Professional Documents

Culture Documents

Tower Scaffold Method Statement

Uploaded by

sajan420Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tower Scaffold Method Statement

Uploaded by

sajan420Copyright:

Available Formats

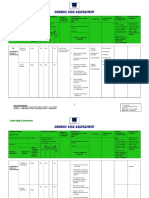

METHOD STATEMENT FOR TOWER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

1. Conduct daily tool box talk before start of work

1.1 Lack of PPE

1.1.1 Inspect,issue and control use of PPE

Scaffolding Supervisor

2. Prepare equipment and scaffold tools

2.2 Incorrect tools and equipment

2.1.1 Provide correct tools and equipment for the job

Scaffolding Supervisor

3. Transport scaffold materials using scaffold division

transportation

3.1 Slip and Tripping hazard

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.1.2 Wear proper PPE especially hand gloves

4. Check the area where the tower scaffold to be install

3.2 Un-safe loading and handling

3.2.1 Correct manual handling techniques

4.1 Unwanted objects,un even ground condition

4.1.1 Clear the area and compact the ground before work start

Scaffolding Supervisor

4.1.2 Barricade the working area with signage

5. The scaffold will be erected by minimum of 2 operatives

and will be erected in accordance with BS-EN 12811-1.

5.1 Not following the correct standards

5.1.1 Follow the BS-EN-12811-1 procedure

Scaffolding Supervisor

5.1.2 Proper PPE,Scaffold belts,tools

6. Sole board and base plate will be placed on the even and

stable ground surfaces at a distance appropriate to the

standards center for the weight capacity of the scaffold.

6.1 Not using sole board/base plate

Un even ground,scaffold may sink

6.1.1 Re-compact the ground

Scaffolding Supervisor

6.1.2 Proper PPE,Scaffold Belts,tools

6.1.3 Barricade the working area with signage

7. The first pair of the standards will then be place on to the

sole boards and base plate and double couplers fitted at lift height.

7.1 wrong coupler use,standard may fall

Hand Injury,Slip/Trips

7.1.1 Double coupler must be use,provide rakers

Scaffolding Supervisor

7.1.2 Proper PPE,Scaffold belts,tools

7.1.3 Barricade the working area with warning signs

8. The first ledger will then be fitted in to the double couplers

and levelled,joining the pair of the standards together to

form a set of goal posts.A set of temporary rakers may then

be used to hold the goal post level and safe against the building

9. An outside standard will then be placed onto a base board

and plate and a transom fixed into place and levelled.

8.1 Wrong scaffold erection sequence

8.1.1 Follow the correct sequence of erection as per

BS-EN 12811-1

8.2 Hand Injury

8.2.1 Wear proper PPE,Scaffold Belts,Tools

8.3 Slip and Tripping hazards

8.3.1 Barricade the working area with warning signs

9.1 Hand Injury/Slips,Trips on the same level

9.1.1 Wear proper PPE,especially hand gloves

9.2 Slip and Tripping hazards

9.2.1 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

Scaffolding Supervisor

METHOD STATEMENT FOR TOWER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

10. A second ledger tube will then be fixed to the outside set of

standards using double couplers.

POTENTIAL HAZARDS

HAZARD CONTROLS

10.1 Hand Injury,Slip/Trips

10.1.1 Wear proper PPE,especially hand gloves

RESPONSIBLE PERSON

Scaffolding Supervisor

10.1.2 Barricade the working area with warning signs

11. Braces will be attached to each end of the structure and

checks made to ensure the structure is plumb and level.

11.1 Hand Injury,Pinch point,Slip,Trips

11.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

11.1.2 Barricade the working area with warning signs

12. Transoms will then be fixed along the top of the ledgers

ensuring that the end transoms are in place to support the

ends of scaffolding boards.

12.1 Hand Injury/Slip,Trips and Falls

12.1.1 Wear proper PPE especially hand gloves

12.2 End transom not fitted/potential trap end

12.1.2 Approved full body harness and hook-up 100%

Scaffolding Supervisor

12.1.3 Secure the transom using single coupler

13. Scaffolding boards will then be placed on to the transoms to

form a boarded platform from which the scaffold operatives

can work when erecting next lift platform.

13.1 Hand injury

13.1.1 Wear proper PPE especially hand gloves

13.2 Boards not properly tied or secured

13.1.2 Secured all the boards using limpet clamps

14. Scaffolders will then access the boarded lift using a ladder

tied on the structures.

14.1 Slip,Trips and Fall

14.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

Scaffolding Supervisor

14.1.2 Approved full body harness hook-up 100%

14.2 Ladders not tied,not correct angle

14.2.1 Access ladder must lashed to the structure

14.2.2 Ladder must project 75 degree or 4 is to 1 ratio

15. Scaffold materials will then be passed or hoisted to the

boarded platform and then used for the erection of second and

remaining lifts with double handrails with toe boards.

15.1 Falling objects,Falling workers

15.1.1 Use approved gin wheel and rope with fitting bags

Scaffolding Supervisor

15.1.2 Approved full body harness hook-up 100%

15.1.3 Barricade the area with warning signs

15.1.4 Wear proper PPE

16. Ties will be fixed in accordance with BS-EN 12811-1 giving

stability to the scaffold.

16.1 Scaffold un-stable,falling object

16.1.1 Fixed scaffold ties for every 4 meters vertical/horizontal

16.1.2 Barricade the area with warning signs

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR TOWER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

17.(Tower Scaffold)A final inspection will be undertake on completion

of the scaffold to ensure the scaffold structure is in compliance with

the relevant standards and codes of practice.

POTENTIAL HAZARDS

HAZARD CONTROLS

17.1 Scaffold incomplete,Falling worker

Not into specification

17.1.1 Inspector must check the scaffold using F-91 as per

BS-EN-12811-1

RESPONSIBLE PERSON

Scaffolding Supervisor

Scaffolding Inspector

17.1.2 Approved full body harness hook-up 100%

18. All safety warning signs,barriers and surplus materials will

be removed prior to leaving on site (House keeping)

18.1 Pinch point,Slip,Trips and Falls

18.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

18.1.2 Approved full body harness hook-up 100%

18.1.3 Barricade the area with warning signs

19. Scaffold modification

19.1 Slip,Trips and Fall,

19.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

19.1.2 Approved full body harness and hook-up 100%

19.1.3 Competent scaffolder only can modified the scaffold

19.1.4 Barricade the area with warning signs

20. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed or

lowered to the ground in a safe manner and loaded on to the vehicle

ready for removal on site.

20.1 Falling objects/Falling workers

20.1.1 Approved full body harness and hook-up 100 %

20.2 Slip and Tripping hazards

20.2.1 Wear proper PPE especially hand gloves

20.3 Incorrect sequence of dismantling/scaffold

collapse

20.3.1 Followed the BS EN-12811-1 dismantling sequence,

reverse the procedure of erection when dismantling scaffold

only when the scaffold is erected from the ground.

20.4 Materials not properly stack and tied or secured

20.4.1 Scaffold materials must properly stacked and tied

20.5 Transport hazards/hitting live plant or object

20.5.1 Use competent flagman to signal the truck especially when

reversing.

3 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR SUSPENDED SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

2. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

2.1 Hand injury/Finger Trap/Strains

2.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

2.1.2 Barricade the working area with warning signs

3. Transport materials to site using scaffold division

transportation.

3.1 Slips and Tripping hazards

3.1.1 Stack materials in an orderly fashion

3.2 Un-safe loading and handling

3.1.2 Apply the correct manual handling procedure

Scaffolding Supervisor

3.1.3 Barricade the working area with warning signs

4. Check scaffold specification

4.1 Scaffolding not to specification

4.1.1 Return non specific material to stores and in to

quarantine area.

Scaffolding Supervisor

5. Assess the structure/beam supporting a suspended

scaffold.

5.1 Structure/beam not suitable

5.1.1 The structure or beam must be sound and suitable

to support the suspended scaffold.

Scaffolding Supervisor

5.2 Falling worker

5.1.2 Approved full body harness and hook-up 100%

6. Fixed ledger tube in the structure/beam using beam clamp set

as a needle tube.

6.1 Falling worker/material

6.1.1 Approved full body harness and hook-up 100%

Scaffolding Supervisor

6.1.2 Barricade the working area with warning signs

7. Provide hangers tube for the desired height of the

suspended scaffold using double couplers with check

fittings.

7.1 Hand injury /wrong fittings used

7.1.1 Wear proper PPE,use double couplers only

Scaffolding Supervisor

8. Using gin wheel,attached the rope at the end of

the tube,then pull the rope until it reached

to the desired level of working platform.

8.1 Wrong hitch/knots to the tube

8.1.1 Use rolling hitch at the end of the tube

Scaffolding Supervisor

8.2 Falling objects/Falling worker

8.2.1 Approved full body harness and hook-up 100 %

8.2.2 Barricade the working area with warning signs

1 of 3

METHOD STATEMENT FOR SUSPENDED SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

9. Connect all the hangers tube in to the needles used

double couplers with check fittings on top

POTENTIAL HAZARDS

HAZARD CONTROLS

9.1 Falling worker/Falling objects

9.1.1 Approved full body harness and hook-up 100%.

RESPONSIBLE PERSON

Scaffolding Supervisor

9.1.2 Barricade the working area with warning signs

10. When all the hangers are secured, Two scaffolders will

suspend to the hangers stepping to butt tube on the bottom

of the hangers.

10.1 Falling worker/materials

10.1.1 Approved full body harness and hook-up 100%

11. They will then connect the ledger and transom to the

standards to make it square levelled and plumb.

11.1 Falling worker/materials

11.1.1 Approved full body harness and hook-up 100 %

11.2 Hand injury

11.1.2 Barricade the area with warning signs

Scaffolding Supervisor

10.1.2 Barricade the area with warning signs

Scaffolding Supervisor

11.1.3 Wear proper PPE especially hand gloves

12. Boarded out and secure the suspended scaffold and

fixed bracing for stability using double/swivel coupler.

12.1 Falling worker/materials

12.1.1 Approved full body harness and hook-up 100 %

12.2 Hand injury

12.1.2 Barricade the area with warning signs

Scaffolding Supervisor

12.1.3 Wear proper PPE especially hand gloves

13. Erect puncheons to support the handrails

13.1 Falling worker/materials

Scaffolding Supervisor

13.1.2 Barricade the working area with warning signs

13.1.3 Erect 1.5 meter tube fixed to the end of

the needles using double couplers,to support

the handrails tube.Install the toe boards and

fix to the puncheon tube using single couplers.

14. Provide access to the working platforms

14.1 Falling worker/materials

14.1.1 Approved full body harness and hook-up 100%

14.2 Slips Tripping on the same level

14.1.2 Barricade the working area with warning signs

14.1.3 Wear proper PPE

14.1.4 Access ladder at right angle with 4 meter up and

1 meter out,secured at least twice and provide 1 meter

above the working platform or five rungs

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR SUSPENDED SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

15. Suspended scaffold

15.1 Not in specification

15.1.1 Fixed red tag and repair the scaffold and once the

scaffold has been repaired fit green tag and entered in

scaffold registered(F-91) and inspect every 7 days.

Scaffolding Supervisor

16. Modification of suspended scafold

16.1 Incorrect method by non scaffolders

16.1.1 Modifications carried out by competent scaffolder

Scaffolding Supervisor

16.2 Falling workers/materials

16.1.2 Approved full body harness hook-up 100%

16.1.3 Barricade the area with warning signs

16.1.4 Show red tag when doing modification works

16.1.5 Notify the inspector for all the changes of the

scaffold due to modification

17. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed

to the ground in a safe manner and loaded on to the vehicle ready

for removal from site.

17.1 Slip,Trips and Falls

17.1.1 Wear proper PPE especially gloves

17.1.2 Approved full body harness

17.1.3 Barricade the working area with warning signs

17.2 Incorrect sequence of dismantling/scaffold collapse

17.2.1 Removed first the handrails,toe boards, then the

platforms,bracing,transoms and ledgers and the last is the

hangers and the remaining scaffold structures.Following

the BSEN-12811-1 for correct sequence of dismantling.

17.3 Materials not properly stacked and tied

17.1.5 Scaffold materials must properly stacked in sizes

and tied before transport.

17.4 Transport hazards/hitting or damage live plant

17.1.6 Use competent flagman to signal the truck

especially when reversing.

3 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR SUSPENDED SCAFFOLD WITH LADDER BEAM

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

2. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

2.1 Hand injury

2.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

2.1.2 Barricade the working area with warning signs

3. Transport materials to site using scaffold division

transportation.

3.1 Slip,Trips unsafe loading and handling

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.1.2 Apply the correct manual handling procedure

3.1.3 Barricade the working area with warning signs

4. Check scaffolding specification

4.1 Scaffolding not to specification

4.1.1 Return non specific material to stores and

quarantine area.

Scaffolding Supervisor

5. Assess the structure/beam supporting a suspended

scaffold.

5.1 Structure/beam not suitable

5.1.1 The structure or beam must be sound and suitable

to support the suspended scaffold.

Scaffolding Supervisor

5.2 Falling worker

5.1.2 Approved full body harness and hook-up 100%

6.1 Falling worker/material

6.1.1 Approved full body harness and hook-up 100%

6. Fixed ledger tube in the structure/beam set as a needle

Scaffolding Supervisor

6.1.2 Barricade the working area with warning signs

7. Provide hangers tube for the desire height of the

suspended scaffold using double couplers with check

fittings.

7.1 Hand injury /wrong fittings used

7.1.1 Wear proper PPE,use double couplers only

8. Using gin wheel, attached the rope at both end of the

ladder beam, then pull the rope until it reached to the desired

level of working platform.

8.1 Wrong hitch/knots to the tube

8.1.1 Use rolling hitch at the end of the tube

8.2 Falling objects/Falling worker

8.2.1 Approved full body harness and hook-up 100 %

8.2.2 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR SUSPENDED SCAFFOLD WITH LADDER BEAM

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

9. Connect all the hangers tube in to the needles used

double couplers with check fittings on top

POTENTIAL HAZARDS

9.1 Falling worker/Falling objects

HAZARD CONTROLS

9.1.1 Approved full body harness and hook-up 100%.

RESPONSIBLE PERSON

Scaffolding Supervisor

9.1.2 Barricade the working area with signage

10. When all the hangers are secured, Two scaffolders will

suspend to the hangers stepping to butt tube on the bottom

of the hangers.

10.1 Falling worker/materials

10.1.1 Approved full body harness and hook-up 100%

11. They will then connect the ledger and transom to the

standards to make it square levelled and plumb.

11.1 Falling worker/materials

11.1.1 Approved full body harness and hook-up 100 %

11.2 Hand injury

11.1.2 Barricade the area with warning signs

Scaffolding Supervisor

10.1.2 Barricade the area with warning signs

Scaffolding Supervisor

11.1.3 Wear proper PPE especially hand gloves

12. Boarded out and secure the suspended scaffold and

fixed bracing for stability using double/swivel coupler.

12.1 Falling worker/materials

12.1.1 Approved full body harness and hook-up 100 %

12.2 Hand injury

12.1.2 Barricade the area with warning signs

Scaffolding Supervisor

12.1.3 Wear proper PPE especially hand gloves

13. Erect puncheons to support the handrails

13.1 Falling worker/materials

13.1.1 Approved full body harness and hook-up 100%

Scaffolding Supervisor

13.1.2 Barricade the working area with warning signs

13.1.3 Erect 1.5 meter tube fixed to the end of

the needles using double couplers,to support

the handrails tube. Install the toe boards and

fix to the puncheon tube using single couplers.

14. Provide access to the working platforms

14.1 Falling worker/materials

14.1.1 Approved full body harness and hook-up 100%

14.2 Slips Tripping on the same level

14.1.2 Barricade the working area with warning signs

14.1.3 Wear proper PPE

14.1.4 Access ladder at right angle with 4 meter up and

1 meter out,secured at least twice and provide 1 meter

above the working platform

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR SUSPENDED SCAFFOLD WITH LADDER BEAM

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

15. Suspended scaffold

POTENTIAL HAZARDS

15.1 Not in specification

HAZARD CONTROLS

15.1.1 Fixed red tag and repair the scaffold and once the

scaffold has been repaired fit green tag and entered in

scaffold registered(F-91) and inspect every 7 days.

RESPONSIBLE PERSON

Scaffolding Supervisor

Scaffolding Inspector

16. Modification of suspended scafold

16.1 Incorrect method by non scaffolders

16.1.1 Modifications carried out by competent scaffolder

16.2 Falling workers/materials

16.1.2 Approved full body harness hook-up 100%

Scaffolding Supervisor

Scaffolding Inspector

16.1.3 Barricade the area with warning signs

16.1.4 Show red tag when doing modification works

16.1.5 Notify the inspector for all the changes of the

scaffold due to modification

17. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed

to the ground in a safe manner and loaded on to the vehicle ready

for removal from site.

17.1 Slip,Trips and Falls

17.1.1 Wear proper PPE especially gloves

Scaffolding Supervisor

17.1.2 Approved full body harness and hook-up 100%

17.1.3 Barricade the working area with warning signs

17.2 Incorrect sequence of dismantling

17.2.1 Scaffolder will removed the handrails,toeboards,

platfroms,transoms,ledger and bracing then all the drop

tubes. Followed the BSEN-12811-1 for dismantling.

17.3 Materials not properly stacked and tied

17.3.1 Scaffold materials must properly stacked and tied

17.4 Transport hazards/hitting plant or object

17.4.1 Use competent flagman to signal the truck

especially when reversing.

3 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR INTERNAL SCAFFOLD WORKS

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

2. Prepare all the necessary documents needed in working

internals(confined space)ie..Work permits, current confined

space workers certificate,rescue equipment and emergency

rescue plan before the work start.

3. Certified gas tester will then be check the confined space

if it's gas free and safe to work.

2.1 Workers not trained confined space

2.1.1 Workers must be trained in confined space and have

current and valid medical certificate.

2.2 No work permits

2.2.1 Raise work permits,JHA,Risk assessment etc.. Before

start work.

2.3 No rescue equipment and emergency

rescue plan.

2.3.1 Provide emergency rescue equipment and rescue

plan before start of work.

3.1 Toxic gas on confined space

3.1.1 Certified gas tester will check and inspect the work

location if its gas free and safe to work.

3.2 Not gas tested before start work

4. Once the confined space is safe to work,they will install

ventillation and lightings.

4.2 Poor lightings

5.1 Not competent watch man

6. All workers to enter to confined space must surrender

their badge to the watch man to monitor how many workers

working inside by using Time in and Time out system.

6.1 Workers not surrender his badge

Scaffolding Supervisor

Certified Gas Tester

4.1 No ventillation/Suffocations

5. After the necessary preparation is done,Scaffold supervisor

will designate a scaffold watch man with the name list of

the worker who will enter to confine space,with radio to

contact with supervisor work inside and to monitor as well

how many workers go in and go out.

Scaffolding Supervisor

4.1.1 FW must ensure that the ventillation is there and

a proper lighthings to be installed before workers enter

in to the confined space.

Scaffolding Supervisor

5.1.1 Watch man must be certified and competent as well

for his duties and properly trained.

Scaffolding Supervisor

5.2 No have communication

Certified Watchman

5.1.2 Watch man must have radio to contact for the

supervisor inside confine space

6.1.1 Workers must inform and give his badge to the watch

man before he enter to confined space

6.2 Watch man is not on the location

6.1.2 Watch man must always on his post in the opening of

the confined space.

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR INTERNAL SCAFFOLD WORKS

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

7. After that, the workers can start their works as per the

request given by the requestor following the correct method

and work procedure.

7.1 Not clear work request

7.1.2 Supervisor must be tied up with the requestor and

discuss the job clearly.ie..type of scaffold,exact location and

purpose of the scaffold.

Scaffolding Supervisor

8. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

8.1 Hand injury/Finger Trap/Strains

8.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

8.1.2 Barricade the working area with warning signs

9. Transport materials to site using scaffold division

transportation.

9.1 Slips and Tripping hazards

9.1.1 Stack materials in an orderly fashion

9.2 Un-safe loading and handling

9.1.2 Apply the correct manual handling procedure

10. Check scaffold specification

10.1 Scaffolding not to specification

10.1 Return non specific material to stores and in to

the quarantine area.

Scaffolding Supervisor

11. Bring the scaffold materials in to confined space entry using

the manhole openings.

11.1 Hand injury/Finger trap

11.1.1 Wear proper PPE especially the hand gloves

Scaffolding Supervisor

11.2 Manhole scratch or damage

11.1.2 Cover or protect the openings with rubber matting

to prevent damage.

12.1 Falling workers/objects

12.1.1 Approved full body harness and hook-up 100%

12.2 Hand injury/Finger trap

12.1.2 Barricade the working area with warning signs

12.3 Slip and Tripping hazards

12.1.3 Wear proper PPE especially the hand gloves

12. Once the scaffold materials are in place,the supervisor will

check the sketch/drawing and start the erection of the scaffold

following the BS EN-12811-1 procedure.

Scaffolding Supervisor

Scaffolding Supervisor

12.1.4 Keep the working area clear and tidy

13. Modification of internal scaffold

13.1 Incorrect method by non scaffolders

13.1.1 Modifications carried out by competent scaffolder

Scaffolding Supervisor

13.2 Falling workers/materials

13.1.2 Approved full body harness hook-up 100%

Scaffolding Inspector

13.1.3 Barricade the area with warning signs

Competent Scaffolder

13.1.4 Show red tag when doing modification works

13.1.5 Notify the inspector for all the changes of the

scaffold due to modification

2 of 3

METHOD STATEMENT FOR INTERNAL SCAFFOLD WORKS

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

14. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed

to the ground in a safe manner and loaded on to the vehicle ready

for removal on site.

POTENTIAL HAZARDS

HAZARD CONTROLS

14.1 Slip,Trips and Falls

14.1.1 Wear proper PPE especially gloves

14.2 Incorrect sequence of dismantling

14.1.2 Approved full body harness

14.3 Materials not properly stacked and tied

14.1.3 Barricade the working area with warning signs

14.4 Transport hazards/hitting or damage plant

14.1.4 Removed first the handrails,toe boards, then the

platforms,transoms, ledgers and bracing followed standards

when the scaffold is erect from the ground.When the

scaffold is suspended,just follow the reverse procedure

of erection when dismantling.

14.1.5 Scaffold materials must properly stacked in sizes

and tied before transport.

14.1.6 Use competent flagman to signal the truck

especially when reversing.

3 of 3

RESPONSIBLE PERSON

Scaffolding Supervisor

METHOD STATEMENT FOR HEAVY DUTY SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

Scaffolding Supervisor

2. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

2.1 Hand injury

2.1.1 Wear proper PPE especially hand gloves

2.1.2 Barricade the working area with warning signs

3. Transport materials to site using scaffold division

transportation.

3.1 Slips and Tripping hazards

3.1.1 Stack materials in an orderly fashion

3.2 Un-safe loading and handling

3.1.2 Apply the correct manual handling procedure

Scaffolding Supervisor

3.1.3 Barricade the working area with warning signs

4. Check scaffold specification

4.1 Scaffolding not to specification

4.1.1 Return non specific material to stores and in to

quarantine area.

Scaffolding Supervisor

5. Consult licenced scaffold engineer for scaffold designed and

load calculations.

5.1 Incompetent scaffold engineer

5.1.1 Heavy Duty scaffold must be designed by Licensed

and competent Scaffold Engineer for loading calculations.

Licenced Scaffold Engr.

6. Once the scaffold engineer designed the heavy duty scaffold

containing all the calculations etc..and the client (FW) agreed

scaffolders will proceed to erection following the engineer

drawing.

6.1 Incompetent scaffolder

6.1.1 Only competent Advance scaffolder with two years

working experience will be responsible for the erection

of heavy duty scaffold.

Scaffolding Supervisor

6.2 Scaffold collapse

Certified Advance Scaffolder

6.1.2 Scaffolders will use all load bearing couplers start

from bracing as well as for the transoms, and the supervisor

must closely monitor and supervised.

7. Heavy duty scaffold

7.1 Not following the designed drawing

7.1.1 Once the heavy duty scaffold complete,the supervisor

will check if it's erected as per the drawing and inform the

inspector for final inspection using the F-91 following

7.2 No loading signage

7.1.2 Fixed the Uniformely Distributed Loading (UDL)

capacity signage for the users reference.

1 of 2

Scaffolding Supervisor

Scaffolding Inspector

METHOD STATEMENT FOR HEAVY DUTY SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

8. Heavy duty scaffold modification

POTENTIAL HAZARDS

HAZARD CONTROLS

8.1 Incorrect method by non scaffolders

8.1.1 All scaffold modifications must carried out by

competent scaffolder and approved by licenced scaffold

engineer.

8.2 Falling workers/objects

8.3 Hand injury,Slips and Tripping hazards

RESPONSIBLE PERSON

Scaffolding Supervisor

Scaffolding Inspector

Scaffolding Engineer

8.1.2 Approved full body harness and hook-up 100%

Competent Scaffolder

8.1.3 Barricade the area with warning signs

8.1.4 Show the red tag when doing modification works

8.1.5 Notify the inspectors for all the changes of the scaffold

due to modifications.

8.1.6 Wear proper PPE especially hand gloves

9. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift and materials will be passed or lowered to the

ground and loaded on to the vehicle ready for removal from site.

9.1 Incorrect sequence of dismantling

9.1.1 Competent scaffolders will follow the BS EN 12811-1

procedure when dismantling scaffold,ie. from top to the

bottom when the scaffold is erected from the ground.

9.2 Falling workers/objects

9.3 Hand injury/Finger trap

9.4 Slips and Tripping Hazards

9.1.2 Approved full body harness and hook-up 100%

9.5 Materials not properly stacked and tied

9.1.3 Barricade the working area with warning signs

9.6 Transport hazards/hitting or damage live plant

9.1.4 Wear proper PPE especially gloves

9.1.5 Keep the area clean and tidy especially after the

completion of work.

9.1.6 Scaffold materials must properly stacked in sizes

and tied before transport.

9.1.7 Use competent flagman to signal the truck

especially when reversing.

2 of2

Scaffolding Supervisor

Competent Scaffolder

METHOD STATEMENT FOR SCAFFOLD OVER 12 METER

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

2. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

2.1 Hand injury

2.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

2.1.2 Barricade the working area with warning signs

3. Transport materials to site using scaffold division

transportation.

3.1 Slips and Tripping hazards

3.1.1 Stack materials in an orderly fashion

3.2 Un-safe loading and handling

3.1.2 Apply the correct manual handling procedure

Scaffolding Supervisor

3.1.2 Barricade the working area with warning signs

4. Check scaffold specification

4.1 Scaffolding not to specification

4.1.1 Return non specific material to stores and in

the quarantine area.

5. Consult licenced scaffold engineer for scaffold designed and

load calculations.

5.1 Incompetent scaffold engineer

5.1.1 Scaffold over 12 meter must be designed by Licensed

and competent Scaffold Engineer for loading calculations.

6. Once the scaffold engineer designed the scaffold

containing all the calculations etc..and the client (FW) agreed

scaffolders will proceed to erection following the engineer

drawing.

6.1 Incompetent scaffolder

6.1.1 Only competent Advance scaffolder with two years

working experience will be responsible for the erection

of scaffold over 12 meter height.

6.2 Scaffold collapse

6.3 Falling workers/objects

6.1.2 Scaffolders will follow the BS EN-12811-1 procedure.

Use load bearing couplers and tied every 4 meter horizontal

and vertically for stability.Then the supervisor will closely

monitorred and supervised.

6.4 Hand injury/Finger trap

6.1.3 Use approved full body harness and hook-up 100%

6.1.4 Wear proper PPE especially hand gloves

1of 2

Scaffolding Supervisor

Licenced Scaffold Engineer

Scaffolding Supervisor

Certified Advance Scaffolder

METHOD STATEMENT FOR SCAFFOLD OVER 12 METER

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

7. Modification of scaffold over 12 meter

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

7.1 Incorrect method by non scaffolders

7.1.1 Modifications carried out by competent scaffolder

Scaffolding Supervisor

7.2 Falling workers/materials

7.1.2 Approved full body harness and hook-up 100%

Scaffolding Inspector

7.1.3 Barricade the working area with warning signs

7.1.4 Show red tag when doing modification works

7.1.5 Notify the inspector for all the charges of the

scaffold due to modification

8. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed

to the ground in a safe manner and loaded on to the vehicle ready

for removal from site.

8.1.1 Slip,Trips and Falls

8.1.1 Wear proper PPE especially gloves

8.1.2 Incorrect sequence of dismantling

8.1.2 Approved full body harness

8.1.3 Materials not properly stacked and tied

8.1.3 Barricade the working area with warning signs

8.1.4 Transport hazards/hitting or damage plant

8.1.4 Removed first the handrails,toe boards, then the

platforms,transoms, ledgers and bracing followed standards

when the scaffold is erect from the ground.When the

scaffold is suspended,just follow the reverse procedure

of erection when dismantling.

8.1.5 Scaffold materials must properly stacked in sizes

and tied before transport.

8.1.6 Use competent flagman to signal the truck

especially when reversing.

2of 2

Scaffolding Supervisor

METHOD STATEMENT FOR INDEPENDENT SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

1. Conduct daily tool box talk before start of work

1.1 Lack of PPE

1.1.1 Inspect,issue and control use of PPE

Scaffolding Supervisor

2. Prepare equipment and scaffold tools

2.2 Incorrect tools and equipment

2.1.1 Provide correct tools and equipment for the job

Scaffolding Supervisor

3. Transport scaffold materials using scaffold division

transportation

3.1 Slip and Tripping hazards

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.1.2 Wear proper PPE especially hand gloves

4. Check the area where the independent scaffold to be install

3.2 Un-safe loading and handling

3.2.1 Correct manual handling techniques

4.1 Unwanted objects,un even ground condition

4.1.1 Clear the area and compact the ground before work start

Scaffolding Supervisor

4.1.2 Barricade theworking area with signage

5. The scaffold will be erected by minimum of 2 operatives

and will be erected in accordance with BS-EN 12811-1.

5.1 Not following the correct standards

5.1.1 Follow the BS-EN-128-11 procedure

Scaffolding Supervisor

5.1.2 Proper PPE,Scaffold belts,tools

6. Sole board and base plate will be place on the even and

stable ground surfaces at a distance appropriate to the

standards center for the weight capacity of the scaffold.

6.1 Not using sole board/base plate

Un even ground,scaffold may sink

6.1.1 Follow the BS-EN-12811-1 proceudre

Scaffolding Supervisor

6.1.2 Proper PPE,Scaffold Belts,tools

6.1.3 Barricade the working area with signage

7. The first pair of the standards will then be placed on to the

sole boards and base plate and double couplers fitted at lift height.

7. wrong coupler use,standard may fall

Hand Injury,Slip/Trips

7.1.1 Double coupler must be use,provide rakers

Scaffolding Supervisor

7.1.2 Proper PPE,Scaffold belts,tools

7.1.3 Barricade the working area with warning signs

8. The first ledger will then be fitted in to the double couplers

and levelled,joining the pair of the standards together to

form a set of goal posts.A set of temporary rakers may then

be used to hold the goal post level and safe against the building

8.1 Wrong scaffold erection sequence

8.1.1 Follow the correct sequence of erection as per

BS-EN 12811-1

8.2 Hand Injury

8.2.1 Wear proper PPE,Scaffold Belts,Tools

8.3 Slip and Tripping hazards

8.3.1 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR INDEPENDENT SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

9. An outside standard will then be placed onto a base board

and plate and a transom fixed into place and levelled.

10. A second ledger tube will then be fixed to the outside set of

standards using double couplers.

POTENTIAL HAZARDS

HAZARD CONTROLS

9.1 Hand Injury/Slips,Trips on the same level

9.1.1 Wear proper PPE,especially hand gloves

9.2 Slip and Tripping hazards

9.2.1 Barricade the working area with warning signs

10.1 Hand Injury,Slip/Trips

10.1.1 Wear proper PPE,especially hand gloves

RESPONSIBLE PERSON

Scaffolding Supervisor

Scaffolding Supervisor

10.1.2 Barricade the working area with warning signs

11. Braces will be attached to each end of the structure and

checks made to ensure the structure is plumb and level.

11.1 Hand Injury,Pinch point,Slip,Trips

11.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

12. Transoms will then be fixed along the top of the ledgers

ensuring that stop end transoms are in place to support the

ends of scaffolding boards.

12.1 Hand Injury,Slip,Trips

12.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

13. Scaffolding boards will then be placed on to the transoms to

form a boarded platform from which the scaffold operatives

can work when erecting next lift platform.

13.1 Pinch point,Finger Trap,Slip and Trips

13.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

14. Scaffolders will then access the boarded lift using a ladder

tied on the structures.

14.1 Slip,Trips and Fall

14.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

12.1.2 Barricade the working area with warning signs

14.1.2 Approved full body harness and hook-up 100%

14.2 Ladders not tied,not correct angle

14.2.1 Access ladder must lashed to the structure

14.2.2 Ladder must project 75 degree or 4 is to 1 ratio

15. Scaffold materials will then be passed or hoisted to the boarded

platform and then used for the erection of double handrail with toe boards.

15.1 Falling objects,Falling workers

15.1.1 Use gin wheel and rope with fitting bags

Scaffolding Supervisor

15.1.2 Approved full body harness and hook-up 100%

15.1.3 Barricade the working area with warning signs

15.1.4 Wear proper PPE

16. Ties will be fixed in accordance with BS-EN 12811-1 giving

stability to the scaffold.

16.1 Scaffold un-stable,falling object

16.1.1 Fixed scaffold ties for every 4 meters vertical/horizontal

16.1.2 Barricade the area with warning signs

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR INDEPENDENT SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

17.(Independent Scaffold)A final inspection will be undertake on completion

of the scaffold to ensure the scaffold structure is in compliance with

the relevant standards and codes of practice.

POTENTIAL HAZARDS

17.1 Scaffold incomplete,Falling worker

Not into specification

HAZARD CONTROLS

RESPONSIBLE PERSON

17.1.1 Inspector must check the scaffold structure using F-91 as per

BS-EN-12811-1

Scaffolding Supervisor

Scaffolding Inspector

BS-EN 12811-1

17.1.2 Approved full body harness hook-up 100%

18. All safety warning signs,barriers and surplus materials will

be removed prior to leaving on site (House keeping)

18.1 Pinch point,Slip,Trips and Falls

18.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

18.1.2 Approved full body harness hook-up 100%

18.1.3 Barricade the area with warning signs

19. Scaffold modification

19.1 Slip,Trips and Fall,Scaffold Collapse

19.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

19.1.2 Approved full body harness and hook-up 100%

19.1.3 Competent scaffolder only can modified the scaffold

19.1.4 Barricade the area with warning signs

20. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed or

lowered to the ground in a safe manner and loaded on to the vehicle

ready for removal on site.

20.1 Falling objects/Falling workers

20.1.1 Approved full body harness and hook-up 100 %

20.2 Incorrect dismantling sequence/scaffold collapse

20.2.1 Followed the BSEN-128-11 correct sequence of dismantling

Reverse the procedure of erection when dismantling only when

the scaffold is erected from the ground.

20.3 Slip and Tripping hazards

20.3.1 Barricade the area with warning signs

Scaffolding Supervisor

Scaffolding Supervisor

20.3.2 Wear proper PPE especially hand gloves

20.4 Materials not properly stack and tied

20.4.1 Scaffold materials must properly stacked and tied

20.5 Transport hazards/hitting or damage to equipment

20.5.1 Use competent flagman to signal the truck especially

when reversing.

Scaffolding Supervisor

3 of 3

METHOD STATEMENT FOR MOBILE TOWER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

1. Conduct daily tool box talk before start of work

1.1 Lack of PPE

1.1.1 Inspect,issue and control use of PPE

Scaffolding Supervisor

2. Prepare equipment and scaffold tools

2.2 Incorrect tools and equipment

2.1.1 Provide correct tools and equipment for the job

Scaffolding Supervisor

3. Transport scaffold materials using scaffold division

transportation

3.1 Slip and Tripping hazards

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.2 Un-safe loading and handling

3.1.2 Wear proper PPE especially hand gloves

3.1.3 Correct manual handling techniques

4. Check the area where the tower scaffold to be install

4.1 Unwanted objects,un even ground condition

4.1.1 Clear the area and compact the ground before work start

Scaffolding Supervisor

4.1.3 Barricade the working area with signage

5. The scaffold will be erected by minimum of 2 operatives

and will be erected in accordance with BS-EN 12811-1.

5.1 Not following the correct standards

5.1.1 Follow the BS-EN-12811-1 procedure

Scaffolding Supervisor

5.1.2 Proper PPE,Scaffold belts,tools

6. The first pair of the standards will then be place and connect double

couplers

6.1. wrong coupler use,standard may fall

Hand Injury,Slip/Trips

6.1.1 Double coupler must be use,provide rakers

Scaffolding Supervisor

6.1.2 Proper PPE,Scaffold belts,tools

6.1.3 Barricade the working area with warning signs

7. The first ledger will then be fitted in to the double couplers

and levelled,joining the pair of the standards together to

form a set of goal posts. A set of temporary rakers may then

be used to hold the goal post level and safe against the building

7.1 Wrong scaffold erection sequence

7.1.1 Follow the correct sequence of erection as per

BS-EN 12811-1

7.2 Hand Injury,Slip/Trips

7.2.1 Wear proper PPE,Scaffold Belts,Tools

Scaffolding Supervisor

7.2.2 Barricade the working area with warning signs

8. An outside standard will then be placed and connect to the transom

and levelled.

8.1 Hand injury,Slip/Trips

8.1.1 Wear proper PPE,especially hand gloves

8.1.2 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR MOBILE TOWER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

9. Set 4 will be repeated at the other end of the scaffold

POTENTIAL HAZARDS

9.1 Hand injury,Slip/Trips

HAZARD CONTROLS

RESPONSIBLE PERSON

9.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

9.1.2 Barricade the working area with warning signs

10. A second ledger tube will then be fixed to the outside set of

standards using double couplers.

10.1 Hand Injury,Slip/Trips

10.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

10.1.2 Barricade the working area with warning signs

11. Insert the 4 castors wheel in each standard

11.1 Hand Injury,Pinch point,Slip,Trips

11.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

12. Braces will be attached to each end of the structure and plan brace

the center of the tower to ensure the structure is stable.

12.1 Hand Injury,Pinch point,Slip,Trips

12.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

12.1.2 Barricade the working area with warning signs

13. Transoms will then be fixed along the top of the ledgers

ensuring that stop end transoms are in place to support the

ends of scaffolding boards.

13.1 Hand Injury,Slip,Trips

13.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

14. Scaffolding boards will then be placed on to the transoms to

form a boarded platform from which the scaffold operatives

can work when erecting next lift platform.

14.1 Pinch point,Finger Trap,Slip.Trips

14.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

15. Scaffolders will then access the boarded lift using a ladder

tied on the structures.

15.1 Slip,Trips and Fall

15.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

15.1.2 Approved full body harness and hook-up 100%

15.2 Ladders not tied,not correct angle

15.2.1 Access ladder must lashed to the structure

15.2.2 Ladder must project 75 degree or 4 is to 1 ratio

16. Scaffold materials will then be passed or hoisted to the boarded

platform and then used for the erection of double handrail with toe boards.

16.1 Falling objects,Falling workers

16.1.1 Use gin wheel and rope with fitting bags

16.1.2 Approved full body harness and hook-up 100%

16.1.3 Barricade the working area with warning signs

16.1.4 Wear proper PPE

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR MOBILE TOWER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

17. A final inspection will be undertake on completion of the scaffold to

ensure the scaffold structure is in compliance with the relevant standards

and codes of practice.

POTENTIAL HAZARDS

HAZARD CONTROLS

17.1 Scaffold in complete,Falling worker

Not into specification

17.1.1 Inspector must check the scaffold using F-91 as per

BS-EN-12811-1

RESPONSIBLE PERSON

Scaffolding Supervisor

Scaffolding Inspector

17.1.2 Approved full body harness and hook-up 100%

18. All safety warning signs,barriers and surplus materials will

be removed prior to leaving on site (House keeping)

18.1 Pinch point,Slip,Trips and Falls

18.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

18.1.2 Approved full body harness and hook-up 100%

18.1.3 Barricade the working area with warning signs

19. Scaffold modification

19.1 Slip,Trips and Fall,Scaffold Collapse

19.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

19.1.2 Approved full body harness and hook-up 100%

19.1.3 Competent scaffolder only can modified the scaffold

19.1.4 Barricade the working area with warning signs

20. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift and materials will be passed or lowered to the

ground and loaded on to the vehicle ready for removal from site.

20.1 Falling objects/Falling workers

Slip,Trips on the same location

20.1.1 Approved full body harness and hook-up 100 %

20.1.2 Barricade the working area with warning signs

20.1.3 Wear proper PPE especially hand gloves

3 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR BIRDCAGE SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

1. Conduct daily tool box talk before start of work

1.1 Lack of PPE

1.1.1 Inspect,issue and control use of PPE

Scaffolding Supervisor

2. Prepare equipment and scaffold tools

2.2 Incorrect tools and equipment

2.1.1 Provide correct tools and equipment for the job

Scaffolding Supervisor

3. Transport scaffold materials using scaffold division

transportation

3.1 Slip and Tripping hazards

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.1.2 Wear proper PPE especially hand gloves

4. Check the area where the Birdcage scaffold to be install

3.2 Un-safe loading and handling

3.2.1 Correct manual handling techniques

4.1 Unwanted objects,un even ground condition

4.1.1 Clear the area and compact the ground before work start

Scaffolding Supervisor

4.1.2 Barricade theworking area with signage

5. The scaffold will be erected by minimum of 2 operatives

and will be erected in accordance with BS-EN 12811-1.

5.1 Not following the correct standards

5.1.1 Follow the BS-EN-128-11 procedure

Scaffolding Supervisor

5.1.2 Proper PPE,Scaffold belts,tools

6. Sole board and base plate will be place on the even and

stable ground surfaces at a distance appropriate to the

standards center for the weight capacity of the scaffold.

6.1 Not using sole board/base plate

Un even ground,scaffold may sink

6.1.1 Follow the BS-EN-12811-1 proceudre

Scaffolding Supervisor

6.1.2 Proper PPE,Scaffold Belts,tools

6.1.3 Barricade the working area with signage

7. The first pair of the standards will then be place on to the

sole boards and base plate and double couplers fitted at lift height.

7.1 wrong coupler use,standard may fall

Hand Injury,Slip/Trips

7.1.1 Double coupler must be use,provide rakers

Scaffolding Supervisor

7.1.2 Proper PPE,Scaffold belts,tools

7.1.3 Barricade the working area with warning signs

8. The first ledger will then be fitted in to the double couplers

and levelled,joining the pair of the standards together to

form a set of goal posts.A set of temporary rakers may then

be used to hold the goal post level and safe against the building

8.1 Wrong scaffold erection sequence

8.1.1 Follow the correct sequence of erection as per

BS-EN 12811-1

8.2 Hand Injury

8.2.1 Wear proper PPE especially gloves

8.3 Slip and Tripping hazards

8.3.1 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR BIRDCAGE SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

9. An outside standard will then be placed onto a base board

and plate and a transom fixed into place and levelled.

10. A second ledger tube will then be fixed to the outside set of

standards using double couplers.

HAZARD CONTROLS

RESPONSIBLE PERSON

9.1 Hand Injury

POTENTIAL HAZARDS

9.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

9.2 Slip and Tripping hazards

9.1.2 Barricade the working area with warning signs

10.1 Hand Injury,Slip/Trips

10.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

10.1.2 Barricade the working area with warning signs

11. Braces will be attached to each end of the structure and

checks made to ensure the structure is plumb and level.

11.1 Hand Injury,Pinch point,Slip,Trips

11.1.1 Wear proper PPE,especially hand gloves

Scaffolding Supervisor

11.1.2 Barricade the working area with warning signs

12. Transoms will then be fixed along the top of the ledgers

ensuring that stop end transoms are in place to support the

ends of scaffolding boards.

12.1 Hand Injury,Slip,Trips

12.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

13. Scaffolding boards will then be placed on to the transoms to

form a boarded platform secured from which the scaffold operatives

can work when erecting next lift platform.

13.1 Pinch point,Finger Trap,Slip.Trips

13.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

14. Scaffolders will then access the boarded lift using a ladder

tied on the structures.

14.1 Slip,Trips and Fall

14.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

14.1.2 Approved full body harness and hook-up 100%

14.2 Ladders not tied,not correct angle

14.2.1 Access ladder must lashed to the structure

14.2.2 Ladder must project 75 degree or 4 is to 1 ratio

15. Scaffold materials will then be passed or hoisted to the boarded

platform and then used for the erection of double handrail with toe boards.

15.1 Falling objects,Falling workers

15.1.1 Use gin wheel and rope with fitting bags

15.1.2 Approved full body harness and hook-up 100%

15.1.3 Barricade the working area with warning signs

15.1.4 Wear proper PPE

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR BIRDCAGE SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

16. Ties will be fixed in accordance with BS-EN 12811-1 giving

stability to the scaffold.

POTENTIAL HAZARDS

HAZARD CONTROLS

16.1 Scaffold un-stable,falling object

16.1.1 Fixed scaffold ties for every 4 meters vertical/horizontal

for stability.

RESPONSIBLE PERSON

Scaffolding Supervisor

16.1.2 Barricade the area with warning signs

17.(Birdcade Scaffold)A final inspection will be undertake on completion

of the scaffold to ensure the scaffold structure is in compliance with

the relevant standards and codes of practice.

17.1 Scaffold incomplete,Falling worker

Not into specification

17.1.1 Scaffold inspector must check the scaffold using F-91 as per

BS-EN-12811-1

Scaffolding Supervisor

Scaffolding Inspector

17.1.2 Approved full body harness hook-up 100%

18. Scaffold modification

18.1 Slip,Trips and Fall,Scaffold Collapse

18.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

18.1.2 Approved full body harness and hook-up 100%

18.1.3 Competent scaffolder only can modified the scaffold

18.1.4 Barricade the working area with warning signs

19. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised and efficient

manner,lift by lift from top to bottom and materials will be passed or lowered

to the ground in a safe manner and loaded on to the vehicle ready for removal

on site.

19.1 Falling objects/Falling workers

19.1.1 Approved full body harness and hook-up 100 %

19.2 Slip and Tripping hazards

19.1.2 Barricade the area with warning signs

19.3 Incorrect sequence of dismantling

19.3.1 Followed the correct sequence of dismantling as per

BSEN-12811-1.Reverse the procedure of erection when dismantling

only when the scaffold is erected from the ground.

Scaffolding Supervisor

Scaffolding Supervisor

19.3.2 Wear proper PPE especially hand gloves

19.4 Materials not properly stacked and tied

19.4.1 Scaffold materials must properly stacked and tied

19.5 Transport hazards/hitting live plant or object

19.5.1 Use competent flagman to signal the truck especially

when reversing.

3 of 3

METHOD STATEMENT FOR CANTELIVER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

2. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

2.1 Slip,Trips and Pinch point

2.1.1 Wear proper PPE especially hand gloves

3. Transport materials to site using scaffold division

transportation.

3.1 Slip and Tripping hazards

3.1.1 Stack materials in an orderly fashion

3.2 Un-safe loading and handling.

3.2.1 Apply the correct manual handling procedure

Scaffolding Supervisor

Scaffolding Supervisor

3.2.2 Wear proper PPE especially hand gloves

4. Check scaffold specification

4.1 Scaffolding not to specification

4.1.1 Return non specific material to stores and

quarantine area.

Scaffolding Supervisor

5. Erect needle tube max. 3m for canteliver

5.1 worker Falling/Falling objects

5.1.1 Approved full body harness and hook-up 100%

Scaffolding Supervisor

5.1.2 Provide 3 boards as temporary working platform

5.1.3 Barricade the working area with warning signs

5.1.4 Needles to project not more than 1.8 meters or

design for 5 boards using double couplers.

5.1.5 Scaffold must be tied to a sound structure

6. Erect ledger to outer edge of the needles using double

coupler

6.1 Falling worker

6.1.1 Approved full body harness and hook-up 100%

6.2 Falling Objects

6.1.2 Baricade the area with warning signs

Scaffolding Supervisor

6.1.3 Provide 3 boards as temporary working platform

7. Boarded the canteliver and secured using limpet clamps

7.1 Worker falling

7.1 Approved full body harness and hook 100%

7.2 Falling objects

7.1.2 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR CANTELIVER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

8. Handrail puncheons

POTENTIAL HAZARDS

HAZARD CONTROLS

8.1 Worker falling

8.1.1 Approved full body harness and hook-up 100%.

8.2 Falling objects

8.1.2 Barricade the working area with warning signs

RESPONSIBLE PERSON

Scaffolding Supervisor

8.1.3 Erect 1.5 meter tube and fixed to the needles with

double couplers to support the handrail tube.Install

the toeboards and fixed to the puncheon tube

9. Access to working platforms

9.1 Worker falling

9.1.1 Approved full body harness and hook-up 100%

9.2 Falling objects

9.1.2 Provide 3 temporary boards

Scaffolding Supervisor

9.1.3 Barricade the area with warning signs

9.1.4 Access ladder at the right angle 4 meter up to

1 meter out.Must be secure twice and have 1 meter

above the working platform.

10. Working platforms

10.1 Material Falling

10.1.1 Barricade the working area with warning signs

Scaffolding Supervisor

10.1.2 Clear all excess scaffold materials on the platform

11. Canteliver Scaffold

11.1 Not to specification

11.1.1 Fixed red tag,and repair the scaffold until it is

safe to use.Enter into scafftag register(F-91) and inspect

every 7 days

Scaffolding Supervisor

Scaffolding Inspector

12. Modifications of canteliver scaffold

12.1 Falling objects/Worker falling

12.1.1 Approved full body harness and wear proper PPE

Scaffolding Supervisor

12.2 Incorrect method of modifications

12.1.2 Modifications are carried out by competent

scaffolders only

Scaffolding Inspector

12.1.3 Notify scaffold inspectors for the changes to due

modifications.

12.1.4 Fixed red tag to the access ladder when doing

modification works.

2 of 3

METHOD STATEMENT FOR CANTELIVER SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

13. Once the scaffold operatives are satisfied that the scaffold

is safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed

or lower to the ground in a safe manner and loaded on to the

vehicle and ready for removal on site.

POTENTIAL HAZARDS

HAZARD CONTROLS

13.1 Falling objects/Falling workers

13.1.1 Approved full body harness and hook-up 100 %

13.1.2 Barricade the area with warning signs

13.2 Slip and Tripping hazards

13.2.1 Wear proper PPE especially hand gloves

13.3 Incorrect dismantling sequence/scaffold collapse

13.3.1 Scaffolder will removed the handrails,toeboards,

platfroms,transoms,ledger and bracing then all the drop

tubes. Followed the BSEN-12811-1 for dismantling.

13.4 Materials not properly stack and tied or secured

13.4.1 Scaffold materials must properly stacked and tied

13.5 Transport hazards/hitting live plant or object

13.5.1 Use competent flagman to signal the truck

especially when reversing.

3 of 3

RESPONSIBLE PERSON

Scaffolding Supervisor

METHOD STATEMENT FOR HANDRAILS AT GROUND LEVELS

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

1. Conduct daily tool box talk before start of work

1.1 Lack of PPE

1.1.1 Inspect,issue and control use of PPE

Scaffolding Supervisor

2. Prepare equipment and scaffold tools

2.2 Incorrect tools and equipment

2.1.1 Provide correct tools and equipment for the job

Scaffolding Supervisor

3. Transport scaffold materials using scaffold division

transportation

3.1 Slip and Tripping hazards

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.2 Un-safe loading and handling

3.1.2 Wear proper PPE especially hand gloves

3.1.3 Correct manual handling techniques

4. Check the area where the handrail scaffold to be install

4.1 Unwanted objects,un even ground condition

4.1.1 Clear the area and compact the ground before work start

Scaffolding Supervisor

4.1.2 Barricade theworking area with signage

5. Erect 1.5 meter standard with base plate and sole

board underneath.

5.1 Standard collapse

5.1.1 Barricade the working area with warning signs

Scaffolding Supervisor

6. Connect double coupler to the standard 300 mm on the

base,and connect ledger tube horizontaly.

6.1 Incorrect fittings

6.1.1 Use double coupler only

Scaffolding Supervisor

7. Measure the gap of bottom handrail (470 mm) and connect

another tube across (1.05 meter) top handrail.

7.1 Incorrect heights of handrails

7.1.1 Follow the correct size of handrails as per BS standard

Scaffolding Supervisor

8. Connect 1.5 meter tube across the standard every 2 meters

apart.

8.1 Pinch Point/Hand injury

8.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

9. Connect 1.5 meter tube to the top handrail using double

coupler with an angle of 45 degree act as bracing to the

handrails.

9.1 Pinch point/Hand injury

9.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

10. Dismantling of Handrails

10.1 Pinch point/Hand injury

10.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

10.1.2 Dismantling is the reverse procedure of erection

METHOD STATEMENT FOR HANDRAILS FOR STEEL WORK

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

1. Conduct daily tool box talk before start of work

1.1 Lack of PPE

1.1.1 Inspect issue and control use of PPE

Scaffolding Supervisor

2. Prepare equipment and scaffold tools

2.1 Incorrect tools and equipment

2.1.1 Provide correct tools and equipment for the job

Scaffolding Supervisor

3. Transport scaffold materials using scaffold division

transportation

3.1 Slip and Tripping hazards

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.2 Un-safe loading and handling

3.1.2 Wear proper PPE especially hand gloves

3.1.3 Correct manual handling techniques

4. Check the area where the handrail scaffold to be install

4.1 Unwanted objects,un even ground condition

4.1.1 Clear the area and compact the ground before work start

Scaffolding Supervisor

4.1.2 Barricade theworking area with signage

5. Erect 1.5 meter standard and fixed to the structure

using a pair of beam clamps only.

5..1 Hand injury,Slip,Trips and Fall

5.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

5.1.2 Barricade the working area with warning signs

5.1.3 Approved full body harness and hook-up 100%

6. Connect double coupler to the standard 300 mm on the

base,and connect ledger tube horizontaly.

6.1 Incorrect fittings,Hand injury

6.1.1 Use double coupler only,Wear Proper PPE

Scaffolding Supervisor

7. Measure the gap of bottom handrail (470 mm) and connect

another tube across (1.05 meter) top handrail.

7. Incorrect heights of handrails,Hand injury

7.1.1 Follow the correct size of handrails as per BS standard

Scaffolding Supervisor

7.1.2 Wear proper PPE esp.hand gloves

8. Connect another 1.5 meter standard to the top and bottom

ledger using double coupler and fixed ties for extra stability

8.1 Pinch Point/Hand injury

8.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

9. Handrails for Steel Work

9.1 Not in specification,not stable

9.1.1 Handrails must erect as per BS-EN 12811-1

Fixed extra ties for stability

Scaffolding Supervisor

10. Dismantling of Handrails

10.1 Pinch point/Hand injury

10.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

10.2 Slips,Trips and Falls

10.1.2 Approved full body harness and hook-up 100%

10.1.3 Barricade the working area with warning signs

10.1.4 Dismantling is the reverse procedure of erection

METHOD STATEMENT FOR BRIDGE SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

1. Conduct daily tool box talk before start of work

POTENTIAL HAZARDS

HAZARD CONTROLS

1.1.1 Inspect issue and control use of PPE

1.1 Lack of PPE

RESPONSIBLE PERSON

Scaffolding Supervisor

1.1.2 Explain daily work activities

2. Prepare equipments,tools,basket/lifting bags

Gin Wheel rope(if required)

2.1 Hand injury

2.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

2.1.2 Barricade the working area with warning signs

3. Transport materials to site using scaffold division

transportation.

3.1 Slip,Trips,unsafe loading and handling

and unsafe handling.

3.1.1 Stack materials in an orderly fashion

Scaffolding Supervisor

3.1.2 Apply the correct manual handling procedure

3.1.3 Barricade the working area with warning signs

4. Check scaffold specification

4.1 Scaffolding not to specification

4.1.1 Return non specific material to stores and

quarantine area.

Scaffolding Supervisor

5. Erect two tower scaffold as per BS-EN 12811-1 with

fully brace on four sides.

5.1 Slip,Trips and Falls,Hand injury

5.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

5.1.2 Provide 3 boards as temporary working platform

5.1.3 Approved full body harness and hook-up 100%

5.1.4 Barricade the working area with warning signs

6. Connect the two tower with the desire length of tube

using double coupler.

6.1 Falling objects/Falling worker

6.1.1 Approved full body harness and hook-up 100%

Scaffolding Supervisor

6.1.2 Barricade the working area with warning signs

6.1.3 Provide gin wheel with rope

7. Using gin wheel,attached the rope at both end of

the tube,then pull the rope until it reached

to the desired level of working platform.

7.1 Wrong hitch/knots to the tube

7. 1.1 Use clove hitch/knots on both end of the tube

7.2 Falling objects/Falling worker

7.1.2 Approved full body harness and hook-up 100%

7.1.3 Barricade the working area with warning signs

1 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR BRIDGE SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

8. Once the two scaffold tube on top,level both side

using spirit level

POTENTIAL HAZARDS

HAZARD CONTROLS

8.1 Falling worker/Falling objects

8.1.1 Approved full body harness and hook-up 100%.

RESPONSIBLE PERSON

Scaffolding Supervisor

8.1.2 Barricade the working area with signage

9. Fix transoms on top of the ledger tube and install

3 temporary boards as working platform.

9. 1 Worker falling/tools falling

9.1.1 Approved full body harness and hook-up 100%

Scaffolding Supervisor

9.1.2 Provide 3 temporary boards

9.1.3 Barricade the working area with warning signs

10. Provide spurs/bracing for tension and compression

using double coupler for stability.

10.1 Tools falling,use incorrect fittings

10.1.1 All scaffold tools must have sufficient

lanyard. Only double coupler must be use

Scaffolding Supervisor

10.2 Incorrect angle of bracing

10.1.2 Follow the ideal angle of bracing(45 degre)

11. Fully boarded the bridge scaffold lashed and secured.

12. Erect puncheons to support the handrails

11.1 Falling objects/Worker falling

11.1.1 Approved full body harness and hook-up 100%

11.2 Hand injury

11.1.2 Wear proper PPE especially gloves

12.1 Falling objects/Worker falling

12.1.1 Approved full body harness and hook-up 100%

Scaffolding Supervisor

Scaffolding Supervisor

12.1.2 Barricade the working area with warning signs

12.1.3 Erect 1.5 meter tube fixed to the end of

the needles using double couplers,to support

the handrails tube.Install the toe boards and

fix to the puncheon tube using single couplers.

13.Provide safe access/egress to the working platforms

tied to the structure

13.1 Workers falling,Slips and Trip

13.1.1 Approved full body harness hook-up 100%

13.1.2 Barricade the working area with warning signs

13.1.3 Access ladder at the right angle 4 meters

to 1 metre,secured at least twice,and 1 meter

above the working platform

2 of 3

Scaffolding Supervisor

METHOD STATEMENT FOR BRIDGE SCAFFOLD

BIBIYANA EXPANSION PROJECT

SEQUENCE OF BASIC ACTIVITY

POTENTIAL HAZARDS

HAZARD CONTROLS

RESPONSIBLE PERSON

14. Bridge Scaffold

14.1 Scaffold not to specification

14.1.1 Red tag, repair the scaffold then fit a green

tag on access ladder,entered in the scaffold

register,inspected every seven days.

Scaffolding Supervisor

15. Modification of bridge scaffold

15.1 Incorrect method by non scaffolders

15.1.1 Modifications carried out by competent

scaffolders.

Scaffolding Supervisor

15.2 Falling workers/materials

Scaffolding Inspector

15.1.2 Notify scaffold inspector of all the changes

of scaffold due to modification

Qualified Scaffolder

15.1.3 Show red tag when carrying out

modification works.

15.1.4 Approved full body harness hook-up 100%

15.1.5 Barricade the working area with warning signs

16. Once the scaffold operatives are satisfied that the scaffold is

safe they will commence dismantling the scaffold in an organised

manner,lift by lift from top to bottom and materials will be passed to

the ground in a safe manner and loaded on to the vehicle ready for

removal on site.

16.1 Slip,Trips and Falls

16.1.1 Wear proper PPE especially hand gloves

Scaffolding Supervisor

16.1.2 Approved full body harness and hook-up 100%

16.1.3 Barricade the area with warning signs

16.2 Incorrect sequence of dismantling