Professional Documents

Culture Documents

Generalni CNC Kodovi

Uploaded by

Leo MilosevOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Generalni CNC Kodovi

Uploaded by

Leo MilosevCopyright:

Available Formats

G & M Codes

G&M Codes make up the most of the contents of the CNC program. The definition of each class of code and specific meanings of

the most important codes are covered next.

G-Codes

Codes that begin with G are called preparatory words because they prepare the machine for a certain type of motion. The most

common G-codes are shown in Table 5.3 and a complete list and their meaning is included in Appx D - G-M Codes Reference.

Note: Older controls required G-codes to be written with a leading zero, like G01. Most machines now

allow the leading zero to be omitted, as shown in the table below.

Table 5.3: Common G-Codes

Code

Meaning

G0

Rapid motion. Used to position the machine for non-milling moves.

G1

Line motion at a specified feed rate.

G2

Clockwise arc.

G3

Counterclockwise arc.

G4

Dwell.

G28

Return to machine home position.

G40

Cutter Diameter Compensation (CDC) off.

G41

Cutter Diameter Compensation (CDC) left.

G42

Cutter Diameter Compensation (CDC) right.

G43

Tool length offset (TLO).

G54

Fixture Offset #1.

G55

Fixture Offset #2.

G56

Fixture Offset #3.

G57

Fixture Offset #4.

G58

Fixture Offset #5.

G59

Fixture Offset #6.

G80

Cancel drill cycle.

G81

Simple drill cycle.

G82

Simple drill cycle with dwell.

G83

Peck drill cycle.

G84

Tap cycle.

G90

Absolute coordinate programming mode.

G91

Incremental coordinate programming mode.

G98

Drill cycle return to Initial point (R).

G99

Drill cycle return to Reference plane (last Z Height)

M-Codes

Codes that begin with M are called miscellaneous words. They control machine auxiliary options like coolant and spindle

direction. Only one M-code can appear in each block of code.

The table below lists the most common M codes and their meaning. A complete list of M-codes is included in Appx D - G-M Codes

Reference.

Table 5.4: Common M-Codes

Code

Meaning

M0

Program stop. Press Cycle Start button to continue.

M1

Optional stop. Only executed if Op Stop switch on the CNC control is turned ON.

M2

End of program.

M3

Spindle on Clockwise.

M4

Spindle on Counterclockwise.

M5

Spindle stop.

M6

Change tool.

M8

Coolant on.

M9

Coolant off.

M30

End program and press Cycle Start to run it again.

You might also like

- Software Bulletin Index: Proprietary InformationDocument20 pagesSoftware Bulletin Index: Proprietary InformationRaul TorresNo ratings yet

- Mach4 G and M Code Reference ManualDocument60 pagesMach4 G and M Code Reference ManualRAKESH PRAJAPATI100% (1)

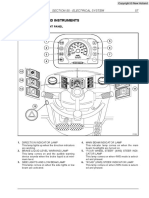

- Equipement Électrique: Instrument Panel InstrumentsDocument73 pagesEquipement Électrique: Instrument Panel InstrumentsAtti PozsonyNo ratings yet

- Audi Q7 A005Q720020-Basic Equipment From Model Year 2007Document1,302 pagesAudi Q7 A005Q720020-Basic Equipment From Model Year 2007Fábio MagnoNo ratings yet

- 2 PDFDocument46 pages2 PDFNenad VlašičekNo ratings yet

- CNC Programming 1Document26 pagesCNC Programming 1mohamed alsalhyNo ratings yet

- G and M Codes For CNC LatheDocument8 pagesG and M Codes For CNC LatheLuis Gonzalo Castañeda GalindoNo ratings yet

- NOx Conversion Is LowDocument13 pagesNOx Conversion Is LowNir PeledNo ratings yet

- TLT35D Section D - CONTROLSDocument34 pagesTLT35D Section D - CONTROLSIgor Ferreira dos SantosNo ratings yet

- SRX ManualDocument20 pagesSRX ManualLucas50% (2)

- ErrorDocument16 pagesErrorيوسف وليد عبد الرحيمNo ratings yet

- 2014 Volkswagen Touareg 88298Document620 pages2014 Volkswagen Touareg 88298Zoltan MarosanNo ratings yet

- RM80 ManualDocument589 pagesRM80 ManualAndrej KapustjonokNo ratings yet

- LNC-Maintenance Manual - CompressedDocument129 pagesLNC-Maintenance Manual - CompressedDANG HOANGNo ratings yet

- KU01 KYO8M v2.4 User Manual enDocument52 pagesKU01 KYO8M v2.4 User Manual enDamir MerdanNo ratings yet

- Instruction Manual: Hako-Trac 1950 DA (8084)Document62 pagesInstruction Manual: Hako-Trac 1950 DA (8084)Aleksandra HreščakNo ratings yet

- Error Codes XMDocument14 pagesError Codes XMnilomell100% (1)

- Case CX ProspektDocument8 pagesCase CX Prospektvejnik070% (1)

- DEF OverhaulDocument26 pagesDEF Overhaulmonk_747246557100% (1)

- Midi Excavators: Product RangeDocument20 pagesMidi Excavators: Product RangeluismdmjNo ratings yet

- Audi A8 No. 802 / 1: FusesDocument42 pagesAudi A8 No. 802 / 1: FusesToks VilmantasNo ratings yet

- TL35 70Document1 pageTL35 70Jan HendriksNo ratings yet

- New Holland T7: I I I I I I I IDocument28 pagesNew Holland T7: I I I I I I I Irenato anklinNo ratings yet

- Iveco Daily 65c15 enDocument12 pagesIveco Daily 65c15 enMary Gligor100% (1)

- Inf12215 GBDocument4 pagesInf12215 GBqyzzypNo ratings yet

- N45ENT 104kW E PDFDocument3 pagesN45ENT 104kW E PDFSecret64No ratings yet

- Rattling Noise After Engine Start For Several Seconds: Complaint: AttachmentsDocument2 pagesRattling Noise After Engine Start For Several Seconds: Complaint: AttachmentsWILFRED TSI-KAHNo ratings yet

- ServiceManuals/LG/GPS/LN500/LN500 Service ManualDocument31 pagesServiceManuals/LG/GPS/LN500/LN500 Service ManualYonny MunozNo ratings yet

- OVERALLEWD95Document20 pagesOVERALLEWD95Chayo MartisNo ratings yet

- TENDLLOD0001Document35 pagesTENDLLOD0001Miguel ViegasNo ratings yet

- MARIRAD.01 Remote Control RepairDocument36 pagesMARIRAD.01 Remote Control RepairNicoleta CosteaNo ratings yet

- ACKS010Document5 pagesACKS010kallatisNo ratings yet

- BPW - Service InstructionsDocument4 pagesBPW - Service InstructionsRajaSekarsajjaNo ratings yet

- Instruction Book IQAN-MDM Menu System: Publ - No HY17 8363/UK Edition 0145Document35 pagesInstruction Book IQAN-MDM Menu System: Publ - No HY17 8363/UK Edition 0145jhonatan_silveira_8No ratings yet

- Tpi 2029086 - 1Document9 pagesTpi 2029086 - 1Marius SuvarNo ratings yet

- Euro 3 Euro 3: Chassis 6x6Document4 pagesEuro 3 Euro 3: Chassis 6x6Dwanny VHNo ratings yet

- Manual: Book ID: 4-P14402CU - ENDocument16 pagesManual: Book ID: 4-P14402CU - ENNick ENo ratings yet

- Installation Instructions For Mercedes-Benz EWAnetDocument12 pagesInstallation Instructions For Mercedes-Benz EWAnetKlaudia PołudniakNo ratings yet

- Kenr5125kenr5125-02 SisDocument13 pagesKenr5125kenr5125-02 Sisygor valdezNo ratings yet

- TSX17 User ManualDocument70 pagesTSX17 User ManualMarco Calderon LaymeNo ratings yet

- RD730Document2 pagesRD730sandi saputraNo ratings yet

- Electrolux Gen4000 Service W465-W4330H S N CompassDocument140 pagesElectrolux Gen4000 Service W465-W4330H S N CompassThếSơnNguyễnNo ratings yet

- Operation Manual 1013Document74 pagesOperation Manual 1013nicoss69No ratings yet

- MX-D2T Schematic DiagramsDocument14 pagesMX-D2T Schematic Diagramsjota_60254No ratings yet

- Goes 800rsDocument43 pagesGoes 800rsrhadamanteNo ratings yet

- 167085-1 A Ersatzteilkatalog en-US PDFDocument6 pages167085-1 A Ersatzteilkatalog en-US PDFHadj Ahmed SaoudiNo ratings yet

- W221 Usa S-ClassmercDocument85 pagesW221 Usa S-ClassmercShreyasNo ratings yet

- Lista de Partes SBC410-IIDocument7 pagesLista de Partes SBC410-IIJuan CarlosNo ratings yet

- KSDiag HelpDocument13 pagesKSDiag HelpalcomNo ratings yet

- Book 1Document2 pagesBook 1Tyler GoodwinNo ratings yet

- Gazpromneft Grease L EP: Multipurpose Extreme Pressure Lithium GreaseDocument2 pagesGazpromneft Grease L EP: Multipurpose Extreme Pressure Lithium GreasenghiaNo ratings yet

- Mitsubishi Electric - Service Manual 0B378Document36 pagesMitsubishi Electric - Service Manual 0B378jborg100% (1)

- Drip-Feed in FE Mode TNC 155Document1 pageDrip-Feed in FE Mode TNC 155Amir RamezaniNo ratings yet

- Butee EmbrayageDocument2 pagesButee EmbrayagewoulkanNo ratings yet

- Lenovo Ideapad S10-3C (BM5999)Document42 pagesLenovo Ideapad S10-3C (BM5999)rasrozi51700% (1)

- Controls and Instruments: 3.1 Front Instrument PanelDocument7 pagesControls and Instruments: 3.1 Front Instrument PanelAdamNo ratings yet

- Konstante Maho 600E2Document6 pagesKonstante Maho 600E2Nikolat84No ratings yet

- DS150e Quick Start Guide: Congratulations On The Purchase of Your New Delphi DS150e Diagnostic System!Document2 pagesDS150e Quick Start Guide: Congratulations On The Purchase of Your New Delphi DS150e Diagnostic System!TarisaiNo ratings yet

- EP31 Manual PDFDocument48 pagesEP31 Manual PDFfrank mutaleNo ratings yet

- Standard G and M Codes of CNC ProgrammingDocument2 pagesStandard G and M Codes of CNC ProgrammingRamesh PariharNo ratings yet