Professional Documents

Culture Documents

Design of Bins and Bunkers - British Steel Assoc

Uploaded by

fujiman35Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Design of Bins and Bunkers - British Steel Assoc

Uploaded by

fujiman35Copyright:

Available Formats

Pa) sit. d 08 Similarly the minimum pressure on the sloping wall Riilbe at Bin Fig. 20, The foregoing equation for Pp. applies equally it this point. Hence the total Bressure on the sloping wall will be the area of the Pressure diagram between B and C. Ip, is the normal presence at Band p, presure at C then the total normal lead acting the sloping wall is R= [= Ee and acts through the e2ntre of gravity of the prosure diagram, as shown in Fig. 22. : ‘| Slant height fl | Fu. The vertical and horigwatsl reactions at Hand € may be resolved to give the normal aid ten Components required t design the ough st These are shown 12 Fie, 2 then the normal reaction or shear at #15 K, Reos dH, sito gangentia! component oF tension at B Rain similarly, the normal reaction or shear at C18 R. = Asin dé and the tange Hos = Ween gs. Fic. 24 ‘Obsiously, the sum of the normal reactions @t B and € should equal the total normal load on the sloping wall, that is Pac +P +R Ry as before, ‘The final forces and pressures necessary 10 enable strength calculations to be prepared ate as shown in Fig. 24 1b. Grapnical SOLUTION The forces set up in a bunker may also he readily solved by graphics. From Fig. 25 it is required 1 Gctermine the pressure on the sloping wall BC Find first the magnitude of the vertical and horizontal pressure at points and C and find their resultants Fic. 25 ‘This may be done conveniently by drawing the ellipse of susess, which is constructed as shown in Fig. 26. At point C set off p, as ou, and po as vb. and sith & as the fulerum draw circles of radii a and of respectively Produce the sloping side BC to p ve From o draw a perpendicular ocd to out the 0 radii 2s shown. ¢ will be a point on an ellipse. and ‘oe will be the resultant and direction of the pressure fon the sloping side BC at C. Repeat fur point 8, Fis. 26 It will be seen that by projecting the line of the sloping wall BC 10 meet a horizontal from 4 at G in Fig, 25 and from G producing a line to meet at Cl, the resultant pressure at Bis therefore in linear proportion to that at C, which is confizmed by the ellipse of stress for these Wo points. The total pressure on the sloping side BC will be the area of the quadrilateral BI’. C1 and will act through the centre of gravity of the quadrilateral BI, Cl. The reactions at B and © may now be found by using the algebraic methods set out under (a) of by using the forse polygons shown in Fig. 27 Clearly as the magnitude and direction of the resultant Toad on the sloping wall is known its vertical and horizontal components will be the total vertical and horizontal pressures acting on BC. As B and C are regarded as hinges, by producing the resultant as set out in the figure the normal reactions and tensions at B and © may he determined. To these tensions at 8 and C must be added the tension due to half the vertical load acting on the botiow plate {called Win the algebraic solution). Lt wil he seen that the final vertical and horizontal reactions at Band C ugice with the method set out at (a) above co ALTERNATIVE Grapitic SoLUtio ‘An alternative graphical solution to that given above is as follows Jn Fig. 28 L represents the total horizontal pressure ccaleviated on the full depth of the bunker, and W’ fhe total vertical load within the triangle CBEd D. Fic. 28 Now R is the resultant of Wand L. and N and 7 the normal and tangential components. Also N is the toll normal pressure on the extended sloping Tide CBE. and therefore equals the arca of the pressure Quagram CBEC™. Hence the normal pressure at C Can be easily determined. However, the actual total Formal pressure AN’on the sloping side BC is the direa of the quadrilateral BB’ CC’ and will act through the centre ef gravity of the pressure diagram. The true revultant total pressure R’ on BC will be parallel to Rthe value of which may be found by using the Consiruction already shown 1m the figure, 1 pressure on the bottom plate and on the vertical dui'imay’ be found as in the previous solutions. Reactions and tensions may also be found in a similar way 2. RECTANGULAR BUNKERS- ‘SHALLOW UNSYMMETRICAL, “The algebraic and graphical solutions ouslined for the ‘umumetrical of balanced bunker may also be applied fb bunkers which are not symmetri¢al about a vertical Cure line passing through the discharge opening Such an arrangement, with all vertical and horizontal Forces imposed symbolically is shown in Fig, 28 Only the algebraic solution will be given here Fic. 29 Above the waist BE the horizontal forses will have exactly the same meanings as already outlined for the symimetrical ease, that is where Ly Below the waist the following differences should be noted Hy + He H, + He Regt Ree By taking moments about point O of all forces to the Jet of C, it will be seen that for the steepest side pa ‘i a = o[ms Wants | Fleeoaaeers 2 hich fs exacly identical with the expresion sie on page 3 Simiarty hs Likewise, for the less steep side Tp aw A =|, is Al poe wy, im ‘The vertical reactions will take the values Ree = Wa te > Ry = We Wt It should be noted that the reactions Re, and Rup are son ine simply supported beard reactions. This. is Tetauve there is an out-of-balance horizontal reaction fat the oullet having the value Ho= Hye Below the waist BE the horizontal forces must be in equilibrium, that 8 H+ bi = bye =9 H, = Ly > by ~My = 9 and Il, ~ He > He ~ He The procedure for calculating the normal and A ential pressures and reactions follows the methods tpiven for the symmetrical bunker. A solution by either of the graphical methods will jJield results which apree with that given above STRENGTH OF RECTANGULAR BUNKERS The forces set wp ina rectangular bunker (square bunkers are included in this context) will induce Ghrect, shear and bending stresses in the various pasts However, because of the shape it is not a practical proposition to accommodate these forces on the skin Fate only. 2s will be shown to be possible in the ease Pi the citcular type. Any attempt to do so, except fh the case of very stall, ightly loaded bunkers, will invariably result in Very’ thick plates and, in conse- ‘quence, totally uneconomic designs. Usually, therefore, the skin plate, which forms the bonker wall, is designed to ‘span between suitably positianed stifleners, which may be either vertical or Ronzontal depending upon the design approach. Normally these stiffeners are arranged to get in the Seal plane and this layout probably forms the [irgee number of burkers in service, The skin plate ak ine treated as & beam, either simply supported mak gntinuous bebveen the stiffeners, which in tur Glo act as, beams, but spanning at’ rightangles 10 the designed direction of the skin plate SkIN PLATES Tt has already been shown that the maximum pressure in the shin pute is at the bottom of the trough wall The skin plate in spanning between successive stilleners Mill be subject 10. bending. some shear, and longi: tudinal tension. Normally the plate is designed for Ekiding, the shear being neglected and the longi Pafinal tension is taken up on the stiffencrs, which reer yelude proportion of the plate, This point Mii, however, be discussed later on. Generally. the plates will tend to span in two directions Shuultancously. that is at right aagles and paaralic} to) the stifleners. In Fig. 30 let L be the length of the plate parallel to the stiffenets, and the corres- ponding, distance centre to centre of stiffeners Provided the ratio L > is less than about 3 advantage may be taken of twoaway bending. If this is pot the case, then Ovo-way bending offers no economs: land is best ignored, the plate being treated as spanning: between the stiffeners only, Skin plate: Stiffeness: Fic. 30 “When the skin plates ure designed for one-way bend Daly, the maximum bending moment will he some geal where between — and depending upon whether the plate is simply supported continuous and the Extent of continuity. IT the available plate ts wide Shough to afford at least three nes of support wid mot give bending moment haying a value of unreasonable resets 0 Where it is found possible to consider the benstits of Twounay bending the design procedure is ne longer quite ay simple. Various authorities 17702 live SQeeested solutions t0 this problem. some of shih are given below Grashor"™ approached the problem ay folion I fi 31a simply supported plate of Henath (and breadth fis subject to a uniform pressure « Let it be assumed that the longer shusted 9 supports & pressure gj aod. the short prenure yy: nother words the presstte ts Such that see setup ae + ) | | | A unit iat | epozerereeerrat Fic. 31 The masimum bending moments and deflections will occur at the intersection of the Uva strips ghiMe qt 8 spilt SN4ET abt 8 Sab 38867 But y, must equal yy, so that lt = abt and since g == 4,+4e it may be seen that on bo e : ny LB Hence, in terms of the shorter span 6, the maximum bending moment would be a and be for simply supported plates ro Where @ represents the distribution factor in the Sorte Span bs and takes the value Lent 11 being equal to Lib Likewise, the deflections would have the values SQ qh* Ee for simply supported plates ys for encastred plates being the plate thickness Heneky" ‘3 solution more nearly ex Shown to fit with good app: nt 4 0-225n* Q=~ also investigated this subject and produced fact. Hencky's results, are oximation the expression tent when 1 takes the meaning previously given. However, Grashof’s formulae have been found by Upesiment to be approximately correct when > 2 In order to overcome this deficiency Pounder's' HRoamptions for maximum bending moment and Geceton in terms of the shorter span, b, are for bending, simply supported plates gpd "iefa-o sl 75 encastred plates ep ul M,=O9—|1+—0-0 wl 35 likewise for deficction, mi Ee simply supported plates mt—1 SQab* “——|14 encastred plates Qa" ea + 3260 de joations Pounder assumed TRat the pressure on the plate was not uniform, but In deducing the above €@ tat intnon linearly from q at the supports to Og vend span, a assumption not made by Grashol Expressing the bending moment equations of Grashof, Pounder and. fenehy equations for a simply supported: plate in bending tn the form fa ditect comparison of the solutions obtained can be shown graphically, by reference to Fig. 32 of unit length of bunker such so miemsher in which Pe > Mand Te > Ty a9 Working on the suggestion by Levy that the solution Ar the plate probier should take the Form of a series Fmosbenkor™ has deduced expressions for the fending moments and deilections of plates having Various, edee conditions. In general terms the pending mootent may be given in the form My Bab and the deflection sh D both formulse being in terms of the shorter side, and Shere anil 8 fe Numerical factors depending upon the nato £2 and the appropriate edge condition, fond Dis the flesural eigidity of the plate [All the foregoing expressions are based upon small Qehection theory, althwugh it should be mentioned, fn. passing Ural where large defections of bunker plates are considered acceptable there may be some Piamage in designing such plates ip accordance ‘with large deflection theory" ‘Trowcu STIFENERS ‘These are required to give support to the trough plate which is carrying the Joad, It has already been Frown that the {rough iS subject to a unitormly Miaying pressure and tension, The trough stiffener Waid iherefore be an inclined heam subject to bending, Shear and direct tension, Fig, 33 shows in terms Fic. 33 Opes pedand Ro =e 6 Atsome distance ¥ fram B the shear will tohe ti L . Sepa FR Pee 6 And the bending moment at the same position So L . # My = = Op_ PVE 6 ‘The maximum valve of M, niccues when §. Table 1 gives values of evetlicients of y and My apul® by expressed in the form x AL aed ML potting = Band LI Ps Example. Ip, 300.7, - 480° then 450 a 5, x -USt6L, Mt 2 b-uest wor ous usta | 01330 a 1aii6 Os tS6d | wins anal 299 0 a i i i 5 1 Coupled with the bending moment will be a direct tension, having the valuc ‘The above bending moment M, and direct tension’ T, will each need to be multiplied by the distance centre to centre of the stiffeners to give the actual Gesign values required to proportion the stiffeners. T= Clearly there is no reason why part of the skin plate Should not be included in the stiffener design. In Tact, where T-type sliffeners are employed, as would, be the obvious case in welded designs, the inclusion Of part of the skin plate will balance up the loss of fneftia experienced in asymmetrical sections. How much skin plate should be incorporated in the stiffener Gesign is 4 matter of opinion, Dut it is suggested that the width of plate should not exceed :— (a) when bit is less than 40, the actual width centre to centre of stiffeners, 6. (8) when b't is greater than 40, not more than 40 1 Tn any event the distance centre to centre of suceessive stiffeners should not exceed 80 In passing it is worth mentioning that similar pro- \isions are given in both B.S.153 Steel Girder Bridges, Part 3B. Stresses, and BS449 The use of Structural Sigel in building Sine Watts Each side wall (and this includes end walls where appropriate) ‘will have to be designed to accommodate Tevshare of the total vertical load, the side pressure Sithin. its own depth, plus the horizontal reactions from the trough, and of course self weight. Fig. 34 shows this loading configuration. | Setfweight H, Fic. 34 2» Thus the side wall will, in fact, resemble 2 plate girder of unusual proportions and, equally, unusual loading Conditions. In the circumstances the normal plate firder design approach will not be entirely relevant Tt has been shown elsewhere that when the span depth ratio is less than 2 the simple beam theory no onger holds true. This situation would obtain in a. square silo, and indeed in many square or near square ‘bunkers of the shallow type. ‘A convenient means of overcoming this problem is to design the walls for side pressure only with the skin stiffeners arranged either vertically or horizontally fs best suits the layout. The trough or cone reactions may then be carried on a beam of reasonable dimen- ion situated immediately at the bottom of the wall This beam may be part of the wall. There is one ‘obvious advantage in this method in that it overcomes any preconceived notions regarding df ratios or Timits considered in ordinary plate girder design. Where the side wall is of such proportions that the simple beam theory may be used, the foregoing remarks are best ignored. The whole wall being treated as a special form of plate girder Whichever design method is used, stiffeners will be ceessary on all but the lightest of bunkers. Vertical Siffeners will be subject to a triangular load distri bution and must be capable of resisting a bending moment of 0-O64IpL* when they extend for the full Uninterrupted depth of the wall. If they are broken due to the presence of horizontal stiffeners the bending moment for each separate length will be the appropriate value taken from Table | Square or near square bunkers may have stiffeners arranged either vertically or horizontally. | Where the former applies the foregoing remarks hold good. If the stiffeners are arranged horizontally they will be ‘subject to a uniformly distributed load, and may be Gesigned either as simply supported beams trimming into an extension of the comer support column, oF where this is not possible as closed rings. In addition to the bending moment, horizontal stiiTeners will also be subject to direct tension due to the pressure on the wall at right angles to the wall actually being designed. Side wall stiffeners may be proportioned to include part of the skin plate, the recommendations given for Trough stiffeners are appropriate Fig, 35 shows a horizontal stiffener treated as 2 closed rectangular ring, Fic. 35 At (c) the ring is in equilibrium under the load W, which js equal 0 the average pressure at the level being considered times the distance apart of the only, (b) shows this quandrant under the influence fof the load w, moments M, aM, and M, and tensions T, and T,. Clearly wb and By considering the strain energy duc to bending only it’ may easily be shown that the moments take the values wot E 443- | aa Where b= and 8 = bh L Table 2 gives values of Mf, M, and M, in terms of | and ® by expressing the moments in the form MGitbere TAS the ring is completely symmetrical f Shout point o it isconvenient to analyse one quadrant M = >wL* é a -=p=1 2 | i i \ M, M iste eae ects vm, | Maueal \ : _4 pene Toute Lo-assss | on0ai6e fo-oisr6 | 0-075%4 | 0-02842 | 0-05499 0-07001 | 9-01000 | + fe 0-04958 | 0-07542 | 002583 | 0-05578 | 0.06922 | 0-01078 | fre can — }0-05005 |0-07495 | 0:02629 | 0-05666 | 0-06834 | 0-01166 | =| = Oes0se jO-08ad | 0-02628 | 0-05768 1006744 | | ee eee = LEONE loots! | o-o3za2 | o-03880 | -05620 =| = = ]oostks joo7316 | 0:02809 | 0-06012 0 ose B= 07 | p= 06 { B05 \ k : 7 = - : bape oe a Pe me aca h | | ' | 7 t} prosnie |o-06s8a” fo b0ns5 | o-osies [o-00335 [-0-0r834 [0.0029 onasy owes | | O.9 | o-ora2e | 6:o47s | —0-00388 | 0-06259 | 0-06201 | ~0-01700 | 0-398 | 0-002 | 0-8 | 0-06149 | 0-06351 | —0-00225 | 0-06452 | 0-06048 001547 | 0-06570 | 0-05930, | \ | 8:5 | O:0e291 | 0-00209. |—0-00083 | 0:06627 | 0-05833 |—0-01372 | 0-06769 | C-05731 9-7 | g-asze! [0 06309 |—0 Cone | Oooese [o-osees |-o-olTer [OvoTune Osis 0.02860 | 88 |. Geeas | o-osess | 0-027! 0-0707S ]0-05425 |-0-00925 | 0-07291 , U-05209 | -D-eRS? | TABLE 2 rere sgt Sa EME 2. CIRCULAR BUNKERS (SHALLOW) ‘The principles involved in finding the vertical and horizontal pressures in a shallow circular bunker are Emilar to those given for the rectangular type. However, the horizontal or lateral. pressure set up will be acting against a radial surface, and for this reason the skin plates will be subject to direct stresses only Prasscnes #8 SHALLOW CIRCULAR BUNKERS As before. the vertical pressure is py = wit fond the lateral pressure 18 pp = py Ky lasing where &y is Rankine’s factor, vis, -— 1 sine 36 (a) shows a cross section through a typical srmevrieal circular banker, section xx at (A) shows, the shell subjected to a uniform radial pressure ps Section at BB" ) © Fic. 36 Considering firstly the cylindrical portion of the honker,. By cutting through the diameter (c), the pr must be in equilibrium under the action of the ture py and the reactions Ty. What is required Rie vive of T,.._ The radial force on the elemental fength of are ds is pals, and the vertical component GF this will be ps cosads, but ds equals rex, hence the total pressure P is 3 par cos « da. hs =2pr ich must equal the sum of the reactions. vis, 2Ty whence Ty = par pel but pe = py Ki, and py whd veh, so that the hoop tension Te Kk and will have a maximum value at the waist BB" Depending upon the manner in which the bunker is supported, there may also be @ longitudinal tension in’ the cylindrical portion. Suppose the bunker is Supported at 66.” The longitudinal tension in the Shell immediately below this plane will be due to the weight of the contents plus the self weight of that part of the shell below 5°. Let W’be the weight of The contents plus an allowance for self weight below hh, then the longitudinal tension per unit length of circumference will be w 7 If the support is at 44, 1 will equal the total com- bined weight of the contents and bunker weight However, if the bunker is supported at the waist BB which is to be preferred this longitudinal tension may be discounted. ‘The next problem is to deal with the forces set up in the conical section. As the means of support is never below the waist, there will be both hoop tension and longitudinal tension, Considering the hoop tension first. It can be shown. that the normal pressure p, acting on the skin of the cone has the value Vsint (6 + 6) sin 6. Ps and the hoop tension due to p, will be found trom the formula Ty = puny cosee d where ¥ takes the value of the pressure at the level Under consideration, Ty has a maximum value at BB Now the inclined tension or tangential tension will depend vpon the vertical pressure acting on the plane cc’e plus the weight of material and shell Tmmediately below the plane. The total vertical load at this plane is therefore wer Var? +—--— + self wt = Wi say 3 ‘and the circumferential tension due to His, Wy, Dany which, when resolved up the cone gives, w, T, = — cose $ The masimum value of the longitudinal tension in the cone will be at BB’ when HW’, equals the otal ‘weight of the contents plus the self weight of the cone, andr, =r. Fig. 37 shows the pressures and resulting tensions, at the plane ev“e. I Fic. 37 Likewise the minimum tension will oecur at the outlet, and will apply to both the hoop and longitudinal tension SHRESSES 18° SHALLOW CIRCULAR, BUNKERS The stresses induced in the shell plates will be due to both hoop and longitudinal tension, In the cylindrical section the actual hoop stress will be Ty hd hon femar and the longitudinal stress, if applicable rT OW Similarly in the cone the hoop stress will be Tr Peta fae te cosee $ 1 t and the longitudinal stress " fata —coses 1 lant where 1 takes the thickness of the plate. SUPPORTING THE BUNKER Whenever possible a circular bunker should be supported at the waist BB" (Fig, 36). In order to provide against heavy local stresses set up duc to the presence of supporting brackets, it is common practice 10 have a ring beam connected to the shell plates, This ring beam will take the load from the bunker uniformly distributed over its full circum ference, and in turn will be supported on the steucturat steelwork frame at at feast three points, The ring beam will be subject to compression, bending and torsion. ‘The ring compression will be w cot é 2 ‘The maximum bending moment will occur at the supports, and will have the value wel my [Efe] pa Paehars and at mid way between the supports witl be P. 2 sinta4 wel x Af, cos = + — | sin 20 dn ai ‘The torsional moment for a given position in the ring beam will be sont" MH #| M, will have zero value at the points of support, and fa moximum value at the point of contraffentre Qn ‘The position of the point of conteaflexure may be found by solving for B in te express 2 In-the above expressions = no. of supports and 2 = nin The meanings assigned to 2 and 6 are shown di grammatically in Fig. 38 Values of My. Me and M, expressed in terms of the total load IF and the number of supports m, together with B the angle locating the point of contraflexure are given in table Point of support Any point on? Secahioronce e Fig. 38 MoweNTs AND SHEARS IN CicULAR BEAMS No. | Load | Max. | i | i of | on post | Shear M, } M, ieecee| posts | Win) With | | i ee | i | | ; can) ee | a Sonim 4 0-125 “D-0sdlsivr | L0-O1T62Hr 0-008308'7 4 | Ore | oss | —o-o1aganre =) +0-007511¥% 0-001511V+ ST Oey Owwea 0.0087 | +0-00sLG 0-00063 1" 10 | Ovtoow | 06-0808" O-00s27r | 40-0028 00003208" 12 | oss | o-asLiy ‘9-003051" | +0:00190Ir 000185187 TABLE 3 3. DEEP BUNKERS (OR SILOS) When a bunker is very deep the theory already out fined may not be directly applicable. Generally, a bunker is said to be deep when the angle of rupture cuts the phine of the Wall, and not the free upper of the contents, The difference berween a tand a deep bunker or silo is illustrated in surface shallow Fig. 39, Cartons: EXPRESSION oe Coulomts'™ gives the angle of rupture as = measured from the horizontal. Hence if d is the diameter or width and f the limiting height a 0 ane ton [| B If h, derived from this equation, is less than the actual height of the material, Rankine’s theory ill fo longer prove to be satisfactory when calculating: vertical and horizontal pressures Plano of rupture L VERTICAL AND LATERAL PRESSURES Jt has been shown that in a silo a certain quantity of the contents will be carried on the walls by friction. Tn a circular silo Janssen! suggested that the vertical pressure would be and the lateral pressure would be ew the | Other authorities, notably Airy! have also. given solutions. to this problem. The formula due to ‘Airy 1s aiven here By way of comparison, and states that the lateral pressure in a circular silo is i eae gat esipeue wd ia v| cle ar VT Vow wel at a Fic. 40 ‘A solution to the cireulsr silo problem, based upon Janssen is as follows, At the instances of movement ‘of the mass there will be resistance against motion due to friction between the wail and the contents. From Fig. 40 it will be seen that the weight of material in the dise abed is wert. ‘This mass is in equilibrium with the vertical pressure (assumed 10 be constant lover the whole area) and the frietional forve around theperimeter, The vertical pressure is ("81 V'] rar® and the Force is y'L 22rd This gives wartih = (= 8P) by putting L ~ KV, and reducing wrbh = r8V 4 2a KV 5h , whence = 2 a0 wr QW KV Vine = Dhar ol Integrating once obtains 4 Logur Upon substitution of this value for 4 in the equ: for h, and rearranging 2u'Kh SO = Log, (wr KV) — Logue 2k row KV from which ¢ pate which gives KV = where K takes the value found by Rankine’s method L 1 sine v T+ sind ‘or more correctly, by experiment. In the case of square silos of side lengtin a, the meu hydraulic radius would be equal to 4a 4 uM | | | | | | | [STRESSES IN DEEP CIRCULAR BUNKERS When the angle of rupture found from Coulomb's Expression cuts the wall of the bunker before the free topper surface, the bunker is said to be deep. Unlike the shallow type, the cylindrical shell witl be subject to hoop tension and longitudinal compression. The hoop tension may be derived directly from Jamasenrs lateral pressure formula, and will take the value Table resulting in a hoop stress of rol ha tot ina deep bunker the vertical pressure is no ‘because part of the contents is This frictional force Now. longer simply eh cartied on the wall by friction {atSing the compression is the difference between the cual Ree vertical pressure wh > 4 and the (otal Jonesen vertical pressure V, <4 and for the level Under consideration takes the value C= wh — FS) 2 resulting in a longitudinal compressive stress. of Cc wh Var at eee arnt Heer Note: The equations for C and J, apply only when wh> ¥ “To find the maximum stress in the plate at the level in question J and fe may be combined in the form Baht te and 35 The plates forming the cone will be subjected to both hoop tension ang longitudinal tension, as was seen tobe ‘the case for the shallow bunker. Janssens Expression for both lateral and horizontal pressure indy be used, but some modifications, of a minor Matte will be necessary, The mean hydraulic radius P Ghould be replaced by half the appropriate cone radius. n/2, and the coefficient of friction on the wall W by the corresponding friction coeflicent for material Ba material, p.. This is because the column of fraterial zs now sliding against the remaining material Buteide the radius r, and not on the bunker wall. See al eral pressure would therefore be | giving a hoop tension of Ty = 1h resulting in @ hoop stress of Ly fe : Likewise the longitudinal tension would take form, as given in the shallow theory W, cosee # the 2n except that WY, must be modified. As previously pen = Pont nt Com sl weight where V takes the val obsied fom Jamsen's epreson Me ee spat or aera preset 2uKh ahh mK resulting in a Jong longitudinal stress of W, cosec poeea Der, 1 Both fy and f, will be a maximum at minimum at the outlet. ‘An alternative procedure for finding the value of F An Muiately delow the waist is to use the limiting Hejgnt found from Coulomb, This method would the waist, and a pore v= 2wr, tan |—— 2 and represents the maximum pressure likely to be ‘obtained WORKED DESIGN NO. 1 RECTANGULAR TROUGH BUNKER fectangulae trough type bunker is required. to AcMamodate. 200. tons of dry Broken coke. the Sey or which te 32°1b, pereuft, and the angle of deny he clear inside dimensions are: length eae Semen walls sO: width Between side was 30 Tt BNSF trough to be 53 approx (35. triangle). and the outlet $1 wide Let it be assumed that the coke will be loaded into HE hunker irom 8 conveying system having a double iheoweft, The approsimate shape of the heap il teas een in Figs 42. ait7 Fi, 42 ‘This figure also shows the dimensions of any cross section, determined as foliows: The volume required to contain a load of 700 tons of coke sill be 700 >: 2240 = 49,000 fs and the volume per linear foot of bunker is 49000 = 816-66 12 0 4 Height of trough hy = 12-5 x — = 16°67 ft 3 Height of surcharge by = 7-5 tan 30° = 4-33 ft EXAMPLES 12-5 x 16-67 Volume of trough = 2 x 5x 16-67 2 = 291-67 Rt 15:0%4:33 ‘Volume of surcharges = 2 2 therefore minimum height of wall 816-66 — 291-67 + 65:0) 30 hy = 15-33 1 433 and the mean height hy = 15-33 = 17-08. Angle of rupture, rupture as Coulomb gives the angle of 90° + 30° At this angle it will be seen from Fig. 43 that the plane of rupture cuts the free upper surface and not the ‘wall, Thetelore shallow bunker theory may be used. 0 Fig. 43 In the calculations which follow the upper free surface of the contents will be considered flat and level. The fact that the material is contained within confined space, and that the surcharges are small compared seth the total volume this assumption is reasonable. Any attempt to use Rankine’s surcharge formula in this particular application sould. yield an unrealistic Vertical Forces In order to take account of the trough, self weight W, and Hy will be suitably adjusted as shown. ‘The vertical side ‘all will not be included here as it does hot influence the trough forces: it will however be Considered Tater when this wail is_designed vertical pressure at B is 32 = 56016 Ft will yield pac and will therefore be used co aa eas sol eld prac om tale Bin the appena, for ae inss ees pre cuaees S28 ton : 0 ‘ro ihstrate the we of the algebraic and graphical re stra ing te pressures and Forces etn oe upon the bunker, both procedures will be fully worked stiffeners and lining eon ions wl befor un length oF bunker so 0°83 Solurian by & a EH a The wetca and horizontal forts due to the pressures 7 ide ta Pure soe ace tun 2s follows 4 \ 196-67 oy Hy 4 4 1268 | \ \ 25-67 w/b wa Bee aeTE ® ® fia at 32 = 1667 » 125 Joke, = = 1488 tons 2240) Wy=coke, 32> (17-S+ 16°67)» 2-5 eee 220tons 2240 self wt of bottom plate 49 «2-5 sy = 0-085 2240 1-265 tons Horizontal Foxces “Those will be due to the lateral pressures set up by the coke, From Fig. 44 (6), the lateral pressure at_B Soll be equal to 32s 1T-S<4 = 186-67 Ib? Whilst at Cat will be 32 07-S= 16°67) 24 S3ed-44 tb! This latter pressure may be con Nemenily separated into two components: a constal iteral pressure between B and C of 186-67 Ib t= plus a varying pressure, maximum at Cof32 - 16°67 = 4 EVN ib? The sum of these component pressures being equal to 186°67 = 177-77 = 364-44 Mhich cheeks with the maximum value at C Then aarst tod = = 0-729 tons by = 32S 17S 16-67 1-389 tons 2 eoF YF — = 0-661 tons From the calculated vertical and horizontal internal forces, the external reactions may be Found, ‘Above the waist, the horizontal reactions at 4 and B 0243 tow and H, 0-486 tons Below the waist, the three reactions are 3646 - 1-488 ~ 1-265 6-399 tons tion at B. By taking moments about Vertical reaction. & Horizontal ree point 0 is Hy 3646 625+ 1488 8-333. 16 P1265 © 12-5—-1-389 - 8-333 “0-661 - 5° 556) 2-145 tons 39 ‘and horizontal reaction at C. By taking moments about B will be 1 = 8-646» 6: 25~ 1-488 8-333 T6672 1265 = 12-51-3892 8-333 =0-661 1D) 4-195 tons ‘And checking to show that © [=O (—ve forces outwards) Forces Reactions ~0-729 “1-243 1-389 0-486 0-661 145 198 2-79 79 which confirms the above calculations ate in order. Pressure ON TrouGH Watts ‘At B the vertical pressure is S60 Ibi, and the horizontal pressure 186-67 Ib ft. Likewise at these pressures are 109333 Ib ft and 364-43 Io ft respectively So that the trough plates and stiffeners can be designed iis necessary to know the total normal and tangential pressures acting upon the trough. For a 3.4.5, slope the normal pressure at B is 34" ay" so» (2) n10r (SJ =o me 5 5 and the tangential pressure 4 (560 186-67) x = * 5 = 179-19 Ife 5 Likewise at C the normal pressure is aN He 109-32 « Spr =) = eeeowne 3 5 and the tangential pressure 4 (1093-33 364-44) » = 3 349-87 Ib fet whence the normal load supported on the trough wall excluding self weight is 321-07-+626-6 5 ~ 416-67 98TE-S61b. oF 4-41 2 4 “The self weight of the trough wall is 0-52 tons and the ‘normal component of this is 0°52 0312, So that the total normal load supported on the trough wall is 4a) = 0-31 = 4°72 tons By resolving the vertical and horizontal reactions at B and C this. will serve as @ check on the preceding calculations. ‘At B, the normal reaction is 3 4 6399 x | 21S we — = 2-12 tons 5 3 and the tangential component is 4 3 6399 x= + 2145 x > = 6-41 tons 5 5 Whilst at C, the normal component will be 4 3 4195» = = 1-265 <= = 2-60 tons 5 5 ‘and the tangential component is 3 4 4195 ¥ = + 1-265 ~ - = 3-53 tons 5 5 Hence the total normal load supported on the trough wall will be 212-4 260 = 4-72 tons which confirms the previous calculation, Solution by Graphical Method ‘The graphical solution outlined on page 23 will be used, From the algebraic solution the vertical and horizontal pressures at Band C were found to be ACB vertical $60-00 Ibyft.t horizontal 186-67 Ibi At vertical 1093-33 Ib, ftt horizontal 364-44 Tb/ft? The maximum normal, tangential and resultant of the vertical and horizontal pressures at B and C may hoe obtained by, drawing the ellipse of stress, Position C will give the maximum normal pressure, and this will be required to design the trough plate: In Fig, 45 set off p) = 1093-3 = 04, and p, = 364.44 ‘ob and with o as the fulcrum draw circles having radii of oa and ob respectively. Produce the trough ‘wall at a slope of 3-4:5 to pass as shown through point o. . From this point draw a perpendicular ocd to Bue both circles. Now produce a vertical from ¢ and & horizonal from d to meet at ¢ which is @ point on fan ellipse. . Then oe will be the direction and magitude Of the resultant pressure at C and equal 717-6 lb/ft. The normal pressure will be represented by the line of having. the ‘value 626-6 Ib/ft? and the tangential pressure by the line ¢f taking the value 349-87 Ib, ft By repeating this procedure at position B the resultant normal and tangential pressures will be found to take the values 367-7, 321-1 and 179-2 Ib. respectively. 40. Fic. 45 ‘The next step isto find the total vertical and horizontal pressures acting upon the sloping wall BC. In Fig. 46 at (a) the vertical load equals the area of the quadrilateral 44° BC, that is 3.125(H,) ~ 1-488 (10) = 4.613 tons (to which may be added the seif weight of the trough, making 4.613 + 0:52 ‘At (b) the total horizontal load will trapezoidal 1-2-3-4, and equals 1-389 (4) ~ 0-661 (Ls) 205 fons. These two loads acting throught their own cg's will meet at a common point 0 in BC, This figure also shows the pressure (due to the contents only) acting on the wall BC, the trough BC, and the bottom plate. When the actual strength calculations fare carried out the pressures on the trough und bottom must be adjusted to include self weight = S434 tons) he area of th Proceesling further, the reactions at positions B and C due to the (rough loads, including an allowance for self weight, may be determined. This is shown at (a) in Fig, 47. The resolution of the forces at B and C duc to the load acting over the bottom plate (#4) is shown, at (6) in the same figure. “The summation of these forces is shown in Fig. 48 und confirms the values previously found by the algebraic method. sonst 31s 1-488 « 368-44 Ib/tt® ) Horizontal and vertical forces acting upon sloping wall BC Fic. 46 a Resolution of the forces at B and C Fic. 47 VN Ci AYR Final forest 8 and C Fic, 48 STRENGEH CALCULATIONS Suflicient information has now been obtained to permit the strength calculations to proceed. Design of Trough Plates The maximum normal pressure is at C and equals 626-616 fe, The tangential pressuce is 349-87 1b Ih “As the bunker is 60 ft, long advantage may be taken of the benefits of continuity, Assume BAT = WL? 12, and ry both q in. and ¥ in. thick plates, the section hhioduli for which are 0-281 in.2and 0-5 in. respectively. Limit the bending stress to about 18,000 Ib in Then with in. plate, piteh of stiffeners would be 6266 © BEX 12 ea = 0.281 18000 2 pe = 8072 He andb = 284ft = 34-1 in or b = 807 30 in. And with J in, plate, piteh of stiffeners would be OO 05» 18000 nD Bad andé =~ 3-79 ft 45.5 in or 6 = 80 = 40 in, The final choice of plate thickness will be deferred until the stiffeners have been designed, Design of Trough Srigeners Actual length of trough stiffeners is i667 = 5 Hs 20-83 fe 4 At A the normal pressure is 321.07 tb ft* and the angential pressure 179-19 Ibif.2 Similarly at C the normal pressure is 626-6 Ib,ft* and the tangential pressure 349-87 Tht Using the procedure described on page 28 6266 a A 195 21.07 then by interpolating Table 1 y= OS2671 and « = 0-1849 the maximum bending moment per unit length is therefore AP, ~ O-849 «321.07 » 20.83 25758 Ib fh 11-50 tons T. The tension to be resisted per unit length is obtained Irom the expression given on page 29. Since 7, tL wonsand x ~ 05267 2083 10.97 fh thon 1 Tenet (1 19> 1097 ia 10.97 [rons 29s] ) 2208s =5:32 tons Try a stiffener arrangement based upon one of the following: 4, Spaced at 30 in., bending and vension carried by plain beam section only. 'b, Spaced at 30 in, bending and tension carried bby a built up section consisting of u split beam séetion and part of the trough plate c. Aa, but spaced at 40 in. d. Ash, but spaced at 40 in. Arrangement a Try 14" = 63" M4 UB Z, 1150 «25 = 48-5 ins, 2 4 Wins 7-1) tons in? 65 532» 25 = = B33 tons int 10 total stress = fy f= 844 tons int Arrangement b Try asplit 21" » 84° » $5 UB plus 40 thicknesses of J in. plate dimensions for which ase shown in Fig. 49 an ae ee } joe (208 aaaee ica 8-08 in? = EI AY SIb. UB. Te ae dint Fic. 49 15% 0375 « OHBS ~ 808 x 8115 7 eae — 15 x 0.375 ~ 8:08 4-86 in. Ing = 5:63. ~ 4.678 © 8.08 » 3.26% ~ 84d = 292.9 ins 2929 So that Z) = —— = 603 in? 4.86 2929 and 2, 2 49.5 ind 592 “The maximum stress will be on the bottom Range and gives is) 25.2 aa 696 tonsin 5 saz x25 , 097 tonsin® : 1371 total stess = fir + fi = 793 tonsfin? Arrangement ¢ Try 16" 77 = 40 UBZ,, = 64-4 in? A = NLTT int 1$0 3:33 x 12 ona 333 7-14 tonsiin® h 532 = 1-51 tonsjin# t= — Ww total stress = Soy + fe Arrangement d Tey a split 217 » 81° » 68 UB plus 40 thicknesses of in. plate, dimension for which are shown in Fig. 50. 8.65 tonsiin# ver soot int PAI" x Oy" 5 6815, UB 20. 05» 025 ~ 10-01 = BATS DW O5- 847s 436 in. Tug = 10% 4115! 10-01 © 411 ~ 102-8 ~ 4414 int 4404 So that Z, =~ 101-2 ins 436 44-4 and Z, = 65.9 in 670 ‘The maximum stress will be on the bottom fang gives: 1s 2 333» 12 Su = = 688 tons, 659 - = 0.89 tons in. total stress = fay fr = 7-87 tons'in.® ‘A comparison of the four stiffeners and plate arrange- ‘ments is shown in Table 4, ooo Tsu |] plate | Toul | Gs we} Type | ib, | tb | wtb | Tb he a | | seas | 722 » | 27 | 3825 65 c | 40 | 680 | 108-00 | 324 a | 34 | 6600 | 10200} 306 TABLE 4 In terms of comsumption of material, zrrangement b is the most economical and will therefore be adopted. ‘The final stresses obtained are thus bending of plate between stiffeners gives # stress of 6266 «25 fuc= 6-2Btons in 12» 2240 « 0-281 [At the point of maximum bending of the stiffener the gnean normal pressure is 482 tb ft, giving a sitess ot 4g2 4 622 = 478 tons ind, foor = 6266 bending of stiffener. Checking stress on compressive side only, gives (1) for the masimum compressive stress which will bein the direction of the stiffeners NS % 25 «2 ite — = $:73 tonsiin? 603 f, = 097 tonsinas belore and combining in the form /* ~ f, vfaives Py. = (S73 = 097) = 03 = 4.78 6-19 tons int (2) for the maximum tensile stress a¢ right angles to the stiffeners, Joo = S73 tons intand f, a before, and combining, as above gives 478 + 03(573 - 097) 6.21 tons in? 0.97 tonsyin® Poe Design af Bottont Plate 4 part plan view of this plate is shown in Fig. 51.1 ‘sill he assumed for the purpose of this example the pening is 10 ft. long by 3 ft, wide, four of whieh ould be required in-the total Jength of the bunker Between the openings the plate must be capable of supporting a vertical pressure of 1093.3 1b fe4. The plate will also be required to sustain the horizontal Feaction H. which equals 4-19 tons t. 1 will be seen that the bottom plate may be treated as a closed rectangular frame, the design dimensions for ‘which are shown in Fig. 3 0.054 0.936 - 1-705 1-563 240.0 == 243.268, 1-705 the = = = 0.007 243.27 1-563 the = ——— = 0007 243.27 240 dey 0986 243.27 The unbalanced fixed-end moments take the values 419» 13.75! Mig Mig = ——— = 601 tons 4:19 x 158 Mog = MP 78:56 tons Distribution of these moments is given in Table § Pinal Bending moments ave shown in Fig. 32, i 0" oe #\e | : = + Tt ZR zi 3 | eF Fic. 51 \ Using moment ditibution techniques the stifnesses / cy vropaion actors used upon unit thickness ot | plat are ie 03 iL Fig. 52 Due to the great difeence in the limb dimensions eae (see Fig, 51) it will De practical and economical to GSSen fhe varlous pars" according to the maximum o. 3L705 Span moments 45 leis I Mbr. ab ba | @tactors ose | 0.007 FEM ~66.01 | +6601 | | balance 361 | +008 Final “a8 66.10 TABLE § Considering firstly the horizontal limbs abor bc. The Hence the maximum bending sisess in the plate will edge nearest the Opening will be in compression, but is restrained against instability by the sloping trough ‘The maximum moment ig 39-32 tons ft. in be wall Assuming 14 in. thick plate the section modulus is Ist 5 z= $6.25 in 6 39:32 > 12 Soci = 839 tonslin#? 56.25 which is satisfactory Considering the vertical limb ag. The outside (eompressive) edge is restrained by the end wall. In addition to the maximum moment of 62-4 tons fi this plate must be capable of supporting a vertical pressure of 1093-3 Ib’? plus a direct tensile force ue to H., Assuming 14 in. thick plate, as before, the section modulus is = 25 in2 Sacto = = 3:33 tonsiin? This portion of the bottom plate will be supported by the two trough walls and the end wall. ‘The fourth edge is unsupported. ‘The approximate bending moment along the unsup- ported edge, taking M — WWL#/10 is, 1093-3 = S* x 12 Mo = "= 14-64 tons in 2240 ~ 10 and the section modulus for unit width of plate is Bs 1s Ze = 45ine fros 3-25 tonsjin® be f= 333 + 3:25 = 658 tons in? Due to the horizontal reaction M, the direct tensile stress in this section of the plate will be 4.19425 + 5) fo = = = 0-Dtonsiint 30015 Giving a total stress of f= 658 ~ 0-70 = 7.28 tonsvin? which is satisfactory Treating the limb hb in a similar fashion obtains for the moment of 12-37 tons ft. a bending stress of 1237 x 12 <6 008 ES for a vertical pressure of 1093 stress of = 0-16 tonsin® Suess = 3 tb it, a bending 1093.3 « SEX 12 <6 fore ~ = 32Stons:in# 2240 «10 « 12 138 and for the horizontal reaction H,, a direct tensile of 4195-55) = ee = 0-70 tonsjin? 60x 15 Resulting in a toral stress of f= 016 = 325 + 0.70 = 4-11 tonsi which is satisfactory Design of Side Walls A preliminary investigation will show that a consider- able amount of stiffening would be required to accam= modate the net horizontal force tthe wast (Bh In addition. trested as a plate girder spanning the full 60 ft would involye the provision of one or wo horizontal splices in order to make transporting to site practical. Moreover the vertical stileners necessary to support the internal pressure would be broke! calling for special jointing to ensure continuity 46 For these reasons the bunker will be carried on four pairs af supports arranged to give three 20 ft. by 30 ft trids, The corner supports will coincide with the junction of the side and end walls, whilst the two pairs ‘oF intermediate supports will be treated as portal frames spanning 30 f., witich is the inside width of the bunker. “The side walls will now span only 20 ft. with a conse- ‘quemial saving in material required (0 form the horizontal girder at the waist. It is also to be observed that the spadepth ratio is now in the order eT 13 which makes plate girder theory meaningless. Catcutations for the side walls will therefore be based japon the assumption that as 2 plate stifened against horizontal pressure, it Will be strong enough in its ral depth to support the vertical Toads without the provision of a separate beam: the horizontal forces Wf and B will be taken by horizontal beams; the skin plate will have vertical intermediate stiffeners. The forces per unit length of side wall are shown in Fig. Skin Plates The ratio of panel height to width is about 3:8, therefore design plate to span in one direction. Take the pressure as 18667 Ib TR less say 10-67 Ib:ft? (tr allow for builtin elfects at the waist) equals 176 [bf and put stifleners at $ ft. centres. Assume 4 bending moment of wL? 10. then 116 «8 x 12 M = = = 2-36 tons in, 2240 10 «plate thickness of £ in. 2 73\t 9 Zor 12in, width of plate = — x (—) == ine 6 Mey 2 246» 2 = 638 tonsiin whence fre which is satistuctory, Heorivat Sufferers oud ta be supported is Total ceiangul W079) using e>etticients in Table 1, singe B= 0, « = 0.0641 chem B45 tons 0041 EN OT IESE x 12 x 5 Mw ~ 98-15 cons in. 47 Try a stiffener out of a split 16" x 54° « 26UBand including 40 plate thicknesses, the properties for which will be found to be Ing = 102-96 in, Zeomp, = 39°82 in, Zinme. = 48-35 in then 9815 She“ a = 246 tonsiin t 39°82 and 5:34 tonsiin® At the position of maximum bending in the stiffener the horizontal pressuce is 79 1b f, giving a bendi stress in the plate of ” 176 combining gives # maximum compressive stress in the direction of the stiffener of Pye = 246 +03 x 3-76 and in the direction of the skin plate a maximum: tensile stress of Py 376 $03 x 246 = 450 tons int which are satisfactory 4838 = 3-76 tonsiins 3-59 tons in# At this stage it will be assumed that the side wall witl be delivered in two pizces, having a vertical joint at mid span, Both the top and bottom horizontal stiffeners will therefore be supplied loose for subse- quent site fixing, Part of the skin plate will not be included in the design of these stiffeners for this reason Horizontal Stiffener at A ‘The horizontal force at this level is 0-243 tons f1., and the bending moment to be resisted is 0-243 x 20% x 12 M= = 145-8 tons in. 8 using a stiffener from a 10" < 34" << 24 chan Zayq = 2-37 in the stress is 1458 frog = ——— = 6-82 tonsyint 2137 the compression flange is fully restrained and the deflection is less than span 360, therefore section 1s satisfactory Horizontal Stiffener at B ‘The net horizontal force at this level is 2-145 — 0-486 1"659 tons/ft., and the bending moment to be resisted is 1-659 x 208 x 12 M 995-4 tons in 8 using a stiffener from a 21° x SY" x 62 UB Zaq ~ 1264 in. (Pee by B.S.449 rules is 8:2 tons ‘in.?) tie stress is 995-4 126-4 ‘The inside (tension) flange of this member will be holed for bolting to the side wall and trough skin plates. ‘The vertical force is 6-4 tons f which must Be resisted in transverse tension in this flange. This force gives a stress of 64 facto £88 tons(in# = 0-87 tonslin® 12 x 0615 Itis of like sign to that of the primary stress and need ‘not therefore be combined, The vertical load carried by the side wall is W = 20 x 6-4 ~ SW (say 35 tons) = giving a shear stress in the wall plate of BIS x 8 -—— = 0-84 tons/in DRITS® 2x3 This shear stress is very small, but before it is dis- missed as safe consideration should be given to the probable critical stress in view of the panel dimensions, Timoshenko" has indicated that in a panel subject to shear the critical stress is ket D 31-5 tons 4 Yor = ° where 1) is the flexural rigidity of the plate, and k is a factor approximately equal to 535 4b" then putting b = 5,4 = 175, bla = — a +4(2)-s0 3 13400 and D= = iate 20-034 then’ dep = S67 X ot DITA Q i, 48 aa = 68659 @ Yin. and b = 60 in. 1 = 1/160 whence 68669 ———— = 2-68 tons ‘int 160 = 160 which leads 10 a F.0.S. against crippling of en 268 with ¢ G0 = ms 3:19 q Oe the plate is therefore safe. It should be mentioned in passing that the above procedure does not take into account the post buckling behaviour of the plate. This phenomena has been considered, with structural benefit, elvewhere Design of End Walls The end wall serves the same purpose as the side wall and will be subject co similar horizontal pressures Values given for fy, L; and £, in Fig. $4 are approp- At the centre of the end wall the horizontal reactions (called levels A, B and C for the side wall) will take the values = 0-243 tons 3 2, i 3 1389 0-664 = 0-486 4 + 1-401 tons L, 2 Hote ee 1389 2» 061 -——4 m= 1-436 ons 2 3 Above the waist the vertical stiffeners will be position ed at 5ft, centres. Their size will be identica! with the side wall stiffeners calculated on page 46. Below the waist the vertical stiffeners in the middle section of the end plate will be placed at 2 ft. 6 in. centres and opened out 10 5 [t. centres towards the tends. Calculation will show that these stiffeners can bbe made indentical with the side wall stiffeners. ‘The horizontal stiffeners at levels 4 and B will be designed assuming that the lateral pressure is shared between the side and end walls Fig. 53 shows the loading arrangement assumed for the horizontal stiflener at level 4. The figures in brackets represent the loading arrangement for the horizontal stiffener at B. en [r-o0ery Ts10t 151g" 49 Then stiffener 4 will be required to resist a bending moment of M = [2[2126 x 15 ~ 1-519 x 6-67 — 0-607 x 1-25] 252-14 tonsin, AIX x 3 9 tonsin, x 28 chan, would be stressed to nearly wat the deflection would be excessive. A 15" > 4° x 37 chan. would be stressed to 5-29 tons in2 but the deflection is less than span 360 and will therefore be adopted Similarly the horizontal stiffener at B will be required to resist a bending moment of M 8.756 12 [12-258 » 15 1454 tons in x SP x 82 6-67 — 3-502 s 1-23), A2U x 8 UB would be stressed 10 8:52 tons in# and the deflection would be less than span 360, The general arrangement and typical details of this bunker are shown in Fig. $4. 18° x4" x37 Chan, 30-0" inside side walls | iol a =I | | 8 | 4 L/ | | t T1 rL so Se Detail at A Part End Elovatlon Part Crass Section Detall at & Fig, 54.4) 50 3 4 ‘Therefore the minimum height of the cylinder would 4(4356-22 — 833-26) 11-532 fe 208 x Now if the cylinder is fabricated to this last deter- mined figure, there will be no margin to guard against spillage which undoubtedly would occur. If, ta the other hand, the cylinder height ismade 13°86. 14 fk. for all practical purposes, spillage will be climinated and, i necessary. oF if possible, the material may be raked level. Before proceeding with the actual design it will be seen on applying Coulomb's formula that the angle of | rupture cuts the free surface of the material and not the wall, Hence shallow bunker theory is approp- riate. B = 625° and = 20 tan 62°5° == 58-42 ft, which is greater than 1153 ft Desicn OF THE SHELL 1. Cylindrical section Immediately above the waist the vertical pressure, assuming the material is raked level is, 50 x 13-86 = 693 Ib. itt Rankine’s factor will be 1 —sin35° 2 0-71 1 sin 35° so that the horizontal pressure will be O27) = 693 = 187-79 PoE iving a hoop tension of 187-79» 20 1877-9 tb. fh and assuming 3 inch thick mild steel shell plate the hoops stress will be WIT m= 625-97 Ib 2 x 025 n is obviously well on the safe side, but for all fctical purposes # inch plate is not unreasonable. Conical seetioas Fwo completely separate cets of calculations will be carried out. Ga) tinmediitely below the waist: and (b) at the outlet ua AL this level the vertical pressure is 693 fb. ft? as arc Ste ich! eee nana rears on the cone pines “03 a) e 2 00:29 02 snap woof ar resling in hoop teson of 0-29 S00 120 » cose 50° = 54 jn i e asaming once agin ish thick wil tes plate the hoop stress will be sas = 2176 Ib.jin+ 0-25 “The inclined tension will have a maximum value at thks fevel. and the loud inducing this tension will be the total bunker enntent ie, 12S tons, plus the self ‘seight of the cone and kning. Taking the shell piate Se inch thick with a litmg material worth about th ca. fie the approximate weight of the cone ‘would be 7:5 tons, ‘he inclined tension is therefore (25 = 75)» 2240 —. » eosee $0° = $13°7 Ibyin, Dees We D resulting in a longitudinal stress of 513-7 0-25 2054-8 [bint n alequaste ving these fa, putting a stress Both the longitudinal very low, and therefore have margin of safety. However. bs stresses in the principal stress. f fi = WSR f= Whand f= Mts will be seen to be = 2084-8 oF — 217%. (0) at eter A ths eel the eri pres Toss) which ua 1300 VBS snets0 = 39) wrso[i Si BO 4 and gives a normal resulting in a hoop tension of 66:3 be TS ¥ cose SI = MEE 38 Bacin 144 ‘and with } inch thick plate will give « Hoop stress off 141-26 a s68-dd thine 0-28 ‘The longitudinal stress at ths outlet will who be due to the vertical pressure of 1200 Ib. {4 (in the hi — = self wt the expression IF, ~ second tio terms Will be equail ty z2re sine there is nothing below the outlet) Hence the longitudinal tension will be rs 0 27-91 Th. in eae S12 fiving a longitudinal stress of 7-91 A = 391-62 Ibn? 0-28 Clearly, the actual stresses at the ou}iet ace minimal moment of and therefore of no coneera. An act this bunker is shown in Pig, 56 | 20-0" internal diameter of lining Bee LT __ butt welded joints \ 1-0" ds ab / oeran wet = shell plates £ thick DETAIL "AY welded joints \ unite lining—=, “shell plates ‘welded joints 1 é Dera [ser ntrnaldnmeter 4 eqully spaced suppor braces DETAIL A’ gate details Fic. 56 55 DESIGN No. 3 DEEP CIRCULAR BUNKER A citeular silo is requited to carry $00 tons of wheat, the density af which may be taken as 50 Ibs. per cu. ft and the angle of repose 25°. The inside diameter of | the shell allowing for lining is to be 20 ft., the cone angle $0° and the outlet 1 ft. diameter. Assume po == O-4and K = 0-466. Following the procedure in the previous example, the minimum volume required to support a Joad of 500 tons will be 22400 fe The cone will have a gross height of 20 tun 50 = 1-917 Te sand the height lost by the cut-off is = tan 50° = 0:596 ft. hence the volume of the cone will be J foe x an — 1 x os R 1247-95 > so that the volume of the cylindrical section is 22400 — 1247-95» 21152-08 ft ‘and assuming a level top surface the minimum height fof the eylinder will be 7°" and f= 20 tan 87-5 31-39. ‘which means that the angle of rupture cuts the wall before the free upper surface, hence silo theory. This is shown in Fig. $7. Using Janssen’s formulae, and assuming the co- ficient of friction between wheat and wall, x’ = 0-4, and the ratio of horizontal to vertical pressure, K = 0-406 Fi. $7 rw the mean hydraulic radius will be 7) = = sth we 0x5 a = 025 Ib ttt Od wk 4 x 0-466 and 0-03728 then the horizontal pressure, L will be 1 I 625 ae and the vertical pressure, V = L'A will be 1341-20 To find L and ¥, multiply the common log of 003728, take the reciprocal of antiloz from unity and multiply the answer by the number outside the bracket. Values of Land V are given in Table 6. 36 ut rtnmaneinnetn, eNAENCNE ESTES TCO EE TE ET CE A A CC Te eet 0-037284 7609 0 320-66 05247 0 374s 0-3610 856-97 0-248 1007-74 O13 mrs 0-1180 1182-98 10-0813 inLD TABLE 6 If Rankine’s formula was used the horizontal pressure under a head of wheat of 67°33 ft, would be 50 4 67:33 x —— = 1366-86 Hb. f= and the vertical pressure 50% 6733 — 3566-66 Ib. which immediately shows up the obvious difference between the Janssen and the Rankine methods. For a shallow bunker /¢ was found to be 31:39 ft AU this depth the maximum vertical pressure would be 50 x 31-39 == 1569-5 Ib. ft? and the horizontal pressure ©3139 x 0-406 = 637-22 Ibe? TTT TTT) Janssen (horizontal [anssen (vertical Rankine ‘Coulomb TP Goonzontan Ne Rankine Couloms . | qworticaty Too 800 12001600 Pressure (lb/ft?) Fig. 58 ‘The vertical and horizontal pressures due to. both Janssen and the shallow bunker theory of Rankine are shown diagrammatically in Fig. 58. Now the amount of wheat stored in the cylindrical portion 472-17 tons 4 But according to the maximum pressure found from Rankine this would be 1569-5 Or from 40x 4 ‘Therefore the amount of wheat earried on the wall will be somewhere between 472-17 ~ 220-11 S1D17 — 179-83 = will be assumed that the top of the silo is enclosed so as to provide a Working platform upon which sil be mounted a conveying and stowing plant. “Allow 25 Ib./ft? for the platform framing and steel deck, plus 75 ib.ift? for plant and other imposed loadine 252-06 tons 292-34 tons and ‘Total load at silo top will therefore be (25-4 78) « 208 = 14-02 tons 2240 + 4 The undesirability of having the internal surfines of the shell of stecl in its as-delivered state is absi0us in view of the contents involved. A lining of wear resistant files will be assumed. the weight toxether swith the shell plate would be. say 35 Ib..tt Make the eylindres! seeion 72 f. deep, This will AMlow for any surchorgine and will provide space for the roo! structure. The deud load of the shell and lining wil therefore be a5 ve Ss 70-69 tons 2 Senmarsing, the veil sto Be ated by Hh Re Dean se om Satie of ella ong Cees ee ma 14-02 tons 0-69 22M Torat 7-05 say 380 tons his gives a load per inch of circumference of 380 2240 Wea und w compressive stress, taking the shell as + inch thick of ~ 1128-95 1b, 2 «16 3612-64 Ib. in? c horizontal pressure (see Table 6) ‘The hoop tension due to this 1s $74-22 Yb. ft pressure will be S742 4 20% 12 478-52 tb fin 144 x 2 civing a hoop stress of 478 6 = 1531-25 tb.lin.® 5 ‘The maximum stresses in the plate, using the Poisson's sitio method would be BOD G4 + 0-3 4 1531-25 = 4072-01 Ib. sine tension TS31-25 0-3 ~ 3612-64 = 2615-08 Tb. fins These stresses are very low and therefore should not sive rise to concern Considering the cone. Immediately below the waist the lateral and vertical pressures obtained by Janssen ould ake’ the maximum values given in, Tale 6, Ghat is = 57422 Mb tt and V = 1282-22 Ib.iit® However, the liniting height for a shallow bunker is found to be 31°39 ft, and would give a higher vertical pressure, equal to 1569-5 Ib.ift® 38 6 ‘There is always some clon true pressures ina deep the cone will be designed Vox 1569-5 Ih. fk? respective ‘The total vertical load 1 will be ducto P1865 6 19 = material to cone $0 1247-95 S.IV, of cone cay Tor ib which gives a longitudinal ten 572.470 1 50 Dew 10 and a longitudinal stress, assum gets » 16 5 The hoop tension will be 514-22 x 10 » 12 BITS Ib. int 14a resulting in a hoop stress, with si AIB-52 + 16 a 183125 Thin inch plate of [As hoth of these stresses ate of ike sign, it i abviows that theie combination in the form f° , wil bbe less than fF At the outlet, the stresses will be of a lower ord than those already determined at waist level, und wii not therefore be calculated The ring beam, This will have to support the full contents plus the self weight of the bunker. snd the platform and plant which is located at the top. total load to be carried will be as follow Contents S00 0 Self weight bunker 1s Platform and plont 1 Ring beam 3 Tora 7 To keep this ring girder within practical dimers! limits provision will be made for eight equa! s spac support positions, In order to avoul ecwvitrie! loading, and to facilitate easy ereetins the ty be arranged 10 be immediately under the waist nel of the same diameter as the shell. The rexction shear and moments, using the ¢oelficienty in Ta will be as follows Reactions 0-125 x $95 = 74-38 tons Shear 10-0625 x 595 37-19 tons: BM at Support 0-60827 % 595 x 10 x 12 = 590-48 tons in, BM at Mid Span D-o0d16 & 59S x 10 x 12 = 297-02 tons in. Torsional Moment "0.00063 > 505 x 10 x 12 = 44:98 tons in, ‘Compression 10:5 x 595 x cot 50 249-60 tons efore proceeding further it is worth giving some thought to the method of fabrication appropriate 10 this type of girder, It could be made by rolling to a 26 ft. radius three lengths of universal beam, ac~ Curately cut to the correct are dimension and spliced fy welding on assembly at site. A completely shop aesembled ring is not oUt of the question, but trans- portation may not be easy. Alternatively, it may be fabricated from plates, The web would present no problem as the plate may be passed through the rolls give the required radius. The flanges would have to be flame cut to the correct profile, involving some waste. After cutting etc. the whole may be welded together to form the ring, which like the UB could arranged in three parts ready for site assembly: For the purpose of this example # universal beam will be assumed, Try 24" x 97 x UB in LYS, 27-63 jn 220-9 in. Bbin* 24°29 in, 0-872 in, Properties are Area = Zz a ft the support the stresses are 590-48 20-9 249-6 = = 2-67 tonsfin# ending foc « compression fi 9-03 tonsjin# 2763 torsionf; = 0 261 4s = 0569 ++ 0184 = 0-753 sand at the point of contraflexute the stresses Pre are: bending fa, = 0 compression f, = 903 tons/in# as before torsion f"s, This will be found by an ap- proximate method as follows: Divide the torsion moment by the distance eentre to centre of beam Manges, thus producing two equal ‘and opposite horizontal forces. Then calculate the bending moment on each flange due to these forces regarded as acting upon a closed ring. My (a1) Where k is a constant, the derivation of which is given in the appendix. For an cight point system from Table Dk = 0-066 Henee Ms x kr 44-98 then M’, = ——-———-— 0-066 » 10» 12 (24-29 — 0°87) = 15-21 tons in, == 1-35 tonsjin* CNore:—The section modulus of each flange about 9 the vertical axis of the beam is approximately equal Zn to 2 then fe Sire 135 42 = 0-569 + — Pe Pac 145 = 0-569 + 0-093 = 0-662 The section selected is therefore satisfactory. An arrangement of this bunker is shown in Fig. 59. main beams. = Shell plates 4" thick circular support beam on eight columns equally spa r | Oxe ne L | —: | | 2" tiled lining a \ x | 24" x 9° x 94 Tb, ULB. I | a z : ona aa xe Ls! gate details Fic. 59 60 ae 12° internal diameter DETAIL ‘A’ Bibliography Lows, E. H, Hydraulics and the Mechanies of Fluids.” Pitman, Janssen, H. A." Versuche Uber Getreidedruck in Silozellen.” Zeitschrift des Vere Deutscher Ingenieure. 1895.) 1085. Auey, W. “The Pressure of Grain (Loads on bin walls)." Inst. Civil Eng. min. of Prac. Vol CXXXI. (1897-8 pt. 1) Reworer, M.and A. “Silo.” Editions Eyroftes, Paris. Rowe, RE. “An Investigation into the Cause of Cracking in a Reinforced Conerete Sito Containing Cement,” Magazine of Concrete Research. Vol. 11. Guy, 1959.) 6. Lencanex, D. The Distribution of Pressure in a Model Sito containing Cement.” Moracine of Concrete Rescarch. Vol. 15, (July, 1963.) 7. Licmiroor, E. and MicHart, D. ™ Prismatic Coal Bunkers in Structural Steelwork.” Structural Engineer, Vol. 44. (February, 1966.) §, Rankine, “On the Stability of Loose Earth.” Phil Trans. Royal Society. Vol. CXLVI 857.) 9, Keren, M.S. Walls, Bins and Grain Elevators." McGraw-Hill, New York, 3rd Ed. 919.) 10. Grastior. “Theorie der Elasticitat und Festigkeit." (Berlin, 1878.) IL Mencky, H. “Der Spannungszustand in Rechteckigen Platten.” Damstadt, publ R. Oldenbourg, Munchen u Berlin. (1913) 12, Pounper, C.C. Design of Flat Plates.” 4#SD. (Session 1924/25). 13, TnMostieNko, S. and WoINowskY-KRIEGER, S. " Theory of Plates and Shells.” McGraw-Hill, (1959) 14, Mansrictp, EH. “The Bending and Stretching of Plates.” Pergamon Press. (1964,) 15, Saab, S. and HeNpay, A. W. "Gravitational Stresses in Deep Beams.” Structural Engineer, Vol. 39. (June, 1961.) 16. Coutoms, “ Mém de Math. et Phys. Acad. Roy. des Sei. Paris. (Année, 1773.) 17, Benson, C. S. “Advanced Structural Design.” London. Batsford. (1959) 18, Brivcts, G. P. The Design and Construction of Silos and Bunkers.” fastinution of Civil Engineers Struct. and Bidg. Eng. Dis. (1951.) 19, Jentke, ANDREW W. * Why Bins don't Flow.” Mechanical Engineering. (May, 1964.) 20, Punts. A. B. “Pressures in Silos." Concrete and Constructional Enginecrine. (October, 1965.) 21. ANDERSON, PAUL. “Temperature Stresses in Steel Grain-Storage Tanks.” Civil Engineering — ASCE. Ganuary, 1966.) 22, Davies, 1. D. and Srerwens, G. L. "Pressure of Granular Materials (Tests on Mode! Container)” Concrete and Constructional Engineering. (September, 1966.) 23, Lexcznrk, D. “Pressure in Containers. of Granular Materials.” Concrete and Com structional Engineering. (May and June, 1964.) 1M, Lexcaner, D. “Cohesive Arching of Bulk Materials in Bunkers and Silos.” Civ Engincering and Public Works Review. (November, 1966.) 25, SaviMEL. P. ““Approaimate Determination of Stresses of MultiChamber Silos with Partial Filling.” Acter Stahl Steel. (December, 1967.) 26. ReimaeRr, M. and A.“ Economical New Stee Silos with Autodeformable Walls for the Storage of Grain, Flour and Forage.” Acier Stahl Steel. (January, 1967.) Krensky, O. A., Flint, A. R., and Brows. W. C. “The Basis for Design of Beams and Plate Girders in the Revised BS 153." Proceedings, Institution of Cisil Engineers. (Aug. 1956) ol APPENDIX WEIGHTS OF MATERIALS, NATURAL ANGLES AND FRICTION ANGI RANKINE FACTORS NO SURCHARGE (K,) RANKINE FACTORS WITH SURCHARGE (K,) BENDING MOMENTS IN CIRCULAR BEAMS SUBJECT TO RADIAL FORCES: WEIGHTS OF MATERIALS, NATURAL ANGLES AND FRICTION ANGLES i fea Mareriat ) waar ’ 4 be Rowanks i (lot?) | | Coal i | PON Bituminousdry8&broken | 50 | 35 | Putverised aerated 35 20 Pulverised compact |) | 35 25 | Welsh ce) | Anthracite } | Dry and broken Sere are 2 27 Paiverised aerated a | 5 20 | | Pubersed compact <. | 60) 25 20 3 | | Coke | i { | | "Bry. broken oF loose 3% | (#0 20 | | Dry dust j 2 | | Washed itt ) 4% | i | ash | | DryCompact 45 ao | a | 3s j | Loose o | » 20 30 ‘Wet, saturated m | 2% 15 20 From pulverised fuel | ay loose 70 30 20 30 | cinders 50 45 Cinder tap 80 | oatranne" 65 40 | Coal gas 56 45-30 Cement 9 | 20 |" Clinker 8390 | 30-33 | | | cla” 103 | ‘sand, dry loose wo—100 | 3-3 | 2 | 0 | Sand, wet saturated 120 25-30 3 | 2 | | Gravel and sand 10-110 25-30 15 2 | | sts 65 min, | ’ | Earth } 100-120 | 26-37 | Grains | i ("Barley wo | 2 Wheat sss 3S Ores \ | |" Dotomite ore 3 | i | Haematite wo | as | Holywell iron ore ; “so | 50 | Labrador “A” | 130 | kabrador °C 163 | Lincolnshire | | Cuenza | 12 | \ | Kiruna | 17 | | Bolivar 14g | | | Magnetite 250 35 j | Manganese 160-180 35 | Mancorvo_ 158 | Wagner Vivaldi 12 | Wabana 151 \ 5 % friction angle on | Limestone 80-112 35 steel Finished Sinter 17 } 4, = friction angle on | Copper | 160180 38 ! | concrete Lead | 320 35 i | Zine [oo | 8 | ' TABLE A o4 ‘Table B gives values of K, obtained from the Rankine formula Table C gives values of A obtained from the Rankine Surcharge Formula be cos5 — aos = cos Sra ECH ee a ! 10° 45 I —| L | | 9 1-0000 - i eet 07919 7 5 0:6738 i : . j | | ootae | 0.7532 | - =-jfrotcr 5 ao | oss | oezar | 0000 | = = = | - - | dx | 94958 | 03620 | 07203 | Bee eee ae = ze | bee | 3ee | 320 | ao | = | = | Br | oss | guns | oft | oso | | i ao | 03849 | 03743 | O-4408 | 05446 | L000 . - 38° | ger | 03073 | 03423 | 0-4007 | +5099 | 1-000 ~ |. 02282 | 02529 | 02665 | 03034 | 0-363 | 0-459 | 1-0000 7 3807792 | o-ta96 | 0.058 | 02304 | 02679 |_0-7201 | oust | 1.0000 TABLE C 65 BENDING MOMENTS IN CIRCULAR BEAMS SUB. TO RADIAL FORCES Consider a circular ring subject to a number of symmetrically disposed equal radial forces 1V as shown in Fis Al (a). The maximum bending moment in the ring will occur at the point of application of the loael. Cut the ring as shown at (6) in Fig. Al, then it will be seen that the moment at point o will be F : 7 — w. —_.w @) ) Fic. Al = RU ~ cost), x = Rain? ra) substituting these values gives WR 1+ cos wR men, UE = ont) by using strain energy methods, 2 eM, and ds = Raw 66 upon integration and reduction it will be seen that, a si CS \G i vm) + cost — 1 — where mis the number of loads aeting upon the ring, then but 2 = wee This expression may conveniently be written in the form M = kWR Table D gives values of factor k in terms of the number of loads n. TABLE D

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- JPCRDM9 - NIST-JANAF Thermochemical Tables, 4th EditionDocument1,961 pagesJPCRDM9 - NIST-JANAF Thermochemical Tables, 4th Editionfujiman35100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- JPCRDS1V14 - JANAF Thermochemical Tables, 3rd Edition JPCRD 14, Supplement No. 1, 1985Document1,858 pagesJPCRDS1V14 - JANAF Thermochemical Tables, 3rd Edition JPCRD 14, Supplement No. 1, 1985fujiman35100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Torque ProceduresDocument1 pageTorque Proceduresfujiman35No ratings yet

- Heat Transfer in Agitated Jacketed VesselsDocument7 pagesHeat Transfer in Agitated Jacketed Vesselsfujiman35100% (5)

- Part A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves FurnacesDocument25 pagesPart A1 Chapter 2 - ASME Code Calculations Stayed Surfaces Safety Valves Furnacesfujiman35100% (1)

- Agitated Vessel Heat Transfer Design PDFDocument3 pagesAgitated Vessel Heat Transfer Design PDFmrariffNo ratings yet

- Convection Heat Transfer in Baffled Mixing TankDocument7 pagesConvection Heat Transfer in Baffled Mixing Tankfujiman35No ratings yet

- Understand The Thermal Design of Jacketed Vessels - Garvin June 1999Document8 pagesUnderstand The Thermal Design of Jacketed Vessels - Garvin June 1999fujiman35No ratings yet

- Torque Values PDFDocument6 pagesTorque Values PDFfujiman35No ratings yet

- Steam-Water Two-Phase Flow in Large Diameter Vertical PipingDocument11 pagesSteam-Water Two-Phase Flow in Large Diameter Vertical Pipingfujiman35No ratings yet

- Fired Heater Design and SimulationDocument6 pagesFired Heater Design and SimulationHarold Fernando Guavita Reyes0% (1)

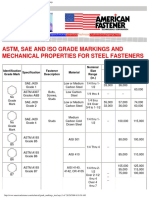

- American Fastener - ASTM, SAE, and ISO Grade MarkingsDocument7 pagesAmerican Fastener - ASTM, SAE, and ISO Grade Markingsfujiman35No ratings yet

- Optimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073Document6 pagesOptimization of Plate Fin Heat Exchangers Used in Natural Gas Liquefaction - ICFD10-EG-3073fujiman35No ratings yet

- NASA - Practical Applications of Nuts and Bolts For The DesignerDocument206 pagesNASA - Practical Applications of Nuts and Bolts For The Designerfujiman35No ratings yet