Professional Documents

Culture Documents

FlashLight Details

Uploaded by

mailbkrao0 ratings0% found this document useful (0 votes)

80 views28 pagesDIESEL LOCO FLASH LIGHT

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDIESEL LOCO FLASH LIGHT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

80 views28 pagesFlashLight Details

Uploaded by

mailbkraoDIESEL LOCO FLASH LIGHT

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 28

nu

Le Bs furl ie

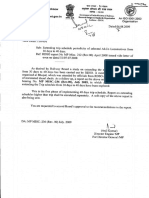

‘ GOVERNMENT OF INDIA “ u 0522- 460/23

MINISTRY OF RAILWAYS

(RAILWAY BOARD)

No.94/M(L)/466/32 Dated: 23.02.2001

jeneral Managers,

I Indian Railways.

Sub: Automatic “Switching-On” of Flasher Lights on Diesel and Electric

Locomotives.

During train parting and alarm chain pulling on air braked trains, the drop observed in

brake pipe pressure on locomotive is very small as the brake pipe is continuously charged by a

bigger opening of %” by the compressor irrespective of train condition. The depletion rate of

air being less than the air charging rate, the drop in brake pipe pressure on loco is not adequate

to give indication to the driver or ensure automatic application of train brakes.

2. To overcome this problem, RDSO has proposed a modification on the brake system of

locomotives to provide two stage charging of the air brake pipe using a magnet valve and a

choke. When brake pipe is charged through the choke, charging rate is less and it is known as

‘Run’ position of the magnet valve. The magnet valve is kept in this position during normal

sunning of the train, When the brake pipe is charged through magnet valve and choke, charging,

rate is more. This position of magnet valve is known as ‘Release’ position and is used at the

of initial charging and brake release,

3. An important by-product of this modification is the ability to ensure automatic “switching-

on” of flasher light by sensing the drop in brake pipe pressure of locomotives which is

otherwise not possible.

4. After extensive laboratory tests and field trials, RDSO has firmed up the scheme of

modification and the details are enclosed as Annexure-I to this letter. Annexure-II gives details

of method of checking by the shed maintenance staff and driver during routine maintenance

and train operation respectively.

5. The modification broadly consists of the following,

© Fitment of two pressure switches and a magnet valve to ensure “release and run” feature

on the locomotive

© Modification of electrical control circuit of locomotive to bring the engine to idle

(diesel) or GRO position (electric)

© Introduction of time delay of 60 seconds to permit build up of requisite 4.8 Kg./Cm*

without actuating flasher light in normal brake application

‘+ A'5.5 mm choke on locomotives,

‘© Increase in orifice size of alarm chain apparatus of coaches from the existing 4 mm to

8mm.

fe

A

6. The system is applicable only to air braked trains. On vacuum brake trains especi

train parting is in the rear coaches with locomotive power in full, the system is not effective and

the flasher light may not be “switched-on” automatically. In addition to train parting, alarm

chain pulling, flasher light will be switched on in ‘Run’ position of magnet valve aller full

service brake application till a brake pipe pressure of 4.8 Kg/Cm* is achieved.

7. During emergency brake application, flasher light not be switched on

automatically, although the engine will come to idle/GRO position.

8. The above modification will ensure that on freight and passenger trains at the time of trair*

Parting/alarm chain pulling, there is automatic application of brake, engine comes to idle/GRO

position and the flasher light is automatically switched on.

9. The cost of modification is estimated at Rs. 20,000/-. The description/specifications and

likely sources for the supply of materials required for the modification as advised by RDSO are

enclosed at Annexure-Il.

10. The scheme of modification to be followed by the Railways will be as under:

+ Asa first step, in order to gain experience on the modification, debug teething problems

and train Loco Inspectors, Railways may carry out the above modification on 10 diesel

& electric loc motives each on their system in the next two months.

‘© Railway Board, in the meanwhile, will finalise the rate contract of pressure switch and

magnetic valve/time delay relays required for the modification

‘© Railways will carry out the modification on all remaining BG main line diesel &

electric locomotives in a time frame of one year from now.

‘* Modification to the orifice of passenger alarm system of coaches fiom the existing 4

mm to 8 mm will be done in a time frame of 4 months after the modification on all

locomotives has been completed

* The size of brake pipe charging line on some of the Electric locomotives would have to

be changed from the existing 2" to %4” diameter to reduce the brake release time on

train

11. The modification is only intended to assist the driver in identifying abnormal situations and

does not seek to absolve him of his role in “switching-on” the flasher light. The ultimate

responsibility for immediate “switching-on” of flasher lights in abnormal situations

causing infringement of adjoining track will continue to be of the driver and the ex

instructions in this regard will continue to be applicable.

12. This letter is issued with the approval of Board (MM & ML)

@\ ~

Enel: As above (Shakeel Ahmed)

Exec.Dir.Mech.Engg.(Trac

n)

Railway Board,

epy bo

PG /RDSC, Lackarn

rer ee

i

t

!

if

I

ii

ity

»

HM

i

I

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Must Change Item in PohDocument23 pagesMust Change Item in Pohmailbkrao100% (1)

- Concepts of SubmarineDocument17 pagesConcepts of Submarinemailbkrao0% (1)

- Pinion and Bull Gear IDocument11 pagesPinion and Bull Gear ImailbkraoNo ratings yet

- Fabricated BogieDocument16 pagesFabricated BogiemailbkraoNo ratings yet

- Move of GM LocoDocument17 pagesMove of GM Locomailbkrao100% (1)

- 125 Ton Drop Table - SEC RailwayDocument34 pages125 Ton Drop Table - SEC RailwaymailbkraoNo ratings yet

- 50T Drop Table SEC RailwayDocument28 pages50T Drop Table SEC RailwaymailbkraoNo ratings yet

- MP Misc 255 April 10 Emd CommissioningDocument6 pagesMP Misc 255 April 10 Emd CommissioningmailbkraoNo ratings yet

- Failure of PinionDocument6 pagesFailure of PinionmailbkraoNo ratings yet

- Fuel Tank CalibrationDocument4 pagesFuel Tank CalibrationmailbkraoNo ratings yet

- 144372311Document201 pages144372311mailbkraoNo ratings yet

- RSB Bolt LooseningDocument5 pagesRSB Bolt LooseningmailbkraoNo ratings yet

- Hyd DamperDocument12 pagesHyd DampermailbkraoNo ratings yet

- Eye Type DamperDocument3 pagesEye Type DampermailbkraoNo ratings yet

- 40 Days SCHDocument23 pages40 Days SCHmailbkraoNo ratings yet

- Susp BRGDocument16 pagesSusp BRGmailbkraoNo ratings yet

- TSCDocument17 pagesTSCmailbkraoNo ratings yet

- Specification For FOG PASSDocument15 pagesSpecification For FOG PASSmailbkraoNo ratings yet

- Rubber Buffer SpringDocument14 pagesRubber Buffer SpringmailbkraoNo ratings yet

- HKKJR LJDKJ Jsy Ea KyDocument18 pagesHKKJR LJDKJ Jsy Ea KymailbkraoNo ratings yet

- Axle Box and BRGDocument20 pagesAxle Box and BRGmailbkraoNo ratings yet

- Happy PadDocument18 pagesHappy PadmailbkraoNo ratings yet

- High Capacity Side BufferDocument9 pagesHigh Capacity Side BuffermailbkraoNo ratings yet

- BR Block 08Document16 pagesBR Block 08mailbkraoNo ratings yet

- Eq BeamDocument13 pagesEq BeammailbkraoNo ratings yet

- H Type CBCDocument22 pagesH Type CBCmailbkrao0% (1)