Professional Documents

Culture Documents

Double Roller Crusher Design by TATA

Uploaded by

Bhanu ChaterjiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Double Roller Crusher Design by TATA

Uploaded by

Bhanu ChaterjiCopyright:

Available Formats

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS

= Length and width of roller screens can be adjusted to suit customers requirement

= Non clogging, smooth, non-vibrating and low noise while running

= Higher screen efficiency

= Less space required

= Higher capacity up to 1500 TPH running at low power compared to conventional screens

= Uniform wearing of crushing surface.

= Produces more uniform material than any other crusher having reciprocating motion.

= Easy and simple to maintain.

= More economical because of its higher production capacity and lower power requirment.

= Used for almost any material and for crushing up to 0.5 mm.

= As the material is CRUSHED ONLY ONCE when it passes through the gap, the percentage of FINES IS MUCH LESS.

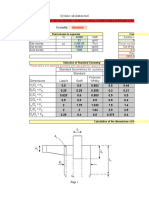

Side View of Double Roll Crusher

Roller Screens

Double Roll Crushers

Enterprise

TRF LIMITED

Double Roll Crushers

Description and Uses

Two rolls rotate in opposite directions in this

crusher. The material is fed between the two

rolls for compressive action and breaking into

fragments of uniform size. Simplicity of

mechanical construction and ease of

operation are the two highlights of this

crusher. The amount of fines generated from

crushing is relatively small, a performance

feature which qualifies this machine for use in

the following installations:

The

with

hard

rolls

TRF LIMITED

Double Roll Crusher is available

heavy duty rolls for crushing such

materials as ore or with light duty

for crushing relatively soft materials.

Construction

(1) Frame

COAL-FUEL POWER PLANTS

SMELTING PLANTS

(for crushing sintered ore and cinder)

CHEMICAL PLANTS

(for crushing lime, coal, coke, rock salt, etc.)

CEMENT PLANTS

(for crushing clay, lime and gypsum rocks)

COAL MINES

(for crushing coal and waste)

SORTING PLANTS OF MINES

(for crushing ore)

A cast-iron or steel-plate frame is used.

The steel-plate frame is fabricated by

welding. The plummer blocks of fixed roll

assembly are integral with the frame.

The Plummer Block for the movable roll

assembly are elastically positioned in

horizontal direction with high-strength

coil springs or hydraulic accumulators

selected for the type of crushing duty.

This elastic mounting includes a means

of adjusting the roll-to-roll clearance (roll

setting) and serves as a protective

feature for preventing motor over load or

damage to the crusher, as the roll will

yield and back away when it grips hard

foreign matters like tramp iron.

(2) Rolls

Roll tyres are of smooth type, corrugated

type or toothed type, depending on the

crushing duty. In the standard design

(for crushing coal)

Enterprise

each roll assembly consist of a roll boss with

hexagonal outer shape rigidly mounted on

the roll shaft which permits easy replacemant

of roll tyre. The roll tyres are held tight by

means of bolts. This arrangement provides

for easy tyre replacement and minimizes

parts subject to wear. The roll tyres are made

of high manganese steel.

(3) Bearings

Spherical roller bearings are used to

support the rolls. The spherical roller

bearings are complete with labyrinth

seals and packings for preventing

entrance of dust and leakage of oil.

(4) Drive

The standard Double roll crusher has

independent belt drives from two

motors, one motor for each roll. This

arrangement eliminates the need for an

intermediate drive transmitting device

resulting in less space utilisation and

reducing the no-load power loss.

Roller Screens

TRF LIMITED

Enterprise

Description

in a circulating oil bath.

determined distance in such a way that they form a square or

direction by two drive units. Drive is fully covered and operates

roller discs are elliptical in shape and arranged at a pre-

alternately with chain and sprocket and are driven in same

spherical roller bearings across the width of main frame. These

arrangement. All roller shaft assemblies are connected

roller disc assemblies mounted on shafts and supported on

These roller shaft assemblies are driven by chain and sprocket

Roller screens consists of a rigid main frame and a series of

rectangular opening in the roller screen at several places. Over

fluid coupling, gearbox and drive sprocket.

material falls through the screen opening. The scrapper

Each roller screen has two drive units along with electric motor,

discs and finally reach the crusher as feed, while undersized

Drive :

sized materials are pushed forward by rotation of elliptical

provided below the elliptical discs ensures clog free screening.

Application :

TRF Roller screens are most suitable for separating coars

wet and sticky raw material. Roller screens are used in soft coal,

MATERIA

LF

LOW DIR

ECTION

FEED CHUTE

and lignite handling plants for preliminary screening of ROM

coal. It acts as relief to crushers and ensures a clog free flow of

wet and sticky materials. TRF roller screens are useful for

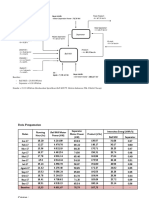

DIMENSIONS (in MM) :

D

600

750

750

750

750

750

900

900

900

900

900

900

1200

1200

1200

1400

L

600

600

750

900

1200

1500

900

1200

1500

1800

2100

2400

1200

1800

2400

2500

A

350

596

596

596

596

596

600

600

600

600

600

600

800

800

800

900

B

650

686

850

1050

1300

1500

1000

1350

1600

1900

2200

2500

1400

2000

2600

2700

A1

1100

1850

1850

1850

1850

1850

1850

1850

1850

1850

1850

1850

2200

2200

2200

2300

B1

650

900

1050

1300

1500

1700

1150

1500

1750

2000

2300

2800

1600

2200

2800

2900

A2

660-730

800-870

800-870

800-870

800-870

800-870

900-1000

900-1000

900-1000

900-1000

900-1000

900-1000

1200-1300

1200-1300

1200-1300

1250-1400

K

830

1010

1200

1300

1350

1450

1300

1400

1660

1800

1950

2100

2100

2400

2600

2700

K1

1475

2200

2200

2200

2200

2200

2200

2200

2200

2200

2200

2200

3000

3000

3000

3200

H

1030

1475

1475

1475

1475

1475

1650

1650

1650

1650

1650

1650

1850

1850

1850

1900

H1

930

1375

1375

1375

1375

1375

1500

1500

1500

1500

1500

1500

1700

1700

1700

1800

separation of undersized material ranging from (-) 20 mm. to (-)

H2

430

625

625

625

625

625

650

650

650

650

650

650

700

700

700

800

60 mm. The roller screens can be placed horizontally or at

UNDER SIZE

DISCHARGE CHUTE

angle of maximum 10 degrees.

OVER SIZE

DISCHARGE

CHUTE

Construction :

The roller screens consist of a rigid frame on which a series of

roller shaft assemblies are mounted with anti-friction bearings

Likhra / Jsr. (0657) 2291356

Likhra / Jsr. (0657) 2291356

Enterprise

TRF LIMITED

SIZE Dia. D x L

600 X 600

750 X 600

750 X 750

750 X 900

750 X 1200

750 X 1500

900 X 900

900 X 1200

900 X 1500

900 X 1800

900 X 2100

900 X 2400

1200 X 1200

1200 X 1800

1200 X 2400

1400 X 2500

HEAD OFFICE & WORKS

HEAD OFFICE & WORKS

TRF Limited

TRF Limited

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

MARKETING OFFICES

MARKETING OFFICES

Business Development Department

Bulk Material Handling Equi pment

Block - D, 3rd Floor,

22 Camac Street, Kolkata - 700 016

Business Development Department

Bulk Material Handling Systems

Port &Yard Equi pment Division

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

Ph : +91-33-44033553

e-mail : biz.development@trf.co.in

Bulk Material Handling Equi pment

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

Block - D, 3rd Floor,

Assistant General Manager

22 Camac Street, Kolkata - 700 016

Cell : + 91 - 9334002278

Ph : +91-33-44033553

Ph : +91-657 - 3046242

e-mail : biz.development@trf.co.in

Bulk Material Handling Systems

Port &Yard Equi pment Division

Assistant General Manager

Cell : + 91 - 9334002278

Ph : +91-657 - 3046242

Fax : +91-657-2345214

Fax : +91-657-2345214

e-mail : dcjha@trf.co.in

e-mail : dcjha@trf.co.in

REGIONAL OFFICES

REGIONAL OFFICES

HYDERABAD

Ph : +91-22-22616853 / 22641320

Ph : +91-11-223310788 / 23314540

Narottam Morarji Marg, Ballard Estate,

11th Floor 23, Kasturba Gandhi Marg

Magnet House, 1st Floor,

Himalaya House,

MUMBAI

NEW DELHI

Fax : +91-40-23297363

Fax : +91-22-22614085

Ph : +91-40-23297630 / 23297631

HYDERABAD

Ph : +91-22-22616853 / 22641320

Ph : +91-11-223310788 / 23314540

Narottam Morarji Marg, Ballard Estate,

11th Floor 23, Kasturba Gandhi Marg

Magnet House, 1st Floor,

Himalaya House,

MUMBAI

NEW DELHI

Flat No. 601, 6th Floor,

Paigah Plaza, Basheerbagh,

e-mail : mum@trf.co.in

e-mail : nd@trf.co.in

Fax : +91-11-23722447

Flat No. 601, 6th Floor,

Paigah Plaza, Basheerbagh,

e-mail : mum@trf.co.in

e-mail : nd@trf.co.in

Fax : +91-40-23297363

Fax : +91-22-22614085

Fax : +91-11-23722447

Ph : +91-40-23297630 / 23297631

e-mail : hyd@trf.co.in

e-mail : hyd@trf.co.in

TECHNICAL SPECIFICATIONS

TECHNICAL SPECIFICATIONS

= Length and width of roller screens can be adjusted to suit customers requirement

= Non clogging, smooth, non-vibrating and low noise while running

= Higher screen efficiency

= Less space required

= Higher capacity up to 1500 TPH running at low power compared to conventional screens

= Uniform wearing of crushing surface.

= Produces more uniform material than any other crusher having reciprocating motion.

= Easy and simple to maintain.

= More economical because of its higher production capacity and lower power requirment.

= Used for almost any material and for crushing up to 0.5 mm.

= As the material is CRUSHED ONLY ONCE when it passes through the gap, the percentage of FINES IS MUCH LESS.

Side View of Double Roll Crusher

Roller Screens

Enterprise

TRF LIMITED

Two rolls rotate in opposite directions in this

crusher. The material is fed between the two

rolls for compressive action and breaking into

fragments of uniform size. Simplicity of

mechanical construction and ease of

operation are the two highlights of this

crusher. The amount of fines generated from

crushing is relatively small, a performance

feature which qualifies this machine for use in

the following installations:

SORTING PLANTS OF MINES

(for crushing ore)

COAL MINES

(for crushing coal and waste)

CEMENT PLANTS

(for crushing clay, lime and gypsum rocks)

CHEMICAL PLANTS

(for crushing lime, coal, coke, rock salt, etc.)

SMELTING PLANTS

(for crushing sintered ore and cinder)

COAL-FUEL POWER PLANTS

(for crushing coal)

The

with

hard

rolls

TRF LIMITED

Double Roll Crusher is available

heavy duty rolls for crushing such

materials as ore or with light duty

for crushing relatively soft materials.

Construction

(1) Frame

A cast-iron or steel-plate frame is used.

The steel-plate frame is fabricated by

welding. The plummer blocks of fixed roll

assembly are integral with the frame.

The Plummer Block for the movable roll

assembly are elastically positioned in

horizontal direction with high-strength

coil springs or hydraulic accumulators

selected for the type of crushing duty.

This elastic mounting includes a means

of adjusting the roll-to-roll clearance (roll

setting) and serves as a protective

feature for preventing motor over load or

damage to the crusher, as the roll will

yield and back away when it grips hard

foreign matters like tramp iron.

(2) Rolls

Roll tyres are of smooth type, corrugated

type or toothed type, depending on the

crushing duty. In the standard design

each roll assembly consist of a roll boss with

hexagonal outer shape rigidly mounted on

the roll shaft which permits easy replacemant

of roll tyre. The roll tyres are held tight by

means of bolts. This arrangement provides

for easy tyre replacement and minimizes

parts subject to wear. The roll tyres are made

of high manganese steel.

Enterprise

(3) Bearings

Spherical roller bearings are used to

support the rolls. The spherical roller

bearings are complete with labyrinth

seals and packings for preventing

entrance of dust and leakage of oil.

Roller screens consists of a rigid main frame and a series of

These roller shaft assemblies are driven by chain and sprocket

roller disc assemblies mounted on shafts and supported on

arrangement. All roller shaft assemblies are connected

spherical roller bearings across the width of main frame. These

alternately with chain and sprocket and are driven in same

roller discs are elliptical in shape and arranged at a pre-

direction by two drive units. Drive is fully covered and operates

determined distance in such a way that they form a square or

in a circulating oil bath.

rectangular opening in the roller screen at several places. Over

sized materials are pushed forward by rotation of elliptical

Drive :

discs and finally reach the crusher as feed, while undersized

Each roller screen has two drive units along with electric motor,

material falls through the screen opening. The scrapper

fluid coupling, gearbox and drive sprocket.

provided below the elliptical discs ensures clog free screening.

(4) Drive

The standard Double roll crusher has

independent belt drives from two

motors, one motor for each roll. This

arrangement eliminates the need for an

intermediate drive transmitting device

resulting in less space utilisation and

reducing the no-load power loss.

Application :

TRF Roller screens are most suitable for separating coars

wet and sticky raw material. Roller screens are used in soft coal,

MATERIA

LF

LOW DIR

ECTION

FEED CHUTE

and lignite handling plants for preliminary screening of ROM

coal. It acts as relief to crushers and ensures a clog free flow of

wet and sticky materials. TRF roller screens are useful for

L

600

600

750

900

1200

1500

900

1200

1500

1800

2100

2400

1200

1800

2400

2500

A

350

596

596

596

596

596

600

600

600

600

600

600

800

800

800

900

B

650

686

850

1050

1300

1500

1000

1350

1600

1900

2200

2500

1400

2000

2600

2700

A1

1100

1850

1850

1850

1850

1850

1850

1850

1850

1850

1850

1850

2200

2200

2200

2300

B1

650

900

1050

1300

1500

1700

1150

1500

1750

2000

2300

2800

1600

2200

2800

2900

A2

660-730

800-870

800-870

800-870

800-870

800-870

900-1000

900-1000

900-1000

900-1000

900-1000

900-1000

1200-1300

1200-1300

1200-1300

1250-1400

K

830

1010

1200

1300

1350

1450

1300

1400

1660

1800

1950

2100

2100

2400

2600

2700

K1

1475

2200

2200

2200

2200

2200

2200

2200

2200

2200

2200

2200

3000

3000

3000

3200

H

1030

1475

1475

1475

1475

1475

1650

1650

1650

1650

1650

1650

1850

1850

1850

1900

H1

930

1375

1375

1375

1375

1375

1500

1500

1500

1500

1500

1500

1700

1700

1700

1800

H2

430

625

625

625

625

625

650

650

650

650

650

650

700

700

700

800

separation of undersized material ranging from (-) 20 mm. to (-)

60 mm. The roller screens can be placed horizontally or at

The roller screens consist of a rigid frame on which a series of

roller shaft assemblies are mounted with anti-friction bearings

HEAD OFFICE & WORKS

TRF Limited

TRF Limited

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

11, Station Road Burma Mines, Jamshedpur-831007, Jharkhand

Phone : +91- 657-3046500/ 598

Fax no. : +91- 657-2345732, e-mail : co@trf.co.in

MARKETING OFFICES

MARKETING OFFICES

Business Development Department

Bulk Material Handling Equi pment

Block - D, 3rd Floor,

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

Ph : +91-33-44033553

e-mail : biz.development@trf.co.in

OVER SIZE

DISCHARGE

CHUTE

Construction :

HEAD OFFICE & WORKS

22 Camac Street, Kolkata - 700 016

UNDER SIZE

DISCHARGE CHUTE

angle of maximum 10 degrees.

Likhra / Jsr. (0657) 2291356

D

600

750

750

750

750

750

900

900

900

900

900

900

1200

1200

1200

1400

Description

DIMENSIONS (in MM) :

SIZE Dia. D x L

600 X 600

750 X 600

750 X 750

750 X 900

750 X 1200

750 X 1500

900 X 900

900 X 1200

900 X 1500

900 X 1800

900 X 2100

900 X 2400

1200 X 1200

1200 X 1800

1200 X 2400

1400 X 2500

TRF LIMITED

Roller Screens

Enterprise

Likhra / Jsr. (0657) 2291356

Enterprise

TRF LIMITED

Description and Uses

Double Roll Crushers

Double Roll Crushers

Bulk Material Handling Systems

Port &Yard Equi pment Division

Business Development Department

Bulk Material Handling Equi pment

Block - D, 3rd Floor,

Assistant Divisional Manager

Cell: +91-9304813195

Ph: +91-657-3046259

Fax: +91 - 657-2345724

e-mail: r.k.shukla@trf.co.in

Assistant General Manager

22 Camac Street, Kolkata - 700 016

Cell : + 91 - 9334002278

Ph : +91-33-44033553

Ph : +91-657 - 3046242

e-mail : biz.development@trf.co.in

Bulk Material Handling Systems

Port &Yard Equi pment Division

Assistant General Manager

Cell : + 91 - 9334002278

Ph : +91-657 - 3046242

Fax : +91-657-2345214

Fax : +91-657-2345214

e-mail : dcjha@trf.co.in

e-mail : dcjha@trf.co.in

REGIONAL OFFICES

REGIONAL OFFICES

NEW DELHI

MUMBAI

HYDERABAD

NEW DELHI

MUMBAI

HYDERABAD

Himalaya House,

Magnet House, 1st Floor,

Flat No. 601, 6th Floor,

Himalaya House,

Magnet House, 1st Floor,

Flat No. 601, 6th Floor,

11th Floor 23, Kasturba Gandhi Marg

Narottam Morarji Marg, Ballard Estate,

Paigah Plaza, Basheerbagh,

11th Floor 23, Kasturba Gandhi Marg

Narottam Morarji Marg, Ballard Estate,

Paigah Plaza, Basheerbagh,

Ph : +91-11-223310788 / 23314540

Ph : +91-22-22616853 / 22641320

Ph : +91-40-23297630 / 23297631

Ph : +91-11-223310788 / 23314540

Ph : +91-22-22616853 / 22641320

Ph : +91-40-23297630 / 23297631

Fax : +91-11-23722447

Fax : +91-22-22614085

Fax : +91-40-23297363

Fax : +91-11-23722447

Fax : +91-22-22614085

Fax : +91-40-23297363

e-mail : nd@trf.co.in

e-mail : mum@trf.co.in

e-mail : hyd@trf.co.in

e-mail : nd@trf.co.in

e-mail : mum@trf.co.in

e-mail : hyd@trf.co.in

You might also like

- Excavation EquipmentDocument32 pagesExcavation EquipmentAlyssa Obligado100% (1)

- L01-Shaft Design For StressDocument29 pagesL01-Shaft Design For Stressmuhammad hashimNo ratings yet

- Double Roll Crusher Machine DesignDocument64 pagesDouble Roll Crusher Machine DesignCyphor Durante88% (26)

- Seismic Lab Exercises Chronostratigraphic ChartDocument12 pagesSeismic Lab Exercises Chronostratigraphic Chartpande_100No ratings yet

- Size Reduction: Department of Chemical Engineering University of Engineering & Technology PeshawarDocument60 pagesSize Reduction: Department of Chemical Engineering University of Engineering & Technology PeshawarRavid GhaniNo ratings yet

- ASTM D 4959-00, ASTM D653-02aDocument39 pagesASTM D 4959-00, ASTM D653-02aPedro Rivera100% (1)

- Causes of Foundation Damage in Black Cotton SoilDocument23 pagesCauses of Foundation Damage in Black Cotton SoilAbhishek Mishra67% (3)

- Study of Hammer Mill Crusher Design and WorkingDocument49 pagesStudy of Hammer Mill Crusher Design and WorkinglokeshNo ratings yet

- Farm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsFrom EverandFarm Machinery - Tractors - A Collection of Articles on the Operation, Mechanics and Maintenance of TractorsNo ratings yet

- REMU ScreeningBucketDocument12 pagesREMU ScreeningBucketScott GuimondNo ratings yet

- EV Hammer Impact Crusher Single Stage CrushingDocument7 pagesEV Hammer Impact Crusher Single Stage CrushingMohamed ShehataNo ratings yet

- Bucket ElevatorsDocument16 pagesBucket Elevatorssdmel100% (3)

- Gundlach Roll Crushers BrochureDocument2 pagesGundlach Roll Crushers Brochurerajeevup2004No ratings yet

- Maximize crusher capacity with optimal roll speedDocument2 pagesMaximize crusher capacity with optimal roll speedWaris La Joi Wakatobi100% (1)

- KilnDocument17 pagesKilnprashant mishraNo ratings yet

- Vibrating FeederDocument7 pagesVibrating FeederRk Upadhyay100% (1)

- Double Roll CrusherDocument6 pagesDouble Roll Crusherjaswanth60% (5)

- CrusherDocument22 pagesCrusherArun PrasadhNo ratings yet

- Calc - Vibrating Screen Single Deck NPK1Document5 pagesCalc - Vibrating Screen Single Deck NPK1Waris La Joi WakatobiNo ratings yet

- Science: Quarter 3 - Module 5: Biodiversity and EvolutionDocument20 pagesScience: Quarter 3 - Module 5: Biodiversity and EvolutionMc Chimochi100% (3)

- ModuDense ManualDocument43 pagesModuDense ManualWilkin Llanca BlasNo ratings yet

- Impact CrusherDocument8 pagesImpact CrusherSharath MenonNo ratings yet

- Belt Feeder Calc. Pns Line 1Document4 pagesBelt Feeder Calc. Pns Line 1Waris La Joi Wakatobi67% (3)

- Experiment 02 Reduction Ratio of Jaw CrusherDocument9 pagesExperiment 02 Reduction Ratio of Jaw CrusherBial50% (2)

- Deepak Project On Jaw CrusherDocument95 pagesDeepak Project On Jaw Crusher9777907190100% (7)

- Chain Breaking Load CalculationDocument1 pageChain Breaking Load CalculationDebkumar958No ratings yet

- MSc Mechanical Engineering Final Year Project on Crusher Feeder System DesignDocument97 pagesMSc Mechanical Engineering Final Year Project on Crusher Feeder System DesignYidenek NgussieNo ratings yet

- Selection of Coil Spring for Vibrating ScreenDocument13 pagesSelection of Coil Spring for Vibrating Screen666667No ratings yet

- Efficient Trommel Screen for Sieving MaterialsDocument2 pagesEfficient Trommel Screen for Sieving MaterialsÁlvaro BarbosaNo ratings yet

- Double Roll CrusherDocument9 pagesDouble Roll CrusherVăn Quang Ngô100% (2)

- Jaw Crusher Kinematics Simulation and AnalysisDocument5 pagesJaw Crusher Kinematics Simulation and AnalysisInternational Journal of Research in Engineering and ScienceNo ratings yet

- Calculation of Key Parameters Roller of The CrusherDocument3 pagesCalculation of Key Parameters Roller of The CrusherAnonymous DQ4wYUm100% (2)

- Conveyor Chain Design GuideDocument64 pagesConveyor Chain Design GuideAtacomaNo ratings yet

- A New Trommel Model PDFDocument22 pagesA New Trommel Model PDFÁlvaro BarbosaNo ratings yet

- Grinding Fundamentals and Theory: Size Reduction, Principles, Methods, and Circuit DesignDocument32 pagesGrinding Fundamentals and Theory: Size Reduction, Principles, Methods, and Circuit DesignVarun InamdarNo ratings yet

- Industrial Screening: Rajan Kumar MISHRA (2019UGMM005) Anshuman Mishra (2019ugmm037) KOTALLA VINAY (2019UGMM089)Document26 pagesIndustrial Screening: Rajan Kumar MISHRA (2019UGMM005) Anshuman Mishra (2019ugmm037) KOTALLA VINAY (2019UGMM089)Anshuman MishraNo ratings yet

- Cyclone DesignDocument11 pagesCyclone DesignAnonymous NxpnI6jCNo ratings yet

- Protection Works For Bridges: SR Prof. Projects IricenDocument134 pagesProtection Works For Bridges: SR Prof. Projects IricenshujaNo ratings yet

- Air Classifier ArticleDocument16 pagesAir Classifier ArticleHemanth KumarNo ratings yet

- IGCSE Environmental Management Chapter 1 NotesDocument26 pagesIGCSE Environmental Management Chapter 1 NotesNiharika81% (21)

- Slurry TB M TunnellingDocument32 pagesSlurry TB M Tunnellinglee_kchan4371100% (1)

- CHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORDocument2 pagesCHAIN PULL AND POWER CALCULATION FOR HORIZONTAL AND INCLINED CONVEYORdeddy ariyanto100% (1)

- Cyclone Design Calculation Tool SimplifiedDocument6 pagesCyclone Design Calculation Tool SimplifiedKevin WilliamNo ratings yet

- Single RollDocument8 pagesSingle RolltashdashNo ratings yet

- Enexco BrochureDocument35 pagesEnexco BrochureErin CraigNo ratings yet

- Plant Eng Part 2 - ConveyorsDocument30 pagesPlant Eng Part 2 - ConveyorsLehlohonoloNo ratings yet

- A Double Roll Crusher AppliedDocument7 pagesA Double Roll Crusher AppliedAnonymous bmFsuvNo ratings yet

- How To Design Roll Crusher PDFDocument64 pagesHow To Design Roll Crusher PDFrizka nur faila50% (4)

- PULSE JET BAG FILTER DESIGNDocument3 pagesPULSE JET BAG FILTER DESIGNNITIN P SHAHNo ratings yet

- Everything You Need to Know About Roll CrushersDocument19 pagesEverything You Need to Know About Roll Crushersnkar037100% (2)

- Screw Conveyor ManualDocument14 pagesScrew Conveyor ManualDavid100% (1)

- Rotary DryerDocument12 pagesRotary DryerImam Baliqin100% (1)

- Muller Mixer Machine - Specifications and Description - SuryaDocument2 pagesMuller Mixer Machine - Specifications and Description - Suryakeshab_machineries100% (1)

- Six Ko Ko Kyi RulesDocument3 pagesSix Ko Ko Kyi Rulesnando100% (2)

- Double Roll CrusherDocument3 pagesDouble Roll CrusherjtpmlNo ratings yet

- Diameter of Roll CrusherDocument1 pageDiameter of Roll Crusherharishkumar.ravichandran0% (1)

- STD Line: Product DescriptionDocument16 pagesSTD Line: Product DescriptionrpmNo ratings yet

- 8531Document3 pages8531Srinivas VenkateshNo ratings yet

- Kinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583Document19 pagesKinds of Conveyor Belts Pipe Conveyor Belt Conveyo 5ad270867f8b9acc4a8b4583nicolasNo ratings yet

- Roll CrusherDocument7 pagesRoll CrusherSudarshan Devarapalli100% (1)

- Kakanj AirDocument95 pagesKakanj AirAnonymous snYQBSUNdyNo ratings yet

- Neraca Massa dan Energi Ball Mill dan SeparatorDocument10 pagesNeraca Massa dan Energi Ball Mill dan SeparatorLuthfanNo ratings yet

- Textile and Engineering InstituteDocument29 pagesTextile and Engineering InstituteNegoita GeorgianNo ratings yet

- Smooth Double Roll CrusherDocument4 pagesSmooth Double Roll CrusheradehriyaNo ratings yet

- Lec-14,15 Jaw Crusher, Roll Crusher, Ball Mill (Mod)Document20 pagesLec-14,15 Jaw Crusher, Roll Crusher, Ball Mill (Mod)prakhar mishraNo ratings yet

- Catb 1001 eDocument4 pagesCatb 1001 estankoubNo ratings yet

- 0086-21-58300272Website: www.sbmchina.comDocument6 pages0086-21-58300272Website: www.sbmchina.comrabiemNo ratings yet

- Single Roll CrushersDocument8 pagesSingle Roll CrushersRinaldi SaputraNo ratings yet

- Roll Crusher BrochureDocument4 pagesRoll Crusher BrochureWaris La Joi Wakatobi100% (1)

- Laboratory Exercise 2 Minerals S18Document15 pagesLaboratory Exercise 2 Minerals S18Jason Wolfe100% (1)

- Mt. Hibok HibokDocument5 pagesMt. Hibok HibokJoanna Marie IINo ratings yet

- Science 11 EARTH AND LIFE SCIENCE Geologic and Time ScaleDocument27 pagesScience 11 EARTH AND LIFE SCIENCE Geologic and Time ScalePrettygin NaparanNo ratings yet

- Concretion Morphology, Classification and GenesisDocument34 pagesConcretion Morphology, Classification and GenesisJohan NikoNo ratings yet

- River Ridge Gateway Master PlanDocument15 pagesRiver Ridge Gateway Master PlanCharlieWhiteNo ratings yet

- 2baker Hughes File 2Document9 pages2baker Hughes File 2Julián Camacho-GómezNo ratings yet

- Earth-and-Life-Science-Q1-Week 4Document18 pagesEarth-and-Life-Science-Q1-Week 4MA. HAZEL TEOLOGONo ratings yet

- Logiq Compensated Spectral Natural Gamma Ray (CSNG™) ToolDocument2 pagesLogiq Compensated Spectral Natural Gamma Ray (CSNG™) ToolChesy MeifaniNo ratings yet

- Technical specifications and highway engineering questionsDocument20 pagesTechnical specifications and highway engineering questionsPetForest Ni JohannNo ratings yet

- SPE 154083 Coupling of Stress Dependent Relative Permeability and Reservoir SimulationDocument12 pagesSPE 154083 Coupling of Stress Dependent Relative Permeability and Reservoir SimulationAlex RicaurteNo ratings yet

- Manual PDFDocument233 pagesManual PDFaltaf_h5No ratings yet

- Application Letter Marlin Tarigan SchlumbergerDocument9 pagesApplication Letter Marlin Tarigan SchlumbergermarlinboimNo ratings yet

- Identification Tables For Common Minerals in Thin Section PDFDocument4 pagesIdentification Tables For Common Minerals in Thin Section PDFLuzNo ratings yet

- Most Interesting Landmarks and Attractions in American SamoaDocument3 pagesMost Interesting Landmarks and Attractions in American SamoaGatis PavilsNo ratings yet

- Managem Tizert MRS Memo 3CM036 005 SBB GC VP 20180212Document13 pagesManagem Tizert MRS Memo 3CM036 005 SBB GC VP 20180212Farouk AzzouhriNo ratings yet

- Center AlignmentDocument5 pagesCenter Alignmentzyrrel perey hoNo ratings yet

- Chapter 2 EarthquakeDocument45 pagesChapter 2 Earthquakecatherine bayaniNo ratings yet

- Divergent Boundaries: Illustration of The Main Types of Plate BoundariesDocument9 pagesDivergent Boundaries: Illustration of The Main Types of Plate BoundariesJhen BonNo ratings yet

- Mantle Petrology and Mineralogy of The Thetford Mines Ophiolite ComplexDocument40 pagesMantle Petrology and Mineralogy of The Thetford Mines Ophiolite ComplexAna Lucia Cardenas CubasNo ratings yet

- GFHGHGDocument24 pagesGFHGHGTefo SethNo ratings yet

- Kami Export - Leilani Lozano-Hooper - Rock Cycle LabDocument2 pagesKami Export - Leilani Lozano-Hooper - Rock Cycle LabLeilani HooperNo ratings yet