Professional Documents

Culture Documents

Excel PV 2016 Report

Uploaded by

mishikhanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Excel PV 2016 Report

Uploaded by

mishikhanCopyright:

Available Formats

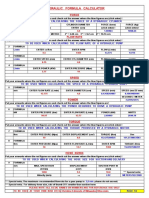

ASME Section VIII, Division 1, 2015 Edition

Excel Design Softwares

Excel PV 2016

Excel Design Softwares

Purchaser:

Tag Number:

Designer:

Excel Design Softwares

0

Irfan Shaikh

Vessel Name:

Mark Number:

Date Printed:

40" ID Sample Tank

S1

17/11/2015

Cylindrical Shell Design Information

Design Pressure:

Static Head:

Shell Material:

480.000

4.329

SA 516 Gr.70

psi

psi

Shell Length:

Inside Diameter:

Inner Corrosion Allowance:

Outer Corrosion Allowance:

Circ. Joint Efficiency:

120.0000

40.0000

0.0300

0.0000

70

in.

in.

in.

in.

%

Shell Surface Area:

106.03

ft

Design Temperature:

250

F

Long. Joint Efficiency:

70

%

Sec:IID,Tab:1A(pg18,ln8(2013)), (pg14,ln28(2011)), (pg 14,ln28 (2010))

Stress at Design temperature:

Stress at 70 F temperature:

Extreme Fiber Elongation:

Minimum Thickness :

20000

20000

1.84

0.12375

psi

psi

%

in.

Shell Estimated Volume:

ShellEstimated Weight:

652.80

3226.10

US Gal.

lb

Cylindrical Shell Design Calculations

Required Thickness at 250 F:

tc(a) = P * R / (S * E - 0.6 * P)

tc(a) = 484.3 * 20.03 / ( 20000 * 0.7 - 0.6 * 484.3 ) =

{Paragraph UG-27(c)(1)}

0.7076

in.

tc(b) = P * R / (2 * S * E + 0.4 * P)

tc(b) = 484.3 * 20.03 / ( 2 * 20000 * 0.7 + 0.4 * 484.3 ) =

tr = Max (tc(a), tc(b), tm) + CA + CA + PA

{Paragraph UG-27(c)(2)}

0.3441

in.

tr = Max (0.7076, 0.3441, 0.1238) + 0.03 + 0 + 0 =

Maximum Allowable Working Pressure, Corroded at 250 F:

Pc(a) = S * E * t / (R + 0.6 * t)

Pc(a) = 20000 * 0.7 * 0.72 / ( 20.03 + 0.6 * 0.72 ) =

{Paragraph UG-27(c)(2)}

1021.173

psi

MAWP = Min (492.6205, 1021.1731) - 4.3287 =

Maximum Allowable Pressure, New at 70 F:

Pc = S * E * t / (R + 0.6 * t)

Pc = 20000 * 0.7 * 0.75 / ( 20 + 0.6 * 0.75 ) =

in.

{Paragraph UG-27(c)(1)}

492.620

psi

Pc(b) = 2 * S * E * t / (R - 0.4 * t)

Pc(b) = 2 * 20000 * 0.7 * 0.72 / ( 20.03 - 0.4 * 0.72 ) =

MAWP = Min (Pc(a), Pc(b)) - Ps

0.7376

488.292

psi

{Paragraph UG-27(c)(1)}

MAP = Pc - Ps

MAP = 513.4474 - 0 =

Extreme Fiber Elongation:

EFE = 50 * (t / Rf) * (1 - Rf / Ro)

EFE = 50 * (0.75 / 20.375 ) * ( 1 - 20.375 / ) =

The extreme fiber elongation does not exceed 5%.

Nominal Shell Thickness Selected = 0.75 in.

513.447

psi

{Paragraphs UG-79}

1.84

ASME Section VIII, Division 1, 2015 Edition

Excel Design Softwares

Excel PV 2016

Excel Design Softwares

Purchaser:

Tag Number:

Designer:

Excel Design Softwares

0

Irfan Shaikh

Vessel Name:

Mark Number:

Date Printed:

40" ID Sample Tank

H1

17/11/2015

Top Head Design Information

Design Pressure:

Static Head:

Head Material:

480.000

0.000

SA 516 Gr.70

psi

psi

Dish Type:

Inside Diameter:

Elliptical

40.0000

in.

Inner Corrosion Allowance:

Outer Corrosion Allowance:

Thinning Allowance:

Polishing Allowance:

0.0300

0.0000

0.0300

0.0000

in.

in.

in.

in.

Design Temperature:

250

F

Joint Efficiency:

100

%

Sec:IID,Tab:1A(pg18,ln8(2013)), (pg14,ln28(2011)), (pg 14,ln28 (2010))

Stress at Design temperature:

20000

psi

20000

Stress at 70 F temperature:

psi

Minimum Thickness :

0.12375

in.

Extreme Fiber Elongation:

6.79

%

Head Depth (h):

10.0000

in.

K Factor=(1/6)*(2+(D/(2*h))):

1.0000

K Factor(corroded):

0.9960

Skirt/Straight Flange Length:

2.00

in.

Head Design Calculations

Required Thickness at 250 F:

tc() = P * D * K / (2 * S * E - 0.2 * P)

tc() = 480 * 40.06 * 0.996 / ( 2 * 20000 * 1 - 0.2 * 480 ) =

tr = Max (tc, tm) + CA + CA + TA + PA

tr = Max (0.48, 0.1238) + 0.03 + 0 + 0.03 + 0 =

{Appendix 1-4(c)}

Maximum Allowable Working Pressure, Corroded at 250 F:

Pc() = 2 * S * E * t / (K * D + 0.2 * t)

Pc() = 2 * 20000 * 1 * 0.565 / ( 0.996 * 40.06 + 0.2 * 0.565) =

MAWP = Pc - Ps

{Appendix 1-4(c)}

Maximum Allowable Pressure, New at 70 F:

Pc() = 2 * S * E * t / (K * D + 0.2 * t)

Pc() = 2 * 20000 * 1 * 0.595 / ( 1 * 40 + 0.2 * 0.595) =

MAWP = 564.8097 - 0 =

0.4800

0.5400

564.810

564.810

in.

in.

psi

psi

{Appendix 1-4(c)}

MAP = Pc - Ps

MAP = 593.2351 - 0 =

593.235

psi

Extreme Fiber Elongation:

{Paragraphs UG-79}

EFE = 75 * (tn / Rf) * (1 - Rf / Ro)

EFE = 75 * (0.625 / 6.9063 ) * ( 1 - 6.9063 / ) =

6.79

%

The EFE exceeds 5 % and the thickness exceeds 5/8 inch. Heat treatment per UCS-56 is required if fabricated by cold forming.

Straight Flange Required Thickness:

{Paragraph UG-27(c)(1)}

tc(s) = P * R / (S * E - 0.6 * P)

tc(s) = 480 * 20.03 / ( 20000 * 1 - 0.6 * 480 ) =

0.4922

in.

tr(s) = tc + CA + CA + TA + PA

tr(s) = 0.4922 + 0.03 + 0 + 0.03 + 0 =

0.5522

in.

Straight Flange Maximum Allowable Working Pressure:

{Paragraph UG-27(c)(1)}

Pc(s) = S * E * t / (R + 0.6 * t)

Pc(s) = 20000 * 1 * 0.565 / ( 20.03 + 0.6 * 0.565 ) =

554.765

psi

MAWP(s) = Pc - Ps

MAWP(s) = 554.7646 - 0 =

554.765

psi

Nominal Head Thickness Selected = 0.625 in.

Minimum Thickness after forming, ts (uncorroded) = 0.595 in.

ASME Section VIII, Division 1, 2015 Edition

Excel Design Softwares

Excel PV 2016

Excel Design Softwares

Purchaser:

Tag Number:

Designer:

Excel Design Softwares

0

Irfan Shaikh

Vessel Name:

Mark Number:

Date Printed:

40" ID Sample Tank

H2

17/11/2015

Bottom Head Design Information

Design Pressure:

Static Head:

Head Material:

480.000

4.329

SA 516 Gr.70

psi

psi

Dish Type:

Inside Diameter:

Elliptical

40.0600

in.

Inner Corrosion Allowance:

Outer Corrosion Allowance:

Thinning Allowance:

Polishing Allowance:

0.0300

0.0000

0.0300

0.0000

in.

in.

in.

in.

Design Temperature:

250

F

Joint Efficiency:

100

%

Sec:IID,Tab:1A(pg18,ln8(2013)), (pg14,ln28(2011)), (pg 14,ln28 (2010))

Stress at Design temperature:

20000

psi

20000

Stress at 70 F temperature:

psi

Minimum Thickness :

0.12375

in.

Extreme Fiber Elongation:

7

in.

Head Depth (h):

10.0000

in.

K Factor=(1/6)*(2+(D/(2*h))):

1.0000

K Factor(corroded):

0.9960

Skirt/Straight Flange Length:

2.00

in.

Head Design Calculations

Required Thickness at 250 F:

tc() = P * D * K / (2 * S * E - 0.2 * P)

tc() = 484.3287 * 40.06 * 0.996 / ( 2 * 20000 * 1 - 0.2 * 484.3287 ) =

tr = Max (tc, tm) + CA + CA + TA + PA

tr = Max (0.4843, 0.1238) + 0.03 + 0 + 0.03 + 0 =

{Appendix 1-4(c)}

Maximum Allowable Working Pressure, Corroded at 250 F:

Pc() = 2 * S * E * t / (K * D + 0.2 * t)

Pc() = 2 * 20000 * 1 * 0.565 / ( 0.996 * 40.06 + 0.2 * 0.565) =

MAWP = Pc - Ps

{Appendix 1-4(c)}

Maximum Allowable Pressure, New at 70 F:

Pc() = 2 * S * E * t / (K * D + 0.2 * t)

Pc() = 2 * 20000 * 1 * 0.595 / ( 1 * 40 + 0.2 * 0.595) =

MAWP = 564.8097 - 4.3287 =

0.4843

0.5443

564.810

560.481

in.

in.

psi

psi

{Appendix 1-4(c)}

MAP = Pc - Ps

MAP = 593.2351 - 0 =

593.235

psi

Extreme Fiber Elongation

{Paragraphs UG-79}

EFE = 75 * (tn / Rf) * (1 - Rf / Ro)

EFE = 75 * (0.625 / 6.6938 ) * ( 1 - 6.6938 / ) =

7.00

%

The EFE exceeds 5 % and the thickness exceeds 5/8 inch. Heat treatment per UCS-56 is required if fabricated by cold forming.

Straight Flange Required Thickness:

{Paragraph UG-27(c)(1)}

tc(s) = P * R / (S * E - 0.6 * P)

tc(s) = 484.3 * 20.03 / ( 20000 * 1 - 0.6 * 484.3 ) =

0.4922

in.

td(s) = tc + CA + CA + TA + PA

tr(s) = 0.4922 + 0.03 + 0 + 0.03 + 0 =

0.5522

in.

Straight Flange Maximum Allowable Working Pressure:

{Paragraph UG-27(c)(1)}

Pc(s) = S * E * t / (R + 0.6 * t)

Pc(s) = 20000 * 1 * 0.565 / ( 20.03 + 0.6 * 0.565 ) =

554.765

psi

MAWP(s) = Pc - Ps

MAWP(s) = 554.7646 - 0 =

550.436

psi

Nominal Head Thickness Selected = 0.625 in.

Minimum Thickness after forming, ts (uncorroded) = 0.595 in.

You might also like

- Asme b31g Calculation Eml-4Document3 pagesAsme b31g Calculation Eml-4GRANRICKY100% (4)

- Spe 99668 MSDocument14 pagesSpe 99668 MSCamilo Andrés GuerreroNo ratings yet

- Marcet Boiler Lab ReportDocument12 pagesMarcet Boiler Lab ReportShameerSamsuriNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- PR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationDocument112 pagesPR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationmishikhanNo ratings yet

- PR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationDocument112 pagesPR-1708 - Lifting and Hoisting Procedure Part 1 Framework, Part 2 Inspection, Testing and CertificationmishikhanNo ratings yet

- PV Elite Vessel Analysis Program: Input DataDocument9 pagesPV Elite Vessel Analysis Program: Input DataAhmed Ammar YasserNo ratings yet

- Engineering Example CalculationDocument78 pagesEngineering Example Calculationkae kaeNo ratings yet

- Acum#2 RoladoDocument1 pageAcum#2 RoladoJuan PabloNo ratings yet

- PV EliteDocument6 pagesPV ElitevikrantgulhaneNo ratings yet

- Sample3 APVDocument40 pagesSample3 APVlaleye_olumideNo ratings yet

- Element ThicknessDocument10 pagesElement ThicknesskhairulakbarNo ratings yet

- Torisperical - Element ThicknessDocument6 pagesTorisperical - Element ThicknessVipul GandhiNo ratings yet

- Asme Viii CalcsDocument20 pagesAsme Viii CalcsSriram VjNo ratings yet

- PV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Document8 pagesPV Elite 2013 Sp3 Licensee: Isgec Filename: Pe-1668 75 - Hydro Asme Ts Calc: Case: 1 12:08P Apr 2,2014Mayank MittalNo ratings yet

- Makkah PSM2 Suction SideDocument4 pagesMakkah PSM2 Suction Sideniyamat89No ratings yet

- Base Ring and SkirtDocument8 pagesBase Ring and Skirtduazo2009No ratings yet

- Blind Flange (10 Bar)Document7 pagesBlind Flange (10 Bar)SyedZainAliNo ratings yet

- Pressure Vessel Engineering LTD.: Design ConditionsDocument30 pagesPressure Vessel Engineering LTD.: Design ConditionsTrishul Nath PallayNo ratings yet

- Torispherical HeadDocument5 pagesTorispherical HeadLiaquat AliNo ratings yet

- Cone Design Tool: Pressure Vessel Engineering LTDDocument1 pageCone Design Tool: Pressure Vessel Engineering LTDkedubhajjiNo ratings yet

- External Pressure CalculationsDocument40 pagesExternal Pressure Calculationsmisterdavi50% (2)

- PV Elite 2016 Licensee: SPLM Licensed User Filename: Flare K-41582 Basering Calculations: Step: 16 4:35Pm Jan 6,2020Document6 pagesPV Elite 2016 Licensee: SPLM Licensed User Filename: Flare K-41582 Basering Calculations: Step: 16 4:35Pm Jan 6,2020DarioNo ratings yet

- Sample4 SpreadsheetDocument21 pagesSample4 SpreadsheetTrishul Nath Pallay100% (1)

- API 650 OutputDocument88 pagesAPI 650 Outputaby_abraham50050% (1)

- Document Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking PlantDocument49 pagesDocument Frontsheet: Project: 3930 - 9 - Olefin Complex Ethane Cracking Plantsusa2536No ratings yet

- Grid Earthing For EHV Switchyards As Per IEEE-80Document3 pagesGrid Earthing For EHV Switchyards As Per IEEE-80kapilNo ratings yet

- Design Calculations For V2703 Rev 0Document9 pagesDesign Calculations For V2703 Rev 0Dilip KatekarNo ratings yet

- FIRE WATER TANK-API-650-Calculation-Report - RVDDocument42 pagesFIRE WATER TANK-API-650-Calculation-Report - RVDahmed aboyosefNo ratings yet

- Rectangular TankDocument38 pagesRectangular TankSam LowNo ratings yet

- Company Name: Input DataDocument4 pagesCompany Name: Input Dataagb71c2478No ratings yet

- Asme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoDocument72 pagesAsme Seccion Viii Div. 1 Ed 2015 Calculos MecanicoSivateja NallamothuNo ratings yet

- Calculation Validation ReportDocument18 pagesCalculation Validation Reportvijay10484No ratings yet

- PV 1390 Cal R1Document44 pagesPV 1390 Cal R1namasralNo ratings yet

- Internal CoilDocument2 pagesInternal CoilwhngomjNo ratings yet

- UG-37 F FactorDocument7 pagesUG-37 F FactorjamesNo ratings yet

- Super CalculationsDocument9 pagesSuper CalculationsNoé MarínNo ratings yet

- 300 - F&D Head Design Tool Ver E4.01Document1 page300 - F&D Head Design Tool Ver E4.01Honey TiwariNo ratings yet

- 620Document33 pages620ccricaNo ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Verifica Giunto Secondo AsmeDocument5 pagesVerifica Giunto Secondo AsmeFabio TemporiniNo ratings yet

- Strength Calculation ARTDocument34 pagesStrength Calculation ARTdenstar silalahiNo ratings yet

- ASME 31 - 8mDocument1 pageASME 31 - 8mMarcoAlbaNo ratings yet

- External Pressure Calculation Results: ASME Code, Section VIII, Division 1, 2013 Elliptical Head From 10 To 20 Ext. Chart: CS-2 at 35 °CDocument3 pagesExternal Pressure Calculation Results: ASME Code, Section VIII, Division 1, 2013 Elliptical Head From 10 To 20 Ext. Chart: CS-2 at 35 °CSekson JunsukplukNo ratings yet

- Material Properties: WARNINGDocument2 pagesMaterial Properties: WARNINGtarekNo ratings yet

- Tor. Dish EndDocument4 pagesTor. Dish EndSiva ShankarNo ratings yet

- Lug Support DesignDocument3 pagesLug Support DesignSajal KulshresthaNo ratings yet

- Copiar de Nozzle - Design - ToolDocument2 pagesCopiar de Nozzle - Design - ToollavascudoNo ratings yet

- ASME 31 - 4 CalcDocument1 pageASME 31 - 4 CalcMarcoAlbaNo ratings yet

- Cylinder #1 ASME Section VIII Division 1, 2001 Edition: S S TV SDocument10 pagesCylinder #1 ASME Section VIII Division 1, 2001 Edition: S S TV Sevrim77No ratings yet

- Digital Signal Processing Using the ARM Cortex M4From EverandDigital Signal Processing Using the ARM Cortex M4Rating: 1 out of 5 stars1/5 (1)

- Advanced Chipless RFID: MIMO-Based Imaging at 60 GHz - ML DetectionFrom EverandAdvanced Chipless RFID: MIMO-Based Imaging at 60 GHz - ML DetectionNo ratings yet

- British Commercial Computer Digest: Pergamon Computer Data SeriesFrom EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Digital Signal Processing: Instant AccessFrom EverandDigital Signal Processing: Instant AccessRating: 3.5 out of 5 stars3.5/5 (2)

- Radio Frequency Identification and Sensors: From RFID to Chipless RFIDFrom EverandRadio Frequency Identification and Sensors: From RFID to Chipless RFIDNo ratings yet

- Autocad Plant3d Quick Reference GuideDocument2 pagesAutocad Plant3d Quick Reference GuideHanna Obeid100% (1)

- Advances in Steel StructuresDocument20 pagesAdvances in Steel StructuresmishikhanNo ratings yet

- OSHA Periodic InspectionsDocument2 pagesOSHA Periodic InspectionsmishikhanNo ratings yet

- De-Mystifying AutoCAD Plant 3D IsometricsDocument71 pagesDe-Mystifying AutoCAD Plant 3D IsometricsJorge Andrés PovedaNo ratings yet

- 0039 - Cable and Membrane: DescriptionDocument4 pages0039 - Cable and Membrane: DescriptionmishikhanNo ratings yet

- Wire RopeDocument28 pagesWire Roperao1962No ratings yet

- Radiation ShieldingDocument28 pagesRadiation ShieldingJayath BogahawatteNo ratings yet

- Experimental and CFD Analyses of Two Bladed Savonius Water TurbineDocument10 pagesExperimental and CFD Analyses of Two Bladed Savonius Water TurbinemishikhanNo ratings yet

- Useful Piping & Structural DataDocument172 pagesUseful Piping & Structural Datahailay83No ratings yet

- Crane Loads N Wharf StructureDocument77 pagesCrane Loads N Wharf StructureMichael Dixon100% (1)

- Os-E304 Rope Info PDFDocument30 pagesOs-E304 Rope Info PDFMikeNo ratings yet

- Design Considerations in Cable-Stayed Roof StructuresDocument7 pagesDesign Considerations in Cable-Stayed Roof StructuresSunil PulikkalNo ratings yet

- Crane Loads N Wharf StructureDocument77 pagesCrane Loads N Wharf StructureMichael Dixon100% (1)

- SKF Thrust BearingsDocument20 pagesSKF Thrust BearingsBùi Văn HợpNo ratings yet

- Pump System Analysis and Centrifugal Pump SizingDocument158 pagesPump System Analysis and Centrifugal Pump Sizingme24370100% (4)

- Adia No-Load TestingDocument7 pagesAdia No-Load TestingjillianixNo ratings yet

- Practical Design Stepped ColumnsDocument12 pagesPractical Design Stepped ColumnstaosyeNo ratings yet

- Basic Mechanical Engineering MCQ PDF Part 1Document7 pagesBasic Mechanical Engineering MCQ PDF Part 1mishikhan100% (4)

- Steel Pipes and Maximum Water Flow CapacityDocument1 pageSteel Pipes and Maximum Water Flow CapacitymishikhanNo ratings yet

- CFP Fluidpower CalculatorDocument13 pagesCFP Fluidpower CalculatormishikhanNo ratings yet

- Copia de Hirsch-Hydraulic-CalculatorDocument1 pageCopia de Hirsch-Hydraulic-Calculatormtbecerrap0% (1)

- ACI Moment Coefficient Design AID PDFDocument13 pagesACI Moment Coefficient Design AID PDFSufian Ahmad50% (4)

- FLRPLATEDocument3 pagesFLRPLATEcravikumar1971No ratings yet

- ASME B31.11 Slurry Transportation Piping Systems CodeDocument2 pagesASME B31.11 Slurry Transportation Piping Systems CodeKevin McGrathNo ratings yet

- Pipe Wall Thickness (ASME B31.3)Document12 pagesPipe Wall Thickness (ASME B31.3)Rachmad HidayatNo ratings yet

- CMAA 70 2000 Structure DesignDocument19 pagesCMAA 70 2000 Structure DesignmishikhanNo ratings yet

- Vba To Remove Password From Excel WorksheetDocument1 pageVba To Remove Password From Excel WorksheetmishikhanNo ratings yet

- Compusoft, 2 (9), 275-284 PDFDocument10 pagesCompusoft, 2 (9), 275-284 PDFIjact EditorNo ratings yet

- Nitrofuran Metabolit by Lcmsms (Just MSMS Method)Document4 pagesNitrofuran Metabolit by Lcmsms (Just MSMS Method)Ageng Wahyu PatrianitaNo ratings yet

- Concrete Pipes Reference ManualDocument65 pagesConcrete Pipes Reference ManualSixto Gerardo100% (1)

- 8 AdsorptionDocument85 pages8 AdsorptionRush WahabNo ratings yet

- Ecological Influence On Selected Aloe Vera Populations in Two Geographical Zones in NigeriaDocument6 pagesEcological Influence On Selected Aloe Vera Populations in Two Geographical Zones in Nigeriaibrahimflora7404No ratings yet

- Aiats-2022 (Cf+Oym) Test-03 Code-A&b Solutions 09.01.2022Document40 pagesAiats-2022 (Cf+Oym) Test-03 Code-A&b Solutions 09.01.2022Yatin PrakashNo ratings yet

- Transpiration ResourceDocument33 pagesTranspiration ResourceGgdhdgsg KdhahshhNo ratings yet

- 9 Health and SafetyDocument2 pages9 Health and SafetyHéctorNo ratings yet

- Chevron Rykon Hydraulic OilDocument7 pagesChevron Rykon Hydraulic OilAbu Saleh ImamNo ratings yet

- Stable Solid Deodorant Product Grape Fruit1Document15 pagesStable Solid Deodorant Product Grape Fruit1sabunbeningNo ratings yet

- Installation Dresser MeterDocument32 pagesInstallation Dresser MeterCoco GalindoNo ratings yet

- Bioreactor Components 2019Document16 pagesBioreactor Components 2019Sivakavi NesanNo ratings yet

- An 335 Natural ProductsDocument3 pagesAn 335 Natural ProductsTonnyLeiteNo ratings yet

- Molecular Laboratory Design QAQC ConsiderationsDocument46 pagesMolecular Laboratory Design QAQC Considerationspunit mauryaNo ratings yet

- Chapter 9Document42 pagesChapter 9Avnish GargNo ratings yet

- Calculation of Pipe Reinforcement ASME B31 3Document5 pagesCalculation of Pipe Reinforcement ASME B31 3Umar Aslam0% (1)

- Sample SOP For Glassware CleaningDocument2 pagesSample SOP For Glassware CleaningdanielmugaboNo ratings yet

- Polymers Unit IIIDocument33 pagesPolymers Unit IIIdinnu14No ratings yet

- Testing of Building Stones - Rock Tests On Lab & FieldDocument3 pagesTesting of Building Stones - Rock Tests On Lab & FieldআকাশআহসানNo ratings yet

- What Is Ozone LayerDocument6 pagesWhat Is Ozone LayerAymun AymiNo ratings yet

- Masterspec Copper SpecificationDocument10 pagesMasterspec Copper SpecificationNabil RamehNo ratings yet

- Spin Physics The Basics of NMRDocument8 pagesSpin Physics The Basics of NMR16_dev5038No ratings yet

- Vapro 5520 ManualDocument102 pagesVapro 5520 ManualmuckrakeringNo ratings yet

- Journal Type (Thesis)Document12 pagesJournal Type (Thesis)api-19649313No ratings yet

- E3877 Optics FormulasDocument6 pagesE3877 Optics FormulasKaran DoshiNo ratings yet

- Zaikov CVDocument3 pagesZaikov CVArif SantosoNo ratings yet

- AdrenochromeDocument8 pagesAdrenochromeFleur Martel83% (6)

- Lakhmir Singh Chemistry Class 9 Solutions Chapter 2Document34 pagesLakhmir Singh Chemistry Class 9 Solutions Chapter 2Devanshi DwivediNo ratings yet

- Chapter 5 - PV Systems - April 11 - 2011 PDFDocument586 pagesChapter 5 - PV Systems - April 11 - 2011 PDFEl ShaarawyNo ratings yet