Professional Documents

Culture Documents

Hemp Hazid

Uploaded by

rwerwerwCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hemp Hazid

Uploaded by

rwerwerwCopyright:

Available Formats

Shell Exploration & Production

HEMP and HAZID

1/11/16

File Title

Copyright: Shell Exploration & Production Ltd.

HEMP (Hazard and Effects

Management Process) and its

associated tools

Design

Integrity

Technical

Integrity

Operating

Integrity

Shell Exploration & Production

HEMP (Hazard & Effects Management Process)

HEMP = four steps:

Identify - what hazards are present in our

activities. Are people, environment, assets or

reputation exposed to potential harm?

Produce a list of these hazards

Assess - we need to know how the hazard

can be released, how likely is loss of control,

what are the potential consequences, and

thus how important each hazard is to us. In

this way we can prioritise. We also ask the

question can we remove the hazard? - is the

hazard an inherent part of our business or can

we remove it and still function.

Control - for all identified hazards we ask the

questions: Can we eliminate the causes

which release the hazard? and What

controls are needed to prevent the release?

How effective are these controls?

Recover - Can the potential consequences or

effects be mitigated? What recovery

measures are needed? Are recovery

capabilities suitable and sufficient?

In Identify & Assess, use the Bow Tie

model

HAZID a structured brainstorming to

identify potential hazards early in the

project

EP2005-0300 HEMP Process (full set of

procedures, specifications, standards,

guidelines)

HEMP (WIKI)

CONSEQUENCE

H

A

Z

A

R

D

SCENARIO

Top

Event

THREAT

BARRIERS OR

CONTROLS

Control (keep within control limits)

reduce likelihood

(proactive)

CONSEQUENCE

RECOVERY

MEASURES

CONSEQUENCE

Prepare for emergencies

mitigate consequences and re-instate

(reactive)

Accountability DCAF states that this is with the HSS

Discipline in EPE it is with Safety Engineering

Bow Tie Model

HAZID

Shell Exploration & Production

HEMP (Hazard & Effects

Management Process)

THREATS

ESCALATION

Hazard :

Hydrocarbon gas

under pressure

Examples:

Corrosion

Erosion

Impact

Fire

Pressure Vessel

Example 1

Rupture and Leak

Hazardous

Event

Leak !

Fire

First Hazardous Event

or

Top Event

Inspection

Corrosion

Allowance

Threat Barriers

CAUSATION

Detection

Process

Shutdown

Detection

ESD

Plant

Separation

Recovery Preparedness Measures

and Mitigation Measures

CONSEQUENCE

Detection

and

Deluge

Shell Exploration & Production

FAULT TREE

(Causes)

EVENT TREE

(Consequences)

e.g.maloperation

e.g. overpressure

H

A

Z

A

R

D

e.g.loss of

gas

containment

e.g.ESD

bypassed

Hazardous Event

(release of hazard)

E

S

C

A

L

e.g.detector failure

A

T

I

O

e.g.deluge failure

N

e.g. explosion

sequence of faults and causes

leading to a hazardous event

sequence of events and failures leading

to the escalation of a hazardous event

CAUSE CONSEQUENCE DIAGRAM (BOW TIE)

Shell Exploration & Production

Event:

Well Kick

HEMP (Hazard & Effects

Management Process)

Threats

Example 2

Blow

out

Escalation

Loss of Hydrostatic head

Swabbing

Hazard:

HC under pressure

Well kick

First Hazardous Event

Or

Top event

Accurate

Pressure

info

Mud

Weight

Control

Kick

detection

Blow

out

Well

design

BOPs

Emergency

Plan

Threat Barriers

Recovery Preparedness Measures

And Mitigation Measures

Causation

Consequences

Shell Exploration & Production

FAULT TREE

(Causes)

EVENT TREE

(Consequences)

Mud weight too low

H

A

Z

A

R

D

Well

Kick

Mud Pit level

alarm by passed

Hazardous Event

Losses

(release of hazard)

sequence of faults and causes

leading to a hazardous event

Rig floor equipment

S

not X-proof

C

A

L

BOP leaking

A

T

I

O

Bad casing design

N

sequence of events and failures leading

to the escalation of a hazardous event

CAUSE CONSEQUENCE DIAGRAM (BOW TIE)

Shell Exploration & Production

What is ALARP?

When is safe, safe enough.

ALARP (As Low As Reasonably Practicable) is the level of risk (tolerability)

below which the money, time and trouble involved in reducing the risk

further would become unreasonably (grossly) disproportionate.

120

Risk

100

80

Risk to

stakeholders

60

Sacrifice (cost)

40

20

0

Legal

Requirements,

Standards

A

L

A

R

P

Risk reduction options

Shell Exploration & Production

HEMP cont. - tools

Tools and (structured) techniques to identify hazards and/or assess the consequences and/or the

level of risk

Examples:

HAZID

Job Hazard Analysis/TRA

Explosion study

HAZOP

Pollution study

Fire modelling (and FirePran)

Escape and evacuation analysis

RIE (Health Risk Assessment)

Sustainable development assessment

Ergonomic layout study

QRA

Technical studies:

IPF/SIL-classification

FMECA

Structural analysis

Shell Exploration & Production

HEMP Tools cont. - 1: HAZID (Hazard Identification Study)

Team session

Involving all disciplines

Independent chairman/facilitator

(qualified)

EP200712228168,

Select Plant AREA or NODE & Section,

Select CATEGORY, Discuss and agree INTENT

Be creative!

Addresses environmental and project

risks

Identify Hazard

Determine threats/barriers

Assess (risk ranking)

Action?

HAZARD

GUIDE WORD

HAZID procedure EPE

IS IT POSSIBLE

IS IT LIKELY ?

NO

YES

BRAINSTORM

THREATS & CAUSES

ASSESS

CONTROLS

WHAT BARRIERS OR CONTROLS

ARE REQUIRED TO PREVENT OR

CONTROL THE EFFECT?

The HAZID

Process

IDENTIFY

http://sww.shell.com/ep/epe/engineering_maintenance/safety_engineering/safety_engineering_hazop_intro.html

Shell Exploration & Production

HEMP Tool 2: HAZOP-technique

Identification of hazards and operability

issues

Team session

Multi-disciplinary

Separate chairman (qualified)

Very rigorous

Relevant for process changes eg. UBD, tie-in

to vent system, flaring.

Decision not to HAZOP to be signed off by a

Process TA2

Ref. EP200712228168

HAZOPprocedure EPE

http://sww.shell.com/ep/epe/engineering_maintenance/safety_engineering/safety_engineering_hazop_intro.html

Shell Exploration & Production

Shell Exploration & Production

HEMP Tool 3.

QRA

Complex situations

(process hazards)

Comparison between

options (helicopter vs

basket)

Statistics may help but

have limitations

Caution about the absolute

level of risk

(Quantitative Risk Assessments)

10-2

INTOLERABLE

Fundamental improvements

needed

Daily commuting

by helicopter

10-3

TOO HIGH

Significant effort required

to improve

HIGH

Investigate alternatives

LOW

Consider cost

effective alternatives

NEGLIGABLE

Maintain normal

precautions

10-4

10-5

10-6

10-7

10-8

Individual risk

Mining

E&P contractors

Average all industries

Traffic accident

Workers in safest

industries

Living near nuclear

installations

Fire or explosion

from gas at home

Lightning (UK)

Shell Exploration & Production

Shell Exploration & Production

Exercise 1: Gas detection

Structural

Integrity

Process

Containment

Ignition

Control

Protection

Systems

Detection

Systems

Gas detection system out of service

- cup of coffee fell into the control

panel:

- unmanned onshore location

- Unmanned offshore location

- manned installation

Shutdown

Systems

Emergency

Response

Lifesaving

Major Accident

HazardEscalating

Consequences

1. What is/are the hazards?

2. What is the source of energy?

3. Barriers - preventive (any additional?)

- mitigative (any additional?)

4. What is the consequence?

5. What is the probability and (level of )Risk?

(with and without additional measures)

Shell Exploration & Production

Exercise 2: Tank level calibration

Condensate storage tank (750 m3)

Level alarm (to control room) @ 70%

Automated shutdown @ 90%

Instrument has been calibrated for water tank iso stabilised

condensate s.g. = 0,85

Tank does contain a pressure relief valve and a local level

indicator

1. What is/are the hazards?

2. What is the source of energy?

3. Barriers - preventive (any additional?)

- mitigative (any additional?)

4. What is the consequence?

5. What is the probability and (level of )Risk?

(with and without additional measures)

Shell Exploration & Production

Exercise 3: Gas leak

-

flange-leak (natural gas) x-mas tree (approx. 7 mm)

Ignited

Pressure 80 bar

Well spacing 20 meters

1. What is/are the hazards?

2. What is the source of energy?

3. Barriers - preventive (any additional?)

- mitigative (any additional?)

4. What is the consequence?

5. What is the probability and (level of )Risk?

(with and without additional measures)

Shell Exploration & Production

Exercise 4: Valve in wrong position

-

Locked open in stead of locked closed (due to drawing error or

maloperation reading error)

4Valve is connected to a 2-phase separator (150 bar)

In use as a manual drain connection for annual maintenance

Drain system has design rating of 10 bar

Drain tank is located on the lowest deck

1. What is/are the hazards (gevaren)?

2. What is the source of energy?

3. Barriers - preventive (any additional?)

- mitigative (any additional?)

4. What is the consequence?

5. What is the probability and (level of )Risk?

(with and without additional measures)

You might also like

- Override Bypass ControlDocument26 pagesOverride Bypass ControlRajesh Krishnamoorthy100% (2)

- Bow Ties in Risk Management: A Concept Book for Process SafetyFrom EverandBow Ties in Risk Management: A Concept Book for Process SafetyNo ratings yet

- PR-1172 - Permit To Work ProcedureDocument155 pagesPR-1172 - Permit To Work Procedurerwerwerw100% (5)

- CBLM-BEAUTY CARE - FinalDocument75 pagesCBLM-BEAUTY CARE - FinalQuimby Quiano100% (3)

- Guidelines for Defining Process Safety Competency RequirementsFrom EverandGuidelines for Defining Process Safety Competency RequirementsRating: 3 out of 5 stars3/5 (1)

- Hazop/HazidDocument20 pagesHazop/HazidOmar DhiebNo ratings yet

- Process Safety AuditDocument21 pagesProcess Safety AuditKailash Pandey100% (2)

- Override-Bypass Safety - Interlock Torus InsuranceDocument2 pagesOverride-Bypass Safety - Interlock Torus Insurancepiolinwalls100% (1)

- HSE Monitoring SampleDocument1 pageHSE Monitoring SamplerwerwerwNo ratings yet

- PR-1066 - Emergency Response Document Part III Contingency Plan, Volume III Production OperationsDocument61 pagesPR-1066 - Emergency Response Document Part III Contingency Plan, Volume III Production Operationsrwerwerw100% (1)

- Guide For Process Safety in DesignDocument35 pagesGuide For Process Safety in DesignpoundingNo ratings yet

- Production of Blue Ternate (Clitoria Ternatea) Flower Extracts in Hand SanitizerDocument37 pagesProduction of Blue Ternate (Clitoria Ternatea) Flower Extracts in Hand SanitizerDiane Vill100% (1)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Essential Practices for Creating, Strengthening, and Sustaining Process Safety CultureFrom EverandEssential Practices for Creating, Strengthening, and Sustaining Process Safety CultureNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- LOPA Enabling ConditionsDocument22 pagesLOPA Enabling Conditionsuserscribd2011No ratings yet

- Omcl Management of ChangesDocument7 pagesOmcl Management of ChangesHans LeupoldNo ratings yet

- Petroleum Development Oman L.L.C.: Document Title: H Sandso Management OperationsDocument33 pagesPetroleum Development Oman L.L.C.: Document Title: H Sandso Management OperationsShambu S VtkNo ratings yet

- Process Safety Day Presentations 2014pptxDocument16 pagesProcess Safety Day Presentations 2014pptxKhuda BukshNo ratings yet

- Manual For SIEP-led HSE AuditingDocument60 pagesManual For SIEP-led HSE AuditingClive NicliNo ratings yet

- TN 015 Overrides 15Document8 pagesTN 015 Overrides 15Luis SantosNo ratings yet

- SIMOPS study methodologyDocument6 pagesSIMOPS study methodologyMuhammad.SaimNo ratings yet

- TSE FrameworkDocument3 pagesTSE FrameworkyeNo ratings yet

- SWP Bypassing Critical Protections GuidelinesDocument10 pagesSWP Bypassing Critical Protections Guidelinesesakkiraj1590100% (1)

- Ep 95-0313 HazopDocument88 pagesEp 95-0313 HazopManjunathBVenkatesh100% (5)

- Alarp Exercise Cba Uk HseDocument2 pagesAlarp Exercise Cba Uk HseMuhammad.SaimNo ratings yet

- Achieved SILDocument4 pagesAchieved SILAkoKhaledi50% (2)

- Software PHADocument2 pagesSoftware PHAafigueredouNo ratings yet

- PHA Process Hazards AnalysisDocument32 pagesPHA Process Hazards Analysisoanzar100% (2)

- Bow-Tie Analysis & HSECES: Course Information SheetDocument3 pagesBow-Tie Analysis & HSECES: Course Information SheetSayed Saad ShehataNo ratings yet

- Global Upstream Tier 1 and 2 Process Safety Event Classification Guidance 2015Document19 pagesGlobal Upstream Tier 1 and 2 Process Safety Event Classification Guidance 2015MIGUELONOFRENo ratings yet

- Sis PDFDocument2 pagesSis PDFsteam100deg1658No ratings yet

- Process Safety Management: Outline for HSE UpdatesDocument24 pagesProcess Safety Management: Outline for HSE Updatesismailines100% (1)

- Upstream Control of Work BP Procedure June 2020 - Rev B06 - PDFDocument361 pagesUpstream Control of Work BP Procedure June 2020 - Rev B06 - PDFRio Reunarudi100% (1)

- Safety Plan For Chemical PlantDocument7 pagesSafety Plan For Chemical PlantM Amir Haris100% (1)

- UKOOA - Oil Amp Gas Uk Guidelines On Risk Related Decision Making Issue 2 July 2014 PDFDocument25 pagesUKOOA - Oil Amp Gas Uk Guidelines On Risk Related Decision Making Issue 2 July 2014 PDFchloeNo ratings yet

- HSE Specification - Flora and Fauna ProtectionDocument11 pagesHSE Specification - Flora and Fauna ProtectionrwerwerwNo ratings yet

- Nuffield HazID GuidewordsDocument24 pagesNuffield HazID Guidewordsuserscribd2011100% (1)

- Barrier Management in Pandemic Era PPNS ITS Rev1-3Document16 pagesBarrier Management in Pandemic Era PPNS ITS Rev1-3Romariyo Andi AbdoemadonNo ratings yet

- Hemp RaddDocument78 pagesHemp RaddMuhammad.SaimNo ratings yet

- WWW - Hse.gov - Uk Comah Buncefield Bstgfinalreport PDFDocument118 pagesWWW - Hse.gov - Uk Comah Buncefield Bstgfinalreport PDFhulmanNo ratings yet

- PHA ProtectionsDocument36 pagesPHA ProtectionsSyed Shiraz AliNo ratings yet

- Hazid RecordDocument21 pagesHazid Recordavanish.vNo ratings yet

- Learning Lessons From IncidentsDocument37 pagesLearning Lessons From IncidentsAugusto Serrano50% (2)

- Integrity Operating Windows ShellDocument28 pagesIntegrity Operating Windows ShellZenon KociubaNo ratings yet

- AI-PS Element Guide No 7Document11 pagesAI-PS Element Guide No 7alokcNo ratings yet

- DNV Process Vs Occupational SafetyDocument17 pagesDNV Process Vs Occupational Safetymarsulex100% (1)

- Integrity Verification of Safety Critical ElementsDocument1 pageIntegrity Verification of Safety Critical ElementsAnonymous 1XHScfCINo ratings yet

- HAZID GuidewordsDocument8 pagesHAZID Guidewordsalex_E_bond100% (2)

- Bow TieDocument2 pagesBow TieAnonymous ocCa18RNo ratings yet

- Blank PSM & RMP Audit FormDocument298 pagesBlank PSM & RMP Audit Formclashu2No ratings yet

- YPMT OPS PR 0027 - 旁路管理程序 OverrideBypass Management ProcedureDocument21 pagesYPMT OPS PR 0027 - 旁路管理程序 OverrideBypass Management ProcedureShanying PengNo ratings yet

- Chapter 5 - Hazard IdentificationDocument53 pagesChapter 5 - Hazard IdentificationChieng Tiew Hing100% (1)

- Pre Safety ReviewDocument27 pagesPre Safety ReviewMagesh KumarNo ratings yet

- GS EP EXP 407 05 Appendix3 Escape GenericPerformanceStandardsDocument181 pagesGS EP EXP 407 05 Appendix3 Escape GenericPerformanceStandardsAzeemNo ratings yet

- Layer of Protection AnalysisDocument9 pagesLayer of Protection Analysiscera211164No ratings yet

- Risk Based Process Safety DesignDocument13 pagesRisk Based Process Safety DesignVan SotNo ratings yet

- Gas Release Tripod Beta Analysis Final-2Document28 pagesGas Release Tripod Beta Analysis Final-2Mostafa KhalifaNo ratings yet

- KPI Process SafetyDocument6 pagesKPI Process SafetyKrishnan RajappanNo ratings yet

- PSM 09 Audits and Observations (MSA)Document16 pagesPSM 09 Audits and Observations (MSA)Shahzad RiazNo ratings yet

- Ep 950100Document62 pagesEp 950100Ram1zNo ratings yet

- 09 COMAH GuidanceDocument8 pages09 COMAH GuidanceSaad GhouriNo ratings yet

- I&E Systems Pty LTD FS Engineer (TÜV Rheinland) Training and CertificationDocument4 pagesI&E Systems Pty LTD FS Engineer (TÜV Rheinland) Training and Certificationfaisal84inNo ratings yet

- Petroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Document15 pagesPetroleum Development Oman L.L.C.: Instrumented Protective Functions Test Procedure Revision1Anjani Prabhakar0% (1)

- 35 Control Mitigation Emergency PreparednessDocument25 pages35 Control Mitigation Emergency PreparednessTri SubaktiNo ratings yet

- RAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREDocument57 pagesRAS MARKAZ CRUDE OIL PARK PSSR PROCEDUREKhan Wasim100% (1)

- PR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionDocument37 pagesPR-1709 - Lifting and Hoisting Procedure Lift Planning ExecutionsurnaikNo ratings yet

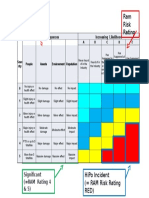

- Ram Severity and Risk Rating GuideDocument1 pageRam Severity and Risk Rating GuiderwerwerwNo ratings yet

- PR-2010 II HSETrainingProvisionApprovalAndQualityAssuranceDocument106 pagesPR-2010 II HSETrainingProvisionApprovalAndQualityAssurancerwerwerwNo ratings yet

- HSE GuidelineDocument59 pagesHSE GuidelineDia Putranto HarmayNo ratings yet

- Managing Human Factor Engineering in Projects User GuideDocument25 pagesManaging Human Factor Engineering in Projects User GuiderwerwerwNo ratings yet

- PR-1081 - The Buddy System ProcedureDocument14 pagesPR-1081 - The Buddy System ProcedurerwerwerwNo ratings yet

- H Sems AssessmentDocument1 pageH Sems AssessmentrwerwerwNo ratings yet

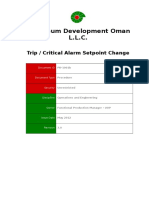

- PR-1001b - Trip - Critical Alarm Setpoint ChangeDocument13 pagesPR-1001b - Trip - Critical Alarm Setpoint ChangerwerwerwNo ratings yet

- Ep 95-0313 HazopDocument88 pagesEp 95-0313 HazopManjunathBVenkatesh100% (5)

- PR-1005 - Maintenance and Inspection Activity Variance Control ProcedureDocument18 pagesPR-1005 - Maintenance and Inspection Activity Variance Control Procedurerwerwerw100% (1)

- Top Physical, Biological, Ergonomic and Chemical HazardsDocument274 pagesTop Physical, Biological, Ergonomic and Chemical HazardsrwerwerwNo ratings yet

- HSE Specification - Smoking, Drugs and AlcoholDocument9 pagesHSE Specification - Smoking, Drugs and AlcoholrwerwerwNo ratings yet

- HSE Specification - Flora and Fauna ProtectionDocument11 pagesHSE Specification - Flora and Fauna ProtectionrwerwerwNo ratings yet

- Managing Change SafelyDocument10 pagesManaging Change SafelyrwerwerwNo ratings yet

- CP-162 Internal Communication CoPDocument10 pagesCP-162 Internal Communication CoPrwerwerwNo ratings yet

- Audit ReportDocument9 pagesAudit ReportrwerwerwNo ratings yet

- AI-PS Element Guide No 6Document10 pagesAI-PS Element Guide No 6rwerwerwNo ratings yet

- GU-725 - Health Risk AssessmentDocument8 pagesGU-725 - Health Risk AssessmentrwerwerwNo ratings yet

- Contract Hse RequirementsDocument7 pagesContract Hse Requirementsrwerwerw100% (1)

- 2013-09-15 Final SP1257Document80 pages2013-09-15 Final SP1257rwerwerwNo ratings yet

- 2012-02-06 Blank HSE Verification Clarification Checklist FinalDocument12 pages2012-02-06 Blank HSE Verification Clarification Checklist FinalrwerwerwNo ratings yet

- 15 Form For Medium Potential Incident InvestigationDocument6 pages15 Form For Medium Potential Incident InvestigationrwerwerwNo ratings yet

- 09 Memory Aid Management InformationDocument1 page09 Memory Aid Management InformationrwerwerwNo ratings yet

- 04 Memory Aid Activity at The TimeDocument1 page04 Memory Aid Activity at The TimeSHANZAY21111111No ratings yet

- GU-612 - v3.1 - Guidelines - Incident Investigation and Reporting v1Document185 pagesGU-612 - v3.1 - Guidelines - Incident Investigation and Reporting v1rwerwerw100% (3)

- Investigations For Diseases of The Tongue A Review PDFDocument6 pagesInvestigations For Diseases of The Tongue A Review PDFShantanu DixitNo ratings yet

- Tugas English Geri PebriansyahDocument10 pagesTugas English Geri PebriansyahAyu AndiniiNo ratings yet

- Semi Solids PDFDocument3 pagesSemi Solids PDFAsif Hasan NiloyNo ratings yet

- Drug in PregnancyDocument5 pagesDrug in PregnancyjokosudibyoNo ratings yet

- The Regent's Park - Risk AssessmentDocument3 pagesThe Regent's Park - Risk AssessmentEiman'E'RostamiNo ratings yet

- Global Guidelines For The Prevention of Surgical Site InfectionDocument186 pagesGlobal Guidelines For The Prevention of Surgical Site InfectionLe Ngoc Quynh GiaoNo ratings yet

- 09022016att ComplaintDocument25 pages09022016att Complaintsarah_larimerNo ratings yet

- Malunggay Para sa PamilyaDocument4 pagesMalunggay Para sa PamilyaJeffrey S. Saballo100% (1)

- Rostering Process FlowchartDocument1 pageRostering Process FlowchartByte MeNo ratings yet

- Operant WorksheetDocument4 pagesOperant Worksheetssnpl1415No ratings yet

- SPS321 Sports Safety and Emergency Care Mohd Fadzil B. Hj. Kamarudin Sr113 Uitm/InstedtDocument9 pagesSPS321 Sports Safety and Emergency Care Mohd Fadzil B. Hj. Kamarudin Sr113 Uitm/InstedtMozil Fadzil KamarudinNo ratings yet

- Research Paper 4Document26 pagesResearch Paper 4Amit RajputNo ratings yet

- Template Clerking PsychiatryDocument2 pagesTemplate Clerking Psychiatrymunii28No ratings yet

- Taking Blood Pressure CorrectlyDocument7 pagesTaking Blood Pressure CorrectlySamue100% (1)

- Chapter 14 Pharmacy Law and Ethics Notes Complete Notes by Noteskarts Acc To ER20Document4 pagesChapter 14 Pharmacy Law and Ethics Notes Complete Notes by Noteskarts Acc To ER20Shamant TNo ratings yet

- Bionics: BY:-Pratik VyasDocument14 pagesBionics: BY:-Pratik VyasHardik KumarNo ratings yet

- Drug Master FileDocument62 pagesDrug Master FileAjay GuptaNo ratings yet

- Nabh CleaningDocument6 pagesNabh CleaningArchana GaonkarNo ratings yet

- The Body and Body Products As Transitional Objects and PhenomenaDocument12 pagesThe Body and Body Products As Transitional Objects and PhenomenaOctavian CiuchesNo ratings yet

- Complications of Caesarean Section: ReviewDocument8 pagesComplications of Caesarean Section: ReviewDesi Purnamasari YanwarNo ratings yet

- Physio Ex Exercise 6 Activity 4Document5 pagesPhysio Ex Exercise 6 Activity 4Roland Calipayan Jr.No ratings yet

- MediterraneanDocument39 pagesMediterraneanJeff Lester PiodosNo ratings yet

- American Psycho Disorders & TriggersDocument5 pagesAmerican Psycho Disorders & TriggersPatricia SmithNo ratings yet

- Chlorhexidine & Its UsesDocument40 pagesChlorhexidine & Its UsesSriya Saatwika ReddyNo ratings yet

- LC (Lethal Concentration) : Uji Toksisitas KuantitatifDocument31 pagesLC (Lethal Concentration) : Uji Toksisitas Kuantitatifbagi_fileNo ratings yet

- Nurse Licensure Examination Review Center for Allied Professions (RCAPDocument15 pagesNurse Licensure Examination Review Center for Allied Professions (RCAPnikko0427No ratings yet

- Dukungan Nutrisi Pra / Pasca BedahDocument22 pagesDukungan Nutrisi Pra / Pasca BedahAfdhal Putra Restu YendriNo ratings yet

- New TNMDocument157 pagesNew TNMShouvik ChowdhuryNo ratings yet