Professional Documents

Culture Documents

Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)

Uploaded by

tutuionutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)

Uploaded by

tutuionutCopyright:

Available Formats

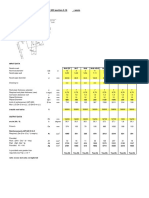

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

INQUIRY NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

1 APPLICABLE TO:

PROPOSAL

REVISION NO.

PAGE

PURCHASE

DATE

1

OF

BY

AS BUILT

2 FOR

UNIT

3 SITE

SERIAL NO.

4 SERVICE

NO. REQUIRED

5 MANUFACTURER

DRIVER TYPE (1-3.1.1)

6 MODEL

DRIVER ITEM NO.

7

8 INFORMATION TO BE COMPLETED:

BY PURCHASER

BY MANUFACTURER

MUTUAL AGREEMENT (PRIOR TO PURCHASE)

OPERATING CONDITIONS

9

10

NORMAL

(ALL DATA ON PER UNIT BASIS)

(1-2.1.1.2)

11

12

GAS HANDLED (ALSO SEE PAGE

13

GAS PROPERTIES (1-2.1.1.4)

14

MMm3/day (m3/h) (1.03 BAR & 0C DRY)

15

WEIGHT FLOW, kg/h (WET) (DRY)

16

INLET CONDITIONS

17

PRESSURE (BAR)(kPa abs)

18

TEMPERATURE (C)

19

RELATIVE HUMIDITY %

20

MOLECULAR WEIGHT

21

Cp/Cv ( K1 ) OR (KAVG ) (NOTE 1)

22

COMPRESSIBILITY (Z1 ) OR (ZAVG ) (NOTE 1)

23

INLET VOLUME, (m3/h) (WET / DRY)

24

DISCHARGE CONDITIONS

25

PRESSURE (BAR)(kPa abs)

26

TEMPERATURE (C)

27

Cp/Cv (K2 ) OR (KAVG ) (NOTE 1)

28

COMPRESSIBILITY (Z2 ) OR (ZAVG ) (NOTE 1)

29

GAS kW REQUIRED

30

TRAIN BRAKE kW REQUIRED

31

BRAKE kW REQUIRED AT DRIVER INCL. EXT. LOSSES (GEAR, ETC.)

32

SPEED (RPM)

33

TURNDOWN (%)

34

POLYTROPIC HEAD (N-m / kg)

35

POLYTROPIC EFFICIENCY (%)

36

CERTIFIED POINT

37

EXPECTED OPERATION AT EACH CONDITION (%)

38

PERFORMANCE CURVE NUMBER

39

PROCESS CONTROL (1-3.4.2.1)

40

METHOD

OTHER CONDITIONS (1-2.1.1.1)

A

VARIABLE INLET

SPEED VARIATION

DISCHARGE

COOLED BYPASS

41

FROM

BAR (kPa abs)

GUIDE VANES

FROM

BLOWOFF

FROM

42

TO

BAR (kPa abs)

(2-2.4.1)

TO

TO

TO

43

SUCTION THROTTLING

SIGNAL

SOURCE (1-3.4.2.1)

44

TYPE

45

RANGE

ELECTRONIC

mA

PNEUMATIC

OTHER

BAR (kPa abs)

46

47

ANTI-SURGE SYSTEM (1-3.4.2.2)

48 REMARKS:

49 NOTE 1: IF GAS ANALYSIS IS GIVEN, MANUFACTURER SHALL SUPPLY DATA, OTHERWISE DATA SHALL BE SUPPLIED BY USER

03/03

SHT 1 OF 7

API617.XLS

319679003.xlsx, Page1

REV 0

Page 1 of 9, Date Printed: 05/30/2016

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

INQUIRY NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

1 APPLICABLE TO:

PROPOSAL

PURCHASE

REVISION NO.

PAGE

DATE

1b

OF

BY

AS BUILT

2 FOR

UNIT

3 SITE

SERIAL NO.

4 SERVICE

NO. REQUIRED

5 MANUFACTURER

DRIVER TYPE (1-3.1.1)

6 MODEL

DRIVER ITEM NO.

7

8 INFORMATION TO BE COMPLETED:

BY PURCHASER

BY MANUFACTURER

MUTUAL AGREEMENT (PRIOR TO PURCHASE)

OPERATING CONDITIONS (INTERMEDIATE CONNECTIONS)

9

10

NORMAL (1-2.1.1.2)

(ALL DATA ON PER UNIT BASIS)

Section 1

11

12

GAS HANDLED (ALSO SEE PAGE

13

GAS PROPERTIES (1-2.1.1.4)

14

MMm3/day (m3/h) (1.03 BAR & 0C DRY)

15

WEIGHT FLOW, kg/h (WET) (DRY)

16

INLET CONDITIONS

17

PRESSURE (BAR)(kPa abs)

18

TEMPERATURE (C)

19

RELATIVE HUMIDITY %

20

MOLECULAR WEIGHT

21

Cp/Cv ( K1 ) OR (KAVG ) (NOTE 1)

22

COMPRESSIBILITY (Z1 ) OR (ZAVG ) (NOTE 1)

23

INLET VOLUME, (m3/h) (WET / DRY)

24

DISCHARGE CONDITIONS

25

PRESSURE (BAR)(kPa abs)

26

TEMPERATURE (C)

27

Cp/Cv (K2 ) OR (KAVG ) (NOTE 1)

28

COMPRESSIBILITY (Z2 ) OR (ZAVG ) (NOTE 1)

29

GAS kW REQUIRED

30

TRAIN BRAKE kW REQUIRED

31

BRAKE kW REQUIRED AT DRIVER INCL. EXT. LOSSES (GEAR, ETC.)

32

SPEED (RPM)

33

TURNDOWN (%)

34

POLYTROPIC HEAD (N-m / kg)

35

POLYTROPIC EFFICIENCY (%)

36

CERTIFIED POINT

37

EXPECTED OPERATION AT EACH CONDITION (%)

38

PERFORMANCE CURVE NUMBER

39

PROCESS CONTROL (1-3.4.2.1)

40

METHOD

OTHER CONDITIONS (1-2.1.1.1)

Section 2

Section 1

Section 2

Section 1

VARIABLE INLET

SPEED VARIATION

DISCHARGE

COOLED BYPASS

41

FROM

BAR (kPa abs)

GUIDE VANES

FROM

BLOWOFF

FROM

42

TO

BAR (kPa abs)

(2-2.4.1)

TO

TO

TO

43

SUCTION THROTTLING

SIGNAL

Section 2

SOURCE (1-3.4.2.1)

44

TYPE

45

RANGE

ELECTRONIC

mA

PNEUMATIC

OTHER

BAR (kPa abs)

46

47

ANTI-SURGE SYSTEM (1-3.4.2.2)

48 REMARKS:

49 NOTE 1: IF GAS ANALYSIS IS GIVEN, MANUFACTURER SHALL SUPPLY DATA, OTHERWISE DATA SHALL BE SUPPLIED BY USER

03/03

SHT 1b OF 7

API617.XLS

319679003.xlsx, Page1b

REV 0

Page 2 of 9, Date Printed: 05/30/2016

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

INQUIRY NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

1 APPLICABLE TO:

PROPOSAL

PURCHASE

REVISION NO.

PAGE

DATE

1c

OF

BY

AS BUILT

2 FOR

UNIT

3 SITE

SERIAL NO.

4 SERVICE

NO. REQUIRED

5 MANUFACTURER

DRIVER TYPE (1-3.1.1)

6 MODEL

DRIVER ITEM NO.

7

8 INFORMATION TO BE COMPLETED:

BY PURCHASER

BY MANUFACTURER

MUTUAL AGREEMENT (PRIOR TO PURCHASE)

OPERATING CONDITIONS (COMPRESSOR WITH TWO SIDESTREAMS)

9

10

CONDITIONS (1-2.1.1.2)

EQUIP. FLNG. COND. SHOWN IN DBL.-WALLED CELLS

(ALL DATA ON PER UNIT BASIS)

11

12

GAS HANDLED (ALSO SEE PAGE

13

GAS PROPERTIES (1-2.1.1.4)

14

MMm3/day (m3/h) (1.03 BAR & 0C DRY)

15

WEIGHT FLOW, kg/h (WET) (DRY)

16

INLET CONDITIONS

17

PRESSURE (BAR)(kPa abs)

18

TEMPERATURE (C)

19

RELATIVE HUMIDITY %

20

MOLECULAR WEIGHT

21

Cp/Cv ( K1 ) OR (KAVG ) (NOTE 1)

22

COMPRESSIBILITY (Z1 ) OR (ZAVG ) (NOTE 1)

23

INLET VOLUME, (m3/h) (WET / DRY)

24

DISCHARGE CONDITIONS

25

PRESSURE (BAR)(kPa abs)

26

TEMPERATURE (C)

27

Cp/Cv (K2 ) OR (KAVG ) (NOTE 1)

28

COMPRESSIBILITY (Z2 ) OR (ZAVG ) (NOTE 1)

29

GAS kW REQUIRED

30

TRAIN BRAKE kW REQUIRED

31

BRAKE kW REQUIRED AT DRIVER INCL. EXT. LOSSES (GEAR, ETC.)

32

SPEED (RPM)

33

TURNDOWN (%)

34

POLYTROPIC HEAD (N-m / kg)

35

POLYTROPIC EFFICIENCY (%)

36

CERTIFIED POINT

37

EXPECTED OPERATION AT EACH CONDITION (%)

38

PERFORMANCE CURVE NUMBER

39

PROCESS CONTROL (1-3.4.2.1)

40

METHOD

Section 1

SS 1

Section 2

SS 2

VARIABLE INLET

SPEED VARIATION

DISCHARGE

COOLED BYPASS

41

FROM

BAR (kPa abs)

GUIDE VANES

FROM

BLOWOFF

FROM

42

TO

BAR (kPa abs)

(2-2.4.1)

TO

TO

TO

43

SUCTION THROTTLING

SIGNAL

Section 3

SOURCE (1-3.4.2.1)

44

TYPE

45

RANGE

ELECTRONIC

mA

PNEUMATIC

OTHER

BAR (kPa abs)

46

47

ANTI-SURGE SYSTEM (1-3.4.2.2)

48 REMARKS:

49 NOTE 1: IF GAS ANALYSIS IS GIVEN, MANUFACTURER SHALL SUPPLY DATA, OTHERWISE DATA SHALL BE SUPPLIED BY USER

03/03

SHT 1c OF 7

API617.XLS

319679003.xlsx, Page1c

REV 0

Page 3 of 9, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

ITEM NO.

REVISION NO.

PAGE

DATE

2

OF

BY

OPERATING CONDITIONS (Continued) (1-2.1.1.1) (1-3.1.2) (1-3.1.3)

OTHER CONDITIONS

2 GAS ANALYSIS:

3

NORMAL

MOL %

REMARKS:

MW

5 AIR

28.966

6 OXYGEN

32.000

7 NITROGEN

28.016

8 WATER VAPOR

18.016

9 CARBON MONOXIDE

28.010

10 CARBON DIOXIDE

44.010

11 HYDROGEN SULFIDE

34.076

(1-2.2.1.6)

12 HYDROGEN

2.016

(1-2.2.1.9)

13 METHANE

16.042

14 ETHYLENE

28.052

15 ETHANE

30.068

16 PROPYLENE

42.078

17 PROPANE

44.094

18 I-BUTANE

58.120

19 n-BUTANE

58.120

20 I-PENTANE

72.146

21 n-PENTANE

72.146

22 HEXANE PLUS

23 CORROSIVE AGENTS

(1-2.2.1.3)

24

25 TOTAL

26 AVG. MOL. WT.

27 LOCATION:

28

(1-2.1.8)

INDOOR

NOISE SPECIFICATIONS: (1-2.1.9)

OUTDOOR

GRADE

29

HEATED

UNDER ROOF

30

UNHEATED

PARTIAL SIDES

31

ELEC. AREA CLASSIFICATION (1-2.1.14)

APPLICABLE TO MACHINE:

MEZZANINE

APPLICABLE TO NEIGHBORHOOD:

CL

GR

DIV

32 SITE DATA (1-2.1.8)

SEE SPECIFICATION

ACOUSTIC HOUSING:

33

ELEVATION

34

RANGE OF AMBIENT TEMPS:

BAROMETER

DRY BULB

36

NORMAL

37

MAXIMUM

38

MINIMUM

39

BAR

YES

NO

APPLICABLE SPECIFICATIONS:

API 617, 7TH CHAPTER 1&2

35

WET BULB

VENDOR HAVING UNIT RESPONSIBILITY (1-1.5.52) (1-1.8) (1-2.1.3)

GOVERNING SPECIFICATION (IF DIFFERENT)

40 UNUSUAL CONDITIONS:

41

42

SEE SPECIFICATION

DUST

C

FUMES

PAINTING:

MANUFACTURER'S STD.

OTHER (1-2.1.8)

OTHER

43

44

COPPER AND COPPER ALLOYS PROHIBITED (1-2.2.1.14)

SHIPMENT: (1-4.4)

45 COATING: (1-2.2.1.16)

DOMESTIC

46

ROTATING COMPONENTS

OUTDOOR STORAGE MORE THAN 6 MONTHS (1-4.4.1)

47

STATIONARY COMPONENTS

SPARE ROTOR ASSEMBLY PACKAGE (1-4.4.3.10)

48 REMARKS:

EXPORT

HORIZONTAL STORAGE

EXPORT BOXING REQ'D.

MO

VERTICAL STORAGE

49

03/03

SHT 2 OF 7

319679003.xlsx, Page2

API617.XLS

REV 0

Page 4 of 9, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

ITEM NO.

REVISION NO.

PAGE

DATE

3

OF

BY

CONSTRUCTION FEATURES

1

2

SPEEDS:

MAX. CONT.

MAX. TIP SPEEDS:

DIAPHRAGMS:

RPM

TRIP

RPM

MATERIAL

m/sec @ 100% SPEED

AXIALLY SPLIT

YES

NO (2-2.4.8)

m/sec @ MAX. CONT. SPEED

LATERAL CRITICAL SPEEDS (DAMPED)

FIRST CRITICAL

RPM

MODE

DISCH. PRESSURE (BARG)(kPaG):

MAX

MIN

SECOND CRITICAL

RPM

MODE

INLET PRESSURE (BARG)(kPaG):

MAX

MIN

THIRD CRITICAL

RPM

MODE

DIAPHRAGM MAX. P (BAR)(kPa):

10

FOURTH CRITICAL

RPM

MODE

11

LATERAL ANALYSIS ADDITIONAL REQUIREMENTS (1-2.6.2.14)

NO.

12

TRAIN LATERAL ANALYSIS REQUIRED (1-2.6.2.6)

NO. VANES EA. IMPELLER

13

TRAIN TORSIONAL ANALYSIS REQUIRED (1-2.6.7.1)

TYPE (OPEN, ENCLOSED, ETC.)

14

TORSIONAL CRITICAL SPEEDS:

15

FIRST CRITICAL

RPM

MATERIAL

16

SECOND CRITICAL

RPM

MIN. YIELD STRENGTH (MPa)

17

THIRD CRITICAL

RPM

HARDNESS: (BNH)(Rc)

MAX

MIN

18

FOURTH CRITICAL

RPM

SMALLEST TIP INTERNAL WIDTH (mm)

19

LIST OF TRAIN UNDESIRABLE SPEEDS (1-2.6.1.4)

20

VIBRATION:

21

ALLOWABLE TEST LEVEL

22

(PEAK TO PEAK)

23

NAMEPLATE (2-2.11.2)

24

INTERMEDIATE MAIN PROCESS CONNECTIONS (2-2.4.5)

IMPELLERS:

DIAMETERS

TYPE FABRICATION

MAX. MACH. NO. @ IMPELLER EYE

MAX. IMPELLER HEAD @ 100% SPD (N-m/kg)

m

SHAFT:

ONE PIECE

BUILT UP

MATERIAL

US CUSTOMARY

METRIC

25

ROTATION, VIEWED FROM DRIVEN END

26

MATERIALS INSPECTION REQUIREMENTS (1-4.2.2.1)

DIA @ IMPELLERS (mm)

CW

CCW

SHAFT END:

DIA @ COUPLING (mm)

TAPERED

CYLINDRICAL

SPLINED

INTEGRAL FLANGE

27

RADIOGRAPHY REQUIRED FOR

MIN. YIELD STRENGTH (MPa)

28

ULTRASONIC REQUIRED FOR

SHAFT HARDNESS (BNH)(Rc)

29

MAGNETIC PARTICLE REQUIRED FOR

MAX TORQUE CAPABILITY (N-m)

30

LIQUID PENETRANT REQUIRED FOR

BALANCE PISTON:

31

LOW TEMPERATURE (1-2.2.1.15.3)

MATERIAL

32

MIN.DESIGN METAL TEMPERATURE (C)

FIXATION METHOD

33

AT CONCURRANT PRESSURE (BARG)(kPaG)

NORMAL CLEARANCE (mm)

34

OTHER TRAIN COMPONENTS (1-2.2.1.15.2)

FLOW WITH NORMAL CLEARANCE (kg/min)

AREA

35

CASING:

FLOW WITH 2x NORMAL CLEARANCE (kg/min)

36

MODEL

PRESS. CONN. BAL LINE DOWNSTREAM (2-2.5.4.3)

37

CASING SPLIT

SHAFT SLEEVES:

38

MATERIAL

39

THICKNESS (mm)

40

MAX. ALLOWABLE PRESS

41

TEST PRESS (BARG)(kPaG):

42

MAX. ALLOWABLE TEMPERATURE (C)

43

MAX OPER. TEMP.

44

MAX CASING CAPACITY (m3/h)

45

SYSTEM RELIEF VALVE SET PT. (2-2.3.1.1)

46

Q.C. OF INACCESSIBLE WELDS (1-2.3.1.11.2)

RESIDUAL BALANCE CHECK (1-2.6.8.7)

47

GUIDE VANES

LABYRINTHS:

48

MATERIAL

INTERSTAGE

49

NO. VANES GUIDE VANE

50

IGV EXTERNAL PURGE (2-2.4.2)

51

AT INTERSTG. CLOSE

CORR. ALLOW. (mm)

SHT 3 OF 7

BARG (kPaG)

319679003.xlsx, Page3

AT SHAFT SEALS

MATL

ACCESSIBLE (2-2.8.3)

ROTOR

API617.XLS

MATL

CLEARANCE POINTS

HYDRO

MIN. OPER. TEMP.

DISASSEMBLY AND REASSEMBLY (1-2.6.8.2.1.1)

AT SPEED BALANCING (1-2.6.8.3)

BARG (kPaG)

SEQUENTIAL LOW SPEED BAL. PREC. AT SPEED BAL. (1-2.6.8.6)

TYPE

MATERIAL

BALANCE PISTON

VANE CONTROL SYSTEM (2-2.4.3)

03/03

(mm )

TYPE

MATERIAL

REV 0

Page 5 of 9, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

ITEM NO.

REVISION NO.

PAGE

DATE

4

OF

BY

CONSTRUCTION FEATURES (CONTINUED)

1

2

SHAFT SEALS:

BUFFER GAS CONTROL SYSTEM SCHEMATIC BY VENDOR

SEAL TYPE (1-2.8.1.3)

PRESSURIZING GAS FOR SUBATMOSPHERIC SEALS (1-2.8.2.4)

MAX SEALING/SETTLING OUT PRES. (1-2.8.1.1)(BARG)(kPaG)

MIN.SEALING PRESSURE (BARG)(kPaG)

SEAL MANUFACTURER

SUPPLEMENTAL DEVICE REQUIRED FOR CONTACT

LEAKAGE TO PROCESS (m 3/DAY/SEAL)

SEALS (1-2.8.3.4)

BUFFER GAS REQUIRED FOR:

BUFFER GAS SYSTEM REQUIRED (1-2.8.1.5)

TYPE BUFFER GAS (1-2.8.1.5)

EDUCTOR

TYPE

AIR RUN-IN

INJECTION (1-2.8.2.3)

OTHER

FLOW (PER SEAL):

10

PRESSURE (1-2.8.1.6)

(BARG)(kPaG)

NORM:

kg/min @

BAR(kPa) P

11

FLOWRATE

(kg/min)

MAX.

kg/min @

BAR(kPa) P

12

FILTRATION

BEARING HOUSING CONSTRUCTION:

13

MANIFOLD (1-2.8.1.7)

TYPE (SEPARATE, INTEGRAL)

14

METHOD OF CONTROL (1-2.8.1.5)

MATERIAL

SPLIT

AXIAL COMPRESSOR

15

STAGE

16

10

11

12

13

14

15

16

17

18

17 ROTOR

18

BLADE MATERIAL

19

BLADE ROOT TYPE

20

CORD WIDTH (mm)

21

OUTER DIAMETER (mm)

22

BLADE HEIGHT (mm)

23

BLADE QUANTITY

24 STATOR

25

BLADE MATERIAL

26

TYPE

27

(MOVABLE, FIXED,

ADJUSTABLE)

28

CORD WIDTH (mm)

29

BLADE QUANTITY

30

STAGE

31

32 ROTOR

33

BLADE MATERIAL

34

BLADE ROOT TYPE

35

CORD WIDTH (mm)

36

OUTER DIAMETER (mm)

37

BLADE HEIGHT (mm)

38

BLADE QUANTITY

39 STATOR

40

BLADE MATERIAL

41

TYPE

42

ADJUSTABLE) (2-3.4.2.3)

43

CORD WIDTH (mm)

44

BLADE QUANTITY

(MOVABLE, FIXED,

45

46 REMARKS:

47

48

49

03/03

SHT 4 OF 7

319679003.xlsx, Page4

API617.XLS

REV 0

Page 6 of 9, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

ITEM NO.

REVISION NO.

PAGE

DATE

5

OF

BY

CONSTRUCTION FEATURES (CONTINUED)

1

2 BEARINGS AND BEARING HOUSINGS

3

MAGNETIC BEARINGS (2-2.7.1.1.2)

4 RADIAL

THRUST

NON-THRUST

ACTIVE

THRUST

TYPE

TYPE

MANUFACTURER

MANUFACTURER

LENGTH (mm)

UNIT LOADING (MAX) (BAR)

SHAFT DIA. (mm)

UNIT LOAD (ULT.) (BAR)

UNIT LOAD (ACT/ALLOW)

AREA (mm)

10

BASE MATERIAL

NO. PADS

11

BABBIT THICKNESS (mm)

PIVOT: CENTER / OFFSET, %

12

NO. PADS

PAD BASE MATL

13

LOAD: B'TWN/ON PAD

14

PIVOT: CTR/OFFSET, %

15

PAD MATERIAL

16

BEARING SPAN

INACTIVE

COPPER BACKED (2-2.7.3.7)

(2-2.7.2.2)

(2-2.7.2.3)

LUBRICATION:

FLOODED

DIRECTED (2-2.7.3.6)

THRUST COLLAR:

INTEGRAL

REPLACEABLE

mm

MATERIAL

17

18 BEARING TEMPERATURE DETECTORS (2-3.4.7.3)

VIBRATION DETECTORS:

19

SEE ATTACHED API-670 DATASHEET

TYPE

20

THERMOCOUPLES TYPE

MFR

21

RESISTANCE TEMP DETECTORS

22

RESISTANCE MAT'L

NO. AT EA SHAFT BEARING

OHMS

ALARM TEMPERATURE (C) (2-2.7.1.3)

24

SHUTDOWN TEMPERATURE (C) (2-2.7.1.3)

25

PROVISION FOR LOCAL DISCONNECT (1-2.7.4.6)

LOCATION

26

LOCATION-JOURNAL BRG

MFR.

27

NO.

28

OTHER

29

LOCATION-THRUST BRG

30

NO.

31

OTHER

32

NO. (INACT)

33

OTHER

EA PAD

MFR

EVERY OTH PAD

MODEL

PER BRG

MODEL

SCALE RGE

EVERY OTH PAD

PER BRG

38

SCALE RGE

39

SHTDWN

EA PAD

EVERY OTH PAD

TIME DELAY

SEC

TYPE

MODEL

MFR

NO. REQUIRED

OSCILLATOR-DEMODULATOR SUPPLIED BY

ENCLOSURE

MFR

MODEL

ALARM

SET @

MODEL

MONITOR SUPPLIED BY (2-3.4.7.2)

SET @

TIME DELAY

LOCATION

SEC

MFR.

41 KEY PHASOR REQUIRED

SHTDWN:

GEAR H.S.

ENCLOSURE

MODEL

SCALE RGE

COMPRESSOR

SEE ATTACH. API-670

DATA SHEET

PER BRG

40

42

SET @

m

SET @

CASING VIBRATION MONITORS (2-3.4.7.6)

MONITOR SUPPLIED BY (2-3.4.7.4)

MFR.

ALARM

AXIAL POSITION DETECTOR:

34

LOCATION

ENCLOSURE

CASING VIBRATION TRANSDUCERS (2-3.4.7.5)

EA PAD

37

TOTAL NO.

MONITOR SUPPLIED BY (2-3.4.7.2)

SHTDWN:

36

DATA SHEET

OSCILLATOR-DETECTORS SUPPLIED BY

23

35

SEE ATTACHED API-670

MODEL

ALARM

SET @

SET @

TIME DELAY

SEC

GEAR L.S.

43 CASING CONNECTIONS (1-2.3.2.2.1)

44

ANSI/ASME

(B16.1; B16.5;

FACING

46

B16.42; B16.47

BORE

FLANGED

MATING FLG

GAS

OR

& GASKET

47

VELOCITY

series A, B;

STUDDED

BY VENDOR

m/sec

48

ISO 7005-1, -2;

(1-2.3.2.2.1)

(1-2.3.2.2.7)

49

OTHER

45

CONNECTION

ORIENTATION

50 INLET

51 DISCHARGE

52

53

54

55

BOROSCOPIC INSPECTION PORTS (2-2.3.2.4)

03/03

SHT 5 OF 7

319679003.xlsx, Page5

API617.XLS

REV 0

Page 7 of 9, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

1

ITEM NO.

REVISION NO.

PAGE

DATE

6

OF

BY

OTHER CONNECTIONS

NO.

2 SERVICE:

SIZE

TYPE

NO.

LUBE-OIL INLET

PRESSURE

LUBE OIL OUTLET

TEMPERATURE

SEAL-OIL INLET

SOLVENT INJECTION

SEAL-OIL OUTLET

PURGE FOR:

SEAL GAS INLET

BRG. HOUSING

SEAL GAS OUTLET

BTWN BRG & SEAL

CASING DRAINS

BTWN SEAL & GAS

10

STAGE DRAINS

11

INDIVIDUAL STAGE DRAINS REQUIRED (1-2.3.2.1.7)

12

VALVED & BLINDED

13

VALVED & BLINDED & MANIFOLD

14

SIZE

TYPE

LUBRICATION AND SEALING SYSTEMS (1-2.10) (1-3.5.1.2)

15

SEE ATTACHED API 614 DATASHEET

16

SEPARATE

17

INTEGRAL OIL RESERVOIR (1-3.3.2.11)

18

OIL TYPE (2-2.10.2)

COMBINED (2-2.10.1)

ACCESSORIES

19

20 COUPLING AND GUARDS (3.2)

21 NOTE: SEE ROTATING ELEMENTS - SHAFT ENDS

22

SEE ATTACHED API-671 DATA SHEET

KEYLESS HYDRAULIC

KEYED

FLANGED

OTHER

23 COUPLING FURNISHED BY

24 MANUFACTURER

TYPE

MODEL

25 COUPLING GUARD FURNISHED BY:

26

TYPE:

FULLY ENCLOSED

SEMI-OPEN

OTHER

27 COUPLING DETAILS

28

MAX O.D.

mm

29

HUB WEIGHT

kg

30

SPACER LENGTH

mm

31

SPACER WEIGHT

kg

PLUG AND RING GAUGES (1-3.2.5)

LUBRICATION REQUIREMENTS:

NON-LUBE

CONT. OIL LUBE

QUANTITY PER HUB

OTHER

kg OR L/min

32

33 MOUNTING PLATES (1-3.3)

34

BASEPLATES FURNISHED BY (1-3.3.2.1)

35

COMPRESSOR ONLY

36

OTHER

37

NONSKID DECKING (1-3.3.2.4)

38

LEVELING PADS OR TARGETS (1-3.3.2.6)

39

COLUMN MOUNTING (1-3.3.2.5)

40

SUB-SOLE PLATES REQUIRED (1-3.3.2.10)

41

STAINLESS STEEL SHIM THICKNESS

42

MACHINED MOUNTING PADS REQUIRED (1-3.3.2.9)

SOLEPLATES FURNISHED BY (1-3.3.3.1)

DRIVER

GEAR

THICKNESS

mm

SUBSOLE PLATES REQUIRED (1-3.3.3.1.3)

SLOPED DECK (1-3.3.2.4.1)

EXTENT OF PIPING (2-3.5.1.1)

STAINLESS STEEL SHIM THICKNESS

mm

COMPRESSOR

mm

COUNTER BORE ANCHOR BOLT HOLES (1-3.3.3.1.2)

43

44

REMARKS:

45

46

47

48

49

03/03

SHT 6 OF 7

319679003.xlsx, Page6

API617.XLS

REV 0

Page 8 of 9, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL AND AXIAL COMPRESSOR

DATA SHEET (API 617-7TH Chapter 2)

SI UNITS (1-1.6.5)

PAGE

DATE

7

OF

BY

UTILITIES

UTILITY CONDITIONS:

STEAM:

INLET MIN

5

6

7

ITEM NO.

REVISION NO.

MANUALS

DRIVERS

DRAFT MANUAL FOR REVIEW (1-5.3.5.1.2)

BARG

NORM

BARG

MAX

BARG

RECOMMENDED STRAIGHT RUN OF PIPE DIAMETERS

BARG

BEFORE SUCTION

EXHAUST. MIN

TECHNICAL DATA MANUAL (1-5.3.5.4)

MISCELLANEOUS:

NORM

BARG

COMPRESSOR TO BE SUITABLE FOR FIELD RUN-IN ON AIR (1-2.1.16)

MAX

BARG

PROVISION FOR LIQUID INJECTION (1-2.1.10)

10

ELECTRICITY:

INJECTION MANIFOLD (2-3.5.1.2)

DRIVERS

11

CONTROL

SHUTDOWN

VENDOR'S REVIEW & COMMENTS ON PURCHASER'S

12

VOLTAGE

CONTROL SYSTEMS (1-3.4.1.1)

13

HERTZ

SHOP FITUP OF VENDOR PROCESS PIPING (1-4.4.3.11)

14

PHASE

WELDING HARDNESS TESTING (1-4.2.1.5)

15

REDUCED VOLTAGE START (1-3.1.6)

INSPECT

CLEANLINESS (1-4.2.1.4)

2

16

NUMBER OF STARTS (1-2.6.7.6.4)

DESIGN

AUDIT (1-5.1.4)

2

17

INSTRUMENT AIR:

18

MAX PRESS

BALANCE PISTON P (1-5.3.2.1.5) (BAR) (kPa)

BARG(kPaG)

MIN PRESS

BARG(kPaG)

PROVIDE TAIL END SCHEDULES (1-5.3.3.2)

19

20 SHOP INSPECTION AND TESTS: (1-4.1.4)

WIT/OBV

REQ'D

VENDOR'S REPRESENTATIVE SHALL (1-2.1.13)

21 HYDROSTATIC (1-4.3.2)

OBSERVE FLANGE PARTING

22 IMPELLER OVERSPEED (1-4.3.3)

CHECK ALIGNMENT AT TEMPERATURE

23 MECHANICAL RUN (1-4.3.6)(2-4.3.1)

BE PRESENT AT INITIAL ALIGNMENT

24

WEIGHTS (kg):

CONTRACT COUPLING

25 OPTIONAL TESTS

COMPR.

26 PURCHASER VIB. EQUIPMENT (2-4.3.1.1.10)

ROTORS:

GEAR

27 VARY LUBE & SEAL OIL PRESSURES

28 AND TEMPERATURES (1-4.3.6.1.5)

COMPRESSOR UPPER CASE

29 POLAR FORM VIB DATA (1-4.3.6.1.2)

TOTAL SHIPPING WEIGHT

COMPR.

DRIVER

BASE

DRIVER

GEAR

MAX. FOR MAINTENANCE (IDENTIFY)

30 TAPE RECORD VIB DATA (1-4.3.6.1.3)

31 SHAFT END SEAL INSP. (1-4.3.6.2.2)

SPACE REQUIREMENTS (mm):

32 GAS LEAK TEST AT DISCH PRESS (2-4.3.2.3)

COMPLETE UNIT:

33 POST TEST INTERNAL INSP. (1-4.3.8.5)

34

BEFORE GAS LEAKAGE TEST

35

AFTER GAS LEAKAGE TEST

REMARKS:

36 PERFORMANCE TEST (GAS) (AIR) (2-4.3.3.1.1)

37 INTERMEDIATE HEAD/PRESSURE TOL. (2-4.3.3.1.6)

38 COMPLETE UNIT TEST (2-4.3.3.2)

39 TANDEM TEST (2-4.3.3.3)

40 GEAR TEST (2-4.3.3.4)

41 HELIUM LEAK TEST (1-4.3.8.2)

42 SOUND LEVEL TEST (1-4.3.8.3)

43 AUX. EQUIPMENT TEST (1-4.3.8.4)

44 FULL LOAD / SPEED / PRESS TEST (1-4.3.8.6)

45 HYDRAULIC COUPLING INSP (1-4.3.8.7)

46 SPARE PARTS TEST (1-4.3.8.8)

47 INSPECTOR'S CHECKLIST COMPLIANCE (1-4.1.6)

48 GAS SEAL TEST VENDOR SHOP (1-4.3.5)

49

03/03

SHT 7 OF 7

319679003.xlsx, Page7

API617.XLS

REV 0

Page 9 of 9, Date Printed: 05/30/2016

You might also like

- Api 617Document14 pagesApi 617ecsuperal100% (1)

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- Instrument Air SizingDocument2 pagesInstrument Air Sizingmilton1987100% (1)

- Pressure Regulator Control Valve Sizing PetroDocument16 pagesPressure Regulator Control Valve Sizing PetroCH1253No ratings yet

- Centrifugal Compressor Specification Sheet: Operating ConditionsDocument6 pagesCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedNo ratings yet

- Restriction Orifice (RO) - Flow Control InstrumentDocument8 pagesRestriction Orifice (RO) - Flow Control InstrumentAnonymous 2g4jKo5a7vNo ratings yet

- Breather Valves DatasheetDocument4 pagesBreather Valves Datasheetmilton1987No ratings yet

- Calculation of Orifice Plate Hole DiameterDocument3 pagesCalculation of Orifice Plate Hole DiameterhiuNo ratings yet

- Compressor Settleout Pressure Temperature EstimationDocument3 pagesCompressor Settleout Pressure Temperature EstimationFahad Maqsood100% (1)

- Restriction Orifice CPPDocument9 pagesRestriction Orifice CPPparykoochakNo ratings yet

- API 610 11th Ed DatasheetDocument13 pagesAPI 610 11th Ed DatasheetHatem ShawkiNo ratings yet

- 13205-PPE-DS-V-003-1 - DataSheet - CVDocument7 pages13205-PPE-DS-V-003-1 - DataSheet - CVAnggun RushNo ratings yet

- Centrifugal Pump Data SheetDocument1 pageCentrifugal Pump Data Sheetpkitchen25No ratings yet

- Odorising SystemDocument36 pagesOdorising SystemSarah DeanNo ratings yet

- Flame ArrestorDocument10 pagesFlame ArrestorAdnan Khan100% (1)

- Restriction Orifice Sizing For A Minimum Recirculation LineDocument5 pagesRestriction Orifice Sizing For A Minimum Recirculation LineChemical.AliNo ratings yet

- Control Valve SizingDocument4 pagesControl Valve SizingAmolNo ratings yet

- Rupture Disk SizingDocument2 pagesRupture Disk Sizingabhishek shindeNo ratings yet

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocument1 pagePages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafNo ratings yet

- Reciprocating Compressor Discharge TemperatureDocument6 pagesReciprocating Compressor Discharge TemperaturesalleyNo ratings yet

- Air Blowe DatasheetDocument1 pageAir Blowe DatasheetMoein PNo ratings yet

- Design Data Performance (Dryer) : ClientDocument2 pagesDesign Data Performance (Dryer) : ClientEDUARDONo ratings yet

- Nioec SP 00 89 (R0) (Ed1)Document8 pagesNioec SP 00 89 (R0) (Ed1)aminNo ratings yet

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- Control Valve Data SheetDocument6 pagesControl Valve Data SheetsisesetNo ratings yet

- Api 670Document10 pagesApi 670ecsuperalNo ratings yet

- TGT M WPP DS 0012 - C - Datasheet For Caisson Sump PumpDocument7 pagesTGT M WPP DS 0012 - C - Datasheet For Caisson Sump Pumpvovancuong8No ratings yet

- Air Blower Haya Water VerfDocument9 pagesAir Blower Haya Water Verfgharsallah mounaNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- Basket Filter CalcDocument17 pagesBasket Filter CalcRajesh NareNo ratings yet

- Instrument Air Consumption CalculationDocument1 pageInstrument Air Consumption CalculationArt G. Enzi100% (1)

- Orifice SizingDocument2 pagesOrifice SizingAvinav Kumar100% (1)

- Instrument Air CalculationDocument11 pagesInstrument Air CalculationMohammad Mehdi Jafari67% (3)

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Flame ArresterDocument2 pagesFlame ArresterAariz KhanNo ratings yet

- Burst PR Calculation PDFDocument1 pageBurst PR Calculation PDFAranga KeerthiNo ratings yet

- Api 617Document7 pagesApi 617Sean_Middleton100% (1)

- Small Bore Orifice For Gas Flow PDFDocument4 pagesSmall Bore Orifice For Gas Flow PDFManufacturer VerifyNo ratings yet

- Air CompressorDocument51 pagesAir CompressorInaam Ur RehmanNo ratings yet

- Mechanical Data Sheet For Nitrogen ReceiverDocument8 pagesMechanical Data Sheet For Nitrogen ReceiversudjonoNo ratings yet

- Balanced Bellows Type Pressure Relief Valve NumbersDocument17 pagesBalanced Bellows Type Pressure Relief Valve NumbersswatkoolNo ratings yet

- 674 Reciprocating Pump DatasheetsDocument6 pages674 Reciprocating Pump DatasheetsAKSHEYMEHTANo ratings yet

- 6206 Guide For Selection Installation andDocument32 pages6206 Guide For Selection Installation andakbavra80% (5)

- Sizing Pressure RelievingDocument20 pagesSizing Pressure RelievingNuch NapapornNo ratings yet

- Snamprogetti: CustomerDocument3 pagesSnamprogetti: CustomeradesloopNo ratings yet

- 25nb y StrainerDocument1 page25nb y StrainerKailas NimbalkarNo ratings yet

- KG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.0Document6 pagesKG982-ONT-PR-OGT-DS-00001 - Process Datasheet For Gas Separators - Rev.0sumit kumar100% (1)

- GE 616 DatasheetDocument11 pagesGE 616 DatasheetrafieeNo ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- 10P87-D0003-046-R0-WHRU by TEPLDocument23 pages10P87-D0003-046-R0-WHRU by TEPLjigarNo ratings yet

- Restriction Orifice Final CalculationDocument1 pageRestriction Orifice Final CalculationJasperTanNo ratings yet

- 3p531-Api 617-C168v-Rev e - C168 - HPCDocument7 pages3p531-Api 617-C168v-Rev e - C168 - HPCYusri FakhrizalNo ratings yet

- 02 190 0012 MK 062Document9 pages02 190 0012 MK 062phuchau nguyenNo ratings yet

- (I S 0 Standards) : 'K) Lntermlttent (Starts1Day)Document9 pages(I S 0 Standards) : 'K) Lntermlttent (Starts1Day)Janakiraman MalligaNo ratings yet

- Nozzle List - 09.09.2014Document1 pageNozzle List - 09.09.2014tutuionutNo ratings yet

- Isover Cryolene InsDocument8 pagesIsover Cryolene InstutuionutNo ratings yet

- 13 394Document14 pages13 394deepakmitrNo ratings yet

- Seismic Design of Inner Tank - FN 14.03.2014Document8 pagesSeismic Design of Inner Tank - FN 14.03.2014tutuionutNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - WarmDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - WarmtutuionutNo ratings yet

- Anchor Straps - Outer Tank - 09.09.2014Document4 pagesAnchor Straps - Outer Tank - 09.09.2014tutuionutNo ratings yet

- TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageTECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterOM PRAKASH PALNo ratings yet

- Welding LNG Tank and Vessel in 5 and 9 Nickel SteelDocument4 pagesWelding LNG Tank and Vessel in 5 and 9 Nickel Steelויליאם סן מרמיגיוסNo ratings yet

- Wind Load - ASCE 7-10Document2 pagesWind Load - ASCE 7-10tutuionutNo ratings yet

- Material Data Sheets For Piping: 1 ForewordDocument50 pagesMaterial Data Sheets For Piping: 1 ForewordhsdeNo ratings yet

- Conversão Metais DIN ASTM Etc PDFDocument1 pageConversão Metais DIN ASTM Etc PDFRafael Perches PierriNo ratings yet

- Open Top Tank - Zero Inner PressureDocument1 pageOpen Top Tank - Zero Inner PressuretutuionutNo ratings yet

- Materials For LNG ServicesDocument10 pagesMaterials For LNG ServicesSung Hyun TakNo ratings yet

- New Steel Plate LNGDocument7 pagesNew Steel Plate LNGtutuionutNo ratings yet

- Technical Insulation - Cryolene PDFDocument8 pagesTechnical Insulation - Cryolene PDFtutuionutNo ratings yet

- Welding LNG Tank and Vessel in 5 and 9 Nickel SteelDocument4 pagesWelding LNG Tank and Vessel in 5 and 9 Nickel Steelויליאם סן מרמיגיוסNo ratings yet

- Aisc Design Examples v14Document125 pagesAisc Design Examples v14Daniyal Ahmed100% (2)

- 9%ni Material FeaturesDocument9 pages9%ni Material FeaturestutuionutNo ratings yet

- AZOBEDocument4 pagesAZOBEtutuionutNo ratings yet

- Vent Guide Website 3.19.13Document36 pagesVent Guide Website 3.19.13Eddy SyahNo ratings yet

- Design Standard - Section 3-3 - Steel Storage Tanks - 12!31!12 - FINALWEBPOST - 201301090858057238Document60 pagesDesign Standard - Section 3-3 - Steel Storage Tanks - 12!31!12 - FINALWEBPOST - 201301090858057238ராபர்ட் ஆன்றோ ரெனிNo ratings yet

- Guidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) EnglishDocument50 pagesGuidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) EnglishSteve IpNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocument17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNo ratings yet

- Api 673 SiDocument11 pagesApi 673 Situtuionut100% (1)

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocument2 pagesSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutNo ratings yet

- Api 670 MpsDocument4 pagesApi 670 MpstutuionutNo ratings yet

- ANSYS FLUENT 12.0 Theory Guide - 4.12.1 OverviewDocument3 pagesANSYS FLUENT 12.0 Theory Guide - 4.12.1 OverviewAA GGNo ratings yet

- 07a40302 Fluid Mechanics & Heat TransferDocument8 pages07a40302 Fluid Mechanics & Heat TransferSRINIVASA RAO GANTANo ratings yet

- Man NR12-SDocument225 pagesMan NR12-STibor Komaromy100% (1)

- Design and Calculation Methods For Uniflow Cyclones Mar19 - SP PDFDocument11 pagesDesign and Calculation Methods For Uniflow Cyclones Mar19 - SP PDFSteve Wan100% (1)

- FlowDocument18 pagesFlowsmpragash123No ratings yet

- Heat Exchanger PipingDocument39 pagesHeat Exchanger PipingBhupender Sharma93% (15)

- ASME - Performance Test CodesDocument1 pageASME - Performance Test CodesanoopkntpcNo ratings yet

- Start-Up & Commissioning Manual 2 To 3Document6 pagesStart-Up & Commissioning Manual 2 To 3S.KNo ratings yet

- Oxygen Cone: Installation and Owner'S ManualDocument12 pagesOxygen Cone: Installation and Owner'S Manualeugenia saldañaNo ratings yet

- SND Spray Nozzle Desuperheater-Installation Maintenance ManualDocument16 pagesSND Spray Nozzle Desuperheater-Installation Maintenance ManualShameer Majeed100% (1)

- Home Assignment-5 - (Assignment Problems) Chapter-6Document2 pagesHome Assignment-5 - (Assignment Problems) Chapter-6Rounak MajumdarNo ratings yet

- ME321 Turbomachines 2020Document4 pagesME321 Turbomachines 2020Ashish DaundkarNo ratings yet

- NPSH - Net Positive Suction HeadDocument8 pagesNPSH - Net Positive Suction HeadQasimNo ratings yet

- J Fluids Engineering 2009 Vol 131 N5Document124 pagesJ Fluids Engineering 2009 Vol 131 N5Нильва АлександрNo ratings yet

- AEC3101 Compressors & Turbines: Dr.P.N.Kadiresh Professor/Aerospace EngineeringDocument75 pagesAEC3101 Compressors & Turbines: Dr.P.N.Kadiresh Professor/Aerospace EngineeringPraveen SundararajanNo ratings yet

- Portfolio Vacuum ProcedureDocument2 pagesPortfolio Vacuum ProcedureAli SalmanNo ratings yet

- GPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For RevisionDocument15 pagesGPSA Engineering Data Book 14th Edition: Revision Date Reason (S) For Revisionrkm_rkmNo ratings yet

- Manual Caldero 750-184 Model Cble-125-200bhpDocument200 pagesManual Caldero 750-184 Model Cble-125-200bhpvicvargNo ratings yet

- Enhanced Indoor Air Quality Strategies LEEDv4Document3 pagesEnhanced Indoor Air Quality Strategies LEEDv4Clifford Allen CooperNo ratings yet

- Ws 2016 13-Pdf-EnDocument2 pagesWs 2016 13-Pdf-EnMuhammadUsmanSaeedNo ratings yet

- HW12 SolutionDocument6 pagesHW12 SolutionudinNo ratings yet

- EERC-82-09 Fluid-Structure Interactions Added Mass Computations For Incompressible FluidDocument126 pagesEERC-82-09 Fluid-Structure Interactions Added Mass Computations For Incompressible FluidBMWrider1453No ratings yet

- Bab 1 SolutionsDocument37 pagesBab 1 SolutionsNgọc HuyềnNo ratings yet

- H11 Espl Comm Rev01Document4 pagesH11 Espl Comm Rev01Norberto NorbertoNo ratings yet

- Vent Sizing SpreadsheetDocument2 pagesVent Sizing SpreadsheetHamid MansouriNo ratings yet

- Astm d1657Document5 pagesAstm d1657Kamruzaman MiahNo ratings yet

- 2010-Ch 6 The Basic Differential Eq-0525 PDFDocument9 pages2010-Ch 6 The Basic Differential Eq-0525 PDFAthulNo ratings yet

- Lec2 Air CompressorDocument21 pagesLec2 Air CompressorHabib A. IslamNo ratings yet

- Price List Senso OilDocument1 pagePrice List Senso Oilsangga kusumanagara jati saputraNo ratings yet

- Gas TurbineDocument14 pagesGas Turbinevasanth11kv100% (2)