Professional Documents

Culture Documents

Inspection Test Plan For Fabrication & Erection 2016

Uploaded by

Boj MingiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Test Plan For Fabrication & Erection 2016

Uploaded by

Boj MingiCopyright:

Available Formats

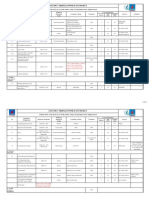

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

Abbreviations

PGCC

QP

AI

F.R Pad

TDC

Petrol and Gas Construction Company

Qatar Petroleum

Authorized Inspector

Reinforcement Pad

Technical Delivery Condition

Applicable Standards

API 650

ASTM A240 SS316

ASME Sec II, Part c

ASME Sec V

ASME Sec VIII, Div.1

ASME Sec IX

ASME B16.5

ASME Sec X

SNT-TC-1A

1.0

Design

1.1

Design review &

Design

Calculation

Tank Design Specification

SS Material Specification

Specification for Welding Rods, Electrodes and

Filler Metals

Non-Destructive Examination

Rules for Construction of Pressure Vessels

Qualification Standard for welding procedures

and welders

Standards of Pipes and Fittings

Fiber-Reinforced Plastic Pressure Vessels

Guidelines to NDT Personnel Qualification and

certification

Meeting all the

Requirements of

Clients P.O

Clients P.O

Data Sheet

Clients P.O Data

Sheet

PGCCs

Design

Calculation

Design Manager

/Design Engineer

QCP.REF.100.14

00

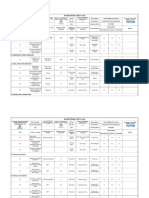

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

1.2

Preparation of

Engineering

drawing and

detail drawings.

2.0

Material Purchase

2.1

Material

Requisition

2.2

Purchase Order

3.0

Material Control

3.1

Material list of

PGCC procured

Materials (Shell

plates, bottom

QC PLAN FOR FABRICATION & ERECTION

Compliance with

design

conditions,

Client

Specification &

Data Sheet

Technical and

Quality

Requirements

as per

Contract/Drawin

gs

Purchasing Data

Complete

Material Size

identification,

test cert. as per

API 650

Reference No.:

Revision No.:

Date:

Clients P.O

Data Sheet

Clients P.O Data

Sheet

PGCC

Drawing

Design Manager

/Design Engineer

Drawing,

Technical

Delivery

Conditions(TD

C)

Matching

Drawing, Clients

spec & Technical

delivery

conditions.

Material

Requisition

Design Engineer,

Draftsman

Buying

enquiry and

offer from

vendor, client

approval

vendor list

Vendors offer

match with the

requirements,

Substitutions

offered are

approved by

TEPQ

Purchase

order

technical

Query

Requests

(in case of

substitution

s)

Purchaser,

Project Engineer

& Operation

Manager

Mill test

certificates,

Dimensiona

l inspection

Material

controller &

Material QC

Inspector

QCP.REF.100.14

00

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

plates, top

plates, pipes,

fittings, etc..)

3.2

Dished Heads

3.3

Material Storage

3.4

Material issue

3.5

Internal

Installation items

(,

3.6

Anodes

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

for pressure

part

report if

required &

NDT Report

(If

applicable)

Clearly

identified,

MCN, PO# and

Stored/

Segregated to

prevent

contamination

and damage

Issue against

authorization

only

Mill TC, Stores

Records

Identification

marking

traceability to

MTC

--

Material

Controller &

QCnspector

Material Issue

Slip

Issue against

authorization

only

Material

requisition

issue Slip

Material

Controller,

Supervisor

Project Engineer

Dimension, trial

assembly at

floor,

MTC Review

As per client PO

and da

Sub-vendors

drawing &

Doc#

Sub-Vendors

Drawing & Doc#

Subcontractors

inspection

reports

Sub-contractors

& Project

Engineer.

QCP.REF.100.14

00

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

4..0

Welding control

4.1

Welding

Procedure

Specification

(WPS)

4.2

Welder

Qualification

records (WPQR)

4.3

Weld Map

4.4

Welding

Consumables

5.0

NDE Testing

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

Covers full

range of

parameters,

processes and

meets CODE

requirements

Covers full

range of

parameters and

process to be

welded

Size ,Batch No

& Test

Certification. API

650 for S. steel

material

consumables;

and 3.1B for all

other material

consumables

WPS

Welding

Engineer

API 650, GS EP

Welder

Qualificatio

n

certificates

Welding

Engineer

PG/WC/001,AS

ME Sec. II part

C & GS EP PVV

611

Consumabl

e Batch

Certificates

Welding

Engineer

Meets

API 650

Drawing &

job specific

WPS

/Procedure

API 650

requirements

and job range

QCP.REF.100.14

00

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

5.1

NDE Testing

5.1.1

NDE Procedures

5.1.2

NDE Personal

Qualification

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

Covers full

range of

parameters and

processes and

meets CODE

requirements

Covers all

methods of NDE

applicable to

the degree of

competence

required

API 650 GS EP

PVV

Meets CODE

requirements and

covers job range

PGs Written

practice ASNT

Meets CODE

requirements and

covers job range

Covers Full

Range of

parameters

Meets API 650

requirements

and covers job

range

QC Manager/QC

Engineer

NDE

personnel

QC Manager/QC

Engineer

Qualificatio

n

Certificates

5.2

Procedures

5.2.1

QC Procedures

6.0

Manufacturing Of 4903F

6.1

Prefabrication

Activities(Sheet,

Nozzles and

Saddles)

Meets API 650

QC Manager/QC

Engineer

QCP.REF.100.14

00

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

QCP.REF.100.14

00

6.1.1

Identification,

marking, cutting

and weld

preparation of

shell plates.

As per drawing

dimensions

within

tolerances.

Drawing, API

650 (UW-31),

Drawing, API 650

&

Inspection

Request &

Material

Summary

sheet.

Supervisor & QC

Inspector

6.1.2

Fit up of shell

long seams along

with Production

Test Coupon (2

Coupons for each

WPS)

As per drawing

dimensions

within

tolerances.

API 650.

API 650

Inspection

report

Supervisor & QC

Inspector.

6.1.3

Mechanical test

on one two

Production Test

Coupon.

100% weld visual

And dimension

inspection on

Shell and

manhole long

seams joints.

Fit-up and

Welding WPS and

Qualified welders

As per concern

PQRs

mechanical

characteristics.

All relevant

drawing dim.

Concern WPS

& PQR.

API 650 & GS EP

PVV 211 Rev: 06

Lab Test

Report

Project Engineer

& QC Welding

Inspector

Drawing API

650, GS EP

PVV 611 Rev:

06 &

MG/NDE/VT/00

6

WPS, list of

qualified and

approved

Weld Map.

Drawing

API 650, GS EP

PVV 611 Rev: 06

&

MG/NDE/VT/)006

Inspection

Request

(Form no

MSF 012)

Supervisor & QC

Inspector

API 650 & GS EP

PVV 211 Rev: 06

Weld Visual

Request

(Form no

MSF 012)

Inspection

Request

(Form no

Supervisor & QC

Inspector

Supervisor & QC

Inspector

6.1.4

6.1.5

6.1.6

Flush Grinding of

Inside Welding

Penetration.

Welding per

WPS and

Qualified

welders.

Smooth

merging of

surface with

Drawing

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

QC PLAN FOR FABRICATION & ERECTION

shell surface.

6.1.7

10% RT on Shell

long seam joints.

Absence of

Internal defects.

6.1.8

100% RT on

Manhole long

seam joints.

Identification,

marking &

cutting and weld

preparation of

nozzle neck,

flange & fittings.

Absence of

Internal defects.

Manhole nozzle

and other Nozzle

neck with W.N

flange fit up (for

all nozzle)

Welding of

Manhole nozzle

and other nozzle

neck with flange.

6.1.1

0

6.1.1

1

6.1.1

2

Reference No.:

Revision No.:

Date:

QCP.REF.100.14

00

MSF 012)

PG/NDE/RT/00

4 API 650, GS

EP PVV 211

Rev: 06 & GS

EP PVV 611

Rev:06

PG/NDE/RT/00

API 650

API 650,

PG/NDE/RT/004,

GS EP PVV 211

Rev:06 & GS EP

PVV 611 Rev:06

RT Report

(Form No

MSF/014)

Level II

Inspector, QC

Inspector

API 650,

PG/NDE/RT/00

RT Report

As per drawing

dimensions

within

tolerances.

Drawing,

API

Drawing,

API 650

Inspection

Request &

Material

Summary

sheet

Level II

Inspector, QC

Inspector

Supervisor & QC

Inspector

As per drawing

dimensions

within

tolerances.

API 650

Drawing, API 650

Inspection

request

Supervisor & QC

Inspector

Welding per

WPS and

Qualified

welders.

WPS, list of

qualified

welders and

approved

Weld Map.

API 650

Weld Visual

Request

Supervisor & QC

Inspector

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

6.1.1

3

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

QCP.REF.100.14

00

100% visual

inspection on

Manhole nozzle

neck and other

Nozzle neck with

Flange welds.

Flush Grinding of

Inside Welding

Penetration

Absence of

defects & all

relevant

drawing dim.

Drawing API

650, &

PG/NDE/VT/00

Drawing API 650

& PG/NDE/VT/00

Inspection

Request

Supervisor & QC

Inspector

Smooth

merging of

surfaces

Drawing

Drawing

Inspection

Request

Supervisor & QC

Inspector

Absence of

Internal defects.

PG/NDE/RT/00,

API 650,

API 650,

PG/NDE/RT/00,

RT Report

Level II

Inspector, QC

Inspector

6.2.1

6

10% RT on

Nozzle with

flange for above

NPS 10 on

circular seam

joints.

Closing Seam Fit

Up

Drawing, API

650

Drawing, API 650

Inspection

Report

Supervisor & QC

Inspector

6.2.1

7

Welding &

Closing Seam

As per drawing

dimensions

within

tolerances

Welding per

WPS and

Qualified

Welders

API 650

Weld Visual

Request

Supervisor & QC

Inspector

6.2.1

8

Weld Visual

Inspection 100%

Drawing, API 650

& PG/NDE/VT/00

Inspection

Request

Supervisor & QC

Inspector

6.2.1

9

10% Radiography

for Circular seam

WPS, list of

qualified

welder sand

approved weld

map

Drawing, API

650 &

PG/NDE/VT/00

PG/NDE/RT/00,

API 650

API 650,

PG/NDE/RT/00

RT Report

Level II

Inspector, QC

6.1.1

4

6.1.1

5

Weld Quality to

meet Code

requirement

Absence of

internal defects

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

welding

6.2.2

0

QCP.REF.100.14

00

Inspector

Spot RT on all

Long seam and

circular seam

intersecting

location. (100%

"T" section/ "+"

Section

100% MPT on all

Category "D"

Joints

Pneumatic

testing of R.F.

pad Nozzles at

1.0 Barg

External

Attachment

Fit up of saddle

support with

Vessel

Absence of

Internal defects

PG/NDE/RT/00,

API 650

API 650,

PG/NDE/RT/00

RT Report

Level II

Inspector, QC

Inspector

Weld Quality to

meet Code

Requirement

Integrity of

welds and leak

PG/NDE/MT/00

API 650

API 650,

PG/NDE/MT/00

MPT Report

Level II Inspector

Proc#

PG/PRTST/00

Proc#

PG/PRTST/00

Inspection

Report

QC Inspector

As per drawing

dimensions

API 650

Weld Visual

Request

Supervisor & QC

Inspector

6.3.2

Welding of saddle

support with

Vessel

Welding per

WPS and

Qualified

Welders

API 650

Weld Visual

Request

Supervisor & QC

Inspector

6.3.3

100% Visual

Inspection

Absence of

Defects

WPS, list of

qualified

welders and

approved weld

map

WPS, list of

qualified

welders and

approved weld

map

Drawing API

650 &

PG/NDE/VT/00

Drawing API 650

& PG/NDE/VT/00

Weld

History

Sheet

Level II

Inspector/ QC

Inspector

6.2.2

1

6.2.2

2

6.3

6.3.1

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

6.3.4

6.3.5

6.3.6

6.3.7

6.3.8

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

QCP.REF.100.14

00

Fit up lifting lugs,

Name plate

bracket, external

attachment and

internal

attachment

Welding of lifting

lugs, Name Plate

bracket, External

& Internal

attachment

100% Visual

Inspection of

external &

Internal

Attachment

100% U.T. and

MPT on lifting lug

welding

Ad per drawing

dimensions

WPS, list of

qualified

welders and

approved weld

map

API 650

Weld Visual

Request

Supervisor & QC

Inspector

Welding per

WPS and

Qualified

Welders

API 650

Weld Visual

Request

Supervisor & QC

Inspector

Drawing, API 650

& PG/NDE/VT/00

Weld

History

Sheet

Level II

Inspector/QC

Inspector

API 650,

PG/NDE/UT/00 &

PG/NDE/MT/00

UT Report

Level II

Inspector/QC

Inspector

100% MPT on all

external

attachments

welds with

Pressure Parts,

Arc Strikes and

temporary

attachments

removal area

Absence of

defects

WPS ,list of

qualified

welders and

approved weld

map

Drawing,

ASME Section

V Article 9 &

PG/NDE/VT/00

6

ASME Section

V,

PG/NDE/UT/00

&

PG/NDE/MT/00

PG/NDE/MT/00

ASME Sec V

Article 7

API 650,

Appendix 6,

PG/NDE/MT/00

MPT Report

Level II

Inspector/QC

Inspector

Absence of

defects

Absence of

Internal defects

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

QCP.REF.100.14

00

7.0

Final Dimensional, Visual Inspection and preparation for Hydro-Test

7.1

Flush Grinding of

All Inside Welding

Penetration

Smooth

merging of

surfaces

Drawing

Drawing

Inspection

Request

Supervisor & QC

Inspector

7.2

Final

Dimensional,

Visual Inspection

before internal

Trial assembly

Dimension

Check, Free of

visual defect

and distortion

Drawing API

650

Drawing API 650

& all related

NCRs closed, all

hot work

completed

QC Inspector

7.3

Trial assembly

internals

Dimension,

Location,

Orientation

Drawing

Drawing

Weld

History

Sheet/

Dimensiona

l Inspection

Report

Inspection

Report

Project

Engineer/QC

Inspector

7.4

Weighing of

Vessel

Final Weight of

vessel with full

internal

arrangements

Drawing

Horizontal lifting

and weight within

design limits and

hook load

specified

Inspection

Report

Project

Engineer/QC

Inspector

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

Removal of all

internal

attachments

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

7.5

Dismantling of all

internal items

and insulated

parts

Drawing

Pressure Test for 4903F

8.1

Hydro test

@required

pressure in

Vertical position.

The integrity of

vessel

8.2

Draining of hydro

test water

Proper venting,

complete

draining.

Final Dimensional Inspection

QCP.REF.100.14

00

Drawing

Project Engineer

API 650&

Proc#

PG/PRTEST/00

Shall not be any

leak @ test

pressure

Pressure

Test Report

Supervisor & QC

Inspector

Proc#

PG/PRTEST/00

Proc#

PG/PRTEST/00

Project

Engineer/Supervi

sor/ QC

Inspector

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

9.1

Dimensional

inspection after

the completion of

Hydro test

10

Fixing of ASME

Name Plate &

Signing of MDR

10.1

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

QCP.REF.100.14

00

Dimensional

Check

Drawing, API

650

Drawing API 650

Weld

History

Sheet/

Dimensiona

l

Inspection

Report

QC Inspector

Name Plate Code

Stamping

As per Drawing

Drawing & API

650

Drawing & API

650

Name

Plate/

Photograph

QC Inspector &

AI

10.2

Name Plate

attachment

vessel

As Per Drawing

Drawing API

650

Drawing API 650

QC Inspector &

AI

10.3

Manufacturer's

Data Report

Prepared per

requirement of

API 650

API 650 & as

Built

Dimensions

API 650

Manufactur

er's Data

Report

Quality Engineer

& AI

QUALITY CONTROL PLAN

Client

Client Ref. No.:

Scope of Work:

11.0

Release Note

11.1

Acceptance,

Inspection and

Release Note

12.0

As Built Dossier

12.1

As Built Dossier

and Records

Reference No.:

Revision No.:

Date:

QC PLAN FOR FABRICATION & ERECTION

QCP.REF.100.14

00

Contractual

requirements

fulfilled

Drawing, API

650

Drawing, API 650

Final

Acceptance

/ Release

Note

Quality manager

All Required

Tests

completed, all

NCRs closed

out, all required

documentation

collated

Contractual

requirement

Contractual

requirement and

API 650

Manufactur

er Data

Dossier

(MDD)

Quality manager

You might also like

- Itp For Steel Structure Erection (Content) Rev.1Document3 pagesItp For Steel Structure Erection (Content) Rev.1Anonymous nLMJGu100% (6)

- QCF309 Welding Summary ReportDocument1 pageQCF309 Welding Summary Reportminhnn100% (5)

- ITP - Fabrication of Structural SteelDocument2 pagesITP - Fabrication of Structural Steelsahad100% (6)

- QA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)Document10 pagesQA-000-AA-5013 ITP For Structure Steel Erection Works Rev1 (APPROVED)miaicarba100% (2)

- ITP Installation of Boiler - R1Document14 pagesITP Installation of Boiler - R1crys100% (4)

- Welding Traceability Record 1Document1 pageWelding Traceability Record 1Alfian Imaduddin100% (1)

- ITP Inspection Test Plan FormatDocument1 pageITP Inspection Test Plan FormatArthur50% (6)

- ITP For Structural Steel WorkDocument3 pagesITP For Structural Steel WorkAbdullah Al JubayerNo ratings yet

- Inspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Document8 pagesInspection and Test Plan For Structural Steel Erection: ITP NO: 7979-ITP-ME-019 Rev.2Santosh Kumar Bogela100% (12)

- Design Portal Frame Using AsDocument358 pagesDesign Portal Frame Using AsJohn Dakota88% (8)

- Inspection and Test PlanDocument58 pagesInspection and Test PlanTouil Houssem100% (1)

- Inspection and Test Plan Steel Structure: 1. Document ReviewDocument2 pagesInspection and Test Plan Steel Structure: 1. Document ReviewMikiRoniWijaya100% (1)

- X6 Structural Steel Erection Inspection Test PlanDocument11 pagesX6 Structural Steel Erection Inspection Test PlanNoor A Qasim100% (1)

- Torque ReportDocument1 pageTorque Reportjarofidz100% (1)

- Weld Map & NDE Extent of Pressure VesselDocument32 pagesWeld Map & NDE Extent of Pressure VesselMahesh Kumar100% (2)

- QAP StructureDocument2 pagesQAP Structureayoki100% (1)

- Working ITPDocument4 pagesWorking ITPStephen BoodooNo ratings yet

- Itp For InsulationDocument14 pagesItp For InsulationHytham El-NoubyNo ratings yet

- Quality Assurance Protocol: Raw MaterialDocument2 pagesQuality Assurance Protocol: Raw MaterialShah Newaz KabirNo ratings yet

- Sample - Template - Itp For Piping Fabrication and InstallationDocument2 pagesSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriNo ratings yet

- ITP - Erection of Static EquipmentDocument4 pagesITP - Erection of Static Equipmentbhct1987No ratings yet

- Holiday Testing ProcedureDocument1 pageHoliday Testing ProcedureSyed Zakiuddin100% (2)

- ITP Format For New PVDocument8 pagesITP Format For New PVDavid LambertNo ratings yet

- Field Itp For Piping Work Samur Project Rev-5 (23 April 2013)Document28 pagesField Itp For Piping Work Samur Project Rev-5 (23 April 2013)Echik KiciNo ratings yet

- Rotating Itp 1Document4 pagesRotating Itp 1abdul aziz100% (1)

- Field Welding Inspection Checklist: Wisconsin Department of TransportationDocument1 pageField Welding Inspection Checklist: Wisconsin Department of Transportationandreafaith biatingoNo ratings yet

- Fit Up & Weld VisualDocument2 pagesFit Up & Weld VisualBhanu Pratap ChoudhuryNo ratings yet

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranNo ratings yet

- ITP For Steel StructureDocument3 pagesITP For Steel Structuretrey100% (4)

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- Owner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionDocument5 pagesOwner:: 275/132Kv Kimanis Switchyard Itp For Steel Structure ErectionLuqman OsmanNo ratings yet

- Itp For Piping Fabrication and Erection CorrectionDocument4 pagesItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- Itp PipingDocument4 pagesItp PipingkennethNo ratings yet

- 2037-PL-PL-0058-IR-T-014 Dated 10.12.19Document16 pages2037-PL-PL-0058-IR-T-014 Dated 10.12.19Dadaso Baburao Jamdar100% (1)

- Chqlist For Fabrication & InspectionDocument12 pagesChqlist For Fabrication & InspectionSuresh ShuklaNo ratings yet

- ITP For REPAIR - MODIFY OF STEEL STRUCTUREDocument8 pagesITP For REPAIR - MODIFY OF STEEL STRUCTUREShewale PravinNo ratings yet

- Itp For Tank Fabrication & Installation Work1 - Rev02Document22 pagesItp For Tank Fabrication & Installation Work1 - Rev02mister pogi100% (3)

- ITP-PRESSURE VESSEL ExistingDocument2 pagesITP-PRESSURE VESSEL ExistingArisNo ratings yet

- Itp For Storage TanksDocument7 pagesItp For Storage TanksHamid MansouriNo ratings yet

- Inspection Test Plan For Pipeline JobsDocument6 pagesInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Attachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Document44 pagesAttachment 6 - Piping Test Package (Manifold 206) - A4A0Z9Ali Hajirassouliha100% (1)

- Itp Piping PDFDocument4 pagesItp Piping PDFdashNo ratings yet

- WPS Pipe 08'' SHD 40 SMAW REV02Document2 pagesWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejNo ratings yet

- WPS - Smaw - 2Document6 pagesWPS - Smaw - 2Harkesh RajputNo ratings yet

- ITP For CW and ACW Piping WorkDocument8 pagesITP For CW and ACW Piping WorkPhong DoNo ratings yet

- Inspection and Test Plan For Steel StrucDocument6 pagesInspection and Test Plan For Steel Strucwawan gunawan100% (1)

- Iqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Document37 pagesIqwq-ce1092-Qpqac-00-0001 - 0 -Quality Control Procedure for Civil 土建质量控制程序Ali MajeedNo ratings yet

- Itp - Tanks - 01Document10 pagesItp - Tanks - 01ravigurajapuNo ratings yet

- Blasting & Painting Inspection Report Format For Bottom Plate 01Document7 pagesBlasting & Painting Inspection Report Format For Bottom Plate 01ABEC Trombay siteNo ratings yet

- Fabrication Division QMDDocument11 pagesFabrication Division QMDRakesh RanjanNo ratings yet

- ED 00 CPL PRC 0021 Construction QC Procedure Rev.2Document24 pagesED 00 CPL PRC 0021 Construction QC Procedure Rev.2Rahmat Hidayat100% (1)

- Storage Tank Foundation Settlement Quality Control and Inspection Report FormDocument1 pageStorage Tank Foundation Settlement Quality Control and Inspection Report FormKhepa BabaNo ratings yet

- 84501-9200-9L-027 - R3 - Welding Procedure & Welder Performance QualificationDocument18 pages84501-9200-9L-027 - R3 - Welding Procedure & Welder Performance QualificationAgus Budiono100% (5)

- QAQCDocument142 pagesQAQCRuhul AmeenNo ratings yet

- Itp Non AsmeDocument7 pagesItp Non AsmeAkhilesh Kumar100% (1)

- Repair Procedure ANNEXUREDocument16 pagesRepair Procedure ANNEXUREShaikh AdilNo ratings yet

- Quality Assurance PlanDocument6 pagesQuality Assurance Planvkrishnamoorthy100% (2)

- Inspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Document7 pagesInspection Test Plan (Itp) Rev.00: DOC - NO. OPR08-01 REV. No: 00Akhilesh KumarNo ratings yet

- Resume of Mohd Illias Uddin (SR Welding-Mech QC)Document7 pagesResume of Mohd Illias Uddin (SR Welding-Mech QC)Mohammed IlliasuddinNo ratings yet

- SM 001 SRV SpecDocument5 pagesSM 001 SRV Specvardan_vardanNo ratings yet

- Lesson 1 Earth and Life ScienceDocument10 pagesLesson 1 Earth and Life ScienceBoj MingiNo ratings yet

- Contemporary WorldDocument170 pagesContemporary WorldBoj Mingi100% (3)

- Division 05 - MetalsDocument43 pagesDivision 05 - MetalsBoj MingiNo ratings yet

- Nominal Size (Inches) Outside Diameter (Inches) Outside Diameter (MM) Wall Thicknes S (Inches) Wall Thicknes S (MM) Weight (LB/FT) Weight (KG/M)Document1 pageNominal Size (Inches) Outside Diameter (Inches) Outside Diameter (MM) Wall Thicknes S (Inches) Wall Thicknes S (MM) Weight (LB/FT) Weight (KG/M)Boj MingiNo ratings yet

- Method Statement For The Flushing of Chilled Water Pipes: Document Number: REE-MS-MOQH-HVAC-014 REV 00Document33 pagesMethod Statement For The Flushing of Chilled Water Pipes: Document Number: REE-MS-MOQH-HVAC-014 REV 00Boj MingiNo ratings yet

- METHOD STATEMENT - Installation of Generator Fume PipeDocument9 pagesMETHOD STATEMENT - Installation of Generator Fume PipeBoj MingiNo ratings yet

- Method Statement For Repair of Underground 14rev 2Document10 pagesMethod Statement For Repair of Underground 14rev 2Boj MingiNo ratings yet

- Re-Engineered Storage TankDocument1 pageRe-Engineered Storage TankBoj MingiNo ratings yet

- Petrol & Gas Construction Co.: Elevator Shaft ErectionDocument9 pagesPetrol & Gas Construction Co.: Elevator Shaft ErectionBoj MingiNo ratings yet

- Lecture Notes Materials and Ecological EngineeringDocument463 pagesLecture Notes Materials and Ecological EngineeringInhake AutechreNo ratings yet

- Rinnai 26e Service Manual PDFDocument68 pagesRinnai 26e Service Manual PDFteddiprintNo ratings yet

- Geas FinalDocument489 pagesGeas FinalroselleNo ratings yet

- Chapter 6 Thermodynamics: The First Law: Systems, States, and Energy (Sections 6.1-6.8)Document12 pagesChapter 6 Thermodynamics: The First Law: Systems, States, and Energy (Sections 6.1-6.8)MostafaRock100% (2)

- Clinical Restorative Dental Materials Guide: University of California Los Angeles School of DentistryDocument43 pagesClinical Restorative Dental Materials Guide: University of California Los Angeles School of DentistrySergioPachecoSerranoNo ratings yet

- The Calorific Value of A Fuel Is TheDocument4 pagesThe Calorific Value of A Fuel Is TheRana PrathapNo ratings yet

- Lamb Meat NutritionDocument3 pagesLamb Meat NutritionMuhammad MuhsininNo ratings yet

- Application Meat Processing HaccpDocument2 pagesApplication Meat Processing HaccpbjaabdouNo ratings yet

- Unit 3: Aldehydes and Ketones: EngageDocument10 pagesUnit 3: Aldehydes and Ketones: Engagejerome timmangoNo ratings yet

- Sika PDS E Intraplast ZDocument2 pagesSika PDS E Intraplast Zlwin_oo2435100% (1)

- Centrifugal CompressorsDocument6 pagesCentrifugal CompressorsGokulAgNo ratings yet

- Threshold Limit Values (TLV)Document7 pagesThreshold Limit Values (TLV)chem_taNo ratings yet

- Catalogue 2018Document44 pagesCatalogue 2018Hoa PhamNo ratings yet

- Unit 8 NotesDocument2 pagesUnit 8 NotesRahna AzaamNo ratings yet

- 772838Document2 pages772838Wilder Atalaya ChavezNo ratings yet

- Special Safety Practices For CSL2Document1 pageSpecial Safety Practices For CSL2ipliprensNo ratings yet

- Buku Miller's Anesthesia BAB 20 Dan 21Document88 pagesBuku Miller's Anesthesia BAB 20 Dan 21Rahma TomuNo ratings yet

- ET-88 MSDS - Electrical Contact Cleaner & Moisture DisplacerDocument4 pagesET-88 MSDS - Electrical Contact Cleaner & Moisture DisplacerVishnu NNo ratings yet

- Windsor Spirit Manual-PartsDocument18 pagesWindsor Spirit Manual-PartsNestor Marquez-Diaz100% (1)

- What Is DrugDocument9 pagesWhat Is DrugFebz CanutabNo ratings yet

- Water Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolDocument11 pagesWater Quality in El Malecón: Colegio Bilingue New Horizons Global Expo 2018 High SchoolLeonard PolancoNo ratings yet

- AHLSTAR PumpDocument6 pagesAHLSTAR PumpJustin TerrellNo ratings yet

- Air CompressorsDocument14 pagesAir CompressorsEduardo Belvis Jr.No ratings yet

- Chemical and MSDS RegisterDocument5 pagesChemical and MSDS RegisterRhen HalfferzrheinsNo ratings yet

- Anomalous Doping Effect in Black Phosphorene From First-Principles CalculationsDocument8 pagesAnomalous Doping Effect in Black Phosphorene From First-Principles Calculationsh shekarlabNo ratings yet

- Lab Activity 5 - PH of Familiar ProductsDocument5 pagesLab Activity 5 - PH of Familiar ProductsCharles Reginald K. HwangNo ratings yet

- SPE Turkey Can Bakiler PDFDocument42 pagesSPE Turkey Can Bakiler PDFZhunio BenavidesNo ratings yet

- 3 HerbsDocument260 pages3 HerbsWahyu Edwin SNo ratings yet

- RP12E Toc PDFDocument10 pagesRP12E Toc PDF황산악No ratings yet

- Group #4: September 25, 2019Document5 pagesGroup #4: September 25, 2019MIKAYLA ELAINE P. DELA CRUZNo ratings yet