Professional Documents

Culture Documents

Vikram Udyogpuri Limited, Ujjain, Madhya Pradesh SPML - Om Metals (JV)

Uploaded by

arif_rubinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vikram Udyogpuri Limited, Ujjain, Madhya Pradesh SPML - Om Metals (JV)

Uploaded by

arif_rubinCopyright:

Available Formats

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

10.0)

10.1)

SPML - OM METALS (JV)

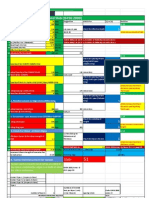

DESIGN OF Precast Concrete Plank as BEAM supported on column

The 60 mm thick precast Plank will be inserted in the 80mm wide spout in the column.

The column will be solid rectangular till ground level. The column above ground level will have 70mm thick x 50 mm deep groove for the Precast plank insert.

The bottom plank will be resting on the column having bearing of 50 mm on either side of column.

Total Number of Planks will be 7 of 300 mm depth.

Bottom Plank will act as simply supported beam resting on column and other 6 planks will be resting on bottom plank.

Bottom Plank is designed as simply supported beam and same design will be applied to all planks.

2.3

Effective span of Plank =

2.30

- 0.05

2.250 m

Design of Bottom Plank supporting other Planks above

Plank Thickness =

60 mm

Plank Depth =

300 mm

Plank Length =

2290 mm

=

=

3.150 kN/m

1.993 kNm

2.990 kNm

3.544 kN

5.320 kN

Uniform Load over Bottom Plank =

Maximum BM @ Midspan =

0.060

3.150

x 2.10

x 2.25 ^2

Ultimate Moment Mu =

1.50

x 1.993

Maximum Shear Force @ Support =

3.15

x 2.25

Ultimate Shear Force Vu =

1.50

x 3.544

Sanguine Infra Tech Pvt.Ltd., Mumbai

x 25

/8

/2

Page | 25

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

SPML - OM METALS (JV)

Design of Individual Plank for its self weight while lifting

Also each Panel shall be designed for its self weight while lifting at both end.

Uniform Load of one Plank due to self weight

Maximum BM @ Midspan =

0.060

0.450

x 0.30

x 2.29 ^2

Ultimate Moment Mu =

1.50

x 0.295

Maximum Shear Force @ Support =

0.45

x 2.29

Ultimate Shear Force Vu =

1.50

x 0.515

10.2) Design of Precast Plank : Grade of concrete

Grade of steel

Load Factor

A. Design of section for flexural

Section Moment

=

=

=

clear

(kN-m)

Force

(kN) (mm)

Bottom Plank

Midspan

Individual Plank

/2

Mbal.

Ast req.

0.442 kNm

0.515 kN

0.773 kN

Astmin Provide Reinforcement Ast

0.133fckbd (for flex.) 0.85/fy

2)

2)

(kN-m)

(mm

(mm

11.72

26

31

(mm)

271

26

30

0.72

38

clear

Shear

Ast prov.

(mm)

cover

(mm)

(mm)

stress

v (N/mm2)

dia

(mm)

60

300

25

271

0.327

Y8

0.77

300

60

26

30

0.086

Y8

Sanguine Infra Tech Pvt.Ltd., Mumbai

0.450 kN/m

0.295 kNm

5.32

Midspan

=

=

20 Mpa

500 Mpa

1.5 For Normal condition

cover

(mm)

25

(mm)

(mm)

Bottom Plank 2.99

60

300

Midspan

Individual Plank 0.44

300

60

Midspan

B. Design of section for Shear

Section Shear

x 25

/8

31

dia

(mm)

Y8

Y8

Nos.

Remark. Pt %

1 Nos.

Prov.

2)

(mm

50

Safe

0.309

1 Nos.

50

Safe

0.559

Pt %

Shear

Remark. Asv minAsv/sv

Provide

Rem

capacity of

ark.

provided concrete

0.4b reqd

stirrups of Asv/sv

provid

c (N/mm2)

0.87fy (v-c)*b

ed

IS456, T-19

fs

2

mm /mm

Provide

1 Nos.

0.309

0.393

0.07

0.00 1 Leg Y 8 0.25 Safe

Min Shear

Reinf

@ 200 c/c

Shear

1 Nos.

0.559

0.225

Reinf Not

Required

Page | 26

VIKRAM UDYOGPURI LIMITED, UJJAIN, MADHYA PRADESH

SPML - OM METALS (JV)

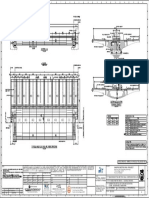

10.3) Check for Bearing strength on concrete column bearing area due to reaction from planks:

Reaction at one end of column

Bearing Area =

1.5 x 2.99 x 2.29 / 2

45

x 60

Bearing Stress on column

5140

/ 2700

Permissible bearing strength on concrete 0.45 fck =

Sanguine Infra Tech Pvt.Ltd., Mumbai

=

=

=

5.14 kN

2

2700 mm

1.90 N/mm

9.00 Mpa

Safe

(Ref IS 456:2000, Cl 34.4)

Page | 27

You might also like

- Day 10 - Wind AnalysisDocument18 pagesDay 10 - Wind AnalysisMaitrayee AdityaNo ratings yet

- Retaining Wall Stability CheckDocument4 pagesRetaining Wall Stability CheckMayurSoniNo ratings yet

- Superstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Document14 pagesSuperstructure Sketch: Fig. Superstructure Dimensions (All Dimensions Are in MM)Himal KafleNo ratings yet

- Solid RC Slab BridgeDocument18 pagesSolid RC Slab BridgeEngineeri TadiyosNo ratings yet

- Footing BiaxialDocument22 pagesFooting Biaxialvimal patelNo ratings yet

- RC Pilecap Design (Beam Method)Document27 pagesRC Pilecap Design (Beam Method)Thaung Myint OoNo ratings yet

- Asmita SchoolDocument19 pagesAsmita Schoolformwork companyNo ratings yet

- Racking Analysis of Underground Structures: Date: Note No. By: Sheet NoDocument4 pagesRacking Analysis of Underground Structures: Date: Note No. By: Sheet NoStructural SpreadsheetsNo ratings yet

- Sump .XLS (2.00 Lakhs)Document35 pagesSump .XLS (2.00 Lakhs)subramanyam kumarNo ratings yet

- DG - Slab Design SDocument7 pagesDG - Slab Design Ssaaz adil100% (1)

- 13920-COLUMN DESIGN ExcelDocument7 pages13920-COLUMN DESIGN Excelyedida viswanadhNo ratings yet

- ZPurlinR1 OdsDocument21 pagesZPurlinR1 OdsRamachandra SahuNo ratings yet

- Load Calculation: Static Water PressureDocument18 pagesLoad Calculation: Static Water PressureSheikh Mizanur RahmanNo ratings yet

- Box Culvert Section: 4 Input Data 4.1 Geometry of The SectionDocument7 pagesBox Culvert Section: 4 Input Data 4.1 Geometry of The SectionmidhunvarNo ratings yet

- Analysis and Design of Pier CapDocument5 pagesAnalysis and Design of Pier CapRoshan KejariwalNo ratings yet

- RCC 5.0c.f Re WallDocument29 pagesRCC 5.0c.f Re WallArun Rawat0% (1)

- Dynamic Calculation For Retaining WallDocument6 pagesDynamic Calculation For Retaining WallSabrina ImloulNo ratings yet

- BC BBS - PRECAST - ApprovedDocument3 pagesBC BBS - PRECAST - ApprovedHegdeVenugopalNo ratings yet

- Reinforced Concrete Retaining Wall Design To BS 8110Document10 pagesReinforced Concrete Retaining Wall Design To BS 8110thabisoNo ratings yet

- Piled Raft Foundations For Tall BuildingsDocument8 pagesPiled Raft Foundations For Tall Buildingsrenzo1221No ratings yet

- Cantilever 1111Document36 pagesCantilever 1111Gaurav GhaiNo ratings yet

- Footings Design ProcedureDocument19 pagesFootings Design ProcedureJanakiram GoudNo ratings yet

- Design of Abutment BridgeDocument51 pagesDesign of Abutment BridgeUmar Keren100% (1)

- Design of Shear Wall: Reference DataDocument8 pagesDesign of Shear Wall: Reference DataKiranNo ratings yet

- Deep Beam CheckDocument10 pagesDeep Beam CheckNikhil AgrawalNo ratings yet

- Beam DesignDocument18 pagesBeam DesignBuddhiraj kadelNo ratings yet

- Solid Slab - 10m.Document8 pagesSolid Slab - 10m.Aditya JoshiNo ratings yet

- Design Retaining WallDocument15 pagesDesign Retaining WallAnindit MajumderNo ratings yet

- Abutment Wall DesignDocument10 pagesAbutment Wall DesigngertjaniNo ratings yet

- Portal Frames DDocument48 pagesPortal Frames DMukonyora SirMartinNo ratings yet

- A. For Column C: Design of Combined Footing (CF) : 1. Design DataDocument12 pagesA. For Column C: Design of Combined Footing (CF) : 1. Design Datap_ignatiusNo ratings yet

- Footing Design-Conn & Lift CheckDocument3 pagesFooting Design-Conn & Lift Checkarif_rubinNo ratings yet

- Part 3 Abut - Well Foundation DesignDocument46 pagesPart 3 Abut - Well Foundation Designshashi rajhansNo ratings yet

- Retaining WallDocument12 pagesRetaining WallKushwah and Kushwah0% (1)

- Usd Slab Sample CalcDocument12 pagesUsd Slab Sample CalcJaycee Bareng PagadorNo ratings yet

- DMIC Design-Work ShopDocument15 pagesDMIC Design-Work ShopMaitrayee AdityaNo ratings yet

- Cross Section Dimension:: Deck Slab DetailsDocument1 pageCross Section Dimension:: Deck Slab DetailsSuman NakarmiNo ratings yet

- L-TYPE RET WALL (WWW - Theengineeringcommunity.org) - 1Document46 pagesL-TYPE RET WALL (WWW - Theengineeringcommunity.org) - 1rymacNo ratings yet

- Seismic ArrestorDocument8 pagesSeismic ArrestorankitNo ratings yet

- Effective WidhDocument17 pagesEffective WidhHimal KafleNo ratings yet

- MEMBER NAME: S1-One Way: MIDAS Information Technology Co., LTDDocument3 pagesMEMBER NAME: S1-One Way: MIDAS Information Technology Co., LTDAlisa Jane TuboroNo ratings yet

- TW-02 Inverted T-Shape TypeDocument28 pagesTW-02 Inverted T-Shape TypeDanni Arman, STNo ratings yet

- Grade Slab NMRCLDocument62 pagesGrade Slab NMRCLmvssrajuNo ratings yet

- Pier Cap DesignDocument2 pagesPier Cap DesignAnand SoniNo ratings yet

- Soil+Surcharge From Adjacent Building On 20m RCC Pile Ø600mmDocument10 pagesSoil+Surcharge From Adjacent Building On 20m RCC Pile Ø600mmPrakash Singh RawalNo ratings yet

- Design of Raft SlabDocument6 pagesDesign of Raft SlabVenkatesha HebbarNo ratings yet

- Design of Two-Way Restrained Slab (IS456:2000)Document3 pagesDesign of Two-Way Restrained Slab (IS456:2000)BasandharaAdhikariNo ratings yet

- Ultimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Document5 pagesUltimate Moment Capacity of Reinforced Concrete Section To EN 1992-2 - Clause 6.1Randhir BharatNo ratings yet

- Computation For Modulous of Subgrade Reaction: 'File:///conversion/tmp/activity - Task - Scratch/606111979.xls'#$introDocument12 pagesComputation For Modulous of Subgrade Reaction: 'File:///conversion/tmp/activity - Task - Scratch/606111979.xls'#$introStructural SpreadsheetsNo ratings yet

- Analysis of Fatigue Life Consumed For Single Axle LoadDocument4 pagesAnalysis of Fatigue Life Consumed For Single Axle LoadvishwasNo ratings yet

- Beam Section Property ChangesDocument33 pagesBeam Section Property Changespratap jadhavNo ratings yet

- 8 No. 25 MM Diameter Longitudinal Bars Max Link Spacing 400 MM Generally, 240 MM For 500 MM Above and Below Slab/beam and at LapsDocument7 pages8 No. 25 MM Diameter Longitudinal Bars Max Link Spacing 400 MM Generally, 240 MM For 500 MM Above and Below Slab/beam and at LapsYHK3001100% (1)

- Design of S R Flanged Beam: Bending Only. (Limit State Method)Document3 pagesDesign of S R Flanged Beam: Bending Only. (Limit State Method)sayali surveNo ratings yet

- Design of Wall For Water Tank Both Side WaterDocument19 pagesDesign of Wall For Water Tank Both Side Waterrushicivil1No ratings yet

- 9 Design of Bed Block Under ABUTMENTDocument2 pages9 Design of Bed Block Under ABUTMENTBalaji Rao Ch100% (1)

- Chapter 4, Design of Slab RevisedDocument30 pagesChapter 4, Design of Slab Revisedzeru3261172No ratings yet

- Combined Footing DesignDocument4 pagesCombined Footing Designrukesh104No ratings yet

- UTHMDocument8 pagesUTHMJoena LindaNo ratings yet

- MBC - NAVEEN - RETURNWALL - 004 - 01102021-Concrete ProfileDocument1 pageMBC - NAVEEN - RETURNWALL - 004 - 01102021-Concrete Profilearif_rubinNo ratings yet

- DBR VupDocument15 pagesDBR Vuparif_rubinNo ratings yet

- PileLatLoadCap1500 10mDocument7 pagesPileLatLoadCap1500 10marif_rubinNo ratings yet

- Vup 002 R0Document1 pageVup 002 R0arif_rubinNo ratings yet

- Technical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424Document9 pagesTechnical Data Sheet For The HSA Stud Anchor Technical Information ASSET DOC 2027424SupervitalikNo ratings yet

- Vup 001 R0Document1 pageVup 001 R0arif_rubinNo ratings yet

- Costing - 2021-2022 - 28.072023Document804 pagesCosting - 2021-2022 - 28.072023arif_rubinNo ratings yet

- Composite CheckDocument1 pageComposite Checkarif_rubinNo ratings yet

- Schedule of Bearing Load (31M Span & R 420M)Document1 pageSchedule of Bearing Load (31M Span & R 420M)arif_rubinNo ratings yet

- Initial Load Test ReportDocument8 pagesInitial Load Test Reportarif_rubinNo ratings yet

- AASHTO Hook DetailDocument1 pageAASHTO Hook Detailarif_rubinNo ratings yet

- Yfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument2 pagesYfc Project PVT Ltd. DMRC: JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubinNo ratings yet

- Spine Girder QtyDocument1 pageSpine Girder Qtyarif_rubinNo ratings yet

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- JV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDDocument540 pagesJV of Shirish Patel & Associates Consultants PVT Limited & Indus Consultrans PVT LTDarif_rubin100% (1)

- Design of 4L 31.25m SpanDocument1 pageDesign of 4L 31.25m Spanarif_rubinNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- Appendix BDocument95 pagesAppendix Barif_rubinNo ratings yet

- 31.25m 4L Concrete Dime DRG - 1Document1 page31.25m 4L Concrete Dime DRG - 1arif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- 4L BOx Girder Concrete Dimension DRGDocument1 page4L BOx Girder Concrete Dimension DRGarif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- Nagpur Metro Rail Project: Systra-Aecom-Egis-RitesDocument1 pageNagpur Metro Rail Project: Systra-Aecom-Egis-Ritesarif_rubinNo ratings yet

- Appendix EDocument51 pagesAppendix Earif_rubinNo ratings yet

- Appendix CDocument18 pagesAppendix Carif_rubinNo ratings yet

- Ground Water Table Value As Per CGWB Data: (Refer Appendix A)Document1 pageGround Water Table Value As Per CGWB Data: (Refer Appendix A)arif_rubinNo ratings yet

- Appendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2Document2 pagesAppendix A: Dead Load & Sidl Load Calculation: SPAN-1 SPAN-2arif_rubin50% (2)

- Appendix DDocument63 pagesAppendix Darif_rubinNo ratings yet

- Appendix BDocument95 pagesAppendix Barif_rubinNo ratings yet

- Wifpl Qap 2019-20-058 Rev 00 Konecranes 18crnimo7 6 SignedDocument2 pagesWifpl Qap 2019-20-058 Rev 00 Konecranes 18crnimo7 6 SignedDeepak HoleNo ratings yet

- HC-33 Maximum Moisture Hair Styling Gel PDFDocument2 pagesHC-33 Maximum Moisture Hair Styling Gel PDFdianaNo ratings yet

- Construction of Genomic and cDNA Libraries-AmitDocument10 pagesConstruction of Genomic and cDNA Libraries-AmitPrashant BajpaiNo ratings yet

- Synergic Antiobesity Effects of Bitter Melon Water Extract and Platycodin-D in Genetically Obese MiceDocument9 pagesSynergic Antiobesity Effects of Bitter Melon Water Extract and Platycodin-D in Genetically Obese Micegege wpNo ratings yet

- Forensic Toxicology: A. Classify Toxins and Their Effects On The BodyDocument28 pagesForensic Toxicology: A. Classify Toxins and Their Effects On The BodySajid RehmanNo ratings yet

- CSEB Korba THERMAL POWER PLANT Mechanical Training ReportDocument20 pagesCSEB Korba THERMAL POWER PLANT Mechanical Training Reporthaxxo24No ratings yet

- 2015 English Grade 7Document16 pages2015 English Grade 7AyushNo ratings yet

- E4 - Review Unit 11 To Unit 20Document16 pagesE4 - Review Unit 11 To Unit 20Tuyen NgoNo ratings yet

- WhatsApp Chat With Chinnu HeartDocument30 pagesWhatsApp Chat With Chinnu HeartSäi DäťťaNo ratings yet

- The Safe Motherhood InitiativeDocument3 pagesThe Safe Motherhood InitiativeAnonymous g6L7jJWNo ratings yet

- CFM56 3Document148 pagesCFM56 3manmohan100% (1)

- Carjackked TrainingDocument7 pagesCarjackked TrainingErios 50No ratings yet

- I. Leadership/ Potential and Accomplishments Criteria A. InnovationsDocument5 pagesI. Leadership/ Potential and Accomplishments Criteria A. InnovationsDEXTER LLOYD CATIAG100% (1)

- Chapter1-The Clinical LabDocument24 pagesChapter1-The Clinical LabNawra AhmadNo ratings yet

- 2023-24 SR - Super60 (Incoming) STERLING Batch CHEMISTRY Teaching & Test Schedule Code@03!04!2023Document16 pages2023-24 SR - Super60 (Incoming) STERLING Batch CHEMISTRY Teaching & Test Schedule Code@03!04!2023K R I S H100% (1)

- Motor DeiselShip Latest PDFDocument154 pagesMotor DeiselShip Latest PDFCadet Prateek SaxenaNo ratings yet

- Chapter 4Document6 pagesChapter 4Aung MyatNo ratings yet

- Soil Mechanics Lecture 1Document86 pagesSoil Mechanics Lecture 1Ammar Ayub100% (2)

- Patrick Califia Speaking Sex To Power Perverts Freethinkers and The Politics of Sex The Politics of Pleasure and PerversityDocument443 pagesPatrick Califia Speaking Sex To Power Perverts Freethinkers and The Politics of Sex The Politics of Pleasure and PerversityStefanos PopofNo ratings yet

- Uas Semt Genap Fix BING XIDocument12 pagesUas Semt Genap Fix BING XISaepulloh KurniaNo ratings yet

- Full Download Test Bank For Nursing A Concept Based Approach To Learning Volume II 3rd Edition 3rd Edition PDF Full ChapterDocument36 pagesFull Download Test Bank For Nursing A Concept Based Approach To Learning Volume II 3rd Edition 3rd Edition PDF Full Chaptersignor.truss.j26uk100% (17)

- Manoshe Street Takeaway MenuDocument9 pagesManoshe Street Takeaway MenuimaddakrNo ratings yet

- Bergey's Manual of Systematic Bacteriology and Determinative BacteriologyDocument2 pagesBergey's Manual of Systematic Bacteriology and Determinative BacteriologyGeetha Anjali0% (1)

- Arecanut DiseasesDocument22 pagesArecanut Diseases314 Bhagyalakshmi SNo ratings yet

- LOKRING Technical Documentation Submittal Brass enDocument32 pagesLOKRING Technical Documentation Submittal Brass enYamilelcNo ratings yet

- 4th Laboratory Activity Gallus DomesticusDocument4 pages4th Laboratory Activity Gallus DomesticusZia Ammarah SaripNo ratings yet

- AppendicitisDocument14 pagesAppendicitispreethijojo2003558288% (8)

- 2007 AP Statistics Multiple Choice ExamDocument17 pages2007 AP Statistics Multiple Choice ExamJalaj SoodNo ratings yet

- Cessna 206 Chapter 24 Illustrated Parts CatalogueDocument33 pagesCessna 206 Chapter 24 Illustrated Parts Cataloguekanwar100% (1)