Professional Documents

Culture Documents

A17

Uploaded by

liviu_dovaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A17

Uploaded by

liviu_dovaCopyright:

Available Formats

AGIP

04029.PIP.MEC.SDS

INTERNAL NORMALIZATION

Revisions

PIPING PROJECT SPECIFICATION

SERVICE : BLOW DOWN - VENTS - DRAINS

Sheet

of

A 17

ITEM

REFERENCE SPECIFICATIONS

150 # RF

20377.PIP.MEC.FUN

DRIP RINGS

15011

A 105

MATERIALS (if not otherw.stated)

ASTM STANDARDS

SPECTACLE BLINDS

15038

A 105

15039

14380 A 105 / 6000# SW

--

SPACERS & BLINDS

THDD FITTINGS

14381 A 105 / 3000# NPT (3)

--

TEMP. STRAINERS 15050-15007

NORMAL (from pipe)

14383 API 5L Gr.B / SMLS (3)

--

SWAGES (from pipe)

14382 API 5L Gr.B / SMLS (3)

NIPPLES

S.W. FITTINGS

PIPES

INCH

WALL THK.

mm

SCHEDULE

MATERIAL

FLANGES

14355

SOCKET WELD

14356

THREADED

14357

SLIP ON

14358

LAP JOINT

14359

BLIND

14360

GASKETS

14365

STUD BOLTS & NUTS

14368

VALVES

15801

RTSW

STSW

STSW

STEE

DN"

HEADER SIZE

M

E

C

80

40

3"

40

4"

6"

40

8"

40

20

20

20

20

20

20

20

20

---

---

---

---

A 105 / 150# - RF125 Ra

VS 235 AG E24 - SW

VB 511 AG 1C2 - RF 125 Ra (R.B.)

VB 511 AG 2C2 - RF 125 Ra (F.B.) (2)

VD 435 AG 7R1 - SW

VD 311 AG A04 - RF 125 Ra

VDR 711 AG 6C2 - RF 125 Ra (WAFER)

VDR 835 AG 3R1 -SW

FT 935 AG 5R1 -SW

FT 911 AG 2C3 RF 125 Ra

90-45 ELBOWS

14370

A 234 Gr.WPB

CONC.REDUCTIONS

14372

A 234 Gr.WPB

ECC.REDUCTIONS

14372

A 234 Gr.WPB

ELLIPT.CAPS

14374

A 234 Gr.WPB

LJ STUB ENDS

14375

PIPE BENDS

15023

METER ELBWS

15020

15021

STEE

Mark

STEE

INTERSECTIONS

STEE

STEE

12

SLET

NLET

14

WLET

PTOP (7)

RTEE

PTOP (7)

16

STEE

STEE

STEE

STEE

20

24

STEE

STEE

36

1/2 3/4 1 1 2

4

F

G

80

2"

VB 515 AG 5C2 - RF125 Ra

10

30

-------

16" 18" 20" 24" 30" 36"

0

0

2

----

-------

32 C 28

18

----

-------

7,92 7,92 9,52 9,52

STEE

T

U

B

5,0

-------

VB 635 AG 6R1 - NPT (3)

STSW

120

A 193 Gr.B7 / A 194 Gr.2H (ZINC. COATING) (1)

15701

STSW

-------

14"

80

2"

A 105 / 600# RF125 Ra

SPECIAL USE

3/4

-------

A 105 / 600# RF125 Ra

15801

" Y " STRAINERS

1/2

5,0

5,0

SMLS

A 105 / 150# - RF125 Ra

MANUAL CONTROL 15801

CHECK

50

7,92

160

1"

P - bar

----

10" 12"

160

1"

T - C

----

100

A 105

AISI 316

P - bar

5,0

API 5L Gr.B

WELDING NECK

ON / OFF

T - C

-29 38

4,78 5,56 4,55 5,08 5,54 5,16 5,49 6,02 7,11 6,35 6,35 6,35

14350

MANIFACTURE

DESIGN CONDITIONS

9,09 10,16 11,07

1/2" 3/4"

125 Ra

Dimensions : ASME B 16.5 / B 16.34

WELDS EXAMINATION

7,82

3 mm

CODES - Design : ASME B 31.3

---

7,47

CORR.ALLOWANCE

MAT.

15017

Date

A 105

RED. S.O. FLG.S

mm

15016

20367.PIP.MEC.FUN

THICKNESS

RED. THDD FLG.S

PIPING CLASS

NOMINAL SIZE

M

O

D

COMPONENTS

20376 / 20368.PIP.MEC.FUN

06--97

Rating & Facing

WELDING AND HEAT TREATMENT

Compiled

6

DN"

10

12

14

16

BRANCH SIZE

18

20

24

30

36

Components

Material

STEE STRAIGHT BW TEE

14371

A 234 Gr.WPB

RTEE REDUCTION BW TEE

14371

A 234 Gr.WPB

STSC STRAIGHT THDD TEE

14381

RTSC REDUCTION THDD TEE

14381

STSW STRAIGHT SW TEE

14380

A 105

RTSW REDUCTION SW TEE

14380

A 105

SWLT SWEEPOLETS

15003

WLET WELDOLETS

15004

TLET THREDOLETS

14381

A 105

SLET SOCKOLETS

14380

A 105

NLET NIPOLETS THDD

14381

A 105

PTOP PIPE TO PIPE

15012

NOTES:

1) All carbon steel bolting on flanges, valves & "Y" strainers shall be zinc coating

(hot-dip) to ASTM A-153.

2) To be used where required by P&I drawings only.

3) Threaded Ends and connections are allowed for instrument taps only (15801).

7) To be used for 45 branch connections only.

Company's sole property document . Company will protect his right by law.

You might also like

- A11Document1 pageA11liviu_dovaNo ratings yet

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- A02Document1 pageA02liviu_dovaNo ratings yet

- Agip STD - Piping Project SpecificationDocument1 pageAgip STD - Piping Project Specificationhalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaNo ratings yet

- A09Document1 pageA09liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_ka100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- 15CSTL NaDocument3 pages15CSTL NaVipin NairNo ratings yet

- D11Document1 pageD11liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Documents Plc150Document7 pagesDocuments Plc150Anonymous cuOIjrLINo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- 61502YDocument9 pages61502YbalajivangaruNo ratings yet

- 094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1Document80 pages094135-PI-MTO-001 - BOM For Piping & Valve - Rev.1thongNo ratings yet

- STD PipingDocument51 pagesSTD PipingRodrigo Iván Latorre AlmirallNo ratings yet

- Chevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceDocument1 pageChevron Corporation 1CS10: Pressure - Temperature Ratings Hydrotest at Ambient ServiceAldeline Sungahid100% (1)

- rc61180 b09Document9 pagesrc61180 b09eww08No ratings yet

- Piping Shortage MaterialDocument12 pagesPiping Shortage MaterialAnonymous i3lI9MNo ratings yet

- Class A1D1Document8 pagesClass A1D1SalimNo ratings yet

- Thread o Ring Flanged FittingDocument4 pagesThread o Ring Flanged FittingsureshisisisNo ratings yet

- 11502Document9 pages11502balajivangaruNo ratings yet

- Ep31492 PDFDocument11 pagesEp31492 PDFJilJilNo ratings yet

- Classif AçosDocument7 pagesClassif AçoslavascudoNo ratings yet

- TOTALDocument11 pagesTOTALmb_sirousNo ratings yet

- Piping Material SpecificationDocument36 pagesPiping Material Specificationravirawat15100% (2)

- 61502Document10 pages61502balajivangaruNo ratings yet

- 11422Document10 pages11422balajivangaruNo ratings yet

- 47 G 106Document26 pages47 G 106ThiruThirunavukkarasuNo ratings yet

- Class A1C1Document16 pagesClass A1C1SalimNo ratings yet

- F9001 Plano Facet para ConstrucciónDocument2 pagesF9001 Plano Facet para ConstrucciónWermer Melgar GutierrezNo ratings yet

- Table BrenchDocument11 pagesTable BrenchLuis GonzalezNo ratings yet

- PN03CL1S01Document4 pagesPN03CL1S01Amreusit SaschimbnumeleNo ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- New Text DocumentDocument1 pageNew Text Documentmanafl salhlNo ratings yet

- Class 11085Document9 pagesClass 11085eww08No ratings yet

- Series 411 Specification SheetDocument2 pagesSeries 411 Specification SheetWattsNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- D11Document1 pageD11liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- C11Document1 pageC11liviu_dovaNo ratings yet

- D12Document1 pageD12liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- C14Document1 pageC14liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_ka100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_ka100% (1)

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- C12Document1 pageC12liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- A35Document1 pageA35liviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- A20Document1 pageA20liviu_dovaNo ratings yet

- 0 1 2 3 4 06 - 97 Service: Item: Internal NormalizationDocument1 page0 1 2 3 4 06 - 97 Service: Item: Internal Normalizationliviu_dovaNo ratings yet

- AGIP STD - Valves Specification SheetDocument1 pageAGIP STD - Valves Specification Sheethalim_kaNo ratings yet

- Week13 TNT Conversion of Piezoelectric Material DataDocument7 pagesWeek13 TNT Conversion of Piezoelectric Material DataDeepak ChachraNo ratings yet

- Sheet Rolling Machine - SynopsisDocument8 pagesSheet Rolling Machine - SynopsisTanviNo ratings yet

- Tool/ Equipment Description/ Function Picture A. Measuring ToolsDocument13 pagesTool/ Equipment Description/ Function Picture A. Measuring ToolsNicolas AntiguaNo ratings yet

- 04.fisa Tehnica Fribra OpticaDocument1 page04.fisa Tehnica Fribra OpticaDorcioman AndreiNo ratings yet

- C Compact EUROMOLDDocument40 pagesC Compact EUROMOLDWalter CahuanaNo ratings yet

- Taka Gas Spring CatalogueDocument14 pagesTaka Gas Spring CatalogueAdem YıldızhanNo ratings yet

- Operation of The First HIsmelt Plant in ChinaDocument8 pagesOperation of The First HIsmelt Plant in ChinaJJNo ratings yet

- Automobile Waste and Its Management PDFDocument7 pagesAutomobile Waste and Its Management PDFBojan TanaskovskiNo ratings yet

- Deh P4950MP PDFDocument68 pagesDeh P4950MP PDFpasantitoNo ratings yet

- Summary NG Pagtatasa NG Pangangailangan (Needs Assessment Survey)Document3 pagesSummary NG Pagtatasa NG Pangangailangan (Needs Assessment Survey)Karlo AvendañoNo ratings yet

- 3.2 Overexcitation and Overvoltage ProtectionDocument6 pages3.2 Overexcitation and Overvoltage Protectionlkt_pestechNo ratings yet

- Junkers Monobloc Planning Guide English PDFDocument184 pagesJunkers Monobloc Planning Guide English PDFReInvieNo ratings yet

- Lighting: Tef 2440 Obstruction Light Low Intensity, Type ADocument2 pagesLighting: Tef 2440 Obstruction Light Low Intensity, Type Apramod_tryNo ratings yet

- Galvanized Peeling Vs FlakingDocument1 pageGalvanized Peeling Vs FlakingECCNo ratings yet

- Manufacturing Companies in PuneDocument3 pagesManufacturing Companies in Puneshyam ubaleNo ratings yet

- All DocumentsDocument12 pagesAll Documentsangusbeef1012No ratings yet

- Tipos Concavos y MantosDocument22 pagesTipos Concavos y MantosJose Luis Atao SantiagoNo ratings yet

- Water-Treatment-For-Closed-Heating-And-Cooling-Systems (Sample) PDFDocument8 pagesWater-Treatment-For-Closed-Heating-And-Cooling-Systems (Sample) PDFstarykNo ratings yet

- Revista ANSYSDocument52 pagesRevista ANSYSEgar MtzNo ratings yet

- Documents - MX - Fisher Desuperheaters Bulletin April 2008 PDFDocument12 pagesDocuments - MX - Fisher Desuperheaters Bulletin April 2008 PDFsaji_t1984No ratings yet

- Integrated Waste Management PDFDocument7 pagesIntegrated Waste Management PDFTechsrijan DriveNo ratings yet

- tp6140 PDFDocument72 pagestp6140 PDFjohnNo ratings yet

- Concrete Proportion and Concrete MixtureDocument12 pagesConcrete Proportion and Concrete MixtureEnrico luis EscobarNo ratings yet

- Air Turbo Ventilator PDFDocument2 pagesAir Turbo Ventilator PDFHiei ArshavinNo ratings yet

- Chap 1Document22 pagesChap 1Zara Sikander33% (3)

- Acm UNIT 1Document19 pagesAcm UNIT 1Samreen KhanNo ratings yet

- Gypsum Products ShanviDocument56 pagesGypsum Products Shanvishanvi agrawalNo ratings yet

- Tutorial IIDocument5 pagesTutorial IIMushtansir AnsariNo ratings yet

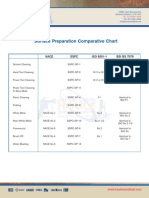

- Surface Preparation Comparative ChartDocument1 pageSurface Preparation Comparative Chartcmms88No ratings yet