Professional Documents

Culture Documents

Structure-Mechanical Properties Relationship in A 700 MPa Grade Low Carbon Low Alloyed Steel With Ultrahigh Ductility

Uploaded by

Srikanth SrikantiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structure-Mechanical Properties Relationship in A 700 MPa Grade Low Carbon Low Alloyed Steel With Ultrahigh Ductility

Uploaded by

Srikanth SrikantiCopyright:

Available Formats

ACTA METALLURGICA SINICA

700 MPa

(, 100083)

,

. , /. ,

/. , /

()/, 29%, , C, Mn,

Ni Cu . , NbC /,

, 10 nm; Cu ,

, 10~30 nm . (TRIP )

, : 700 MPa, 900 MPa,

20%, 30%.

, , , ,

TG142.1

THE

REGULATION

OF

MULTI-PHASE

0412-1961(2015)00-0000-00

MICROSTRUCTURE

AND

MECHANICAL PROPERTIES IN A 700 MPa GRADE LOW CARBON LOW

ALLOY STEEL WITH GOOD DUCTILITY

ZHOU Wenhao, XIE Zhenjia, GUO Hui, SHANG Chengjia

School of Materials Science and Engineering, University of Science and Technology Beijing, Beijing 100083

Correspondent: SHANG Chengjia, professor, Tel: (010) 62332428, E-mail: cjshang@ustb.edu.cn

Supported by National Basic Research Program of China (No.2010CB630081)

Manuscript received 2014-10-23, in revised form 2015-01-26

ABSTRACT Low carbon and low alloy steels require good combination of strength and ductility to ensure

safety and stability of structures. Heat treatment in intercritical area can not only produce multi-phase

microstructure, but also lead to the redistribution of alloying elements in different phases. Multi-step intercritical

heat treatment is favorable to obtain retained austenite that is stabilized by repeated enrichment of alloying

elements in reversed austenite and nanometer-sized precipitate that are primarily formed during temepring.

Excellent mechanical properties are contributed by transformation-induced-plasticity effect of retained austenite

and precipitation hardening effect of nanometer-size precipitates. In this paper, the microstructural evolution and

relative mechanical properties were investigated in a low carbon low alloy steel processed by a three-step heat

treatment, namely, intercritical annealing, intercritical tempering and tempering. The microstructure was a typical

dual-phase microstructure consisting of intercritical ferrite and bainite/martensite after intercritical annealing, and

primarily comprised of intercritical ferrite, tempered bainite/martensite and retained austenite after intercritical

tempering. Retained austenite with volume fraction of 29% distributed at the ferrite/bainite (martensite)

boundaries and betweent bainitic/martensitic laths. Retained austenite was stabilized by enrichment of C, Mn, Ni

ACTA METALLURGICA SINICA

and Cu in reversed austenite during the reversion transformation process. NbC precipitates with average size of 10

nm was formed in ferrite matrix and bainite/martensite, while Cu-containing particles in size range of 10~30 nm

precipitated in ferrite and retained austenite during intercritical tempering and tempering process. The morphology

of NbC precipitates was spherical, elliptical and irregular, and copper precipitates were spherical. With the

combination of transformation-induced-plasticity (TRIP) effect of retained austenite and precipitation hardening,

the steel possessed outstanding mechanical properties: yield strength > 700 MPa, tensile strength > 900 MPa,

uniform elongation > 20%, and total elongation > 30%.

KEY WORDS high performance, intercritical heat treatment, multi-phase microstructure, retained austenite,

nanometer-sized precipitate

. ,

. , ,

. , ,

GPa . , ,

, [1].

(TRIP), ,

, . ,

. .

, , Ni [2,3] Mn

(TWIP)[4,5]. ,

. , TRIP[6,7](Q&P)[8,9]

. , C ,

, . C ,

C 0.2%(). , C

. , C , ,

, .

, + ,

. , ,

, [10]. , C ,

. , .

70 , Miller[11] Niikura [12] Mn . Ni

, . , Ni

, . , Luo [13] Shi [14](ART),

0.2C-5Mn , 40%. ,

. Ni , Ni

, . , ,

[15].

, , . ,

, .

C, Nb-Cu , ,

. , ,

. ,

. ,

.

ACTA METALLURGICA SINICA

700 MPa (, %): C 0.10, Mn 2.01, Si 0.78, Al 0.78, Nb 0.078,

Cu 1.0, Ni 1.0, Mo 0.26, Fe . , C , Mn Ni , Nb, Cu

Mo , Si Al , C

. 50 kg , 8 mm .

10 mm8 mm90 mm , 5 mm ( 25 mm)

. YB/T 5127-93 , 0.05 oC/s.

, Ac1

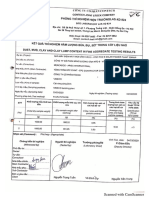

Ac3 660 928 oC. : 780 oC 30 min ,

660 oC 30 min , 500 oC 30 min ( 1).

[15, 16]. , A, B

C. , , LePera , BX51M

(OM); 3% Ultra 55 (SEM).

(EBSD), HClO4: C3H8O3: C6H2O0.5: 1: 8.5(),

20 kV, 15 mm, 70, 0.08 m. DMAX-RBX X (XRD)

, , GB8362-87. 0.4 mm

, 100 m , 3 mm , 50~60 m

. 5%, -20 C. (EDS) JEM-2100 F (TEM)

, 200 kV.

1

Fig.1 Schematic of heat treatment of the experimental steel (Ac1 and Ac3 are transformation start and finish

temperature from bcc to fcc during the reheating process, respectively. Ac1 and Ac1 is transformation start

temperature from bcc to fcc during the reheating process after the first- and second- step heat treatment,

respectively)

2.1

2 . , bcc fcc

Ac1 660 oC, 641 oC, , Ac1 607 oC.

, 660 oC , bcc fcc . Ac1

, , . Ac1

, .

ACTA METALLURGICA SINICA

120

C/

Hot rolled

Sample A

Sample B

5

.0

,0

ing

at

80

He

Dilatation / m

100

Ac1=660 C

o

Ac1'=641 C

60

Ac1''=607 C

500

600

700

800

900

1000

1100

Temperature / C

2

Fig.8 Determination of critical point of experimental steel in different heat treatment process by dilatometric

method

3 4 OM SEM . , ,

/ ( 3a 4a). , 780 oC ,

/, /

( 3b 4b). 660 oC , , /, SEM

/, ( 4c). OM ( 3c),

. , , /

. 1 m . 500 oC , ,

, /, ( 3d 4d).

1 . , 686 MPa,

1178 MPa, , 6.3%, 17%. ,

707 MPa, 845 MPa, , 20%

30%, 30 GPa%. , 17 MPa, 78 MPa,

.

ACTA METALLURGICA SINICA

3 OM

Fig.3 OM images of experimental steels processed after different heat treatments with air cooling

(a) hot rolling (b) Sample A (c) Sample B

(d) Sample C

4 SEM

Fig.4 SEM images of experimental steels after different heat treatments with air cooling

(a) hot rolling (b) Sample A (c) Sample B (d) Sample C

ACTA METALLURGICA SINICA

1

Table 1 Mechanical properties of experimental steels in different heat treatment steps

Sample

s / MPa

b / MPa

Ag / %

A/%

Hot rolling

663

1015

6.3

17

686

1178

6.3

17

707

845

22.8

35

724

923

20.8

31

Note: syield strength, btensile strength, Agpercentage elongation at maximum force (uniform elongation),

Apercentage elongation after fracture (total elongation)

2.2

5 EBSD XRD .

10o , . 5a~c , . XRD

, , , 5%, ,

29%, , . ,

. TEM ( 6),

/. . EDS ,

Mn Ni ( 6a), Xie [17]. ,

/. ,

.

Thermal-Calc 780 oC 30 min

, 2 . 780 oC , 55% 45%.

C, Mn, Ni Cu . (Ms)

333 oC. , . ,

/, . SEM , ,

/. , 660 oC . 2

660 oC . Thermal-Calc , Cu

680 oC, 660 oC Cu . 660 oC ,

, C 0.5%, Mn 6.1%, Cu Ni .

Ms=120 oC, . ,

29%. ,

. Takaki [18], , Ms , .

1 m , , .

, .

. ,

. 3 C, Mn, Ni Cu . , C

. 660 oC , Mn, Ni Cu 212, 95

120 nm. 500 oC , C , .

SEM /, .

C 0.5%, TRIP

(1.1%~1.7%)[19]. EDS Mn 5.0%, Ni 1.6%. ,

ACTA METALLURGICA SINICA

Mn Ni .

TRIP Q&P , C

, . , C .

, [20]. Mn Ni ,

. , Mn Ni

, C , . , Si

Al . , , ,

.

(211)

(d)

Intensity / a.u.

(200)

(200)

(311)

(220)

Sample C

Sample B

Sample A

45

60

75

2 /

90

5 EBSD XRD

Fig.5 EBSD images of retained austenite in sample A (a), sample B (b) and sample C (c), and corresponding XRD

spectra (d)

6 B TEM

Fig.6 Bright (a) and dark (b) field TEM images of sample B

ACTA METALLURGICA SINICA

2 780 oC 660 oC 30 min

Table 2 Distribution of alloying elements in different phases in experimental steel annealed at 780 oC and

tempered at 660 oC for 30 min at equilibrium state

Temperature / oC

Phase

780

660

Ms / oC

Volum

fraction / %

Mass fraction / %

C

Mn

Ni

Cu

Austenite

Ferrite

Austenite

45

55

37.9

0.2

0.5

3.1

1.2

6.1

1.4

0.7

2.6

1.4

0.6

1.7

333

120

Ferrite

61.5

1.2

0.7

0.4

Cu

0.6

96.9

2.0

Note: Ms=499-324wC-32.4wMn-27wCr-10.8wSi-10.8wMo-10.8wW (wX is concentration of alloying element X in

austenite). The calculation data of 660 oC is based on the C-Mn-Ni-Cu alloy system in austenite which is obtained

at 780 oC and transforms to bainite/martensite during the cooling process

3

Table 3 Diffusion distances of austenite stabilizers elements at different temperatures (2D space)

Diffusion coefficient / (cm2s-1)

o

Temperature / C

780

660

500

Mn

-7

6.510

1.910-7

2.110-8

Ni

-12

3.910

12.510-14

2.510-16

Diffusion distance / nm

Cu

-12

3.110

2.510-14

3.610-17

C

-12

2.610

4.010-14

2.010-17

Mn

5

Ni

4.810 1185 1050

2.6105 212

95

8.8104 10

4

Cu

970

120

3

2.3

. Nb Cu

, 1200 680 oC (Thermal-Calc ). , Nb

, Cu . Nb Cu ,

TEM , . 7

TEM . , , 2 : 20

nm , , , ; 4~14

nm , ( 7a), .

10.9 nm ( 7b), EDS NbC. , NbC

7~15 nm , ( 7c d). , NbC 6.0 nm ,

(3~8 nm) ( 7e f). , NbC ,

Cu ( 8a). Cu 10~30 nm ( 8b),

. Nb , Cu 10 nm

. , Nb , , ,

. Cu , .

, ( 8c~e). EDS Cu ( 8f).

10~20 nm . Cu , . Cu

, Cu ,

, ( 7c), Cu ,

. , Cu , . Chi

[21]

Cu , Cu

ACTA METALLURGICA SINICA

Cu , . Cu Cu (

>2%), (>5h). , , Cu

Cu ; 500 oC Cu , , Cu

.

(b)

Average size: 10.9 nm

Frequency / %

40

30

20

10

12

16

20

24

Size / nm

Frequency / %

40

(d)

Average size: 10.4 nm

30

20

10

40

12

10

Size / nm

(f)

14

16

Average size: 6.0 nm

Frequency / %

30

20

10

10

11

Size / nm

7 Nb TEM

Fig.7 TEM images (a,c,e) and statistical size analysis (b,d,f) of carbon replica extraction indicating the distribution

of Nb-containing precipitates in hot-rolled sample (a,b), sample A (c,d) and sample B (e,f)

16

(b)

Average size: 15.1 nm

Frequency / %

12

10

12

14

16 18

Size / nm

20 20-25 25-35

ACTA METALLURGICA SINICA

8 Cu TEM EDS

Fig.8 TEM image (a) and statistical size analysis (b) of copper-containing precipitates in sample B, TEM images

(c~e) and EDS (f) of Cu-containing precipitates in sample C

, , ,

bcc fcc Ac1, 2 . Ac1

, , ,

Nb Cu . , 50%[16], C-Mn-Si TRIP

[22], TRIP ( 400~600 MPa, 20%~30%)[23].

. TRIP

, , /,

. Q&P (ART),

. ,

. Funakawa [24] Yen [25], 5 nm ,

300 MPa . , , .

, Cu , Cu ,

, , 17 MPa, . Cu

. , [26],

; , ,

[27]

, Cu , . ,

, Cu . ,

[28], , .

ACTA METALLURGICA SINICA

1, ,

. ,

, . ,

, ,

TRIP . TRIP ,

: 700 MPa, 900 MPa,

20% 30%.

2, ,

/. 1 m, /()

/. , C, Mn, Ni Cu

, 29%. .

, , .

3 NbC Cu . ,

, /. ,

. NbC ,

. , ,

.

[1] Dong H, Wang M Q, Weng Y Q. Iron Steel, 2010; 45 (7): 3

( , , . , 2010; 45: 3)

[2] Liu L, Yang Z G, Zhang C, Liu W B. Mater Sci Eng, 2010; A527: 7205

[3] Yoo J D, Hwang S W, Park K T. Mater Sci Eng, 2009; A508: 234

[4] Misra R D K, Challa V S A, Venkatsurya P K C, Shen Y F, Somani M C, Karjalainen L P. Acta Mater, 2015; 84: 339

[5] Lee T, Koyama M, Tsuzaki K, Lee Y H, Lee C S. Mater Lett, 2012; 75: 169

[6] Sugimoto K I, Mobayashi M, Hashimoto S I. Metall Mater Trans, 1992; 23A: 3085

[7] Sugimoto K I, Tsunezawa M, Hojo T, Ikeda S. ISIJ Int, 2004; 44: 1608

[8] Speer J G, Matlock D K, De Cooman B C, Schroth J G. Acta Mater, 2003; 51: 2611

[9] Misra R D K, Zheng H, Wu K M, Karjalainen L P. Mater Sci Eng, 2013; 579A: 188

[10] Kang J, Zhou X G, Wang G D. Steel Rolling, 2009; 26 (3): 34

(, , . , 2009; 26: 34)

[17] Miller R L. Metall Trans, 1972; 3: 905

[18] Niikura M, Morris J W. Metall Trans, 1980; 11: 1531

[13] Luo H W, Shi J, Wang C, Cao W Q, Sun X J, Dong H. Acta Mater, 2011; 59: 4002

[14] Shi J, Sun X J, Wang M Q, Hui W J, Dong H, Cao W Q. Scr Mater, 2010; 63: 815

[15] Zhou W H, Guo H, Xie Z J, Wang X M, Shang C J. Mater Sci Eng, 2013; A587: 366

[16] Zhou W H, Wang X L, Venkatsurya P K C, Guo H, Shang C J, Misra R D K. Mater Sci Eng, 2014; A607: 569

[17] Xie Z J, Yuan S F, Zhou W H, Yang J R, Guo H, Shang C J.

Mater Des, 2014; 59: 195

* 2010CB630801

: 2014-10-23, : 2015-01-26

: , , 1987 ,

DOI: 10.11900/0412.2014.00576

[18] Takaki S, Fukunaga K, Syarif J, Tsuchiyama T. Metall Trans,

2004; 45: 2251

[19] Sakuma Y, Matsumura O, Takechi H. Metall Trans, 1991;

22A: 489

[20] Thomas G. Metall Trans, 1978; 9A: 447

ACTA METALLURGICA SINICA

[21] Chi C Y, Dong J X, Liu W Q, Xie X S. Acta Metall Sin, 2010; 46: 1145

(, , , . , 2010; 46: 1145)

[22] Ray A, Dhua S K. Mater Charact, 1996; 37: 1

[23] Zhang Y H, Zhao H J, Kang Y L. Hot Working Tech, 2006; 35 (6): 62

(, , . , 2006; 35 (6): 62)

[24] Funakawa Y, Shiozaki T, Tomita K, Yamamoto T, Maeda E. ISIJ Int, 2004; 44: 1945

[25] Yen H Y, Chen P Y, Huang C Y, Yang J R. Acta Mater, 2011; 59: 6264

[26] He B B, Huang M X, Liang Z Y, Ngan A H W, Luo H W, Shi J, Cao W Q, Dong H. Scr Mater, 2013; 69: 216

[27] Zhang K, Zhang M H, Guo Z H, Chen N L, Rong Y H. Mater Sci Eng, 2011; 528A: 8486

[28] Zhou W H, Guo H, Xie Z J, Shang C J. Mater Des, 2014; 59: 195

You might also like

- Folder Roll-Bonded-Clad-Plates E 291014 PDFDocument40 pagesFolder Roll-Bonded-Clad-Plates E 291014 PDFVinay TrivediNo ratings yet

- Stainless Steel A Bright Future in A Changing World PPG May 2012Document29 pagesStainless Steel A Bright Future in A Changing World PPG May 2012Srikanth SrikantiNo ratings yet

- ISSF 2011 Sustainability Case Studies EnglishDocument44 pagesISSF 2011 Sustainability Case Studies EnglishSrikanth SrikantiNo ratings yet

- ISSF Sustainability Case StudiesDocument82 pagesISSF Sustainability Case StudiesSrikanth SrikantiNo ratings yet

- The Science of Forming - Higher Strength Steel Options Keep Growing - Metalforming MagazineDocument2 pagesThe Science of Forming - Higher Strength Steel Options Keep Growing - Metalforming MagazineSrikanth SrikantiNo ratings yet

- AggarwalDocument12 pagesAggarwalSrikanth SrikantiNo ratings yet

- ISSF Sustainability Award 2013Document60 pagesISSF Sustainability Award 2013Srikanth SrikantiNo ratings yet

- Noteonthesensitivityofstainlesssteelstostrainrate 1Document10 pagesNoteonthesensitivityofstainlesssteelstostrainrate 1Srikanth SrikantiNo ratings yet

- Steel Grades Properties Global StandardsDocument20 pagesSteel Grades Properties Global StandardsJonald PoquizNo ratings yet

- Outokumpu Corrosion Management News Acom 3 4 Edition 2013Document10 pagesOutokumpu Corrosion Management News Acom 3 4 Edition 2013Srikanth SrikantiNo ratings yet

- Xirouchakis & Manolakou 2011 5th ICONFBMP - 255Document10 pagesXirouchakis & Manolakou 2011 5th ICONFBMP - 255Srikanth SrikantiNo ratings yet

- Outokumpu Stainless Steel HandbookDocument92 pagesOutokumpu Stainless Steel HandbookcutefrenzyNo ratings yet

- Niobium - Charles Hatchett AwardDocument1 pageNiobium - Charles Hatchett AwardSrikanth SrikantiNo ratings yet

- Lindsay Greer Jan12 Lecture1Document73 pagesLindsay Greer Jan12 Lecture1ranjan_ganapathiNo ratings yet

- Finnish Steel Major Outokumpu Bags 700 Tonne Steel Order in India - The Economic TimesDocument3 pagesFinnish Steel Major Outokumpu Bags 700 Tonne Steel Order in India - The Economic TimesSrikanth SrikantiNo ratings yet

- Outokumpu Corrosion Management News Acom 3 4 Edition 2013Document10 pagesOutokumpu Corrosion Management News Acom 3 4 Edition 2013Srikanth SrikantiNo ratings yet

- Advanced Materials-Bulk Metallic GlassesDocument2 pagesAdvanced Materials-Bulk Metallic GlassesSrikanth SrikantiNo ratings yet

- Ferritic Grade 1.4509Document1 pageFerritic Grade 1.4509pipedown456No ratings yet

- Materials Science & Engineering - Metallic GlassesDocument1 pageMaterials Science & Engineering - Metallic GlassesSrikanth SrikantiNo ratings yet

- Amorphous Metal - Wikipedia, The Free EncyclopediaDocument6 pagesAmorphous Metal - Wikipedia, The Free EncyclopediaSrikanth SrikantiNo ratings yet

- Outokumpu Stainless Steel Wall ChartDocument1 pageOutokumpu Stainless Steel Wall ChartSrikanth SrikantiNo ratings yet

- Pol Duwez - Wikipedia, The Free EncyclopediaDocument1 pagePol Duwez - Wikipedia, The Free EncyclopediaSrikanth SrikantiNo ratings yet

- AISI 409 1.4512 DatasheetDocument1 pageAISI 409 1.4512 DatasheetSadashiva sahooNo ratings yet

- Article - Sulphidation Resistance of Stainless SteelsDocument1 pageArticle - Sulphidation Resistance of Stainless SteelsSrikanth SrikantiNo ratings yet

- Materials 09 00229Document19 pagesMaterials 09 00229Srikanth SrikantiNo ratings yet

- 463638Document14 pages463638Srikanth SrikantiNo ratings yet

- Outokumpu Pocket Folder Stainless Steel Grades en ASTM UNS ISODocument2 pagesOutokumpu Pocket Folder Stainless Steel Grades en ASTM UNS ISOSrikanth Srikanti100% (1)

- AggarwalDocument12 pagesAggarwalSrikanth SrikantiNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CBSE Papers, Questions, Answers, MCQ ... - CBSE Class 6 Science CH 4 - Sorting Material Into GroupsDocument3 pagesCBSE Papers, Questions, Answers, MCQ ... - CBSE Class 6 Science CH 4 - Sorting Material Into Groupssundar100% (1)

- Environmental Pollution MCQ (Free PDF) - Objective Question Answer For Environmental Pollution Quiz - Download Now!Document27 pagesEnvironmental Pollution MCQ (Free PDF) - Objective Question Answer For Environmental Pollution Quiz - Download Now!Prathamesh NaikNo ratings yet

- PX 2100 TDS 2016Document4 pagesPX 2100 TDS 2016odbayNo ratings yet

- Guide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)Document1 pageGuide For ASME AUDIT - 2018: Table - U3 Mandatory Appendix 43 UG-20 (F)anon_673643629No ratings yet

- Nourishing and Moisturizing Conditioner For Dry Hair Hot Process Formulation and Production e BookDocument6 pagesNourishing and Moisturizing Conditioner For Dry Hair Hot Process Formulation and Production e BookLuis MateranNo ratings yet

- BFD of Kurnell RefineryDocument1 pageBFD of Kurnell RefineryMuhammad Ibad AlamNo ratings yet

- The Oxidation of Azo DyesDocument245 pagesThe Oxidation of Azo Dyesglen dunnNo ratings yet

- Majestic True Beauty Matt: Technical Data SheetDocument3 pagesMajestic True Beauty Matt: Technical Data SheetBilher SihombingNo ratings yet

- (Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Document459 pages(Semiconductors and Semimetals 56) Robert Hull and John C. Bean (Eds.) - Germanium Silicon - Physics and Materials-Elsevier, Academic Press (1998)Domenico BarillariNo ratings yet

- Kremlin Rexson General Guide V03 Édition 2015 - A4bdDocument252 pagesKremlin Rexson General Guide V03 Édition 2015 - A4bdVaughanNo ratings yet

- Proposal PDFDocument3 pagesProposal PDFওয়াহিদ মুরাদNo ratings yet

- Claycraft-Magazine 8 2017Document82 pagesClaycraft-Magazine 8 2017Marjorie Agreda100% (2)

- Deformation of Ceramics and PolymersDocument41 pagesDeformation of Ceramics and PolymersJane Erestain BuenaobraNo ratings yet

- RMC Mix Design PDFDocument19 pagesRMC Mix Design PDFluongiccNo ratings yet

- Low Cost HousingDocument11 pagesLow Cost HousingLahari 06No ratings yet

- Interior Material StudyDocument37 pagesInterior Material StudyMaira NoorNo ratings yet

- SCRM BrochureDocument6 pagesSCRM BrochureRizwan TonoyNo ratings yet

- Combustion LectureDocument26 pagesCombustion LectureJohn Raymart RaferNo ratings yet

- 2 AnchorageDocument16 pages2 AnchorageAditi GuptaNo ratings yet

- 2.stones and AggregatesDocument10 pages2.stones and AggregatesBry RamosNo ratings yet

- Repair Application ProceduresDocument6 pagesRepair Application ProceduresSatheesh Rama SamyNo ratings yet

- Chem Assignment Unit IDocument1 pageChem Assignment Unit ISumit NegiNo ratings yet

- 06 Durability of ConcreteDocument27 pages06 Durability of ConcreteHassen Ben Ali GannouniNo ratings yet

- Nanotechnology For Bioplastics: Opportunities, Challenges and StrategiesDocument7 pagesNanotechnology For Bioplastics: Opportunities, Challenges and StrategiesBintang kecilNo ratings yet

- Laser Cut Lamp: Color With Shadows: 8 Steps (With Pictures) : ToolsDocument50 pagesLaser Cut Lamp: Color With Shadows: 8 Steps (With Pictures) : Toolsjaglover2No ratings yet

- Final Report: Industrial Training (Construction of Flyover)Document16 pagesFinal Report: Industrial Training (Construction of Flyover)Abhishek kumar100% (1)

- Spares Price List UnoxDocument82 pagesSpares Price List UnoxNeo Nov50% (2)

- Data Sheet For HDPEDocument1 pageData Sheet For HDPEShowkath AliNo ratings yet

- Aircraft Materials BrochureDocument6 pagesAircraft Materials BrochureAdnan ColoNo ratings yet

- Msds Rockwool Insulation WebDocument8 pagesMsds Rockwool Insulation Websrikandi marketingNo ratings yet