

|AIME (1956) 207, 182

7. Fetkovich, MJ. Fetkovich, EJ.,and Fetkovich, M.D.:“Useful

Concepts for Decline Curve Forecasting, Reserve Estimation,

and Analysis,” SPERE (February 1996) 13

8. Slider, H.C.: “A Simplified Method of Hyperbolic Decline

Curve Analysis.” JPT (March 1968) 235

9.Fetkovich, MJ: “Decline-Curve Analysis Using Type

Curves," JPT (June 1980) 1065.

10, Long, D.R, and Davis, M.J: “A New Approach tothe Hyper-

bolic Curve," JP7 (uly 1988) 909,

1, Kelkar, B.G. and Perez, G.: "Discussion of A New Approach

to the Hyperbolic Curve,” JPT (December 1988) 1617,

DECLINE-CURVE ANALYSIS

12, Fraim, M.L, and Wattenbarger, R.A. "Gas Reservoir Decline-

Curve Analysis Using Type Curves With Real Gas Pseudopres

sure and Pseudotime.” SPEFE (December 1987) 620.

13. Gentry, RW: "Declne-Curve Analysis” JPT January 1972) 38,

14, Gentry, R.W. and McCray, A.W.: "The Effect of Reservoir and

Fluid Properties on Production Decline Curves," JPT (Septem-

ber 1978) 1327.

15, Levine, J. and Prats, M.: “The Calculated Performance of

Solution-Gas-Drive Reservoits,” SPEJ (September 1961) 142;

Trans.. AIME, 222.

16, Bailey, W.: “Optimized Hyperbolic Decline Curve Analysis of

Gas Wells” Oi! & Gas J. (15 February 1982) 116,

17, MeNolty, RR. and Knapp, RM. “Statistical Decline-Curve

Analysis.” paper SPE 10279 presented a the 1981 SPE Annual

Technical Conference and Exhibition, San Antonio, Texas, 5-7

October,

18. Towler, B. and Bansal, S.: “Hyperbolic Decline-Curve Analy

sis Using Linear Regression,” J. Pet Sei. & Eng. anary

1993) 8,257,

19. Slider, H.C: Worldwide Practical Petroleum Reservoir Engi

‘neering Methods, PennWell, Tulsa, Oklahoma (1983) 542,

20, Walpole, R.E. and Meyers, R.H.: Probability and Statisties

‘Jor Engineers and Scientists, MacMillan and Co., New York

City (1972),

‘SI Metric Conversion Factors

bbl X 1,589 873

ft 2.831 685

wr

ice

Appendix A

Values and Tabulations

‘TABLE A-1—VALUES FOR EXPONENTIAL INTEGRAL (adapted from Ref. 1)

=Ei(= 9, 0.000=0.208, interval 0.001

x ° 1 2 a 4 5 7 8 2

000° += 693256395205 ada 708 49024259 a2

001 4038 «3948 = 385837793705 3.637 3514 3458 3.405,

oo2 3955 39073261 328176 3.137 3062 30282002

003 2959 ©2827 baer 267 28982810 2758 2731 2.706,

00s 2681 Bess 26382122590 568 2527 25072487

005 2408 ©2449 bast 2132.95 277 pase 2ae7 at

005-2295 = 2279 a6e © BD 2205 2.200 21g2 2178 6s

007 2151 24982125 2220992087 2062 © 20502039

008 202720152008. «3.991.982 1.97 4.950 1.939 1.929

009 1919 4.909 1.890.889 1.8791 869 1850 1881 1.892

010 48291814 = 1805 1.705.788 1.779 1762001754 1.745

om 737.729 tata 4.705 1.697 16621674 1.667

012 1.600 1.652645 1638 611.628 1603 1.603 1.596

0131588 158215761569 15621556 158315371830

ox 1524 ©1518 451215061500 1.498 14s20 1476 4.470

015 1404164581453 naa? tae? 1498 14251420 1.418

016 1.409 140¢ 1900 1.993 4.988) 1.988 1373 1.968 1.968

On7 4958 1983138194339 1.399 1328 13191314

O18 1910 1.905301 1.206.291 1.287 12781274 1.269

0x8 1.285 128112581252 «4.248 1.083 1285 12311287

020 1.2230 121912181210 1.208202 4195 tot 187

—_ = Bil, 000< x 200, inter _ —_

00 +2 4038985592681 2H8§= 2285S TST SCT ~C«NND

O1 1823 1.737 486015891824 t464 1.408 4.358 1.3001 208

02 1223 1.189.145. t.110=1078 04 = 1.014 850887 oat

03 0.906 0.882 Oass 088s ots oes © 774 = o785 ora? O79

04 0702 0.686 087008554025 Ost = s88 «©0888 72

05 056005480536 0s8S asta ©0503] a7 (Ose

06 045s ads 043740012 =o 0.396888 381

07 0378 036703600888 oa7 adds g8 ee 6

08 0311 0308-0300 0850289284 ©=— 279740630288

09 0260 0258 ©0281 ond? 2430209) 0235 «oat oer 0223

19 0219 oz oz12 020902050202 0198 «195 «tg.

44 0486 0.183 0.180 0.177.174.7269 e664 ote

12 0158 0.550.153 Ots1 01490148 tad tae.

13 0438 013303109 0.t27 0.125 tesa t20 nt

14 06 ote = oS ott 0.109.108 0.806. ~—0 1050103 tae

15 0.1000 00985 0.0971 0.0857 0.043 0.0929 091s 0.0902 o.0889 © 0.0876

18 0086300851 0.0898 0.0825 0.0814 080200791 0.0780 0.0768 -—«O.0TST

17 00747 0.0736 0072500715 0.0705 0.0698 O.08RS 0.0675 0.0668 0.0686

18 0.0847 0.0698 0.0629 0.0620 0.0612 0.0503 00595 0.0586 © 0.0578 0.0870.

19 00562 0.0554 0.0548 0.0539 0.0531 0.0524 0.0517 0.0510 0.0503 0.0896

20 00489 0.0482 0.0475 00469 0.0463 00455 0.0850 .OK4A —OOHSB OOS

2.0 7.189,

18x10 6447 25x10 6605 BOxt0> 7.098 60x10 7.026 TOx10 7.114 90x10 7.238,

20x10? 6494 90x105 6.681 90x105 7.056 7.0x109 7.082 BOxI08 7.167 1.0108 7280

25x108 6587 35x105 6.738 10x10 7.067 BOx10° 7.123 90xI05 7.210 158x108 7.407

380x108 6652 4.0x105 6.781 12108 7.080 90x10° 7.156 10x10 7.244 20x10® 7459,

40x108 6729 45x10% 6813 14x10 7.005 1x10 7.177 18x10 7.394 © S0xt08

4SK105 6751 50x105 6897 16x10 7.088 15x 108 7.229 20x10 7.964 © 40x108 7.495

50x10 6766 55x 105 6.854 18x10 7.089 20x10 7241 25x10 7373 50x10 7.495

SSx10° 6777 60x15 6.868 19x10 7.089 25x108 7.243 30x108 7.376 SAxt08 7.495

80x10 6.785 7.0x105 6.885 20x10 7.090 30x10 7248 38x109 7977 S2xt08 7.495

70x10 6794 80x05 6.895 21x10 7.090 31x10 7246 40x108 7.978 Saxt08 7.495

80x10 6798 9.0x105 6.901 22x10 7.090 32x10 7246 442x108 7978 Saxto® 7495,

80x10 6800 1.0x10% 6.904 23x10 7.090 339x109 7246 44x10 7378 Sexto® 7.495,

10x10 6801 12x10 6907 24x10 7.090

to. _fop=2.2000 op=2.4000 _ _ tgp =2,6000 fa=28000 __49=3,0000

bm bm bm _b m _» m » pw

40x105 6854 50x10" 6.966 60x10 7.057 7.0x105 7.194 80x10 7201 10x10 7912

50x10 6966 55x10" 7.013 70x15 7.134 BOx105 7201 90x105 7260 12%108 7403,

60x10 7.056 60x05 7.057 BOx10§ 7200 90x10 7259 10x108 7912 14x08 7480

7Ox108 7192 65x10° 7087 BOxI0% 7.259 10x10 7.912 12108 7409 16x10 7.545

Box108 7.196 7.0x105 7.139 Loxto8 7310 12x10 7401 16x10 7.542 1ext0® 7.602

90x10 7251 75x10% 7.167 12x10 7.998 14x10 7475 20x10" 7.644 20x10 7.651

410x108 7.298 80x105 7.199 18x10 7525 16x10 7596 24x10 7.719 24x10 7790

12x18 7974 95x105 7229 2ox10% 76H 18x10 7588 Zax 7.775 268x108 7794

14x108 7431 90x105 7.256 24x10 7.668 20x10 7631 30x08 7.797 a0x108 7.820

168x108 7474 10x10 7307 28x10 7706 Zax 108 7.699 35x10 7e40 © asx10 7871

18x10 7.506 12x10 7.990 30x10 7.720 2axioh 7.746 40x10° 7.870 40x108 7.908,

20x10 7590 16x10 7.507 35x10 7745 30x10 7.765 5.0xI08 7.905 45x10 7.995

25x10 7506 2ox10% 7579 40x10 7760 35x10 7.709 6.0x10° 7.922 sox 7.955,

30x10 7584 25x10 7.631 50x10 7.75 40x10 7.821 7.0x10° 7990 Baxi 7.979

85x10 7.593 90x10 7.661 GOx10% 7780 50x10 7.845 B.0x10° 7994 70x10 7.992

40x10 7597 95x10 7.677 7x10 7.782 60x10 7.856 9.0x10° 7.996 80x10 7.999

50x10 7.600 40x10 7.688 80x10 7.783 70x10 7.860 10x10? 7997 90x10 8.002

60x10 7.601 $0x108 7.693 GOx10 7.783 BOx10° 7.962 12x10" 7997 1.0x107 8.004,

64x10 7.601 60x10 7.695 95x10 7.783 90x10 7063 19x10? 7937 12x10? 8.006,

70x10 7.696 10x10” 7.863, 15107 8.006

80x10° 7.696

‘VALUES AND TABULATIONS,

is

‘TABLE A-3—TABULATED SOLUTIONS TO EQ 6.34, CONSTANT TERMINAL PRESSURE

ININFINITE CYLINDRICAL RESERVOIR

ee ee Oe SB I Be ca

000 0.000 «© 40.«— (20.804 4o6es 330 «114738 —«670-—208.502 321.032

oor ome 412.208.0345 116.189 675 200.825. 323517

005 0g7@ 422.701 954.385 © 340117638 «680.211.1485, 324.760

010 0404” 43 2101-96 41.735 345 119.083 600215. 784 326.000

015 052044 «= «22.500 97 a.084 © 350120826 © 700 216.417 328.480

020 0806 «45. 2.85798 ads 385 t2t968 «710 «219.046. 330.958

025 0889 «48 «23.201 99 az 7B1 360123403 «720 221.670 333.433

050 0758 © 47.23.68 1004.29 65 takaa8 «72522980 335.906

040 0.898 «48S 28.078 «= 1054.58) 7D 126270 «790 2aa.209 37.142

050 1020 «492.465 «10S «48.574 7527699740 (226,904, 338.376

060 114050285 HS 48.277 380.128.126.750 2.514 340.843

070 1.251 «St 25.284 © 120«S «49.968 985190550 760 282.120, 348.308

080 1359 5225633125. 1648 390191972 -70—«238.721, 348.770

090 1469536020130 S317 995. 138:01 75 296.020 348.290

1 1569 54 26.406 «135 «54.976 400134808 «780 287.918 349.460

2 2447 5528781 14088625. «405196223 «790 209812 350.608

a 3202 5827.74 14588265 410197695 «800242501, 353.148

4 38035727585 15059805 415 130045 B10 245.086 355.597

5 4539 58 27.935 15561517 420140453820 (247.668 358.048

6 5153 5928314160313 425141859825 (248.057 360.496

7 5743 60 «28.691 «165 GATST 490 148.262 «830 250.245 361.720

a e31¢ 612.088 «17065336. 435 © T4kE5s B40 (252819 962.942

9 aco 6220.49 175 67.928 440 148.064 «850 (255.988 965.986

10 7a 6320818180 wast 445. 147.461 6D 257.959, 367.228

" 7940 64 ~=—-30.192185=74.090 45014856 «870260515 370267

2 8457 65—«90.565 «19072661455 «150249 «B75 (261.795 372.708

13 8964 65 «90.937 19574226 © 480 «151.460 © «88D (268073 373902

“ 9461 67 «31.808 200««75.785 485153028 «890265629 375.198

15 9949 6831679205 77.9398 «470 «154416 «= «800 —268:181 s7s72

16 10.434 «69S 52.088 210=S«7.8BG 475155801 © 10270729 380.008,

17 109137 seat7 158A 480157188 © 920278274. 382.432

13 1138671 32.7B5 2081.95 485158565 925274545 364.859

19 185572, 33151225 8B497 490159945 930 275815 386.070

2 123197333517 2305.23 «495 t61.322 940 «278.353 387.283

21277874 aa 2056 SKS «= 500 taz69e © 950 2a0.AEe 389.705

22 192037534247 ©2402 «S10 165.444 © 960 283.420 92.125

23 1968478 KUTT 245 O75 520 168:183 © 970 285.988 306.543

24 tata 77349742509. 525tNSAD aS 27.2 396.968

| 2 1457379 95336 255 92889 830170914 «980 288.473, 998.167

| 25 1501379 35.697 200» 94.090 S40 17639 990 200,095, 399.373

27 18450 «88058265588 S50 176.57 1,000 293514 401.706

| 28 15883 st 36.418 270 97.081 560 «178.069 1,010 296.030, 404.197

[29 t6s13 2 8.777275 9s71 570 teL.774 © 1,020 298543, 406.606

[90 16742 63.97.1968 280 100057 580104473 1,028 290.700 1,470 400.013.

[ot wrse7 a 285 101540 590 187.166 1,090 301.053 1475 410.214

|s2 1759085 290 103.019 600» t89.852 1,040 303860 1480 411.418

[33 tom 898.207 205104495 BIO «192533 1,050 308065 1,490 418.820

4 = 1842979569300“ T05.68 620195208 1,060 908567 1,800 416220

95 1884S WB ROI] 90S T07AGT © 62516544 1,070 31.068 1.825 422214

36 19259 a9 «39272-10008 GD T97ATB 1.075. 31214 1.850 428196

a7 19671 «99628315 HOST © GH 2NSAZ 1,080 319562 1.875 434.168,

38 20080 © gtSa.979 g208T— BSD 209201 1,090 916055 1,600 440.128

3920488 924.3355 113.284 66020554 1,100 318545 1.625 448.07

186

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

TABLE A-S—TABULATED SOLUTIONS TO EQ 6.34, CONSTANT TERMINAL PRESSURE

ININFINITE CYLINDRICAL RESERVOIR (continued)

bo ° % b o © > be _

1850 452016 3.100 72992 5.800 1.950205 0,000 aoese00 78x10? ie0axi07

1875 497.945 3,150 7a4.042 5.900 1.379.927 25,000 5.008728 20x10? 2108107

1700 469.069 9200 805.075 6.000 1.400593 30,000 5.800.508 25x10" 2607107

1728 46071 9250 816.090 6.100 1.421.228 © 35,000 6.780.287 30x10 3.100010"

1780 475669 3500 27.0086 200 1.441.820 40,000 7.850096 40x10 407i 107

175 481558 3.350 898.067 6.300 1.462.983 50,000 91963099 S 0x10? 00107

1800 487.497 3400 a49.028 6.400 1.482912 60.000 11047299 60x108 saB 107

1825 493.907 3.450 859.974 6.500 1.503.408 70,000 12708.358 70x10? 6.908107

1850 499.167 3.500 870.903 6.600 1.523872 75,000 13531487 @Ox10? 7.865107

1875 5050193850 861.816 6,700 1,544,905 80,000 14,960.121 90x10" B77 107

1.900 510861 31600802712 6.800 1.864.706 90.000 15.9075.389 10x10? 97254107

192 51669531650 909.504 6.900 11585.077 100,000 17596284 15x10? 1.409108

1950 622520 3,700 914.459 7,000 1.605.418 125,000 21560732 20x10? 1.880108

1975 528997 3750 926.909 7,100 1.625.729 180,000 2598x10' 25x10? 2226108

2000 594.145 3.800 996.144 7.200 11648.011 200.000 3308x104 3.0%109 2771x108

2025 599945 3.850946 986. 7,300 1.666.265 250.000 4.086x10' 4.0%109 3.645. 108

2050 545.737 3.800 957.779 7.400 1.686.490 900.000 4817x108 Sox102 asioxio8

2075 951.522 3.950 968.588 7,800 1.706688 400.000 6.267x10' 60x10? 5.968108

2100 587.299 4000 979.344 © 7.600 1726859 500.000 7690x10 7.0%109 6.220% 108

2125 86.068 4.050 990.108 7,700 1.747.002 600.000 8.11310 0x10? 7.068. 108

2450 568.800 4,100 1,000.85 7,800 1.767.120 700000 1051x105 9.0109 7.900% 108

BATS 974585 4,150 1.011505 7,900 1.787212 00000 1.189105 1.010" 8.747% 108

2200 580332 4200 1,022.318 8.000 1.007.278 900.000 1326x105 15x10! 1.288.108

2225 886.072 4,250 1098028 8,100 1.827.919 10x10 1462x105 20x10" 1.657% 108

2250 591.085 4.300 1.049.724 8.200 1.847.956 15x108 2126x105 25x10 2109. 10?

227s 597592 4.380 11054409 8.300 1.867.329 20x108 278x108 30x10" 2508x107

2900 60925 44001065082 8.400 1887298 25x10 3427x105 4.0% 101 3.200% 108

2825 608965 4.450 1.075743 8500 1.907249 30x10 4084x105 50x10" 4.087% 108

2350 614672 4.500 1.096990 8600 1.927.168. 40x10 5.313105 60x10" 4.868.109

2a7S 620972 4.550 1.097.024 8700 1.947.065 50x10 6544x105 70x10 5.649109

2400 626.088 460014107646 81800 1.966942 OXI 7761x105 BOx109? Eaten io?

2425 691.755 4650 1,118257 8,900 1.986796 70x10 965x105 90x10! 7.189% 108

2450 637.437 4.700 1.128854 9.000 2.008.628 80x10 1016x108 tox10" 794ex 108

2475 643.113 4,750 1,199499 9,100 2.026498 90x10 1134x109 s.Sxt0 117K 108

2500 648.781 4800 1,150012 9200 2.046227 tox10? 1282x108 20x10! 435x010

2550 6600834850 1,160574 9,300 2.065996 15x10? 1828x108 25x10" 182% 1010

2600 671.379 4.900 4.171.125 94002085744 20x10? 2308x105 30x10" 2.204100

2650 682.640 4.950 1.181.688 9500 2.105479 25x10 2961x105 40x10" 302x101

2700 693877 5.000 1,192198 9.600 2.125.184 B0x107 35I7x10® s0x10" 9375x1010

2750 705.000 5,100 1.219.202 © 9.700 2144878 40x107 410x108 GoxI0" 4.47% 1010

2900 716280 5.200 1.294.208 9800 2.164555 50x10? S689x10° Toxt0! 519% 1010

2850 727449 5.300 1.255.161 9900 2.184218 80x10? 6758x109 BOx10" sa9n1010

2900 798598 $400 1,276.037 10,000 22200861 7.0x107 7816x108 90x10" @s8x1010

2950 749725 5.500 1206899 12.500 2.688987 BOx107 Basex108 10x10" 728% 1010

3000 7608335600 1.917.709 15.000 3,164.780 90x107 g.atx10 15.10% 108~1010

9080 771922 5,700 1.298486 17,500 __ 3633.60 1.0x108 1.095107 20x10" _taexi0!"

VALUES AND TABULATIONS

17

‘TABLE A-4—TABULATED SOLUTIONS TO EQS. 6.34 AND 6.40, CONSTANT TERMINAL PRESSURE

IN BOUNDED CYLINDRICAL RESERVOIR

fp=18—_ teo=20 3 _wo=30_pn35_ apna

bw & b a = —% b _G _b

005 0276 005 0278 0.10 0408 0.30 0755 1.00 1571 200 2442

006 0304 0075 0345 015 0509 040 0895 1.20 1.761 220 2598

007 0330 010 040s 020 0599 050 1023 140 1980 240 2748

008 0954 0125 0458 025 ost 060 1.143 160 2111 260 2803

009 0375 0150 0507 090 0758 070 1.256 180 2273 280 90%

010 0395 0175 0553 035 0.829 080 1.363 200 2427 300 3.170

O11 0414 0200 0597 040 0.897 090 1.485 220 2574 325 a9%4

012 0431 0225 0698 045 0.962 100 1.563 240 2715 350 3493 60 4985 65 5.345

0.13 0446 0250 0678 050 1.024 125 1.791 260 2849 375 3645 65 5231 7.0 5.605

014 0461 0275 0715 055 1.083 150 1.997 280 2976 400 3792 70 Séo4 75 5.85t

045 0.474 0900 0751 060 1.140 175 2184 300 3008 425 3992 75 Sea 80 60%

0.16 0.486 0825 0785 065 1.195 200 2953 3.25 3242 450 4068 80 5802 85 6.325

0.17 0.497 0350 0817 070 1248 225 2507 350 3379 475 4198 85 6089 90 6547

0.18 0507 0975 0848 075 1.299 250 264 375 3507 S00 4923 90 6276 95 6760

019 0517 0400 0877 080 1948 275 2772 400 3628 550 4560 95 6453 10 6.965

0.20 0525 0425 0905 085 1995 300 2885 425 3742 600 4779 10 seat 11 7.350

021 0533 0450 0932 090 1440 325 2990 450 3850 650 4982 11 6930 12 7,706

0.22 0541 0475 0958 095 1484 350 3084 475 3951 7.00 5169 12 7.208 13 8035

0.23 0548 0500 0963 10 1526 375 3170 500 4047 750 S949 12 7457 14 8300

024 0854 0550 1028 11 1.608 400 3247 550 4222 800 5504 14 7680 15 8.620

025 0859 0600 1070 12 1679 425 3317 600 4378 850 5653 15 7.880 16 8.879

025 0565 0650 1108 13 1747 450 3381 650 4516 900 5790 16 8050 18 9.398

028 0574 0700 1.143 14 181 475 9499 7.00 4699 950 S917 18 865 20 9791

030 0582 0750 1178 15 1870 500 3491 750 4749 10 6035 20 6m 22 1007

032 0588 0800 1203 16 1924 550 3581 800 4m6 11 6246 22 8809 26 10.5,

034 0594 0900 1253 17 1975 600 3656 850 402 12 6425 24 ag68 25 1059

096 0599 1.000 1295 1.8 2022 650 3717 9.00 5009 13 6580 26 9.097 28 1080

038 0603 11 1330 20 2108 700 3767 950 5078 14 6712 28 9.200 30 1098

040 0606 12 1.888 22 2178 750 3809 10.00 5.198 15 6825 30 9.283 34 11.26

045 0619 13 1382 24 2241 B00 3843 11 5241 16 6922 34 940d 981148

050 0617 14 1402 26 2204 900 sao 12 5321 17 7.008 98 9481 42116

060 0621 16 1492 28 2940 1000 2928 139 5285 18 7076 42 95% 46 1171

070 0623 17 1444 30 2380 11.00 3951 14 5435 20 7.189 46 9.565 501179

080 0624 18 1453 34 2444 1200 3967 15 5476 22 7272 50 9.586 60 1191

20 1468 38 2491 1400 3.985 16 5508 24 7.32 60 9612 70 11.96

25 1487 42 2525 1600 3.993 17 5531 26 7377 70 9621 80 1198

30 1495 46 2551 1800 3.997 18 5551 90 7.434 80 9623 90 11.99

40 1499 50 2570 2000 3999 20 5579 34 7.464 90 9624 100 1200

50 1800 60 2599 2200 3.909 25 SEI! 38 7.481 100 9625 120 1200

70 2613 2400 4000 30 5621 427.490,

80 2619 95 5624 46 7.494

90 2622 40 ©5625 507.497

100 2624

8

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

TT €

‘TABLE A-4—TABULATED SOLUTIONS TO EOS. 6.34 AND 6.40, CONSTANT TERMINAL PRESSURE.

IN BOUNDED CYLINDRICAL RESERVOIR (continued)

® qa=7d a=20

% b _% > 6 ~ _&

60 58 90a Tai 5 ona 4291

65 suo 957127 107008 15S” osm 5278

70 878107989 17.920 2012.28 02975 61.98

7S 6002 «6 = 79022 east ae t319S a ozres 7398

80 62732 ast7 13800028 tao ozso2 ea.ea

85 6557 13 aera wt] o297 arot

90 675 4 att 150s) 281559 e170 1177

95 7087 159781018 we os 1036

too 723 «6 «= 0237 soe we 1710 ome ae

10s 75 «1710658287 0.0025 1587

7787184081917 twse 8 os 105.4

2 am 9 14a a9 BCC oma 74

13 8651201851205 gta ota 1878

14 9063-22288 2k 1974 ak asad oe 1994

13 9455281027 mts ak ta 00055 196.9

16 9829-25 139228528 Gata 0.0008 1992

17 1019-28 145392822285

te 1053905722 50 mame

18 1085359398 toas 52028

20 1840749408975 28D

2 N74 451843452028 5824308

2 1228501028 sanz 58288

25 1250 «)20S1 55 ed8 2585S

31374 72s 600405284870

35 14408 22.19 7th 70 arse 75

% 453 902263 802875280

51 1605 100 ©2000 «90 728) 2058s

eo 1656 120«S 2047100 as), ws 9018

7 69140. ma71 120 nat) 8083s

eo 1741160 = 2085 M8008 «85 ahs 100,

| 90 1727 10 = za92 1609058100 sea7 120 ast

100 1796200396 180 8120940 40.89

01741500 2400200124 aSg2 1604275

1201745 2409194 160 70k $80 aaatt

1901748 290 9143 1009785 200 45.06,

wo 1748 3203147 200 8s 240 48.95

1501749 3809149 240 ant? ao a7.

1601749 400 9150 200 9956 2048.54

10 1750 500 9150 9209977 8048.

20 1750 380 3988 4004014

m0 1750 400 3994 4404028

43097 4004926,

4902098

VALUES AND TABULATIONS 9

‘TABLE A-4—TABULATED SOLUTIONS TO EQS. 6.94 AND 6.40, CONSTANT TERMINAL PRESSURE

IN BOUNDED CYLINDRICAL RESERVOIR (continued)

=50 7e0=200 7g 500

o _@ & bo & b_ _® % bb _w %

600 02652 1892.00 02904 832x104 01943 219X109 1x10 01866 1.75x108

800 02915 241 3.000 0217975713104 0.1860 277xI0> 13x10 01498 221x104

4.000 02393” 200 4.000 02070 9691. 6x104 0.1820 399x109 16x10 0.1435 265x104

1300 02220 359 5.000 01967 1.171 2x10 01742 408x109 — 2x 10501954 B.21x104

11600 02060 473 6.000 01869 1,963 24x10 0.1869 472x109 24x10 01277 379x104

2.000 0.1865 502 8.000 0.1686 1,718 «x10 0.1262 569x109 ax105 0.1170 447x104

2400 0.1682 5731x104 0.1596 2,000 4x10 0.1401 7.17%109 4x10 0.1012 5.56% 104

3000 01543 667 13x10" 01904 246x107 5x10 0.1236 850x109 Sx 10° 0.0875 650x108

4000 0.1133 795 16x10" O11 262x109 Bx IO 01126 968x109 6x10 O75 7.a1x104

5.000 0.0833 695 2x10" GON 323x107 —ax10 0.0905 1.47%I0' ax IO 0.0585 | B62x 10

6.000 0.0682 974 24x14 O74: 356x109 1x105 00728 133xI0' tx 10 0.0822 9.60% 10

8.000 0.0413 1,082 3x10* 00645 394x107 1.3x105 OOS24 12x10 19x10 0.0273 1.06% 105

TAO 0.0258 1,148 410% 00326 437x109 1.6109 00878 1.65x10' 16x10 0.0176 1.19% 108

13x10 00120 1,201 5x10 0.0195 462x109 2x 107 0244 1.7Ax104 2108 0.0098 1.18% 105

16x10 00056 1,227 GxI0 DONT 477x109 24x10 0.0138 1.86x104 24x108 0.0055 121x108

2x10 oot 1241 8x10 0.0042 492x109 3x 10 0.0082 192x104 3x10 0.0023 1.23108

2Ax 10 0.0006 1.246 1105 00015 497x109 —4x105 0.0028 197xI0+ 4x 108 0.0005 1.25% 108

Sx10* 0.0002 1,249 1.410 0.0009 498x109 5x10 0.0009 1.99108 x10 0.0001 1.25x108

19 FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

a

TABLE A-4—TABULATED SOLUTIONS TO EOS. 6.34 AND 640, CONSTANT TERMINAL PRESSURE

IN BOUNDED CYLINDRICAL RESERVOIR (continued)

Tap =2.000 a =4000 iap=1.0%108

o & bo w ® ob _@ _& bo _@

‘3xi08 Ba0x109 1x10 01606 9x 108 0.1366 3x 108 0.1263. 406x105

axtot 754x108 2108 0.1820 t1 53 10!2not determined

9x10! 0.0568 6.85108,

1x10" 0.0858 751x107

‘teto" 0069 85x 10°

19x10" 0059938310?

18x10! 05st tera

2x10" 004041. g2x 1010

24x10" 044s 51x 1010

3x10" 00078 1758x1010

4x10" 00285 208x010

Sx10H 90817 aaax 1010

7x10" 90128 -2ars rato

1x10! 00055 agax1010

13x10 90024 04x 1010

‘extol aot a00x 1010

2x10 0004 attx1o¥

VALUES AND TABULATIONS, 93

"TABLE A‘S—TABULATED Gp AND qp VALUES FOR USE AFTER

FINITE-ACTING PERIOD FOR EXAMPLE 6.5

7 @ 4 9

thurs b _% (sta) (ST) w (sto)

1 tees = awa2 82 czas ORNED «ta

2 373632 7.1882 4908485089997 ©5784

3 s60448 10.9827 708 «=e O82

4 747263 13.4888 «= 9195080 0.178703 848.2

5 934079165324 «127878 OTSA 566

6 112095 195278 1331 4899 © on7a147 5200

7 1907711 224844 15324838 «= OnTt0M «507

8 494527 25.4085 1732478369950 S174

9 188.1943 2.3088 1929 «4737 oteTeAs 5128

10 188.6158 = 31,1789 21254097 = 865175087

15 280.2238 © 45.2538 30844605 O.161802 489.7

2 © S736317 889857 402042 O.tSBBS aI

25 467.0396 © 724718 4939 «412 O.SSHON 4760

90 s604475 85,7683 54S 450 O.SSHBE 4700

35 6538554 = egI2 © 6741 aa «0.18206 4850

407472633 1118253 7628 «4257 0.180823 4608

45 HOG71S 1248289 © 8507 azz 04062648.

50 9340702 1376358 93804189 «0.148567 4539

55 1027487 1503570 10254161 0.147624 4510

60 1.120895 t63.0012 1.111 41360146773 448.4

65 1218303 «1755758 1.197 «4113159094880

7 107,71 188.0867 ©1282 «= 4093 O.t45290 aan.

75 140119 2005001 1.367 «4073 0.aaBIS aan

80 1498527 at2.9574 1481 4056 0.144008 4400

85 1567905 225.2853 1535 409) Odes a8

80 1.661.343 2575863 1619 ©4024 042004 «467

95 1,774,750 249.8832 1.703 «4009 0.424g7 «4852

100 1,868,158 «2620587 1.786 «= 3898 O96) ©4887

105 1,961,566 274.2951 1,869 «9983141526 «aa

M0 2058978 286.9745 1.952 BTN ONTOS 41.1

115 2,148:362 298.4787 2034 ©3860 040708 «4209

120 2,241,700 © 3105496 2.118 989 O.t4oa29 ©4287

125 2395,198 922.5886 2198 988 0.130068 276

130 2.428.605 «9345872 2280 ©3828 0198620 «4286

195 2522018 948.5787 2962 «3819 N82BD «HBS

140 2615422 «988.5284 2443 ©3010 eO7 «42k

145 2708630 970.4832 2525 «3804018668423

150 2.602288 8.3524 2608 ©3892 «=O NaST2 «aaa

155 2.695645 994.2267 2687 38840198089 «aah

160 2.989053 4050772 2767 3877 OSTBIB 21.0

165 3.082461 «417.9047 288 ©3869 OSTSS2 4202

170 3,175,869 29,7099 2928 «= 9862137208 4195

175 3260277 441.4036 © 3.009 3855 0.137051 4187

180 3.362685 «4532565 ©3080 3848 0.136813 4180

185 3.456093 464.9992 3,169 ©5841 .136582 «4173

190 3549501 475,7223 3249 ©9835 0.138057 4166

195 3.642909 488.4285 3,909 382.9 0.136199 159

2003796317 500.1122 340898293 0.195028 415 3

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

E A‘S—TABULATED Qp AND ap VALUES FOR USE AFTER

FINITE-ACTING PERIOD FOR EXAMPLE 6.5 (continued)

r a 4 9

(ous) _tp C7 (st) (S730) _ qm (STB)

208 3aza7es «T1779 «38887 =— 0.198722.

214 4000619 503081. 3.633 3809 © 0.135350 4135

268 500x108 §— SAX IO 4455 688.2100 aT

321 600x108 §— 774x108 «827567 © NT9MOD EK

428 800x108 tor 108833608 0.115500 3829

585 100x107 124x108 waST 54 tt1800 «a4 6

642 120x107 148x108 99503361 0.108100 3003

749 140x107 167x108 4,981 208 © on04600 196

856 160x107 ta7x 108 © 12.744 3058 0.101200 309.2

964 180x107 207% 10° 14,107 30568 0.097000 200.1

1071 200x107 227x108 15.470 «3056 0.094800 289.6.

1281 290x107 254x108 17.310 ©2750 0.090200 2756

11606 300x107 3.14% 10 21,909 «2619 ©0000 as

2141 400x107 88x10 26442228. 0.068100 208.1

2676 500x107 51x10 30,7985 1925 0.057700 «1783

| ara7 700x107 s4ax10® 37.614 149.7 0.081500 126.8

4282 800x107 887x108 40,004 161 -——0.098200 1075,

4818 900x107 20x10 42,253 008 © 0.029800 at.

5953 1.00108 Ga7x10 44,008 «82S 0.025200 77.0,

6423 120x108 6 90x10 47.0287 == tet00 55.9.

7494 140x108 721x108 49,138 47.4 0.013000 87

9100 170x108 752x108 51,249 «31.6 000700

10708 200x108 771x108 52.543 19.4-——0.004800 147

12912 280x108 © 72x10 §3.293 «1.2 ———0.002000 89

ya917 260x108 789x108 59,770 74 0.001800 55

16059 300x108 794x108 54,t11 38 0000900 27

aiatt 400x109 799x109 54,452 15 0.000200 06

26764 500x108 800x108 54,520 03 0.000100 os

Reference ‘SI Metric Conversion Factor

1 Nisle, RG.: “How To Use The Exponential Integral." Per. Eng

(August 1956) BITL bbl x 1.589873 E-01 =m}

\VALUES AND TABULATIONS,

ws

Appendix B

Answers to Chapter Problems

Chapter 2

Problem 2.2 Tae!

Se ho ow

00 1.0000 ‘0.0000

02 0.8000 0.0000

03 0.4000 ‘200

0 o2er0 0.0570

os 0.1090 0.1000

os 0.0854 0.1370

o7 ooret o.1940

075 0.0090 0.2290

os 0.0000 0.2630

10 0.0000 1.0000

Problem 2.3,

& 4 4

015 3196255 985778 761078 4.820471

016 2227882 8406s S.408409 3.426419

0.17 1559562 6egt042 a. 7e4504 2.298562

0.18 1336640 5.906046 3.243629 2.055715

019 11.1304 4922003 270m204 1.71921

02 © 10.86331 4.711654 2587669 1.630987

025 7526388 3325592 1.826431 1.187597

03 564425 2493948 1.360688 0.868067

035 4391601 1.940502 1.085733 067543,

04 3.764307 1.663287 0.913486 057894

05 2500538 1.108858 0.60889 038596

[06 2195845 0.970251 osse867 0.337715

07 2087887 0900456 0.494535 0313421

08 — 1.882153 ogst64s © 0.456743 028047

09 1.882153 osst64a 0.456743 0.28047

11882153 o.@s1644 0.456743 0.20047

Problem 2.4 = = 0.7731

196

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Problem 2. c, = 522.9 x 10° psi!

Problem2.6 4, = 00172 ep

Problem2.7 1. z = 0.8570

22 = 08569

Problem 28 1. p, = 11.35 Ibm/ft

2. B, = 0.919 RBMef

Problem 2.9 0.0213 ep

0.0208 ep

97.0 x 10°* psi!

96.8 x 10°* psi!

Problem 2.10 =

Problem 211 [xg

%

(98)

93.674

11.060

6515

3960

36

2345

1874

1.480

1179

2651.7 413

Problem 2.12

1,000

1300

1.600

2,000

2.500

4870x106

11670% 10-8

984% 10-6

585% 10°6

451<10"6

390% 10-8

249% 10-8

184x10°6

sat 10-8

ANSWERS TO CHAPTER PROBLEMS

wr

nn |

Problem 2.13 1. p, = 2,509.7 psia

2.

TABLE BS

> @ % 6 Ho 8

(esa) _(psi-!)_(MeWSTB) (RBISTA) _(ep)__(RBMMH)

100 2290x10°F 0016-10847 1.8141 91.151

500 2220x10°§ ©0110 4.089.040 «S870

900 94.68x10-§ ©0222 1.1622 O7e71 3.076

11300 S555x10-€ © o348 = 1.2097 0.85a2 2022

1,700 9765x108 0.472 1.2808 0.8582 1.489

S204x10°F 0599 1.9128 Osea 1.816

2,100 0607 1.3446 0.4907 1.188,

2510 1897x10-6 0.750 .4128 0488 0.992

3000 1581x10-6 0750 1.9044 4602

3500 1955x10-® 0750 1.9875 0.4858

4000 11.86x10°S 0750 1.9828 5148

4500 1054x106 0750 1.4784 0.5467

5000 948x10-F 0750 1.9752 0.5819

3.

TABLE 8-58

egbo

(oo)

1.3891

9631

07440

06135

05268

0.4995

0.4648

0.4170

4. py = 2,775 psia

198 FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Problem 2.14 1. p,

2.

TABLE BS

P & Rs & Mo By

tose) _tpsi"")_(MetiSTB) (RANSTA) ep) __(RBIMe)

100128010" 00147 10828 S0720 29a1

200 4722x10- © og's 1060744781 14.279

300 2623x109 o0490 1.0788 39018 ©9580

400 1728x108 00671 4.0849 35000 6000

500 125.1%10"S 90857 10019 32628 5.40

600 98.01x10- 01048 s.0006 2.9860 4.449,

700 767810" 03125813074 27818 3781

a0 ea27x10-§ «0143115425509 3.200

e041 §955x10-F o1s00 1.1181 24890 3.080

1000 1368x106 1500 1.1158 2.5288

1500 9123x10°§ oso ani 204

2000 6842x10- 91500 1.1003 tae

2800 $474x10- 01500 1.1000 9.1898

3000 456x10- 01500 1.1071 9.4008

Problem 2.15 1. Undersaturated

2 py = 2,144.7 psa

3. By = 1.473 RBISTB

Ry = 740 scfSTB

4

TABLE BT

®

tos

erxt0-®

g6x10-8

1e6x10-8

21ax10°8

25.2%10°8

s2ox10°8

392x106

a7axto-e

ro9x10-®

e5.ax10°8

te9.1%10°8

390.1% 10-6

ANSWERS TO CHAPTER PROBLEMS

Problem 2.16

Chapter 3

TABLE 8-8

Diferential ~

. Pos Ba a R @

(osia) (soVSTB) —(RBISTB)-—(RBISTB)-—(sclSTB)—_(osi"

3515 7340 1372 705 14.28% 10

3415 7340 1374 705 © -20.87%10"S

31s 7340 1a77 705 14.25x10-8

3.215 7340 1379 75 Harx10-6

315 7340 1.381 75 21.29x10-6

3015 340 1.386 705 14:17%10°6

2ers 7340 1.386 705 1817 10-8

2ats 780 1388 5 13.11 10°8

2s 7340 1.390 75 19:14 10-6

2615 7a80 1.392 705 1809 10-8

2515 7380 1.395 70S 1305x10°6

2ats 7340 1.296 705 17.08«10-8

2318 7380 1.299 ms 1732x108

2.263 7349 1426 1.400 708 95.4% 10"

1970 6430 1.382 1387 6157 120.710

1.725 5740 1349 1328 5479 179.5«10-6

1470 4980 1316 1am 4733 2176x10"8

1215 4300 1.288 1.260 40858 8768x10"S

970 3540 1.252 1229 3319 o7.tx10-®

ns 2020 1221 1.199 ari 808.8% 10-8

465 2180 1.192 1.170 1984 14725% 10-8

as 140.0 1161 1.140 1218 68144x10-F

15 0 1.085 1.026 00

Problem 3.1

Problem 3.2

Problem 3.3,

Problem 3.4

20

1, 0.24682 psift

5.579 KPa/m,

2. 0.33478 psi/t

7.516 kPam,

3.0.27499 psist

6.223 kPa/m

Could be the same reservoir. Pressure for both wells

2,128 psia at 3.474 fiss.

‘The pressures differ by 24 psi at datum depth, but this may

not be significant, depending on the accuracy of the pressure

‘measurements. Therefore, it could be the same reservoir.

12 = 089

2. py = 0.0758 psilft

p= 3,423.6 psia

3. With Eq. 3.1, p

With Eq. 3.5, p

2,847.7 psi

2,891.7 psi (more accurate)

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING.

Problem 4.1

Problem 4.2

Problem 4.3

Problem 4.4

Problem 4.5

Problem 4.6

Problem 4.7

Chapter 6

1

2

3

15,354,000 STB

2-441 000 m?

1,563,000 STB

248.650 m?

848,500,000 STB

134°900 000 m?

260,600,000 STB

41 440 000 m?

166,300,000 STB

26 440 000 m?

41.38 Bset

1,996 Bsef

1,974.4 Beef

650.8 Bsef

190.47 Bet

With the trapezoidal rule, 222,509 MSTB

With Simpson's rule, 269,821 MSTB

With the pyramidal rule, 221,028 MSTB

27,704 MSTB

28,610 MSTB.

7,916 Bet

16,450 MSTB

—

Problem 6.1

Problem 6.2

Problem 6.3,

Problem 6.4

After I hour, p = 2,

8.7 psia

‘After 100 hours, p = 2,389.2 psia

After 1 hour, p = 2,528.7 psia

After 100 hours, p= 2,

89.2 psia

Alter | hour, p = 6,599.7 psia

After 100 hours, p = 2,389.2 psia

Finite acting at 5063 hours

Afier 1 hour, p

528.7 psia

‘Afier 100 hours, p ~ 2,389.2 psia

ANSWERS TO CHAPTER PROBLEMS

201

Problem 6.5 Finite acting at 60.8 hours

TABLES

_ thous) (esa)

° 3200

1 2500

2 2551

5 2902

10 2465

20 2428

0 207

4 2201

0 2279

© 2:70

70 22988

0 22959

% 22988

100 22054

Problem 6.7 Taare a

T a

(hous) (st)

1 1.762

2 1.861

5 1545

0 1466

2 1.306

2» 1.358

40 ase

50 1s12

60 1297

70 1.208

20 1279

| 90 1,264

100

202

1.255

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Problem 68

Problem 6.9

Chapter 7

TABLE 8.12

7 >

thous) (osie)

° 3.200

1 2588

2 2581

5 2502

10 2.465

" 2,988

2 2910

8 292

20 2943

at 2760

2 2750

2s 2737

20 2.726

t @

(hours (sta0)

1 1.762

1861

1.545

10 1.466

2 1,396

ay 1978

2s 2916

26 2804

2 ane

4 2620

“4 2545

“ 2522

*° 1.856

50 1,889

5 1919

58 1927

6 1921

a 1916

CS

Problem 7.1

Problem 7.2

Problem 7.3,

Problem 7.4

Problem 7.5

Problem 7.6

k = 100.0md

1,169 psia

102.5 md

= 034

Infinite-acting: & = 101.6 md

Finite-acting: k= 95,3 md (area= 173.3 acres)

k= 1.68md

5 = 034

kh = 105.5 md-f

k= 030md

s= - 062

ANSWERS TO CHAPTER PROBLEMS

a |

Problem 7.7. @ x ¢ = 1.57 x 10° psi~!

V, = 974.9 MRB

20.6 md

549

k

Problem 7.8 k= 930 md

k

12.0 md

2.85

Problem 7.9

Problem 8.1 1. Influx rate = 18,696 MRB

2! Schilthus k’ = 31.16 RB/Dipsi

Problem 8.2. Incremental water influx = 16,112 MRB.

TABLEB-14

ite > tie rr a

(vonths) (si BID) (months) (MBO)

° 2500 ° tt 7.689

1 2475 sat 12 8.500

2 2.450 3 9.395

3 2405 4 10269

4 2.400 2408 8 196

5 2375 3.140 16 2,100 rats

6 23380 3.839 "7 2075 13001

7 2905 4561 18 2.050 14.075

8 2300 5308 9 2,008 15.082

9 2275 6078 20 2,000 16.112

10 2.250

Problem 83 TABLE B15

r

(months)

°

3

6

| 9

| e

8

Problem 84 TABLE B16

t Wo

(ons) ci)

° °

3 °°

6 90

° eat

2 1402

15 2058

208 FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING.

Problem 8.5

Problem 8.6

Problem 8.7

Problem 88

Problem 8.9

2 493

8 465

‘Schilthuis representation is acceptable.

TABLE 8-18 -

te

2

15 615

18 870

a 1185

24 1.508

TABLE 6-19)

I ie %

(months) (wre)

° °

3 13

6 52

° 18

2 27

15 353

18 528

2 40

24 993

1. Water influx rate =7,298 RB/D

2. = 97.3RB(D-psi)

3. AW, = 30,277 MRB

MK’ = 335.4 RB/D-psi)

ANSWERS TO CHAPTER PROBLEMS

Problem 8.10 1, For intial oil in place = 801,440 MSTB and initial gas

cap = 336,980 Msc, the corresponding net water influx is:

‘TABLE 6-20—CONROE

Material Fetkovich van Everdingen

Balance Total Cumulative" Cumulaive

Lite infu Tux influx

years) __ (RB) (RB) (wae)

00 ° 0 °

os 3532 92 204

10 5327 490 1017

15. 131 1774 3554

20 20.879 4.432 8.426

2s 27.424 8242 14.880

30 35,67 we 21258

as 46.232 17316 27.308

40 52,354 zany 33,398

45 59.141 27.388 40.173

50 66,360 s2.945, 47.051

55 70,754 39,030, 54.693

60 795588 45.561 62796

65. 89,349 51.902 ea.a86

70 97012 57.901 76,123

75 103,646 636¢1 81,987

80 110,178 69,148 87.461

85 115.999 74503 92778

90 121691 79901 98207 |

9s 127673 35,430 104,090

100 139,485, 91275 1104873,

105 199,824 97586 117.627

110 146,138 1043392 125,466

15 154,785, 111759 134,056,

120 164,003 9973 143,998,

125 w4at7 129.47 155,983,

130 192.872 199.739 168,466,

138 206,061 150,480 181,123,

140 219019 162,006 194851

145 231.449 174251 200,320

150 26,194 187,182 224,479

155 261.601 200.883, 240,002

160 279.381 214540 255,797

165 293.813 220.208 272.695

170 313.045, 244.369 289;855

175, 328.065, 259.408 306,087

180 340.949 274.181 321.463

185 353.368 288.563, 336,423

190 368.212 303,309 351,727

195, 379.996 318.581 368,178

200 397.918 334.323 385,348

3. Adjustment to the VEH Method= increasing the aquifer

permeability to 300 md improves the fit to the material bal-

ance total water influx.

‘Adjustment to the Fetkovich Method= increasing the

aquifer permeability 350 md improves the fit to the materi

al balance total water influx,

4, With Plot 8.5:

B= 18.6 MRB/psi

‘Noi = 801,440 MSTB

206 FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Problem 8.11

Problem 8.12

Problem 8.13,

Problem 8.14

1. The plot is not linear, which means that the Schilthuis

‘model is not appropriate for this reservoir.

2, A large reduction inthe estimated aquifer permeability,

to 10md, provides a good fitof the van Everdingen-Hurstcal-

culation to the material balance history.

Furthermore, the Fetkovich calculation with this 10 md

also provides a good fit. This Fetkovich fit is much improved

lover that shown in Fig. 8.10,

‘TABLE 6-21—ALTON

Material

Balance —_Fetkovich—_van Everaingen

Cumulative Cumulative "Cumulative

Lite ux nx ius

(years) (RB) (wae) (RB)

0.00 ° ° 0

0.08 5 3 5

025, 8 25 4

058 87 108, 14

1.08 va 288 267

200 514 6a 559

400 1216 1.389 1,155

6.00 1.686 11570 4791

8.00 197 1.88 2047

10.00 2061 2.026 2210

14.00 2.205 2.213 2art

3.B'=0.232 MRB

Ni = 6.572 MSTB.

11,176 MRB (VEH Aquifer h=31.8 1)

3,000 MRB (IF Aquifer h=71.7 f)

2, 3,062 MRB (Fetkovich Aquifer

3. 3,098 MRB (Schilthuis)

17K,

TABLE B-22—MOONIE

Material ~——Fetkovicn van Everdingen

Balance Total Cumulative" Cumulative

Lite Influx inux Influx

(years) (MRE) (WRB) (was)

0.00 ° °

075 1.198 506

100 1719 907

125 2391 1,353

167 3749 2.198

225 5.838 3414

325 9.798 5.493

1342 58,793, 27.025

1742 73,465 36433

21so 100.563 asm

1. Recovery factor = 42.4% (with N= 48,735 MSTB)

2. Sweep efficiency = 93.1%

1. VEH Constant = 2.17 MRBYpsi

Tocaleulate 1D, the Huet factor is 0.0060

2. 001P=71,000 MSTB

3. Volumetric OOTP = 71,000 MSTB

ANSWERS TO CHAPTER PROBLEMS

207

Chapter 9

Problem 9.1 1. 30,600 MMscf

20.642

Problem 9.2 |

TABLE B23

> @

(sia) amis

2825 1027.68

2525 1,197.49

2.125 1413.48

4

TABLE 8-24

p We

(osia) (uste)

3,200 °

2,925 0.756

2525 27.007

2.125 174251

Problem 9.3 239,000 MMscf

Problem 94 330,000 MMscf; gas expansion is predominant. Aquifer in-

fluxis significant. And, especially in the early tages, the pore

volume-water compressibility is important.

Problem9.5 1. Gy = 1,644,000 MMscf

2

TABLE B25

' P We

(ron (pia (Re)

° 20989 °

2 2981 41677

‘ 2er 132,909

6 2.808 1,091,873

8 2987 1432449

10 2040 2954200

2 zen 3.360.381

1 2828 4569.07

6 2.808 6.429.259

18 2706 108.377

20 2782 9.925.608

2 2767 1.917.065,

By 2755 s4os7 i

25 2m 16475:533

28 276 18810,138

90 ane 21,152.749

2 2600 pazir.oae

u 2.688 25,720,485

36 2667 29913671

208 FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Problem 9.6

Problem 9.7

Chapter 10

Problem 10.1

Guy = 450,000 MMsef

With GIP = 328,700 MMsef, aquifer influx

10,806 MRB

9,750,473 fe

1,830.8 acres

12,500 MMsef

749.6 psia

0913

684.44 psia

3. G, = 20,500 MMscf-

piz = 1,229.44 psia

r= 087

P= 1,069.61 psia

1G = 191,461 MMscf

31,687 MSTB

2. Recovery =7,917 MMef gas and 1,310 MSTB condensate at dewpoint

3

TABLE 6-26

- Gas Condensate

Gas__Recovery Condensate Recovery

Pp Recovery Eficeney Recovery Eicioncy

(psia) (Me) MSTE) Se

5.800 0 00 ° 00

5450 79174 1310 a

590 1003082 164 52

| 4800 19231 100.282 8s

490 20783155 3.60

3800 4291922447142

3900 57,988 903521885

2800 72250 «303520184

2500 94172 49262081989

100 114235978673.

1300 194,660 703 6.980220

800185042 6107285229

4

TABLE 6-27

eB 3 R R

(psa) (RBISTB) (RBMMsct) (Msci'STB) (STEMS

5.450 06st 1655

5900 2314 0654 3.005.188:

4800 1785 0688 ats t139

4300 16 06981725 aot

3600 1472782 t4e7 52

3300 1968 083311758

2800 1.276 0955 23

2300 1197 1.156 776

18001126 1.475 606

1300 1086 2040 aa

800 0.996 3.288 203

ANSWERS TO CHAPTER PROBLEMS

209

Problem 10.2

Problem 10.3

Problem 10.4

TABLE 8-28

Total

Stago-1 Stage2_Gas_—_Condensate

Recovery Recovery Recovery Rocovery

(psia) (MMe). (Met) “(Met)” _(MSTB)

5728 000 000 0.00 0.00

4018 1012-129 wa 181

35151489183 m9 254

2918 223279 267 56

2ms 4389 40.9 4905 454

13186730837 “0s 519

20 8699 as 9516 sat

G = 96,752 MMsef (by volumetrics)

G, = 8.369 MSTB

‘These figures obviously are much higher than those ob-

tained by material balance. ILis possible that the net-thickness

figure is much lower than the 50 ft mentioned in the text. It

should be more like 12 to 13 f.

TABLE 6-29

Gas Condensate

P Recovery Recovery

tos) 0) a)

3.428 0.00 0.00

3.000 950 561

2.400 2530 tae

1.800 4522 1560

1.200 e462 1919

700 20.34 22.53

2

TABLE 6-30

P 3 % Re ®

(osia)(RBISTB) (RBMscf) _(MclISTB) _(STBMsef)

3428 0778 1481

3.000 1.886 08st 15550875

2400 1.859 0.981 to2t 0503,

1s 1371 4.318 06% ose

120 © 1201 2007 oz 0274

700 1.080 3572 01080296

Problem 10.5 G = 81,000 MMcf

210

G, = 11,664 MSTB

FUNDAMENTAL PRINCIPLES OF RESERVOIR ENGINEERING

Fon

—

Problem 11.1 OOIP==56,505 MSTB

Problem 11.2 Fy, = 3.90%

Recoverable oil = 2,469 MSTB

Problem 1. 312,000 MsTB

202,800 MMsef

TABLE B31

> We

—(osia)_ ure)

2.740 °

2.500 3.096

2.290 12204

2,108 za

1,989 34,607

1818 45.910

1.720 56.591

1,608 65.115,

1.535 mart

1480 81,527

1.440 7298

Problem 11.5, '= 280,000 MSTB

Problem 11.6 20,000 MSTB

Oil properties differ, but pressure connection through an aquifer is possible.

Problem 11.7 OOIP=N’=300,000 MSTB

indeterminate because R,; is not specified.

'= 86,000 MSTB

‘The above ignores the pore volume and water compressibility. These are important for this reservoir, which

produces above the bubblepoint pressure.

0x 10 psi-tis assumed,

Problem 11.8

Ifa pore volume + water

OOIP == 84,500 MST