Professional Documents

Culture Documents

VCB1

Uploaded by

Anonymous DKv8vp0 ratings0% found this document useful (0 votes)

8 views4 pagesVCB1

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVCB1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pagesVCB1

Uploaded by

Anonymous DKv8vpVCB1

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Receiving, Handling and Storage

Introduction

‘This manual covers the Receiving, Handling and Storage

Instructions forlype 3AH vacuum eircuit breakers shipped

separately from the switchgear. This cection of the manual

Is intended to help the user identity, inspect and protect the

circuit breaker prior to its instalation,

Recsiving Procedure

Make a physical inspection of the shipping container before

removing or unpacking the circuit breaker. Check for ship-

ment damage or indications of rough handling by the carrier

Check each item against the manifest to identify any short-

ages

Accessories such as the manual charging crank, the racking

‘crank and the split plug jumper are shipped separately.

Shipping Damage Claims (when applicable) - Follow normal

shipment damage procedures, which should inelude:

1. Check for visible damage upon arrival.

2.Visible damage must be noted on delivery receipt, and

acknowledged with driver's signature. Notation, "Pos

sible internal damage, subject to inspection” must be on

delivery receipt

3. Notify the Siemens Sales office immediately of any ship

ment damage

4. Arrange for carrier's inspection, Do not move the unit

from its unloading point

Handling Procedure

1. Carefully remove the shipping carton from the circuit

breaker Keep the shipping pallet for later use ifthe cim

cult breaker isto be stored prior te its installation.

2.Inspect for concealed damage. Notification to cartier must

‘ake place within 15 days te assure prompt resolution of

claims

3. Each circuit breaker should be appropriately lifted to

avoid crushing the side panels of the circuit breaker, or

damaging the primary disconnect subassemblies,

PAYEE

Heavy weight, Can eause death, serious

injury. or property damage.

of a qualified rigger toh

breaker

the erouit

Circuit breaker weights (Table A.)

4.The palleted circuit breaker can also be moved using @

properly rated forklift vehicle. The pallets are designed

for mavement by a standard forklift vehicle

Storage Procedure

1. When the circuit breaker will be placed on its pallet for

‘storage, be sure the units securely bolted to the pallet

and covered with polyethylene film at least 10 mils thick

Indoor Storage -Whenever possible, store the circuit breaker

indoors, The storage environment must be clean, dry and

free of such items as construction dust, corrosive atmo=

sphere, mechanical abuse and rapid temperature variations

Outdoor Storage - Outdoor storage is not recommended.

When no other option is available, the circuit breaker must

be completely covered and protected from rain, snow, dirt

and all other contaminants,

Space Heating -Space heating must be used forboth indoor

and outdoor storage to prevent condensation and corrosion,

When stored outdoors, 250 watts per circuit breaker of space

heating is recommended.

Installation Checks and Initial Functional Tests

Introduction

‘This section provides a description of the inspections,

checks and tests to be performed on the circuit breaker

module only,

Inspections, Checks and Tests without Control Power

Vacuum circuit breakers are normally shipped with their

primary contacts open and their springs discharged, How

fever it i critical to first verity the discharged condition of

the spring-loaded mechanisms after de-energizing control

power.

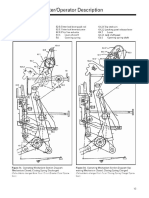

Spring Discharge Check (Figure 1)

Perform the Spring Discharge Check before removing

‘the circuit breaker from the pallet or remaving it from the

switchgear.

‘The spring discharge check consists of simply performing

‘the following tasks in the order given, This check assures.

that both the opening and closing springs are fully disr

charged

ADANGER

fe | Hazardous voltages and high:

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Structure of Power System 1Document3 pagesThe Structure of Power System 1Anonymous DKv8vpNo ratings yet

- Improving Thermal Efficiency1 PDFDocument4 pagesImproving Thermal Efficiency1 PDFAnonymous DKv8vpNo ratings yet

- Improving Thermal Efficiency3Document5 pagesImproving Thermal Efficiency3Anonymous DKv8vpNo ratings yet

- VCB2Document5 pagesVCB2Anonymous DKv8vpNo ratings yet

- VCB3Document4 pagesVCB3Anonymous DKv8vpNo ratings yet

- Improving Thermal Efficiency2 PDFDocument6 pagesImproving Thermal Efficiency2 PDFAnonymous DKv8vpNo ratings yet

- Improving Thermal Efficiency1Document4 pagesImproving Thermal Efficiency1Anonymous DKv8vpNo ratings yet

- Power Swing Part4Document6 pagesPower Swing Part4Anonymous DKv8vpNo ratings yet

- Power Swing Part8Document5 pagesPower Swing Part8Anonymous DKv8vpNo ratings yet

- Ans KeyDocument2 pagesAns KeyAnonymous DKv8vpNo ratings yet

- VCB2Document5 pagesVCB2Anonymous DKv8vpNo ratings yet

- Power Swing Part7 PDFDocument5 pagesPower Swing Part7 PDFAnonymous DKv8vpNo ratings yet

- EC 3 AnsKeyDocument2 pagesEC 3 AnsKeyAnonymous DKv8vpNo ratings yet

- Power Swing Part5Document5 pagesPower Swing Part5Anonymous DKv8vpNo ratings yet

- Power Swing Part5Document5 pagesPower Swing Part5Anonymous DKv8vpNo ratings yet

- Power Swing Par11Document5 pagesPower Swing Par11Anonymous DKv8vpNo ratings yet

- Power Swing Part6Document5 pagesPower Swing Part6Anonymous DKv8vpNo ratings yet

- Power Swing Part9Document5 pagesPower Swing Part9Anonymous DKv8vpNo ratings yet

- HPS 5Document3 pagesHPS 5Anonymous DKv8vpNo ratings yet

- Power Swing Part10Document5 pagesPower Swing Part10Anonymous DKv8vpNo ratings yet

- Power Swing Part1Document5 pagesPower Swing Part1gppNo ratings yet

- HPS3Document4 pagesHPS3Anonymous DKv8vpNo ratings yet

- rf4 PDFDocument10 pagesrf4 PDFgppNo ratings yet

- Power Swing Par12Document4 pagesPower Swing Par12Anonymous DKv8vpNo ratings yet

- Power Swing Par11Document5 pagesPower Swing Par11Anonymous DKv8vpNo ratings yet

- RF 4Document10 pagesRF 4Anonymous DKv8vpNo ratings yet

- CT 1Document3 pagesCT 1Anonymous DKv8vpNo ratings yet

- HPS2Document5 pagesHPS2Anonymous DKv8vpNo ratings yet

- HPS 4Document4 pagesHPS 4Anonymous DKv8vpNo ratings yet