Professional Documents

Culture Documents

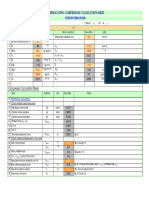

Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP Comp

Uploaded by

tutuionutOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP Comp

Uploaded by

tutuionutCopyright:

Available Formats

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

TURBOEXPANDER/COMPRESSOR

DATA SHEET

SI UNITS

1 APPLICABLE TO:

PROPOSAL

PURCHASE

REVISION NO.

PAGE

OF

BY

AS-BUILT

2 SERVICE

NO. REQUIRED

3 MANUFACTURER

4 NOTE:

DATE

1

MODEL

INFORMATION TO BE COMPLETED:

BY PURCHASER

BY MANUFACTURER

EITHER, BUT BY VENDOR IF NOT BY PURCHASER

OPERATING CONDITIONS

NORMAL CASE

7

(ALL DATA ON PER UNIT BASIS)

EXP

CASE A

COMP

EXP

CASE B

COMP

EXP

COMP

9 INLET CONDITIONS:

10

MMm3/day (m3/h): (1.03 BAR & 0C DRY)

11

WEIGHT FLOW, kg/HR (EXP: WET / DRY; COMP: WET / DRY)

12

PRESSURE (BAR abs)

13

TEMPERATURE (C)

14

MOLECULAR WEIGHT

15

16

17 DISCHARGE CONDITIONS:

18

PRESSURE (BAR abs)

19

TEMPERATURE (C)

20

WEIGHT PERCENT LIQUID (%)

21

GAS kW

22

SPEED (RPM)

23

ADIABATIC/POLYTROPIC EFFICIENCY (Exp/Comp, %)

24

25

26

GUARANTEE CASE (check one case)

27

28 VARIABLE INLET GUIDE VANE PROCESS CONTROL SIGNAL SOURCE:

29

TYPE:

30

ELECTRONIC

RANGE:

MA

PNEUMATIC

BARG

31

32

33

34

35 CASING CONNECTIONS:

36

37

FLANGED

SIZE

CONNECTION

38

NPS/RATING

FACING

POSITION

MATING FLG

GAS

OR

& GASKET

VELOCITY

STUDDED

BY VENDOR

m/SEC.

39 EXPANDER INLET

40 EXPANDER DISCHARGE

41

42 COMPRESSOR INLET

43 COMPRESSOR DISCHARGE

44 REMARKS:

45

46

47

48

49

319679146.xlsx, page 1

Page 1 of 6, Date Printed: 05/30/2016

JOB NO.

TURBOEXPANDER / COMPRESSOR

DATA SHEET

SI UNITS

PAGE

DATE

OF

BY

OPERATING CONDITIONS (Continued)

1

NORMAL

2 GAS ANALYSIS:

3

ITEM NO.

REVISION NO.

MOL %

EXP

WT %

CASE A

COMP

EXP

CASE B

COMP

EXP

SEAL

COMP

REMARKS:

GAS

MW

5 HELIUM

4.000

6 HYDROGEN

2.016

7 NITROGEN

28.016

8 WATER VAPOR

18.016

9 CARBON DIOXIDE

44.010

10 HYDROGEN SULFIDE

34.076

11 METHANE

16.042

12 ETHYLENE

28.052

13 ETHANE

30.068

14 PROPYLENE

42.078

15 PROPANE

44.094

16 I-BUTANE

58.120

17 n-BUTANE

58.120

18 I-PENTANE

72.146

19 n-PENTANE

72.146

20 HEXANE PLUS

21

22

23

24

25 TOTAL

26 AVG. MOL. WT.

27 SITE DATA

28

APPLICABLE SPECIFICATIONS:

ELEVATION

BAROMETER

BARA

VENDOR STANDARD

29

RANGE OF AMBIENT TEMPS:

30

NORMAL

API 617, 7TH EDITION

31

MAXIMUM

NOISE SPECIFICATIONS:

32

MINIMUM

VENDOR STANDARD

OTHER:

33 LOCATION:

PURCHASER SPECIFICATION

34

INDOOR

OUTDOOR

GRADE

35

HEATED

UNDER ROOF

MEZZANINE

36

UNHEATED

PARTIAL SIDES

37

AREA CLASSIFICATION

38

CLASS

GROUP

39

ZONE

GROUP

40 UNUSUAL CONDITIONS:

41

WINTERIZATION REQ'D.

42

OTHER

43

SEE SPECIFICATION

ACOUSTIC COVERING:

YES

NO

PAINTING:

NEC

IEC

DIV.

OTHER

TEMP CLASS

DUST

VENDOR STANDARD

SHIPPING PREPARATION:

FUMES

TROPICALIZATION REQ'D.

DOMESTIC PACKING

EXPORT PACKING (MIL-P 116J METHOD II)

SPECIAL:

DELIVERY:

44 REMARKS:

FCA FACTORY

45

OTHER:

FOB SITE (DOMESTIC ONLY)

46

47

SPARE ROTATING ASSEMBLY:

48

WOODEN SHIPPING CONTAINER

49

METAL SHIPPING CONTAINER W/ PURGE PROVISION

319679146.xlsx, page 2

Page 2 of 6, Date Printed: 05/30/2016

JOB NO.

TURBOEXPANDER / COMPRESSOR

DATA SHEET

SI UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

OF

BY

CONSTRUCTION FEATURES

1

2

SPEEDS:

MAX. CONT.

IMPELLERS:

TIP SPEEDS:

RPM

TRIP

RPM

EXP

EXPANDER

m/SEC @ MCS

TYPE (OPEN, ENCLOSED)

COMPRESSOR

m/SEC @ MCS

TYPE FABRICATION

LATERAL CRITICAL SPEEDS (DAMPED)

FIRST CRITICAL

EXPANDER WHEEL MATERIAL

YIELD STRENGTH (MPa)

MAX

UNDAMPED CRITICAL SPEED MAP

HARDNESS:

BNH / RC

RPM

BENDING MODE

COMPLETE ROTORDYNAMIC ANALYSIS

COMPRESSOR WHEEL MATERIAL

10

YIELD STRENGTH (MPa)

MAX

11

HARDNESS:

BNH / RC

12

CASINGS:

13

MODEL

14

EXP

15

CASING SPLIT

16

MATERIAL

BRG HSG

ASTM A-351 CF8

18

ASTM A-352 LC3

19

ASTM A-352 LCC

20

ASTM A-216 WCB

(TYP)

MIN

(TYP)

(TYP)

COMP

MATERIAL

SHAFT END:

21

TAPERED

CYLINDRICAL

YIELD STRENGTH (MPa)

22

DESIGN PRES, PSIG

23

MAX DESIGN TEMP, C

24

MIN. DESIGN TEMP, C

25

VISUAL INSPECTION

26

CHARPY TESTING

27

MAGNETIC PARTICLE

28

LIQUID PENETRANT

SINGLE PORT BUFFERED LABYRINTH

29

CRITICAL AREA X-RAY

DOUBLE PORT BUFFERED LABYRINTH

SHAFT HARDNESS (BNH)(Rc)

SHAFT SEALS:

30

TRIPLE PORT BUFFERED LABYRINTH

BLEED PRESSURE:

31

HYDROTEST PRESS

1.5 X DESIGN

CASING LEAK TEST

1.0 X DESIGN

33

34

MIN

(TYP)

SHAFT:

17

32

COMP

DIAMETER (mm)

BARG

DRY GAS SEAL:

TYPE BUFFER GAS

35

100% NITROGEN

36

NITROGEN / HELIUM MIX (90 / 10)

37

100% HELIUM

TYPE:

BARG

MAX SUPPLY PRESS.

40

MIN SUPPLY TEMP.

41

MAX SUPPLY TEMP.

42

NORMAL FLOW

nm3/min @

BAR P

MAX FLOW

nm3/min @

BAR P

39

LEAK TEST PERFORMED FOLLOWING

SEAL GAS REQUIREMENTS :

MIN. SUPPLY PRESS.

38

NOTE:

BARG

BUFFER GAS SUPPLY PRESSURE

OTHER

HYDROTEST USING SOAP BUBBLE METHOD

43

44

NOTE: PURCHASER TO SUPPLY SEAL GAS

45

COMPOSITION ON SHEET 2.

46

47

48

49

319679146.xlsx, page 3

Page 3 of 6, Date Printed: 05/30/2016

JOB NO.

TURBOEXPANDER / COMPRESSOR

DATA SHEET

SI UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

OF

BY

CONSTRUCTION FEATURES (CONTINUED)

1

2 BEARINGS:

3 RADIAL:

4

THRUST:

TYPE:

TYPE:

SLEEVE BEARING

TAPERED LAND THRUST BEARING

TILTING PAD BEARING

TILTING PAD THRUST BEARING

ACTIVE MAGNETIC BEARING

ACTIVE MAGNETIC THRUST BEARING

OTHER

OTHER

MATERIAL:

MANUFACTURER

10

ALUMINUM (BABBITTED)

LUBRICATION:

11

BRASS / BRONZE(BABBITTED)

THRUST COLLAR / DISK:

12

CARBON STEEL (BABBITTED)

VIBRATION DETECTORS:

13

OTHER

14

SHAFT DIA. (mm)

15

MANUFACTURER

TYPE:

INDUCTIVE

MODEL

TYPE

NO. PER JOURNAL BEARING

THERMOCOUPLES

19

RESISTANCE TEMP DETECTORS

21

EDDY CURRENT

TYPE:

TOTAL NO.

IF REQ'D, OSCILLATOR-DEMODULATORS SUPPLIED BY:

RESISTANCE MAT'L

OHMS

VENDOR

MODEL

PURCHASER

MODEL

MACHINE VIBRATION PROTECTION LOGIC DEVICE:

LOCATION / QTY

22

SINGLE DUAL ELEMENT (MAIN & SPARE)

23

TEMPERATURE PROTECTION LOGIC DEVICE:

PER BRG

VIBRATION MONITOR

DCS

PLC

OTHER

24

TEMPERATURE MONITOR

DCS

LOGIC DEVICE PROVIDED BY:

25

PLC

OTHER

LOCATION OF VIBRATION PROTECTION LOGIC DEVICE:

26

LOGIC DEVICE SUPPLIED BY:

VENDOR

27

LOCATION OF TEMPERATURE PROTECTION LOGIC DEVICE:

28

LOCAL CONTROL PANEL

REMOTE CONTROL PANEL

29

MAIN CONTROL ROOM

OTHER

30

PURCH

VENDOR

LOCAL CONTROL PANEL

REMOTE CONTROL PANEL

VIBRATION AMPLITUDE DISPLAY

VIBRATION MONITOR

BEARING TEMPERATURE DISPLAY TYPE:

MODEL

ALPHANUMERIC DISPLAY

TEMPERATURE MONITOR

32

ALPHANUMERIC DISPLAY

OTHER

33

MMI / VDU

DISPLAY DEVICE PROVIDED BY:

34

PURCHASER

LOCATION OF DISPLAY DEVICE:

36

MODEL

MMI / VDU

OTHER

VENDOR

PURCH

37

LOCATION OF TEMPERATURE DISPLAY DEVICE:

38

LOCAL CONTROL PANEL

REMOTE CONTROL PANEL

39

MAIN CONTROL ROOM

OTHER

YES

UPS SUPPLIED BY:

LOCAL PANEL

MAIN CONTROL ROOM

43

TYPE:

44

QUANTITY

ELECTROMAGNETIC

VENDOR

PURCHASER

EDDY CURRENT

REMOTE PANEL

CABLE LENGTH FROM MACHINE SKID

m

TO CONTROL CABINET:

45

49

NO

LOCATION OF CONTROL CABINET:

42 SPEED PROBES:

48

REMOTE CONTROL PANEL

MAGNETIC BEARING CONTROL CABINET, IF REQUIRED

41

47

PURCH

MAIN CONTROL ROOM

KEY PHASOR

40

46

VENDOR

LOCAL CONTROL PANEL

DISPLAY DEVICE PROVIDED BY:

PURCH

MAIN CONTROL ROOM

31

35

N/A

SEPARATE

LOCATION AND QUANTITY:

18

20

DIRECTED

INTEGRAL

MFR

16 BEARING TEMPERATURE DEVICES:

17

FLOODED

POWER AND SIGNAL CABLES:

MACHINE PROTECTION LOGIC DEVICE:

SWITCH

SPEED MONITOR

MODBUS

LOCATION OF SPEED DISPLAY:

LOCAL PANEL

319679146.xlsx, page 4

SUPPLIED BY PURCHASER

REMOTE DISPLAY

SUPPLIED BY VENDOR

COMUNICATION PROTOCOL

POWER CONSUMPTION:

OTHER:

kW

Page 4 of 6, Date Printed: 05/30/2016

JOB NO.

TURBOEXPANDER / COMPRESSOR

DATA SHEET

SI UNITS

1

ITEM NO.

REVISION NO.

PAGE

OTHER CONNECTIONS

DATE

OF

BY

ALLOWABLE PIPING FORCES AND MOMENTS:

NO.

2 SERVICE:

SIZE

TYPE

1.85 X NEMA SM23

3 LUBE-OIL INLET

3 X NEMA SM23

4 LUBE OIL OUTLET

OTHER:

5 SEAL GAS INLET

CASING DRAINS:

6 SEAL GAS OUTLET

PLUGGED

FLANGED AND VALVED

7 CASING DRAINS, EXP / COMP

FLANGED

FLANGED, VALVED, AND MANIFOLDED

8 INTERMEDIATE BLEED

9 THRUST PRESSURES

10 WHEEL PRESSURES, EX / COM

11 BEARING HOUSING PRES

12

13

14

15

ACCESSORIES

16

17

18

EXPANDER INLET TRIP VALVE:

TYPE:

19

BUTTERFLY VALVE

20

OTHER:

21

DESIGN PRESSURE:

22

MATERIAL:

23

SIZE:

RATING:

BARG

STAINLESS STEEL

ALLOWABLE PRESSURE DROP:

DESIGN TEMPERATURE (MIN / MAX)

LOW TEMP CARBON STEEL

24

TRIP VALVE SUPPLIED BY:

25

INLET SCREENS AND PIPE SPOOLS:

26

INLET SCREENS:

CARBON STEEL

VENDOR

EXP

OTHER:

COMP

INLET SPOOLS FOR INLET SCREENS:

EXP

TYPE: (CONE, BASKET, OTHER)

SIZE

28

SIZE (DIA. IN mm)

RATING

29

MESH SIZE

FACING

30

PRESSURE DROP (BAR)

DESIGN PRESSURE:

31

MATERIAL:

DESIGN TEMPERATURE (MIN/MAX)

DESIGN TEMPERATURE (MIN/MAX)

33

STAINLESS STEEL

OTHER

COMP

BARG

MATERIAL:

STAINLESS STEEL

34

35

PURCHASER

27

32

BAR

INLET SCREENS SUPPLIED BY:

36

VENDOR

LOW TEMP CARBON STEEL

PURCHASER

CARBON STEEL

37

OTHER:

SPOOL CONSTRUCTION:

38

39

SLIP-ON / SOCKETWELD

40

SOCKETWELD

WELDNECK / BUTTWELD

41

42

PIPE SPECIFICATION:

43

44

COMPRESSOR ANTI-SURGE SYSTEM

45

CONTROLLER:

46

RECYCLE VALVE

47

PID CONTROLLER

TYPE:

DESIGN PRESSURE:

BARG

NOISE LIMIT:

VENDOR STD

INLET FLOW DEVICE

49

COMP. INLET FLOW TRANSMITTER

SPECIAL:

DESIGN TEMPERATURE (MIN/MAX)

TYPE:

48

319679146.xlsx, page 5

OTHER:

MTL:

BY:

COMP. DIFF. PRESSURE TRANSMITTER

Page 5 of 6, Date Printed: 05/30/2016

JOB NO.

TURBOEXPANDER / COMPRESSOR

DATA SHEET

SI UNITS

PAGE

1 SHOP INSPECTION AND TESTS:

DATE

OF

BY

UTILITY CONDITIONS:

REQ'D

ITEM NO.

REVISION NO.

3 CLEANLINESS

OBSRV

WTNS

INSTRUMENT AIR FOR GUIDE VANE ACTUATOR:

MAX PRESS

BARG

MIN PRESS

BARG

4 HYDROSTATIC

5 LOW SPEED BALANCE (ISO 1940 G2.5)

6 IMPELLER OVERSPEED (115% OF MCS)

7 IMPELLER RESONANCE TEST

8 MECHANICAL RUN

9

10

MAIN

SPARE

CONTRACT PROBES

MISCELLANEOUS:

SHOP PROBES

RECOMMENDED STRAIGHT RUN OF PIPE DIAMETERS

11 VARY LUBE & SEAL OIL PRESSURES

12 AND TEMPERATURES

AT EXPANDER DISCHARGE:

AT COMPRESSOR INLET:

13 POLAR FORM VIB DATA

VENDOR TO REVIEW & COMMENT ON PURCHASER'S

14 TAPE RECORD VIB DATA

PIPING & FOUNDATION

15 TAPE DATA TO PURCHASER

VENDOR TO REVIEW & COMMENT ON PURCHASER'S

16 PERFORMANCE TEST (AIR)

CONTROL SYSTEMS

17 COMPLETE UNIT TEST

18 HE/N2 CASING LEAK TEST

19 SOUND LEVEL TEST

20 FULL POWER TEST

21

WEIGHTS (kg):

22

EXP / COMP UNIT

kg

23

MAINTENANCE (SPARE ROTATING ASSY)

kg

24

TOTAL MACHINERY SKID WEIGHT:

kg

25

TOTAL SUPPORT SYSTEM SKID WT. (IF SEPARATE):

kg

26

27

28

SPACE REQUIREMENTS (m):

29

MACHINERY SKID:

30

SUPPORT SYSTEM SKID:

31

32

33

34

35

36

37

38 REMARKS:

39

40

41

42

43

44

45

46

47

48

49

319679146.xlsx, page 6

Page 6 of 6, Date Printed: 05/30/2016

You might also like

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- DAT - Centrifugal CompressorDocument4 pagesDAT - Centrifugal CompressorEDUARDONo ratings yet

- Bog CompressorDocument7 pagesBog CompressorsswahyudiNo ratings yet

- E07 QDocument20 pagesE07 QSoledad Fernández SantosNo ratings yet

- IPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsDocument22 pagesIPS-M-PM-160-Positive Displacement, Oil Sealed-Rotary Vacuum PumpsAbdi RahimianNo ratings yet

- Industrial GasesDocument20 pagesIndustrial GasesRiazNo ratings yet

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationFrom EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosNo ratings yet

- Multiphase Flow 1995From EverandMultiphase Flow 1995A. SerizawaNo ratings yet

- PDQ Process - Process - ThyssenKrupp Industrial SolutionsDocument2 pagesPDQ Process - Process - ThyssenKrupp Industrial SolutionsIhwan LimantoNo ratings yet

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectFrom EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectNo ratings yet

- API 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitsDocument8 pagesAPI 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitstutuionutNo ratings yet

- GPSA Section 2Document6 pagesGPSA Section 2braianvegas12No ratings yet

- Compressor Packager Guide WEB NewDocument4 pagesCompressor Packager Guide WEB NewJaroslav KurucNo ratings yet

- QB Johnson Water Bath HeaterDocument3 pagesQB Johnson Water Bath HeaterMuhammad AhsanNo ratings yet

- RG Integrally Geared Compressors PDFDocument6 pagesRG Integrally Geared Compressors PDFJaswindersingh BhatiaNo ratings yet

- F34776 ArielDocument119 pagesF34776 ArielBraulio GomezNo ratings yet

- ReciprocatingCompressorPower-US Field UnitsDocument2 pagesReciprocatingCompressorPower-US Field UnitshihihiNo ratings yet

- Data Sheet Ejector PDFDocument2 pagesData Sheet Ejector PDFSuryaprakashNo ratings yet

- Compressor Station Optimization Using Simulation-Based OptimizationDocument10 pagesCompressor Station Optimization Using Simulation-Based OptimizationAmbrish SinghNo ratings yet

- Standart 0508Document3 pagesStandart 0508carlosNo ratings yet

- Calculate Horizontal Cylinder VolumeDocument10 pagesCalculate Horizontal Cylinder VolumearifcoyNo ratings yet

- Combustion Table Industrial Energy ProcessDocument4 pagesCombustion Table Industrial Energy Processsara_ghaemNo ratings yet

- Api 610Document3 pagesApi 610rajkmuarNo ratings yet

- Reciprocating CompressorsDocument5 pagesReciprocating CompressorsthirumalaiNo ratings yet

- SLM Avp ManualDocument48 pagesSLM Avp Manualkeyur1109No ratings yet

- Toyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpDocument4 pagesToyo Pumps Specification Sheet & Quotation: DEC Series Heavy Duty Vertical Cantilever PumpNicolas Celis Perez100% (1)

- Control Valve Data Sheet Form S20 50 PDFDocument4 pagesControl Valve Data Sheet Form S20 50 PDFPanner2009No ratings yet

- Thomasssen Comp SelectionDocument2 pagesThomasssen Comp Selectionmahesh_eilNo ratings yet

- Vent Dispersion CalcDocument9 pagesVent Dispersion CalcPeddy Nesa0% (1)

- MR For Non Slamming Check ValveDocument5 pagesMR For Non Slamming Check ValveAlvin SmithNo ratings yet

- Fractionation SystemsDocument8 pagesFractionation SystemsKha Damayantirika Tsf 'reall'No ratings yet

- IP 10-4-1 (Reciprocating Process Compressors)Document9 pagesIP 10-4-1 (Reciprocating Process Compressors)luisNo ratings yet

- Reciprocating Compressor Capacity Control Simple Reliable 1670707033Document13 pagesReciprocating Compressor Capacity Control Simple Reliable 1670707033mohammad1412No ratings yet

- Blowdown TankDocument1 pageBlowdown TankShameer Majeed0% (1)

- Art's Process Spec SheetsDocument27 pagesArt's Process Spec SheetsSaid Alauddeen FaiszNo ratings yet

- FRP Flange DesignDocument29 pagesFRP Flange DesignSubhadip RoyNo ratings yet

- Centrifugal Pumps NPSHDocument6 pagesCentrifugal Pumps NPSHSubrata MukherjeeNo ratings yet

- Kramer H.J.M. - 2000 - Modeling of Industrial Crystallizers For Control and Design Purposes PDFDocument7 pagesKramer H.J.M. - 2000 - Modeling of Industrial Crystallizers For Control and Design Purposes PDFhusseinNo ratings yet

- Vessel Volume Calculation1Document2 pagesVessel Volume Calculation1eino6622No ratings yet

- Control TechnologiesDocument51 pagesControl TechnologiesrajuNo ratings yet

- GE Reciprocating Compressor BrochureDocument13 pagesGE Reciprocating Compressor Brochurearvind pillaiNo ratings yet

- Fertilizers Industry Ammonia PlantDocument75 pagesFertilizers Industry Ammonia Plantnayear100% (1)

- CVC AlcsDocument10 pagesCVC Alcsmanoj_amritkarNo ratings yet

- Exxon IP 10-3-4 Axial Compressors For Air ServiceDocument7 pagesExxon IP 10-3-4 Axial Compressors For Air ServiceGilvan SilvaNo ratings yet

- Brown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsDocument12 pagesBrown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsPebriyantoNo ratings yet

- Pipe Material For OxygenDocument3 pagesPipe Material For Oxygenc_pythonNo ratings yet

- February 2017Document52 pagesFebruary 2017Alfred LamNo ratings yet

- Unit 8 Reciprocatng Compressors: StructureDocument26 pagesUnit 8 Reciprocatng Compressors: StructureRakeshKrNo ratings yet

- Compressor Size CalulatorDocument2 pagesCompressor Size CalulatorŞef Utas Awij100% (1)

- Flare Gas Recovery - by Reliance Industries Ltd. (Refinery Division)Document3 pagesFlare Gas Recovery - by Reliance Industries Ltd. (Refinery Division)sriram84No ratings yet

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Restrictive Orifice Calc For Tube FinalDocument12 pagesRestrictive Orifice Calc For Tube FinalsafaldNo ratings yet

- Economic Implementation of The Organic Rankine Cycle in Industry PDFDocument11 pagesEconomic Implementation of The Organic Rankine Cycle in Industry PDFKendra TerryNo ratings yet

- Defence: The Las Tlineo FDocument5 pagesDefence: The Las Tlineo FMuhamad Nur HusenNo ratings yet

- BS&B Process System Inc Fired Heater Input SheetDocument52 pagesBS&B Process System Inc Fired Heater Input SheetAnonymous bHh1L1No ratings yet

- Pages From 05-01269 Regeneration API-617-datasheet-rev11 PDFDocument1 pagePages From 05-01269 Regeneration API-617-datasheet-rev11 PDFalikajbafNo ratings yet

- Selection of Gas CompressorsDocument4 pagesSelection of Gas CompressorsDiegoNo ratings yet

- Mayekawa DOC.2011-200 R5 PDFDocument28 pagesMayekawa DOC.2011-200 R5 PDFadNo ratings yet

- Universal Nozzle Calculator Ver 3 0Document10 pagesUniversal Nozzle Calculator Ver 3 0madodandembeNo ratings yet

- New Steel Plate LNGDocument7 pagesNew Steel Plate LNGtutuionutNo ratings yet

- Technical Insulation - Cryolene PDFDocument8 pagesTechnical Insulation - Cryolene PDFtutuionutNo ratings yet

- AZOBEDocument4 pagesAZOBEtutuionutNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNo ratings yet

- Api 673 SiDocument11 pagesApi 673 Situtuionut100% (1)

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocument2 pagesSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- API 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)Document10 pagesAPI 614-Chapter 4 DATA SHEET Dry Gas Seal Module Si Units: System Responsibility: (2.1.2)tutuionutNo ratings yet

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document9 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocument17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNo ratings yet

- API 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitsDocument8 pagesAPI 614-Chapter 3 DATA SHEET General Purpose Oil System Si UnitstutuionutNo ratings yet

- API 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentsDocument3 pagesAPI 614-Chapter 1 DATA SHEET Scope and Attachments Si Units: Applicable DocumentstutuionutNo ratings yet

- API 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitsDocument7 pagesAPI 614-Chapter 2 DATA SHEET Special Purpose Oil System Si UnitstutuionutNo ratings yet

- Required System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitsDocument20 pagesRequired System Performance - Purchaser: Elevated Flare Data Sheet No. 1 SI UnitstutuionutNo ratings yet

- Special Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitsDocument4 pagesSpecial Purpose Gear Units Api 613 Fifth Edition Data Sheet Si UnitstutuionutNo ratings yet

- Combustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable ToDocument10 pagesCombustion Gas Turbine (Api 616-4Th) Data Sheet S I Units: Applicable Totutuionut100% (1)

- Storage Tank Normal Venting Capacity CalculationsDocument1 pageStorage Tank Normal Venting Capacity CalculationstutuionutNo ratings yet

- Tank 305Document74 pagesTank 305tutuionutNo ratings yet

- Temperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldDocument8 pagesTemperature Measuring Instrument (1-Channel) : Testo 925 - For Fast and Reliable Measurements in The HVAC FieldMirwansyah TanjungNo ratings yet

- Dodge ALL-STEEL Pillow Blocks: Instruction Manual ForDocument2 pagesDodge ALL-STEEL Pillow Blocks: Instruction Manual ForWisnu BharataNo ratings yet

- Underwater Wireless CommunicationDocument18 pagesUnderwater Wireless CommunicationNeelasha Baa100% (1)

- Yousif Yassin PDFDocument124 pagesYousif Yassin PDFJAVIYAROSNo ratings yet

- 14 Design of Bolted JointsDocument13 pages14 Design of Bolted JointsPRASAD32675% (4)

- Lectut MI 106 PDF MI 106 Sol Tut 5 76vs9e5Document4 pagesLectut MI 106 PDF MI 106 Sol Tut 5 76vs9e5Pritam PaulNo ratings yet

- Paper GuideDocument77 pagesPaper Guideandhika yudhistiraNo ratings yet

- Ieeeee13caf2 935f 20150515073915Document9 pagesIeeeee13caf2 935f 20150515073915Jennifer YoungNo ratings yet

- Volvo Ec35D: Parts CatalogDocument461 pagesVolvo Ec35D: Parts Cataloggiselle100% (1)

- African Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-ExaminedDocument9 pagesAfrican Music Re-Examined in The Light of New Materials From The Belgian Congo and Ruanda Urundi Akab P Merriam African Music Re-Examinedberimbau8No ratings yet

- Aggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinDocument15 pagesAggregate Planning and Master Scheduling: Mcgraw-Hill/IrwinKushal BhatiaNo ratings yet

- 02whole PDFDocument313 pages02whole PDFAme Ra100% (1)

- About Us ThinksynQ TeamDocument1 pageAbout Us ThinksynQ TeamSai KrishanNo ratings yet

- Neurophone Ebook EnglDocument19 pagesNeurophone Ebook EnglViolin_teacher100% (3)

- VarmaDocument86 pagesVarmanandy39No ratings yet

- Azuma 2015 Metrologia 52 360Document17 pagesAzuma 2015 Metrologia 52 360Rudolf KiraljNo ratings yet

- Authorization For Entering Manual ConditionsDocument15 pagesAuthorization For Entering Manual ConditionsSushil Sarkar100% (2)

- Justeq07 Product BulletinDocument1 pageJusteq07 Product BulletinjusteqNo ratings yet

- 460 Mr. Abhijit GadekarDocument4 pages460 Mr. Abhijit GadekarAbhishekSengaokarNo ratings yet

- LCD Interfacing With Microcontroller 8051Document50 pagesLCD Interfacing With Microcontroller 8051Darshan Vala100% (2)

- Performance Considerations Before Upgrading To Oracle 19c DatabaseDocument48 pagesPerformance Considerations Before Upgrading To Oracle 19c DatabaseJFLNo ratings yet

- Taking Off - RC Works (Complete)Document4 pagesTaking Off - RC Works (Complete)Wai LapNo ratings yet

- Testing A SCRDocument2 pagesTesting A SCRtenisonNo ratings yet

- QP Cluster Manager PDFDocument31 pagesQP Cluster Manager PDFkanisha2014No ratings yet

- Food Delivery Through Mobile App - India (A Case Study)Document11 pagesFood Delivery Through Mobile App - India (A Case Study)Niraj Singh100% (1)

- MyLLP Customer Portal User Guide - RegistrationDocument10 pagesMyLLP Customer Portal User Guide - RegistrationEverboleh ChowNo ratings yet

- Emission Test Station - Workshop: Multi-FuelDocument2 pagesEmission Test Station - Workshop: Multi-FuelARMANDO HERNANDEZNo ratings yet

- BER-E222 PMDocument8 pagesBER-E222 PMItalo MendozaNo ratings yet

- Qty. Description MG160LB: Company Name: Created By: Phone: DateDocument1 pageQty. Description MG160LB: Company Name: Created By: Phone: DateKim Howard CastilloNo ratings yet

- Settle 3 DDocument2 pagesSettle 3 DSheril ChandraboseNo ratings yet