Professional Documents

Culture Documents

Hindstan Nylons - Ptfe Catalogue

Uploaded by

SatyamEng0 ratings0% found this document useful (0 votes)

126 views11 pagesPTFE

Original Title

Hindstan Nylons- Ptfe Catalogue

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPTFE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

126 views11 pagesHindstan Nylons - Ptfe Catalogue

Uploaded by

SatyamEngPTFE

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

P. OLY Tetra iz LUORO Ernyene

Yolo GV ae w Cele Oe) ANY

HINDUSTAN

NYLONS

VET LE A (6

PTFE - Paly Tetra Fluora Ethylene

PTFE is high performance engineering specialty polymer invented

by Dr.Roy J. Plunkett at Du Pon's Jackson Laboratory, New Jersey,

US, on 6th April 1938. As the polymer was foundto have exceptional

properties with regards to chemical inertness, heat resistance &

frictional properties; developmental manufacturing began in 1943

with joint efforts of Kinetic Engineering Inc., USA. The commercial

production went operational by E.|,du Pont de Nemours & Co, inc.,

USA in 1948, The worldwide consumption of PTFE is around

1,00,000 Tones in 2011 & expected to grow at the rate of 10% per

annum.

PTFE - Polymer Science

PTFE Monomer is generally manufactured by synthesis of Calcium

Fluoride (Fluorospar), Sulphuric Acid & Chloroform. The

polymerisation of TFE is carried out in carefully controlled

conditions to form PTFE,

‘The chemical structure of PTFE is

Due to presence of stable & strong C-F bonds, PTFE molecule

possesses outstanding chemical inertness, high heat resistance &

remarkable electrical insulation characteristics; in addition to

excellentfricional properties

PTFE polymer is produced worldwide on commercial basis by a

number of chemical industries under different registered trade-

names such as Du Pont (TEFLON), ICI (FLUON), Hoechst

(HOSTAFLON), Mantefluos (ALGOFLON), Deikin (POLYFLON),

HFL (HIFLON), Nitto Chemicals (TETRAFLON) GFL (INOFLON).

PTFE - Basic Properties

PTFE is polymer which is extensively used in chemical, mechanical,

electronic & electrical industries due to its unique characteristics.

» Chemical inertness to all known chemicals, however attacked by molten alkali

metals, chlorine, trifluorides, fluorine & related fluorine complexes at elevated

temperature & pressure.

» Resistance to solvents, insoluble in all solvents upto 260°C. Certain high

fluorinated oils swell & dissolve PTFE at temperature close to crystalline melting

point.

» Wide operating temperature range -250°C to +260°C, at atmospheric pressure.

» Lowest coefficient of frictionamong all known metals & nonmetals.

» Nontoxic &anti-stick properties.

» Negligible water absorption.

) Nonflammable,

» Resistance to radiations, electrical properties remain practically unchanged

during & after irradiation, both inair & vacuum.

) Excellent weathering resistance.

Chemically Modified PTFE (TFE-M) - asic Properties

To over come some of the weaknesses of conventional PTFE, scientists have develooed chemically modified PTFE,

available as DuPont's Teflon NXT or Dalkin's TFMandhave improved some of the properties for the benefit of consumers.

Improved Creep Resistance

As PTFE Gasketing & Sealing materials used in chemical process industries, due to improved creep resistance & increased

stiffness even atelevated temperatures, the modified PTFE components can be used for higher pressure conditions.

Enhanced Permeation Resistance

The vessal linings, Tubings, Sealing materials, Expansionjoints, Made out of modified PTFE have more lfe & less /near zero

leakage due this enhanced permeation resistance.

Superior Surface Finish

The Components, surfaces made out of modified PTFE have superior surface finish with silky / glossy surfaces. The

componentsremain absolutely cleanas thereis virtually no place for impurities to geta grip.

Reduced Porousity

The paris made out of modified PTFE have low microvoid content, thus showing the transmigration of aggressive liquids &

gases through.

Better High Voltage Insulation

Modified PTFE allows better high voltage insulation giving new opportunity to improve performance particularly in electrical

appications

Weldability

The threaded joints/snugs fitjoints can beavoided by using directly welded part, thus it reduces the risk of

Leakage through threaded joints.

PTFE Filled Compositions ~ Basic Properties

SR eudb Filer Content

No. by Weight

1 | Vign PTFE — ‘© Excelent chemical resisance.

@ Outstanding electrza properties.

€ xcllet rural operies

2 | Chemicaly Mofied PTFE © Improved Elextical properties.

( Bete fictional reer

Acvanced pemeaton resistaoe.

3 | Glass filed PTFE © High compressive stength,

15-25 | @ Batter wear sistance

€ Excelent chemical resistance.

4 | Carton Coke filed PTFE ( High compressive stength.

25.95 | @ Beterwear resistance

Better thermal conduct.

© | Graphite ed PTFE © Excellent chencalresstance

6 © Outstanding electrical properties

© Excelent flexural sroperes.

@ | Bronze fled PTFE ‘© High compressive stength,

40.69 | Brolet woar resétanc.

© Very low cold ow.

© Good thermal conduct

7 | Bronze pls Molybdenum Disuiphide © Improved ficional ropes.

filed PTFE © High compressive strengh.

55+8 | © Excellent wear esstance

© Very low cold ow.

© Geod thermal conductivity.

8 | Glass Ps Moybdenum Disultide High conpessie stench

Filed PTE (@ Beter wear resistance

jo ice chemicals

9 | Aluminum Oxide (Ceramic) filed PTFE] 5.49 ‘© Excellent Electrical properties,

Excelent compressive stengh

10 | Slicon Dixie (Silica Filed PTFE 5-10 Exemplary compressive strength

Excellent chemical resistance.

yoallent chemical resistance,

5-19 | @ Excelent wear resistance

© Excelent compressive stengh

© Good wth chamioasthat attack glass

Properties

‘11 | Caloum Fluoride led PTFE

12 | Stoniess Stel filed PTFE S10 | © Baoelltcheicalresisance

| ¢ Outstanding mechanical properties.

13 | Mica filed PTFE ‘© Excellent compressive strength. ‘

5-10 © Very low coeficien’ of thermal expansion.| |)

| @ Peor tense properties.

14 | Bronze ps TSO Filba PTFE © Figh compressive srengh

Bxcllent wear resitance i

40+1 | @ Vey low coldfow.

© Good tora conduct

¢ Batter fictional provers.

15 | Pignented PTFE © Color cxng

Caution: The presence of filer generally causes following negative features in compounds:

‘Reduction in tensile strenath & break elongation. # Reduction in volume & surface resistviy. ¢ Diffculty in processing & fabrication

emical resistance depending upon types of filler. @ Recuction in coefficient of linear thermal expansion.

PTFE - Product Range

D)

Sr.

No,

Product

Standard Dimensional Specification

Tolerance

1 PTFE Moulded Rod

© 25mm upto 500mm Dia

¢ 300mm L.

+#0.2 - 0.00mm D

#4.0 - 0.00mm L

2 PTFE Moulded Bush

# Upto 500mm / 1000. mm OD

# Upto 100mm / 390mm Length

40.2 — 0.0mm D

+4.0- 0.00mmL

3. PTFE Moulded Sheet

© 300mm* up to 1200mm’ Area

¢ 2.5mm to 100mm Thk

+5.00 ~ 0.00mm LiW|

42.0 - 0.0mm T

4°) PTFE Ramex Rod

© Smim Diameter up to 100mm Diameter

© 900mm /1000mm /2000mm Length

40.2 - 0.00mm D

+#5.0- 0.00mm L

5 PTFE Skived Sheet

¢ 300mm Wieth up to *200mm Width

# 0.25mm to 3.00mm Thk

45.00 - 0.00mmW,

+0.tmm ~ 0.00mm T)

6 | PTFE Ramex Pipe

© 25mm OD X 12.5mm ID

© upto 100mm OD x 75mm 1D

Upto 3300 mm Length

+#0.2 - 0.0mm D

#4.0- 000mm L

PTFE Nachined

‘Components

(Standerd)

# Ready Cut Gaskets

Envelope Gaskets - Sit type! Milled type

© Expansion Joints/ Bellows

= Upto 900mm NB

General Tolerance of

£0.1mm

PTFE Machined

‘Components

T-D) (Non standard)

Valve components of Ball Vave, Plug

Valve, Buttertly Valve

© O/V/D/U —Rings and Washers

Other custom made components as per

Drawing and Specification.

= Upto 1200mm OD, Upto 300mm L

General Tolerance of

+ 0.1mm

Standard Grades of material of Composition:-

4) Virgin PTFE

)

2) Chemically Modified Virgin PTFE )

3) 15% - 25% Glass Filled PTFE 7)

4) 5% 1 15% Glass + 5% MOS2 Filled PTFE 8)

5) 25% - 35

40% -60

% Carbon Filled PTFE

6) 15% Graphite Filled PTFE

% Bronze Filled PTFE

8) 55% Bronze + 5% MOS2 Filled PTFE

eal lia

PTFE - Product Specifications

Us

chemical applications.

I-General Purpose For electrical,

mechanical & chemical applications

not requiring premiummaterial

ll-Mechenical grade tor non ertical

chemical, electrical & mechanical

appiications

IV-Utility having no electrical

requirements and with mechanical

properties ata lower level

Sr] ]

N Product Spectfiction) Type Grade Class

0! |

1 |*PTFE Moulded Rods | ASTM-D-1710| Premium having maximum physical | 4 - Virgin Aes nomal dimensional

& electrical properties to meet rigid * » Repr Lapel J

oe na requirements " ° RAS: B - Meeting specific dimensional

I-Generel Purpose having properties stability

required of general, electrical C- Having normal dimensional

+ mechanical & chemical stability & completely examined

Applications. for internal defects

IENon citical chomical, electrical & D.- Having specific dimensional

Mechanical applications. stability & completely examined

| for internal defects

2 "PTFE Moulded Bushes | ASTM-D-1710 |I-Premium having maximum physical | 1 - Virgin * cetea normal dimensional

bere aaealad 8 lect properies to meet igi | 2°-Rapro | St mension

hes quirements

‘l-General Purpose having stability

properties required of general C- Having normal dimensional

electrical, mechanical & chemical stability & completely examined

applications for internal defects

II-Non critical chemical, electrical & D- Having specific dimensional

Mechanical applications. stablity & completely examined

for internal defects

3 | PTFE Moulded Sheets | ASTMD-3294|F-Premium Normally used for] 1-virgin | A- Resistance to thermal

exacting electrical, mechanical or| 2*- Repro | dimensional change not

|_ Chemical applications exceeding 0.5%

I-General Purpose For electrical, B- Thermal dimensional change

mechanical & chemical applications not exceeding 5.0%

notrequiring premium material = No requirement for thermal

Ill-Mechenical Grade For Non critical Dimensional change

chemical, electrical & mechanical

appications

IV-Utility having no electrical

requirements and with mechanical

Propertios ata lower level

4| PTFE Skived Sheets | ASTM-D-3308/1-Premium Normally used for | 4-Virgin

exacting electrical, mechanical or | 2%. Repro

rut?

INTERNATIONAL

Standards Worldwide

* Hindustan Nylons does not produce this product of this Grade as Products have inferior physical properties,

tray fail premature,

accident prone & not fail safe

Al

B]

cc]

PTFE - Applications

Chomical Process Industries:

4 Rods, Bushes, Tubes, Sheets.

4 Expansion Joints, Bellows, Line bellows, Valve bellows, PTFE & GFT Composite bellows, Custombellows,

4 Gaskets, Envelope gaskets, Ready cut gaskets, Universal rope gaskets, Fused joint circular /elliptical equipment

envelope gaskets.

4 Mechanical Packings, Chevronpackings, OIV/DIU Rings, Cup seals.

4 Vaive Components Bali seats, Stem seals, Body seals, Plug sleeves, Diaphragms, Butterfly valve seats

4 PumpsComponents Mechanical Seals, Balls, Diaphragms.

4 Laboratoryware Beakers, Plugcocks.

4 Thread seal tapes.

Mechanical Industrie:

Liners for machine tools guideways & slideways.

4Piston rings for non-lubricated air compressors.

4 Chemically treated Sodium itched sheet.

4 Low load, high speed bush bearings.

4 Guidebands & piston seals for hydraulic & pneumaticactuators.

Thin walledtubings.

4 Hydraulic & pneumatic seals.

4 Hystersis Friction washers for clutches.

Bridge bearings, Pipe line expansion supports.

Electrical & Electronic Industries :

4 Nozzles for SF6 circuit breakers.

4 Sintered insulation tapefor insulation.

Capacitor fim.

4Chemicallytreated Insulator bushes for traction machines.

Brush holders.

4 Thin walled Spaghetti tubings for insulation.

PTFE - End User Industries

4 Aeronautical

4 Atomic/Thermal/ Hydro Power Plants

4 Chemical

4 Defense Establishments

4 Electrical & Electronics:

4 Food processing

4 High Voltage Switch-Geer Manufacturers

4 Machine Tool Manufacturers

4 Pharmaceuticals

4 Petroleum Refineries

4 Petrochemical

4 Railways

4 Space Research Organization

4 Valves & Pump Manufacturing Industries

VE LE AP

Company Prafile - Total Manufacturing

Hindustan Nylons is wholly Indian owned, private company, formed in 1979 to

manufacture & market PTFE & other fluoroplastics’ semi finished stockshapes &

machined components. Ithas been, one of the largest processor of PTFE in India & has

‘expanded its range to encompass the full spectrum of PTFE products. The group is i,

comprised of two independently managed manufacturing facilities based in western ‘|

part of India at MIRAJ, State Maharashtra, employing around 100 people & trading \

throughout India,

The group is major converter of PTFE resins & manufactures semi finished stock-

shapes in all forms - Moulded rods upto 500mm diameter, 300mm length & Moulded

bushes - rings up to 1000mm diameter. Moulded sheets upto 1200x 1200 mm2 & skived

sheet-tape materials upto 1200 mm width, Ram Extruded Rods upto 100mm diameter; 900/ 1000/ 200mm Length & Ram

Extruded Rigid Pipes upto 100mm diameter; 3300mm Length - the widest range of such products in india,

The company has huge, wide & state of art manufacturing facilities; comprising Hydraulic Presses, Ovens, Ram Extruders,

Lathes, Turrets, Milling Machines, Skiving Machine, Calendaring Machine etc to cover producing most of the products in PTFE

- serving the customer under one roof. The latest technology in machine tools such as. NC controls. Automatic PID / Profile

temperature controlled ovens, Rotary bed sintering, Air conditioned / dust free environment, fully automatic Extrusion is in use

‘The PTFE Machined Components are fabriceted in the state of theart workshop comprisinglathes, turrets, milling machine and

other fabrication machines, running in three shifts. The machining facility upto 1200mm diameter, 1000mm Length is available

with precision tolerance within +/- 0.2mm. The company has most advanced chemical itching & application facility along with

automatic slitting machines for manufacturing chemically treated insulation tapes.

The present manufacturing capacity (2011) of group is about 20000 Kgs per month, utilizing elmost 75%, & expansion at the

rate of 10% per annum is being carried out to cover maximum sizes & range of products, availing complete range of PTFE

products under one roof- most convenient forcustomers.

Company Commitment - total Gulty

‘As one of the leading processor of PTFE, Hindustan Nylons hereby commits to produce most

quality products & provide the best pre-post sales & technical services

Hindustan Nylons operates on Quality Management System (ISP 9001:2008), right from

inspection & testing of raw material upto final/pre-dispatch inspection & testing of end

products, through out the manufacturing to ensure Zero Defect Quality

The testing of Input Raw Materials & Output Finished Goods is carried out at In-house

uality Laboratory. The testing equipments to verify various properties of Input Raw Materials

TASSUTANCE ©2851 for cour, Paticle Snape, Purity, Flowabity, Buk Densiy, Compressive Rati,

Filler Content, Water Content, Shrinkage & Pollution Index. The Output Finished Goods are

tested for Density, Tensile Strength, Elongation, Compressive Strength, Deformation Under

Load, Hardness, Water Absorption, Heat Resistance, Continuous Service Temperature,

Wear Rate, Dielectric Strength, Chemical Resistance pereatity, Chemical Resistance

Dissolton, Pool off songth / Bond stongih for sodum ichod parts, spark tosing &

pneumatic pressure testing. The in-house testing facility offers the unique advantage of

assured / tested quality. The products confirm national & intemational standards such as |S,

ASTM, BS, DiNetc.

Company Highlights ~ Total Engineering

Hindustan Nylons offers design, development laboratory

testing facilities to handle customer projects from concept

to full manufacture. It advisos on material soloction &

product design to optimize the unique properties of

company's extensive range of materials, with engineers

fully supporting the sales field staf.

Through in-house test laboratory, company guides

customers to develop the new product from concept /

replace existing material of construction. to suit specific

service condition & particular application.

——

(Foc

‘on

\ Qualit Company Focus - Total Customers Satisfaction

Hindustan Nylons assumes the responsibility of continuous

upgradation of products & services through innovative engineering

& newest technology to achieve the TOTAL CUSTOMERS

SATISFACTION

«The company guarantees the endless improvements in qualities,

skills & standards of manpower through latest management

techniques toprovide the bestof Company to all. the customers.

With uncompromising , assured quality , maximum procuct range

under one roof , pro-post sales and technical sorvico and

CUSTOMER AS MAIN FOCAL POINT , Hindustan Nylons has

reputed & prestigious customers all over India.

| The company exports PTFE Stock shapes & Machined

Components-majorly to Middle East Countries, Part of Europe, Part

of South Africa & Australia

Customer Satisfaction

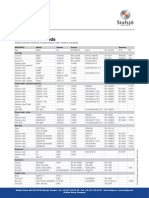

PTFE & Filled Compositions - Physical Praperties

Saw Pop ‘at | —Tstetioa | igin[Ghonicany | txts ZPGlne'| Pvt | scimnoi |-2caon | SPiCaton [1H Gre] abou] eines

[oe que | asmo-na [prea | aecao | ais-am | gz-70s [gaan | amon | z0-nis | go-21e | pio-aw | a0e32 [seca

2 ee Sng igion | astm: em | yo. an- aon | wo no [rama vecaso | noosa [taboo [two [wn azo | as aon | as a0

Ervin tk =n | aa t san ‘ott [4 i

1 [conan Sier ‘aie | —astu-eos | soso | asa | sezs | eas | so70 com [ rss) mm | ers |e | nee

| connie ei iglien”—| ASTD | son aio | on aio _| sino eno | can | smo | — inca | roto |_tsnerao| nono | tao aso —| eno anon

6 | betaine.

[a ais 286 x | sso 3 2 7 nA e r ® 2 a 5 ri

J elem * as) te z as 7s as 2 as 2 2s 2

ihe wom = ‘© By Ey 2 2% 2% 5 2 e ‘o ‘o

217 [rena Sten ‘otvew | _ASTHD-780_| S057 80 we | sea Bo ry m8 0 Bo od 7580 75:00

Feuer tg [ astm [Seem | — po | sr | in| ae a a TT

| nest gh

aL awe. cntator’ | aso ate [9 aaa ra B 2 2 a = = = a

aber © ee 2 2 *° 2 ie ° nH “0

AL omemcig ini asuo-too¢ [Goro | aosom | ostesr | oeom | oem | area | sea [asa | anew | —enam | omaw [ence

a] such sigte dasoae | aaeous | oioare | onars | eosayn | —oxno10 | eapann | osoare | aosam | amore | eosaxa | ouraoo

72" wear) aus |nenwcb-va7 | oo | oon] 001 | oa aot oot oor [aor | ann ‘01 aot 2a

‘gore Pa

72 Wet ites =| casiwco-eaa [oar | oar [oan | oa a8 oo a aor aoi om

1 Thema Cina (ic) | aien'S| ae ED t = ra ra = = =

{nese atetareyals | ayet are | ape | ale] ajay ala] ala | apa] aye

Also nemo (t2lis|telas [vs [s | aster] ve] s | ost" | ae] “S| feo | 5) | ais] oo | rs oo | in| oo

2 [_a[-awe a | za [aa | aa] oa [ea [ie [a2] 1] 2a} ve [93] ae | 1a | as | te[sa [2 [ar | ses] sas | te] 1s | vel a5

olm-20t aelae[astae [as tee) acl vel sal oe | aa) ep [orl on] asl ea | bast oes ems | onl op | esl ae

| ie ais T

=| to «| amo-oe Fan pas ees | ee ee ee ee

i 19 | Younes onm em astoast | >10" > >105 >0" p10 > 10" bat >a >a >10, >0. >"

et Two borin Oi % ASTM DSTO o o 001s 0013 0015 ‘o015 oT > o o o o

2 chon etn)

so < [xsiwcocaa [oar [ oreo] oa aor oor aor [aor] ae 7 oo oa

3s [rrr sean ert wate atom cena cr meteo! ahve wal es BlyPeesin Raum; Cs ney Ae px cea re np h aes dan erpSahre

Fe Enea crn rstnes epg ere pa Flr J

‘teats quote ave average vats ony and shoul nat be usa ae specication fo aeigning epee apples.

—

cs

id

a

2

rt

EB

So

‘4

Quality

Endorsed

Company

BO woo1 2008

Plot No. C - 23, C - 27, Telephone : 91 - 233 - 2644468, 2644868

M.1.D.C. Industrial Area, Facsimile : 91 - 233 - 2644772, 2645772

Miraj - 416 410. E = contact@hindustan-nylons.com Tae

(MS,) India Web : wwwhindustan-nylons.com mms = MXONETOISY

You might also like

- Tank Linings Resistance GuideDocument7 pagesTank Linings Resistance Guideenrico100% (1)

- Material Selection GuideDocument0 pagesMaterial Selection GuidebbmokshNo ratings yet

- Welding Rod For c5 & f5 - Er 80s-b6Document1 pageWelding Rod For c5 & f5 - Er 80s-b6SatyamEngNo ratings yet

- Stainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseDocument1 pageStainless Steel Grade Comparision System Diagram of Stainless Steel - Corrosion &heat Resistance Strength, Machinability WiseSatyamEngNo ratings yet

- Adjustable Floating ReamersDocument1 pageAdjustable Floating ReamersSatyamEngNo ratings yet

- Conversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowDocument3 pagesConversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowSatyamEngNo ratings yet

- TorcUP Rebirth Bolting IndustryDocument4 pagesTorcUP Rebirth Bolting IndustrySatyamEngNo ratings yet

- Equivalencia de MaterialesDocument1 pageEquivalencia de MaterialesHelden Jasmani100% (1)

- Fittech Brochure Companion Flanges and FittingsDocument16 pagesFittech Brochure Companion Flanges and FittingsSatyamEngNo ratings yet

- GEE ElectrodeDocument17 pagesGEE ElectrodeSatyamEngNo ratings yet

- Cast Iron Pressure Temperature RatingDocument1 pageCast Iron Pressure Temperature RatingSatyamEngNo ratings yet

- 3M Abrasives - Catalogue For AutoComponents PDFDocument48 pages3M Abrasives - Catalogue For AutoComponents PDFSatyamEngNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Parker O-Ring Material Guide-2008Document72 pagesParker O-Ring Material Guide-2008Ian Pillay50% (2)

- MechIndia Burnishing ToolsDocument4 pagesMechIndia Burnishing ToolsSatyamEngNo ratings yet

- Weartech Electrode Stellite Cobalt NickleDocument1 pageWeartech Electrode Stellite Cobalt NickleSatyamEngNo ratings yet

- Surface Roughness Tester Page 1Document1 pageSurface Roughness Tester Page 1SatyamEngNo ratings yet

- ENERPAC 00682GB - LPwrenchDocument4 pagesENERPAC 00682GB - LPwrenchSatyamEngNo ratings yet

- Enerpac NC E324Document1 pageEnerpac NC E324SatyamEngNo ratings yet

- Material standards cross reference guideDocument2 pagesMaterial standards cross reference guideSatyamEng80% (5)

- Equivalent Materials Grade DIN ASTM BS GOSTDocument4 pagesEquivalent Materials Grade DIN ASTM BS GOSTSatyamEngNo ratings yet

- Tank Linings Resistance GuideDocument7 pagesTank Linings Resistance Guideenrico100% (1)

- Enerpac HXD - E324Document2 pagesEnerpac HXD - E324SatyamEngNo ratings yet

- Material Conversion TableDocument5 pagesMaterial Conversion TableMilin DesaiNo ratings yet

- Enerpac NC E324Document1 pageEnerpac NC E324SatyamEngNo ratings yet

- Casting Grade Wise Welding Electrode Grade and MakeDocument1 pageCasting Grade Wise Welding Electrode Grade and MakeSatyamEngNo ratings yet

- Conversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowDocument3 pagesConversion Factors, Pressure Conversion, Pressure Equivalents, Unit of Vaccum, Unit of FlowSatyamEngNo ratings yet

- TorcUP Rebirth Bolting IndustryDocument4 pagesTorcUP Rebirth Bolting IndustrySatyamEngNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)