Professional Documents

Culture Documents

Chemical Reaction Between Chromates and Galvanized Steel

Uploaded by

pbp29560 ratings0% found this document useful (0 votes)

12 views1 pageCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 pageChemical Reaction Between Chromates and Galvanized Steel

Uploaded by

pbp2956Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

Thave a customer who wants to understand the chemi

cal reaction betzoeen the galvanized steel and the cl

‘mate passfoation treatment and why they should

request chromate treatment. Wht isthe chemical ren

tion of this process? What are some of the advantages

of using a chromate treatment for galuanized reinfore-

ing steel?

This question refers to the chromate passivation treat

rent that galvanizers use to protect the galvanized

steel from wet storage stan ard also use to control the

volition of hydrogen gas when galeanized reinforcing

steel reacts with highly alkaline concrete

‘The passivation of the zine surface is often done by

chromating the galvanized steel. The high corrosion resis-

tance offered by the use of chromate films is atributed to

the presence of hexavalent and trivalent chromium in the

coating. The trivalent chromium is believed to be present

as an insoluble hydrated oxide (chromium hydroxide o-

zinc chromate), whereas the soluble portion of hexavalent

chromium imparts a “self-healing” chazacter to the film

during the oxidative (corrosive) attack by species, such as,

chloride ions,

The chromate film on the galvanized reinforcing steel

is formed by the chemical reactions of hexavalent clyomi-

‘um with a metal surface in the presence of other compo-

nents, or “activators” in acid solution, Hexavalent chromi-

‘um is partially reduced to trivalent chromium during the

reaction, with a concurrent rise in pH, forming a complex

mixture consisting largely of hydrated basic chromiuin

chromate (Cry03 Cr03 x HO) and hydrous oxides of

Doth chromium and the basis metal (zine). As the acid is

consumed, the combining power of chromium ia the solu.

tion changes and precipitates chromium hydroxide. A film

builds until the face next to the zine becomes nonacid and

this stops the reaction. The resulting gel-like film is

allowedl to harden, Cheomate coatings on galvanized steel

are usually yellow and consist of a mixture of trivalent

and hexavalent chrome solution.

‘The chemical reaction of the chromate to the galva-

nized steel is shown below:

1, Reduction of hexavalent chromium fo trivalent

chromium

3Zn+2Cr* pe 3Zn" + 20x”

2. Dissolution of metal by acid (hydrogen loss)

accompanied by a local rise in pH at the metal

interface

Zn+ 2H pe Zn + Hp (gas)

Soy 1989 VSN. 43

A redox reaction occurs at acidie pH where hexava.

lent chromium is reduced to trivalent chromium while

zinc is oxidized.

Zn Zn” +26

—>

>

HCrOy + 14H + 6 2Cr" + 7H,0

The primary reason for the use of chromate treat-

‘ments on the galvanized steel parts is to prevent the for-

mation of wet storage stain during the first six weeks after

galvanizing, The zine coating is most vulnerable to the

formation of excessive amounts of zinc oxide and zine

hydroxide during this period. The thin layer of chromate

passivation layer inhibits the formation of these zine

oxides, The coating generally lasts about six weeks before

itis consumed, Galvanized steel will then weather natu-

rally after the chromate is gone.

‘Chromate passivation treatments are used to control

reactions between the zinc and the concrete, The main

reaction that chromate treatment prevents is the hydrogen

evolution that may affect the bonding properties between,

the zinc and concrete, Zinc is amphoteric (reactive in

acidic and alkaline environments) so the maximum rate of

attack on zine occurs in alkaline conditions over a pH of

125, The passivation of zine is effected in the pH range of,

8 to 125, cue to the initial formation of a layer of zine

hydroxide and subsequently of a complex calcium zinc

compound, calcium hydroxy-zineate (CalZn(OH)3]

21,0). The reaction of zine with the concrete effectively

ceases in a few days and gives just sufficient corrosion

products to ensure a strong and reliable bond to the con:

crete when fully hardened,

‘The bonding between gal

is essential for reliable performance of concrete structures,

Many factors, such as concrete mix and additives, curing

conditions, and age, may affect the bondling between the

galvanized steel and concrete. The chemical reaction that

i of concer is the reaction of zine with ealeiun hydrox:

ide, This reaction occurs during the curing of the concrete.

During the curing process, hydrogen gas evolution occurs

between the galvanized rebar and the concrete, The use of

a passivation treatment, such as the use of chromates, can,

help to reduce the hydrogen gas from forming. In solu-

tions with such a high pH, the zinc is attacked by the

alkalis (calcium hydroxide) in the fresh concrete, leading

to the formation of caleiuim hydrozineate and hydrogen,

‘This reaction could give rise to poor adhesion. Once the

concrete sets, the hydrogen evolution ceases; the coating

of calcium zincate formed apparently provides a protec

tion to the reinforcement and no further attack takes

places after initial setting. Tests of the bond strength on

galvanized rebars showed equal to or slightly better bond

performance when compared to black rebars.

nized rebar and concrete

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Kaizen PrinciplesDocument42 pagesKaizen PrinciplesRaj100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Selecting Statistically Valid Sampling Plans: Dr. Wayne A. TaylorDocument15 pagesSelecting Statistically Valid Sampling Plans: Dr. Wayne A. Taylorpbp2956No ratings yet

- Pipe Galvanizing ProcessDocument32 pagesPipe Galvanizing ProcessPatrick DominguezNo ratings yet

- Effect of C & Cr. On Brightness of Galvanizing SurfaceDocument1 pageEffect of C & Cr. On Brightness of Galvanizing Surfacepbp2956No ratings yet

- GSL Appearance GuideDocument4 pagesGSL Appearance Guidepbp2956No ratings yet

- Tolerance For CHSDocument1 pageTolerance For CHSpbp2956No ratings yet

- Freezing Points of High-Purity Hydrocarbons: Standard Test Method ForDocument11 pagesFreezing Points of High-Purity Hydrocarbons: Standard Test Method Forpbp2956No ratings yet

- ASTM D1018-1999 Standard Specification For PVC Plastic Pipe Schedule 40,80 & 120Document11 pagesASTM D1018-1999 Standard Specification For PVC Plastic Pipe Schedule 40,80 & 120pbp2956No ratings yet

- Steel 2141967Document388 pagesSteel 2141967Seifeldin Ali Marzouk100% (1)

- Corus Steel Shape Specification Catalog BS5950 Sept 13Document1 pageCorus Steel Shape Specification Catalog BS5950 Sept 13pbp2956No ratings yet

- Beta SD RSquared-Mutual Fund KnowledgeDocument2 pagesBeta SD RSquared-Mutual Fund Knowledgepbp2956No ratings yet

- Nonvolatile Residue of Polymerization Grade Butadiene: Standard Test Method ForDocument2 pagesNonvolatile Residue of Polymerization Grade Butadiene: Standard Test Method Forpbp2956No ratings yet

- Hydrogen in Petroleum Fractions: Standard Test Method ForDocument4 pagesHydrogen in Petroleum Fractions: Standard Test Method Forpbp2956No ratings yet

- Advance To BS5950 Sept 13Document60 pagesAdvance To BS5950 Sept 13getnihalNo ratings yet

- Adhesion Tape Specification 51596.Document1 pageAdhesion Tape Specification 51596.pbp2956No ratings yet

- Thomas Cook 13D 12N-Premimum Budget13Document9 pagesThomas Cook 13D 12N-Premimum Budget13pbp2956No ratings yet

- Basic Understanding of FCAWDocument4 pagesBasic Understanding of FCAWpbp2956No ratings yet

- Flux Skimming PDFDocument6 pagesFlux Skimming PDFpbp2956No ratings yet

- Satrangi Europe 11D 10MDocument6 pagesSatrangi Europe 11D 10Mpbp2956No ratings yet

- Defects Per Million OpportunitiesDocument6 pagesDefects Per Million Opportunitiespbp2956100% (1)

- SlaDocument13 pagesSlapbp2956No ratings yet

- Inspection of HDG After FabricationDocument27 pagesInspection of HDG After Fabricationpbp2956No ratings yet

- Influence of Alloy Elements On Structure and Corrosion ResistanceDocument10 pagesInfluence of Alloy Elements On Structure and Corrosion Resistancepbp2956No ratings yet

- PresentingSixSigma NewDocument56 pagesPresentingSixSigma Newpbp2956No ratings yet

- GB 1591 Q420 Steel PropertiesDocument6 pagesGB 1591 Q420 Steel Propertiespbp2956No ratings yet

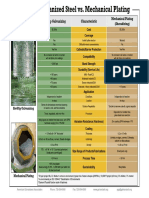

- Hot-Dip Galvanizing Vs Mechanical PlatingDocument2 pagesHot-Dip Galvanizing Vs Mechanical Platingpbp2956No ratings yet

- GB700-88 Stanadard Extract PageDocument1 pageGB700-88 Stanadard Extract Pagepbp2956No ratings yet

- Corrosion Behaviour of Zinc Coating by Polarization MeasurementDocument6 pagesCorrosion Behaviour of Zinc Coating by Polarization Measurementpbp2956No ratings yet

- B897 - 03 - Zinc Jumbo BlockDocument4 pagesB897 - 03 - Zinc Jumbo Blockpbp2956No ratings yet