Professional Documents

Culture Documents

Spring Isolator

Uploaded by

JuanPabloGonzalezFiblasCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spring Isolator

Uploaded by

JuanPabloGonzalezFiblasCopyright:

Available Formats

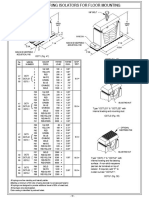

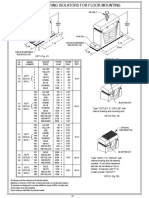

HOUSED SPRING ISOLATORS FOR FLOOR MOUNTING

1/2" BOLT

5/8" BOLT

OPER.

HGT.

OPER.

HGT.

9/16 SLOT

5

8

9/16 DIA.

6

NON-SKID NEOPRENE

ACOUSTICAL PAD

7 1/4

2 3/4

9 1/2

10 3/4

5

8

2 3/4

NON-SKID NEOPRENE

ACOUSTICAL PAD

OCT1 (Fig. 47)

OCT2 (Fig. 48)

Fig.

No.

47

49

50

47

49

50

47

49

50

48

49

50

48

49

50

COLOR

CODE

MODEL

NUMBER

OCT1

OCTLS1

OCTL1

OCT1

OCTLS1

OCTL1

OCT1

OCTLS1

OCTL1

OCT2

OCTLS2

OCTL2

OCT2

OCTLS2

OCTL2

RATED

LOAD

1

2

3

4

5

6

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

100

200

295

380

530

750

7

8

ORANGE

GOLD

1125

1500

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

F41

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

ORANGE

GOLD

RED/SILVER

RED/YELLOW

RED/WHITE

RED/GREEN

155

220

310

420

540

710

900

1030

1275

1630

2100

3000

F60

F61

F62

F63

F64

F65

F66

F67

F68

F69

SILVER

YELLOW

RED

GREEN

BLUE

ORANGE

GOLD

WHITE

RED/SILVER

RED/YELLOW

60

109

155

210

275

365

500

715

945

1190

F37

F38

F39

F40

F41

GOLD

RED/SILVER

RED/YELLOW

RED/WHITE

RED/GREEN

2060

2550

3260

4200

6000

F66

F67

F68

F69

GOLD

WHITE

RED/SILVER

RED/YELLOW

1000

1430

1890

2380

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

RATED

DEFL.

SHIP.

WGT.

1.00"

1.00"

.80"

.80"

.80"

.75"

/2

11

9.0

10.0

.75"

.75"

1.85"

1.70"

1.55"

1.40"

1.25"

1.15"

1.05"

1.00"

1.00"

1.00"

1.00"

1.00"

ADJUSTING NUT

Type "OCTLS1" & "OCTLS2" with

internal leveling and mounting stud.

OCTLS (Fig. 49)

3.00"

2.72"

2.58"

2.32"

2.20"

2.08"

2.00"

2.00"

2.00"

2.00"

OPTIONAL

NEOPRENE PAD

9.0

ADJUSTING NUT

#

#

1.00"

16.5

2.00"

15.0

#

#

#

#

Type "OCTL1" & "OCTL2" with

internal leveling and flat bearing

surface. A non-skid neoprene

pad can be furnished on top of

isolator. If required, add "P" to

model number "OCTLP1".

OCTLP (Fig. 50)

All springs are free standing and laterally stable.

(Meeting a minimum of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

- 19 -

FREE STANDING SPRING ISOLATORS FOR FLOOR MOUNTING

F-BOLT

F-BOLT

D

D

NEOPRENE COVERED

BASE PLATE WITH CUP

NON-SKID NEOPRENE

ACOUSTICAL PAD

E-HOLE

E-HOLE

B

A

B

A

OST1, OST3 (Fig. 52)

OST2R (Fig. 51)

F21 to F27 springs: Color coding is identified by color of spring.

All others: Color coding is identified by colored label.

Fig.

No.

COLOR

CODE

MODEL

NUMBER

OST1

52

51

OST2R

OST3

52

RATED

LOAD

1

2

3

4

5

6

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

100

200

295

380

530

750

7

8

ORANGE

GOLD

1125

1500

F21

F22

F23

F24

F25

F26

F27

YELLOW

RED

WHITE

GREEN

BLUE

ORANGE

BROWN

40

100

150

210

300

400

500

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

F41

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

ORANGE

GOLD

RED/SILVER

RED/YELLOW

RED/WHITE

RED/GREEN

155

220

310

420

540

710

900

1030

1275

1630

2100

3000

RATED

DEFL.

#

#

#

#

#

SHIP.

WGT.

"A"

"B"

"C"

"D"

"E"

"F"

21

51

4

9

16

5

8

3.5

1.00"

3

4

7

16

1

2

1.2

1.85"

1.70"

1.55"

1.40"

1.25"

1.15"

1.05"

1.00"

1.00"

1.00"

1.00"

1.00"

9

16

5

8

5.0

1.00"

1.00"

.80"

.80"

.80"

.75"

.75"

.75"

#

#

#

#

1

8

#

#

#

#

#

#

#

#

#

#

#

#

#

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

2 1/2

3 1/2

2 1/2

1 3/4

11/16 DIA. HOLE

4 1/2

9/16 DIA. HOLE

BRACKET FOR OST2R (Fig. 53)

BRACKET FOR 0ST1, OST3 (Fig. 54)

- 20 -

FREE STANDING SPRING ISOLATORS FOR FLOOR MOUNTING

F-BOLT

E-HOLE

B

A

NON-SKID NEOPRENE

ACOUSTICAL PAD

OST4, OST6 (Fig. 55)

Fig.

No.

COLOR

CODE

RATED

LOAD

F50

F51

F52

F53

F54

F55

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

260

400

555

690

840

1025

F56

F57

F58

F59

ORANGE

GOLD

RED/SILVER

RED/YELLOW

1220

1730

2340

3000

F60

F61

F62

F63

F64

F65

F66

F67

F68

F69

SILVER

YELLOW

RED

GREEN

BLUE

ORANGE

GOLD

WHITE

RED/SILVER

RED/YELLOW

60

109

155

210

275

365

500

715

945

1190

MODEL

NUMBER

OST4

55

OST6

55

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

RATED

DEFL.

3.00"

2.80"

2.58"

2.42"

2.28"

2.13"

"A"

"B"

SHIP.

WGT.

"C"

"D"

"E"

"F"

1

2

81

9

16

3

4

10.5

71

9

16

5

8

4.0

2.00"

2.16"

2.00"

2.00"

3.00"

2.72"

2.58"

2.32"

2.20"

2.08"

2.00"

2.00"

2.00"

2.00"

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

3 1/2

2 1/2

3 1/2

6

6 1/2

4 1/2

13/16 DIA. HOLE

11/16 DIA. HOLE

6

BRACKET FOR OST4 (Fig. 56)

BRACKET FOR OST6 (Fig. 57)

- 21 -

FREE STANDING SPRING ISOLATORS FOR FLOOR MOUNTING

F-BOLT

E-HOLE

B

A

NON-SKID NEOPRENE

ACOUSTICAL PAD

OST5, OST7, OST8 (Fig. 58)

Fig.

No.

58

58

58

COLOR

CODE

RATED

LOAD

F91

F92

F93

F94

F95

F96

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

300

600

975

1260

1530

1893

F97

F98

ORANGE

GOLD

2238

2634

F71

F72

F73

F74

F75

F76

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

355

770

1075

1470

1980

2575

F77

F78

ORANGE

GOLD

3270

4050

F83

F84

RED

WHITE

4775

5900

MODEL

NUMBER

OST5

OST7

OST8

SHIP.

WGT.

RATED

DEFL.

"A"

"B"

"C"

"D"

"E"

"F"

3.00"

51

91

9

16

3

4

10.0

10

81

13 1

4

9

16

36.0

10

14

1

2

9

16

53.0

#

#

#

#

5.90"

5.30"

5.00"

4.75"

4.50"

4.20"

#

#

#

#

#

3.90"

3.65"

4.30"

4.10"

11

1

2

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

3 3/4

5 1/2

7 1/2

7 1/2

13/16 DIA. HOLE

10 1/2

8 1/2

1 1/16 DIA. HOLE

1 1/16 DIA. HOLE

BRACKET FOR 0ST5

(Fig. 59)

14 1/4

13

BRACKET FOR 0ST7

(Fig. 60)

- 22 -

BRACKET FOR 0ST8

(Fig. 61)

FREE STANDING SPRING ISOLATORS WITH HORIZONTAL RESTRAINT

3/4" BOLT

NEOPRENE ISOLATOR

D

9/16" DIA. HOLE

E

B

NON-SKID NEOPRENE

ACOUSTICAL PAD

OST3-HR, OST4-HR, OST6-HR (Fig. 62)

Fig.

No.

62

62

62

COLOR

CODE

MODEL

NUMBER

OST3-HR

OST4-HR

OST6-HR

RATED

LOAD

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

F41

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

ORANGE

GOLD

RED/SILVER

RED/YELLOW

RED/WHITE

RED/GREEN

155

220

310

420

540

710

900

1030

1275

1630

2100

3000

F50

F51

F52

F53

F54

F55

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

260

400

555

690

840

1025

F56

F57

F58

F59

ORANGE

GOLD

RED/SILVER

RED/YELLOW

1220

1730

2340

3000

F60

F61

F62

F63

F64

F65

F66

F67

F68

F69

SILVER

YELLOW

RED

GREEN

BLUE

ORANGE

GOLD

WHITE

RED/SILVER

RED/YELLOW

60

109

155

210

275

365

500

715

945

1190

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

#

RATED

DEFL.

1.85"

1.70"

1.55"

1.40"

1.25"

1.15"

1.05"

1.00"

1.00"

1.00"

1.00"

1.00"

3.00"

2.80"

2.58"

2.42"

2.28"

2.13"

"A"

3

4

3

4

1

4

1

4

- 23 -

"C"

"D"

1

2

1

4

"E"

3

16

SHIP.

WGT.

8.0

17.0

8.0

2.00"

2.16"

2.00"

2.00"

3.00"

2.72"

2.58"

2.32"

2.20"

2.08"

2.00"

2.00"

2.00"

2.00"

3

4

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

"B"

3

4

1

4

1

4

VERTICALLY RESTRAINED SPRING ISOLATORS FOR FLOOR MOUNTING

STUD

F

9/16" DIA. HOLE

TAP

NON-SKID NEOPRENE

ACOUSTICAL PAD

B

TOP PLATE CAN BE FURNISHED

WITH STUD OR TAPPED TO SUIT.

KW2, KW3 (Fig. 63)

Fig.

No.

MODEL

NUMBER

"A"

"B"

"C"

1KW2

1

6

4

2KW2

3

4

4

1

7

2

1

2

2

1

2

2

12

1

2

13

1

15

2

"D"

NUMBER

OF HOLES IN

BASE PLATE

SHIP.

WGT.

5.0

9.0

13.0

22.0

46.0

50.0

78.0

"E"

"F"

1

1

4

1

1

4

1

2

1

2

3

4

4

3

4

4

NOMENCLATURE

1KW3

63

2KW3

4KW3

6KW3

8KW3

1

2

1

13

2

11

14

1

2

17

1

2

1

1

2

1

1

2

1

2

1

7

2

1

7

2

KW2

63

F21

F22

F23

F24

F25

F26

F27

F30

F31

F32

F33

F34

F35

F36

F37

F38

F39

F40

F41

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

ORANGE

GOLD

RED/SILVER

RED/YELLOW

RED/WHITE

RED/GREEN

SPRING SERIES

SUFFIX SPRING NO.

2KW2

RATED

DEFL.

(IN.)

RATED LOAD IN POUNDS

YELLOW

RED

WHITE

GREEN

BLUE

ORANGE

BROWN

ISOLATOR MODEL

KW3

1KW2

COLOR

CODE

MODEL

NUMBER

NO. SPRINGS

PER UNIT

MODEL NO.

ISOLATOR MODEL

Fig.

No.

1 KW 3 - F38

40

100

150

210

300

400

500

#

#

#

#

#

#

#

1KW3

155

220

310

420

540

710

900

1030

1275

1630

2100

3000

80

200

300

420

600

800

1000

#

#

#

#

1.00"

#

#

#

2KW3

4KW3

6KW3

8KW3

#

#

#

#

#

#

#

#

#

#

#

#

2550

3260

4200

6000

#

#

#

#

5100

6520

8400

12000

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

- 24 -

#

#

#

#

7650

9780

12600

18000

#

#

#

#

10200

13040

16800

24000

#

#

#

#

1.85"

1.70"

1.55"

1.40"

1.25"

1.15"

1.05"

1.00"

1.00"

1.00"

1.00"

1.00"

VERTICALLY RESTRAINED SPRING ISOLATORS FOR FLOOR MOUNTING

TOP PLATE CAN BE FURNISHED

WITH STUD OR TAPPED TO SUIT.

Fig.

No.

MODEL

NUMBER

"B"

3

4

1

16

2

10 1

11

1KW4

2KW4

"A"

3KW4

9/16"

DIA. HOLE

15

1

2

1

12

2

1

17

2

1

22 2

19

4KW4

14

6KW4

19

8KW4

24

1KW6

1

2

1

13

2

1

7

2

2KW6

NON-SKID NEOPRENE

ACOUSTICAL PAD

1KW10

1

2

1

4

2

17

64

E

"C"

6

10

10

10

"D"

3

3

3

1

82

1

82

1

82

12

"E"

3

4

3

4

1

1

2

3

4

3

4

3

4

1

2

1

2

1

1

2

"F"

NUMBER

OF HOLES

IN BASE

PLATE

1

2

1

9

2

1

9

2

1

9

2

28

48

72

105

10

117

10

164

13

22

KW4, KW6, KW10 (Fig. 64)

ISOLATOR MODEL

Fig.

No.

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

260

400

555

690

840

1025

F56

F57

F58

F59

ORANGE

GOLD

RED/SILVER

RED/YELLOW

1220

1730

2340

3000

KW6

F60

F61

F62

F63

F64

F65

F66

F67

F68

F69

SILVER

YELLOW

RED

GREEN

BLUE

ORANGE

GOLD

WHITE

RED/SILVER

RED/YELLOW

ISOLATOR MODEL

KW10

V40

V41

V42

V43

V44

V45

SILVER

YELLOW

RED

GREEN

BLUE

ORANGE

3KW4

4KW4

6KW4

8KW4

RATED

DEFL.

(IN.)

RATED LOAD IN POUNDS

F50

F51

F52

F53

F54

F55

ISOLATOR MODEL

64

2KW4

COLOR

CODE

MODEL

NUMBER

KW4

1KW4

#

#

#

#

#

#

1KW6

60

109

155

210

275

365

500

715

945

1190

3.00"

2.80"

2.58"

2.42"

2.28"

2.13"

2440

3460

4680

6000

#

#

#

#

3660

5190

7020

9000

#

#

#

#

6920

9360

12000

#

#

#

10380

14040

18000

#

#

#

13840

18720

24000

#

#

#

2.00"

2.16"

2.00"

2.00"

2KW6

#

#

#

#

#

#

#

#

#

#

730

1000

1430

1890

2380

#

#

#

#

#

3.00"

2.72"

2.58"

2.32"

2.20"

2.08"

2.00"

2.00"

2.00"

2.00"

1KW10

40

80

120

180

250

350

#

#

#

2.00"

#

#

#

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

- 25 -

SHIP.

WGT.

VERTICALLY RESTRAINED SPRING ISOLATORS FOR FLOOR MOUNTING

TOP PLATE CAN BE FURNISHED

WITH STUD OR TAPPED TO SUIT.

Fig.

No.

MODEL

NUMBER

"A"

1KW5

13

2KW5

19

1KW7

12

9/16"

DIA. HOLE

65

2KW7

B

E

NON-SKID NEOPRENE

ACOUSTICAL PAD

"C"

"D"

1

2

1

17

2

1

10

2

11

1

2

1KW8

14

2KW8

1

22

2

19

"B"

7

7

18

12

1

2

21

8

8

1KW5

ISOLATOR MODEL

COLOR

CODE

MODEL

NUMBER

KW5

KW7

RATED LOAD

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

300

600

975

1260

1530

1893

F97

F98

ORANGE

GOLD

2238

2634

#

#

#

#

1950

2520

3060

3786

4476

5268

SILVER

YELLOW

RED

WHITE

GREEN

BLUE

355

770

1075

1470

1980

2575

F77

F78

ORANGE

GOLD

3270

4050

4775

5900

For greater deflections and/or loads refer to factory.

- 26 -

3.00"

#

#

#

#

2940

3960

5150

6540

8100

#

#

5.90"

5.30"

5.00"

4.75"

4.50"

4.20"

3.90"

3.65"

2KW8

#

#

9440

11800

All springs are free standing and laterally stable. (Meeting a minimum

of 0.8 ratio of spring diameter to compressed height.)

All springs are designed to provide additional travel of 50% of rated load.

All hardware zinc-electroplated.

Color coding is identified by colored labels.

1KW8

RED

WHITE

2KW7

F71

F72

F73

F74

F75

F76

F83

F84

RATED

DEFL.

(IN.)

1KW7

ISOLATOR MODEL

KW8

2KW5

F91

F92

F93

F94

F95

F96

ISOLATOR MODEL

65

31

2

1

3

2

31

2

31

2

"F"

SHIP.

WGT.

1

4

1

1

4

3

1

4

3

1

4

1

2

4

1

2

4

10

47

10

138

89

116

108

240

All isolators have 4 holes in base plate.

KW5, KW7, KW8 (Fig. 65)

Fig.

No.

1

2

31

2

"E"

#

#

4.30"

4.10"

1

2

1

14

2

1

15 2

1

15

2

14

You might also like

- Spring IsolatorDocument8 pagesSpring IsolatorJuanPabloGonzalezFiblasNo ratings yet

- Floor Mounted Spring Isolators GuideDocument8 pagesFloor Mounted Spring Isolators GuideJuanPabloGonzalezFiblasNo ratings yet

- Gooseneck Shaffer SchahinDocument2 pagesGooseneck Shaffer SchahinVRV.RELATORIO.AVARIA RELATORIO.AVARIANo ratings yet

- Piping and flange dimensions documentDocument59 pagesPiping and flange dimensions documentExsan Othman100% (1)

- HH 102 SemitrailerDocument6 pagesHH 102 SemitrailerleoNo ratings yet

- Estado Mecanico Tyc-04Document13 pagesEstado Mecanico Tyc-04Byron marinNo ratings yet

- F 34145Document143 pagesF 34145María Gómez ZerpaNo ratings yet

- SEO-optimized title for pump part document groupDocument3 pagesSEO-optimized title for pump part document groupwillNo ratings yet

- Pexgol Pipes and FittingsDocument30 pagesPexgol Pipes and FittingsFlorin StanciuNo ratings yet

- 1 Row Tilt Up For Flat Roof 20 30 DegDocument1 page1 Row Tilt Up For Flat Roof 20 30 DegFulki Kautsar SNo ratings yet

- Da 950068 002 PDFDocument1 pageDa 950068 002 PDFpremNo ratings yet

- Star Parts Rice List Effective 07-05-10Document208 pagesStar Parts Rice List Effective 07-05-10Kevin Swotek0% (1)

- Ware Rack DDocument2 pagesWare Rack DLamco2012No ratings yet

- Section 31Document13 pagesSection 31Fabian LopezNo ratings yet

- AAP S18 Butterfly Valves E2 SDocument9 pagesAAP S18 Butterfly Valves E2 SPete KardumNo ratings yet

- PR RaiseDocument12 pagesPR RaiseRey MbayangNo ratings yet

- Replacement Parts: Swing Check ValveDocument1 pageReplacement Parts: Swing Check ValvefatraskyNo ratings yet

- Hot Rod Deville Service Manual GuideDocument8 pagesHot Rod Deville Service Manual GuideFrank L. BaumNo ratings yet

- New Items Jul '07Document4 pagesNew Items Jul '07Valery GerasimovNo ratings yet

- Section E: EnclosuresindexDocument32 pagesSection E: EnclosuresindexNMETETRNo ratings yet

- Hardware: Hand Rail FittingDocument1 pageHardware: Hand Rail FittingRoddy GonzalezNo ratings yet

- Espct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberDocument1 pageEspct - Tba Ensamble Total Monobore 3k Acording With Kom 3-1-8 3k Forging Anda Part NumberJeaneth HerreraNo ratings yet

- Válvula Angular MidlandDocument1 pageVálvula Angular MidlandAdemilsonNogueiraNo ratings yet

- S02 Rock Drill PDFDocument22 pagesS02 Rock Drill PDFDavidNo ratings yet

- 5zone Temp - ControlDocument1 page5zone Temp - ControlSutowiNo ratings yet

- Manual de Partes Famio 8 PDFDocument37 pagesManual de Partes Famio 8 PDFfernandojhonatan100% (1)

- Lexus - GS300 - GS430 - Service - Manual 5Document40 pagesLexus - GS300 - GS430 - Service - Manual 5seregap84100% (5)

- Catalogo Pecas Dr800Document83 pagesCatalogo Pecas Dr800Joao Paulo RamalhoNo ratings yet

- Electrodes EquivalentDocument15 pagesElectrodes Equivalentgrameshkreddy2013No ratings yet

- Ariel Corporation sales order parts listDocument46 pagesAriel Corporation sales order parts listpapashoNo ratings yet

- Audi RS4 Avant quattro technical documentationDocument62 pagesAudi RS4 Avant quattro technical documentationJustin Sandifer100% (1)

- Nieliwocki StrollDocument5 pagesNieliwocki StrollgescarteroNo ratings yet

- Trinity Touch Terminal LugsDocument9 pagesTrinity Touch Terminal Lugseye4aneye1989No ratings yet

- Balajee Rolling Mill - 22Document5 pagesBalajee Rolling Mill - 22Anonymous RXXdbl36ANo ratings yet

- Manual de Compresor Ariel JGKDocument145 pagesManual de Compresor Ariel JGKDany Godinez100% (1)

- Pipe 2.5" SCH Standard (4 Ea) SQ. TUBE 50X50 (4 EA) SQ. TUBE 50X50 (4 EA)Document1 pagePipe 2.5" SCH Standard (4 Ea) SQ. TUBE 50X50 (4 EA) SQ. TUBE 50X50 (4 EA)NanangNo ratings yet

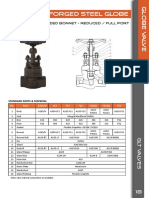

- BOLTED / WELDED BONNET - REDUCED / FULL PORT globe valve DIMENSIONSDocument3 pagesBOLTED / WELDED BONNET - REDUCED / FULL PORT globe valve DIMENSIONSArieNoviyantoNo ratings yet

- NAS577Document5 pagesNAS577Andrei Cozma100% (1)

- Catalogo de Partes DR 650Document84 pagesCatalogo de Partes DR 650descargas221No ratings yet

- Raw Material Specs and Part Numbers for Automotive ComponentsDocument14 pagesRaw Material Specs and Part Numbers for Automotive Componentsakbars.thasimaNo ratings yet

- Outlook BodyDocument27 pagesOutlook BodyAmir PrnjavoracNo ratings yet

- Yukon Bolts ChartDocument23 pagesYukon Bolts Chartzyka1No ratings yet

- 250 SXS-F 2007: Spare Parts Manual: ChassisDocument28 pages250 SXS-F 2007: Spare Parts Manual: ChassischarlesNo ratings yet

- CRICRI Materials ListDocument8 pagesCRICRI Materials ListAnubhav JoshiNo ratings yet

- 8475-3A Gardner Denver PZ-7 5000PSIDocument8 pages8475-3A Gardner Denver PZ-7 5000PSIAmauri CortesNo ratings yet

- Ariel Corporation Sales Order Cover Sheet and Parts ListsDocument115 pagesAriel Corporation Sales Order Cover Sheet and Parts Listsshahzad100% (1)

- Catalago Motor STX 200Document32 pagesCatalago Motor STX 200Moto Peças CruzeiroNo ratings yet

- Kip 3000 PartsDocument97 pagesKip 3000 Parts33angleNo ratings yet

- Fisher-Paykel Dd601 Dd601i Dd601v2 Dd601v2i Dd602 Dd602i Parts ListDocument31 pagesFisher-Paykel Dd601 Dd601i Dd601v2 Dd601v2i Dd602 Dd602i Parts ListGeoff RobertsNo ratings yet

- Alfond Inn - Set For Portfolio - Part 5Document52 pagesAlfond Inn - Set For Portfolio - Part 5api-224231722No ratings yet

- Ring Gage WBCODocument3 pagesRing Gage WBCOESTEBAN NEUTO ROJASNo ratings yet

- Yosemite: Service PartsDocument5 pagesYosemite: Service PartsDan DelfinoNo ratings yet

- Brother PT-550 Parts ManualDocument18 pagesBrother PT-550 Parts ManualDuplessisNo ratings yet

- Atlas Espuma WXF Final 1470411531Document4 pagesAtlas Espuma WXF Final 1470411531JuanPabloGonzalezFiblasNo ratings yet

- LSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDDocument8 pagesLSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDJuanPabloGonzalezFiblasNo ratings yet

- LSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDDocument8 pagesLSA Pump Series - Low Maintenance, Abrasion Resistant: LSA-S, LSA-Expanded Range, LHD, MHDJuanPabloGonzalezFiblasNo ratings yet

- Desalineamiento Acoplamientos FalkDocument2 pagesDesalineamiento Acoplamientos FalkJuanPabloGonzalezFiblasNo ratings yet

- SS A Service ManualDocument65 pagesSS A Service ManualJuanPabloGonzalezFiblasNo ratings yet

- Desalineamiento Acoplamientos FalkDocument2 pagesDesalineamiento Acoplamientos FalkJuanPabloGonzalezFiblasNo ratings yet

- Trunnion Bearing ClearanceDocument1 pageTrunnion Bearing ClearanceJuanPabloGonzalezFiblasNo ratings yet

- IMG - 0092 PSME Code 2012 90Document1 pageIMG - 0092 PSME Code 2012 90Bugoy2023No ratings yet

- Mahamrityunjaya MantraDocument8 pagesMahamrityunjaya MantraBalakrishnan KannanNo ratings yet

- Sony Ericsson K610i, K610m, and V630i Service ManualDocument53 pagesSony Ericsson K610i, K610m, and V630i Service ManualJane TodoroskiNo ratings yet

- Picard's Existence and Uniqueness TheoremDocument2 pagesPicard's Existence and Uniqueness Theoremmanjoy dasNo ratings yet

- CH 01Document24 pagesCH 01Gabriel FlorêncioNo ratings yet

- Djoko The Indonesian Mineral Mining Sector Prospects and ChallengesDocument42 pagesDjoko The Indonesian Mineral Mining Sector Prospects and ChallengesUmesh ShanmugamNo ratings yet

- Interaction of Radiation With Matter: Dhruba GuptaDocument36 pagesInteraction of Radiation With Matter: Dhruba GuptaHala SweetNo ratings yet

- GRT9165 Product GuideDocument23 pagesGRT9165 Product GuideEslamAldenAbdoNo ratings yet

- User Manual ConsoleDocument45 pagesUser Manual Consoledhana0809No ratings yet

- Final 401Document8 pagesFinal 401Hong Chul NamNo ratings yet

- Rec2009 025 PDFDocument172 pagesRec2009 025 PDFEkaStaVTVNo ratings yet

- Elcometer Wet-Film Gage 115 Spec SheetDocument2 pagesElcometer Wet-Film Gage 115 Spec SheetMary CasillasNo ratings yet

- CrankDocument9 pagesCrankKresna BayuNo ratings yet

- Error Codes (DTC) : 15 Electrical TroubleshootingDocument13 pagesError Codes (DTC) : 15 Electrical TroubleshootingPoyraz PoyrazNo ratings yet

- TATA Gluco PDFDocument5 pagesTATA Gluco PDFsidharth dasNo ratings yet

- Chapter 6 Exercises (Bonds & Interest)Document2 pagesChapter 6 Exercises (Bonds & Interest)Shaheera SuhaimiNo ratings yet

- Sri Lanka's Mineral Resources Can Enrich Country's CoffersDocument139 pagesSri Lanka's Mineral Resources Can Enrich Country's CoffersPrashan Francis100% (3)

- Mtech Geotechnical Engineering 2016Document48 pagesMtech Geotechnical Engineering 2016Venkatesh ThumatiNo ratings yet

- Countable UncountableDocument4 pagesCountable UncountablePaoLo Mena la TorreNo ratings yet

- Presentation 1Document26 pagesPresentation 1Vaibhav Hireraddi100% (1)

- 123 Rule For TRS MMD DG ShippingDocument2 pages123 Rule For TRS MMD DG ShippingGurjit SinghNo ratings yet

- 1 5109354204116287644 PDFDocument336 pages1 5109354204116287644 PDFGerardoNo ratings yet

- WozairDocument4 pagesWozairRajakumar Bajji SubburamanNo ratings yet

- Aspirasi MekoniumDocument17 pagesAspirasi MekoniumimanNo ratings yet

- ImmortalDocument4 pagesImmortalMaNithyaVishalanandaNo ratings yet

- Potensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliDocument8 pagesPotensi Energi Listrik Yang Dihasilkan Dari Emisi Gas Metana Di Tpa Suwung Provinsi BaliNuyul FaizahNo ratings yet

- Finger Print Based Voting System For Rigging Free Governing SystemDocument2 pagesFinger Print Based Voting System For Rigging Free Governing SystemArvind TilotiaNo ratings yet

- Chips Unlimited Blend LibraryDocument20 pagesChips Unlimited Blend Librarymizan sallehNo ratings yet

- Plant Seedling Classification Using CNNDocument12 pagesPlant Seedling Classification Using CNNYugal Joshi0% (1)

- Hanoi 2023 Peoples Picks AwardsDocument113 pagesHanoi 2023 Peoples Picks AwardsNguyen Anh VuNo ratings yet