Professional Documents

Culture Documents

12

Uploaded by

solidworm0 ratings0% found this document useful (0 votes)

1 views1 page12

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document12

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1 views1 page12

Uploaded by

solidworm12

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

in WON-Ce-B-SiC (unused, thermal spray

coating vate

for Incr alloying 6

lubricant indicators ad range of sensitivities. 301

Spt orleans sect 800

Segregation and solid frtion|

Spectrometric metals analysis. 00

oron-alursinum composites, guid impingemeat

"rosion protection applications 322

Boron carbide

Yor ex brcated bearings. 532

friction cctiien data 2

‘Vickers and Knoop mcroindetation havdness

‘numbers 16

Boron nitride (BN), fr inser cladding 08

Boron oxide (8.04), direct evsporation ©... 84

Boron phosphide, protective coating against

“guid impingement erosion an

Bottomend bearing. See Big-end bearing

Boundary additives, or metalworking

Tubriants Osi, 142, 143

Boundary lubricani, defined a

Boundary lubrication. See also

Elaiohyrodynamic lubrication

[Eqteme pressure lubrication: Thin-flm

Inbricaton 80, 99,94, 96

cemically eased sae is 36

hemisorption 3

‘chines :

Bhysisoepion %6

‘alve tin assembly of intemal combustion

engine 538

Bowden-Tabor model, fcion coctiien 46

Bradelloy (Hastelloy X honeycomb +

‘Drazelaicel aluminum), abradable seat

material 89

Bragg angle “8 68

Bragy diffraction 388

a 8 to

36

rag ik as

Brake asperiy “fash iemperaiares 570

Brake effectiveness Si 316

[Brake heatsink 5

Brake ie ee

Brake ining 309

lemtr, defined 4

Bess

bearing material systems 748, 147

cage material for oling-slemeat earings 503,

‘contact bridge when sliding on son carbide

surface 236

ceting tool material seicton based on machining

operations ol

damage dominaied by Shar frie 19

fersivealack of telt on die surface 630, 631

foe shallow forming des 633

Taser clad or

ras, 0Cuaz

Tahesive wear versus too tel 27288

fiction cocfficen dats cit

Brass, 70Cw-302, thermal properties a

‘Bras alloys, lubrication for foo teks ie

Brayeoat 8182 polymer 156

Breakaway torque, See Sarng torque

‘realcin® coatings 15

Brehmsstrahlung radiation 46

Brehmsstralung xrays ams

‘Bri, tcton coethicint dita 78

‘Bright stock, defined 4

Brinell hardness number (iB). 4

‘Briel hardness test, defined 4

Brineling. See alto Fale Benclng.

‘defined 4

nell pressure ‘6

ite surface fracture 1

Bronze

‘bearing material systems 146

applications od

Bearing peeformance characiosies 1746

fad eapeity rating 386

‘onde to aluminum slcontin ot

‘minumsicon lead alloys ms

‘age material for rolling element bearings 503,

easing armcesses 754,788

fisher material 530

fardlacing alloys 738,768

later cladding

Teadedgallingvesitaace wih Varios miei

combinations 596

low-end. bearing mia

microstructures 743, 744

porous

sliding bearings st6

sling bearmgs tht are scat Backed and

“impregnated wit PIFE and lead". .S16

sling earings with graphite impregnation S16

seal adhesive wear 54)

sing zing din sal ice mas S16

Spray material for oxyfel wire spay process 429

thermal properties (793-238) 2

Bronze, commercial, bearing maierial

‘stems "45, 786, 747

applications a6

bearing pecformance characiessics Tie

Toad capuiyvaing 48

Beonze-graphite, bearing mata yates 786-009

osion tt reals 200

erosion test ess 300

I erosion test esl 300,

erosion text els 00

BBE-24, erosion test els 300

Bubbly ol detinea q

Balers in noncngin brian fornlaions iit

Bal

shason reste 139

plications 358

compositions 338

impasse 735

ones 338

Ialicwp edge (HUB). Se aso Wie

‘ormation ‘510,613, 617

defined 4

prow behavior during potsing 98

Bulge test a2

Bulk modules

Tsearope secant 7

othermal secant %

Bulk temperature 39, 40,41

ren 39, 540

Smbois an is BY

Bulk volumetric temperature a

Bamp fol strip 33

Burgers vector 388, 68

Burning, Se aio Metairecal bur

ined 4

Burnlsh, defined a

Burrishing surface modification technique 8

Bush bearing, dened i

Butt joint test 408

c

Cada

son to aluminun-tase bearing alloys. ..752

compatibility in bearing materials ms

fnction cette dats

plang for ool sels iM

ekets and Koop mictoindctaion harness

‘ners ls

‘Cadmitm Muoride, aed to Siicone vapor to

contol dusting 88

(Cadmium oxide graphite, lye aie old

Tubeat us

Cadmiumplated aioy, galing 1s

Cages See eso Separator. 88, 303

‘ined 4

acnals 03

Caleined magpesiuim sltcate, abeasive ta

commercial prophylactic paste 66, 668

Eaters 33

Thrsantindiewtors and range of sensitivities, 30

Spectrometne metals analysis 30

ted to make detergents 00

Calcium aluminate, carburivng affected by

omtnt in soc 875

Index / 903

Calcium carbonate

denice rave 65, 668

Miler numbers, as

Calcium complex soap 136, 123

CGilelom Horde

Intricate behavior fr thermoplastic

‘composts 823

rolling element bearing isbeisant 138

thermogravimetrc analysis 2

Calcium 2shydroxystearate 19

Calcium pyrophosphate, denice abrasive | 688

(Calc sap" 126, 129

(Calcium sulfate, denice abrasive 6s

(Calcium sulfate dihydrate (gypsum) 235,433,

‘ie material for demure tot 85

Properties 66

Calcium sulfonate iy

Camber angle si

8

3

Capacity number (C), dtined 4

Capiiay condensation “iio

Capture efficiency. See Colleton eflicency

Carbide

Shrasive wear materials 89

foating fining 31

wang thickness imitations B31

txtenston of fol le, sit fon implantation

‘xamples 3

mets used for syhesis 02

plasma-assisted physical vapor deposi

process. 888

spray materia for oxyfuel powder spray

‘method 330

arenas ion sppicaion, 0 ng.

materials

Carbotras D, erosion ist rest. 20

Carbon

‘CDI. properties 549, 551

‘oating for SEM specimen. 300

‘compatiblity wath sce! 7a

‘Sodeposted with chromium electroplating 839

‘difusion cocficen m nirocarburzing 78

for ler alloying st

impregnation effects on fica graphite bse

‘hater 817

in bearing sees D5

In coblthase trough alos 56, 78

in hardacing alloys 58, 760, 761

7, 703, 754

in saintess sels 710, HENS. 16

In thermal spray coaing mails 2

In toolsets 784, 735-796, 137, 738, 139

ion implantation of titanium alloys... 779, 780

Miler numbers Bs

properties an

Eegezation and solid ftion 28

‘Vickers and Kncop mietoindniation haidness

‘unis, Ai6

Carbon and alloy tees, friction and

‘wear of 702-108

carbon conic 707

‘omeaton to relative wear content 707

heavaffected zoae (HAZ) 707

depth of hardened regions 06

‘elon of hardness Yo microstiture 707708

feel neallgy 70008

microstructures. 5302-708, 905

[opetiesinflucnced by ncrovirctre «704

steel eiecton based on relative cont td

Stel transfoomation diagram 704-105

toughness. “05-107

‘wear properties of carbon seat 705-706

‘Comosion resistance improved by alicing

rmicosrutue 706

hardness 8 function of eatbon content -— 70S

Impeoving wear peopertios of sald sels 708

CCarbor-carbon composites

{or brake lninse 570

for carbon srrat brakes. sa

in icra brakes 5H

CCarbor-earbon deposits, manufacturing

tmatbods 816, 817

Carbon-earbon friction materials, fr earbow

‘aera brakes 584

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 07 Centre DistanceDocument1 page07 Centre DistancesolidwormNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 06 Helix AngleDocument1 page06 Helix AnglesolidwormNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 08 Face WidthDocument1 page08 Face WidthsolidwormNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- 11.8.2.3 Opening The Calculation File: 11 I-235 3D InterfacesDocument14 pages11.8.2.3 Opening The Calculation File: 11 I-235 3D InterfacessolidwormNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Recommended: 72 Chapter 8: Performing Sample Case LessonsDocument1 pageRecommended: 72 Chapter 8: Performing Sample Case LessonssolidwormNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

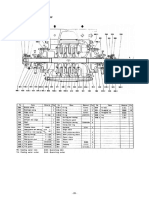

- Sectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NDocument1 pageSectional Drawings and Lists of Components: Size MMK 40, 50, 65 Stuffing Box Housing: Type NsolidwormNo ratings yet

- Cadtranslator™ User Guide: Translating The Max 5 Case 55Document1 pageCadtranslator™ User Guide: Translating The Max 5 Case 55solidwormNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Changing Edge Direction: To View The Sense of An EdgeDocument1 pageChanging Edge Direction: To View The Sense of An EdgesolidwormNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Size MMK 40, 50, 65 Tuffing Box Housing: Type HW SDocument1 pageSize MMK 40, 50, 65 Tuffing Box Housing: Type HW SsolidwormNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 04 Normal ModuleDocument1 page04 Normal ModulesolidwormNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 66 Chapter 8: Performing Sample Case LessonsDocument1 page66 Chapter 8: Performing Sample Case LessonssolidwormNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- To Set Axis of Revolution, Flow Direction, and View Rotation LinesDocument1 pageTo Set Axis of Revolution, Flow Direction, and View Rotation LinessolidwormNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- S Pare PartsDocument1 pageS Pare PartssolidwormNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- And Liquid Viscosity: Stress ZDocument1 pageAnd Liquid Viscosity: Stress ZsolidwormNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- 4.2.3. Re-Assembly of Pumps With End Suction NozzleDocument2 pages4.2.3. Re-Assembly of Pumps With End Suction NozzlesolidwormNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Fluid Statics: Manometers and Pressure MeasurementsDocument1 pageFluid Statics: Manometers and Pressure MeasurementssolidwormNo ratings yet

- Essentials of Turbo Machinery in CFD: Ideen SadrehaghighiDocument9 pagesEssentials of Turbo Machinery in CFD: Ideen SadrehaghighisolidwormNo ratings yet

- Stub shaft details and packing requirementsDocument1 pageStub shaft details and packing requirementssolidwormNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 6Document7 pages6solidwormNo ratings yet

- Bhabani P.Mohanty Fluid Engineering DevelopmentDocument1 pageBhabani P.Mohanty Fluid Engineering DevelopmentsolidwormNo ratings yet

- Fluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressureDocument1 pageFluid Properties: Density, Specific Volume, Specific Weight, Specific Gravity, and PressuresolidwormNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1Document7 pages1solidwormNo ratings yet

- VibrationDocument2 pagesVibrationsolidwormNo ratings yet

- Fluids 5: Buoyancy and Continuity EquationDocument1 pageFluids 5: Buoyancy and Continuity EquationsolidwormNo ratings yet

- 5Document7 pages5solidwormNo ratings yet

- 2Document7 pages2solidwormNo ratings yet

- 3Document7 pages3solidwormNo ratings yet

- Personal Computer) : Includes: Drop Box, The Cloud, and Any Other Site Off of Your Personal Computer)Document6 pagesPersonal Computer) : Includes: Drop Box, The Cloud, and Any Other Site Off of Your Personal Computer)IAmDanaNo ratings yet

- General Requirements:: 1062 16 Pump TestingDocument1 pageGeneral Requirements:: 1062 16 Pump TestingsolidwormNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Test loop configurationsDocument1 pageTest loop configurationssolidwormNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)