Professional Documents

Culture Documents

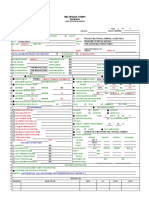

Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary Units

Uploaded by

tutuionutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary Units

Uploaded by

tutuionutCopyright:

Available Formats

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

1 APPLICABLE TO:

PROPOSALS

2 FOR/USER

3 NOTE:

PURCHASE

DATE

OF

NO. WITH CYLS.

NO. REQ'D

BY MANUFACTURER OR

PURCHASER AS APPLICABLE

SERIAL NO(S)

NOMINAL FRAME RATING

MAX/MIN ALLOWABLE SPEED

8 DRIVER MFGR.

BHP @ RATED RPM OF

RPM

DRIVER NAMEPLATE HP/OPERATING RPM

9 DRIVE SYSTEM:

DIRECT COUPLED

10 TYPE OF DRIVER:

IND. MOTOR

GEARED & COUPLED

SYN. MOTOR

STEAM TURBINE

GAS TURBINE

YES - PURCHASER TO FILL IN "REQUIRED CAPACITY" LINES.

12

NO - PURCHASER TO FILL IN "MFGR.'S RATED CAP." LINES

(NNT)

MAX ACCEPTABLE AVG PISTON SPEED

15

SERVICE OR ITEM NO.

16

STAGE

17

NORM. OR ALT. CONDITION

18

CERTIFIED PT. (X) MARK ONE

19

MOLECULAR WEIGHT

20

Cp/Cv (K) @ 150F OR

21

INLET CONDITIONS:

AT INLET TO:

22

PRESSURE (PSIA) @ PUL. SUPP. INLET

24

PRESSURE (PSIA) @ CYL. FLANGE

25

TEMPERATURE (F)

26

27

REF: SIDE STREAM TEMPS (F)

COMPRESSIBILITY (Zs )

28

INTERSTAGE:

INTERSTAGE P INCL:

29

P BETWEEN STAGES, %/psi

30

DISCHARGE CONDITIONS:

31

PRESSURE (PSIA) @ CYL. FLANGE

32

PRESS. (PSIA) @ PUL. SUPP. OUTLET

33

TEMP., ADIABATIC, F

34

TEMP., PREDICTED, F

COMPRESSIBILITY (Z2 ) OR (ZAVG )

36 * REQUIRED CAPACITY,

LBS/HR

38

39

AT OUTLET FROM:

y

LUBE

NON-LUBE

PULSE DEVICES

COMPRESSOR CYLINDER FLANGES

SIDE STREAM TO

STAGE(S), THESE INLET PRESS. ARE FIXED

PULSE DEVICES

PULSE DEVICE

PIPING

COOLERS

SEPARATORS

COMP. CYL. FLANGES

OTHER

OTHER

RATED FOR PROCESS, AT INLET TO COMPRESSOR, NO NEGATIVE TOLERANCE (-0%)

CAPACITY SPECIFIED

IS

WET

DRY

MMSCFD/SCFM (14.7 PSIA & 60F)

40 * MFGR.'S RATED CAPACITY

41

OTHER

CYLINDERS:

FT/MIN

NOTE:

23

37

ENGINE

OPERATING CONDITIONS (EACH MACHINE)

14

35

V-BELT

11 NO NEGATIVE TOLERANCE APPLIES:

13

BY

SERVICE

BY MANUFACTURER

AFTER ORDER

TYPE MODEL NO(S)

6 COMPR.THROWS: TOTAL NO.

17

AS BUILT

BY MANUFACTURER

WITH PROPOSAL

5 COMPR. MFGR

PAGE

SITE/LOCATION

INDICATES INFO. TO BE

COMPLETED BY PURCH.

REVISION NO.

LBS/HR

42

(AT INLET TO COMPRESSSOR) & BHP @ CERTIFIED TOLERANCE OF 3% FOR CAP. & 3% FOR BHP

CAPACITY SPECIFIED

IS

WET

DRY

43

ICFM

44

MMSCFD/SCFM (14.7 PSIA & 60F)

45

BHP/STAGE

46

TOTAL BHP @ COMPRESSOR SHAFT

47

TOTAL HP INCLUDING

48

49

50

51

52

V-BELT & GEAR LOSSES

* CAPACITY FOR NNT

MANUFACTURER'S = REQUIRED 0.97

THEREFORE REQUIRED = MFR'S x 0.97

06/95

SHT 1 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

REMARKS:

REV 0

Page 1 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

1

ITEM NO.

REVISION

PAGE

DATE

2

OF

17

BY

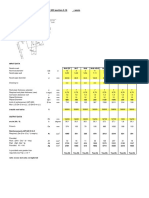

GAS ANALYSIS AT OPERATING CONDITIONS

MOLE % (BY VOLUME) ONLY

2

3

SERVICE/ITEM NO.

STAGE

NORMAL OR ALT

REMARKS

M.W.

7 AIR

28.966

8 OXYGEN

O2

32.000

9 NITROGEN

N2

28.016

10 WATER VAPOR

H2O

18.016

11 CARBON MONOX.

CO

28.010

12 CARBON DIOX.

CO2

44.010

13 HYDRO. SULFIDE

H2S

34.076

14 HYDROGEN

H2

2.016

15 METHANE

CH4

16.042

16 ETHYLENE

C2H4

28.052

17 ETHANE

C2H6

30.068

18 PROPYLENE

C3H6

42.078

19 PROPANE

C3H8

44.094

20 I-BUTANE

C4H10

58.120

21 n-BUTANE

C4H10

58.120

22 I-PENTANE

C5H12

72.146

23 n-PENTANE

C5H12

72.146

25 AMMONIA

NH3

17.031

INDUSTRY SERVICES

26 HYDRO. CHLOR.

HCI

36.461

NACE MR-O175 (2.14.1.10)

27 CHLORINE

Cl2

70.914

APPLICABLE SPECIFICATIONS

API-618-RECIPROCATING COMPRESSORS

FOR PETROLEUM, CHEMICAL AND GAS

24 HEXANE PLUS

28 CHLORIDES - TRACES

29

30

31

32

33

CALCULATED MOL WT.

Cp/Cv (K) @ 150 OR

34 NOTE:

IF WATER VAPOR AND/OR CHLORIDES ARE PRESENT, EVEN MINUTE

35

TRACES, IN THE GAS BEING COMPRESS'D, IT MUST BE INCLU'D ABOVE.

36

SITE/LOCATION CONDITIONS

37 ELEVATION

FT.

BAROMETER

PSIA

AMBIENT TEMPS: MAX

38

MIN DESIGN METAL TEMP

F (2.14.8)

39 COMPRESSOR LOCATION:

INDOOR

HEATED

UNHEATED

40

OUTDOOR

NO ROOF

UNDER ROOF

41

OFF-SHORE

42

WINTERIZATION REQUIRED

43 UNUSUAL CONDITIONS:

CORROSIVES

AT GRADE LEVEL

FUMES

F

%

MIN

ELEVATED:

PARTIAL SIDES

WEATHER PROTECTION REQ.

DUST

F MIN

RELATIVE HUMIDITY: MAX

FT.

PLATFORM:

ON-SHORE

TROPICALIZATION REQ.

OTHER

44

45

ELECTRICAL CLASSIFICATIONS

46

HAZARDOUS

NON-HAZRDOUS

47 MAIN UNIT

CLASS

GROUP

DIVISION

48 L.O. CONSOLE

CLASS

GROUP

DIVISION

49 CW CONSOLE

CLASS

GROUP

DIVISION

50

51

52

06/95

SHT 2 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

REV 0

Page 2 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

1

ITEM NO.

REVISION

DATE

PAGE

OF

17

BY

PART LOAD OPERATING CONDITIONS

2 CAPACITY CONTROL

BY:

FOR:

WITH:

USING:

MFG'S CAP. CONTROL

PURCHASERS BY-PASS

BOTH

PART LOAD COND.

START-UP ONLY

BOTH

AUTO LOADING DELAY INTERLOCK (3.6.2.2)

FIXED VOLUME POCK.

OTHER

AUTO IMMEDIATE UNLOADING

SUCTION VALVE UNLOADERS:

ACTION:

NUMBER OF STEPS:

FINGER

PLUG

DIRECT (AIR-TO-UNLOAD)

ONE

OTHER

REVERSE (AIR-TO-LOAD/FAIL SAFE)

THREE

FIVE

OTHER

RAIN COVER REQUIRED OVER UNLOADERS

8

9

ALL UNLOADING STEPS BASIS MANUFACTURERS CAPACITY SHOWN ON PAGE 1.

10 INLET AND DISCHARGE PRESSURE ARE

AT CYLINDER FLANGES

11

SERVICE OR ITEM NO.

12

STAGE

13

NORMAL OR ALTERNATE CONDITION

14

PERCENT CAPACITY

15

WEIGHT FLOW, LBS/HR

16

MMSCFD/SCFM (14.7 PSIA & 60F)

17

POCKETS/VALVES OPERATION *

18

POCKET CLEARANCE ADDED %

19

TYPE UNLOADERS, PLUG/FINGER

20

INLET TEMPERATURE, F

21

INLET PRESSURE, PSIA

22

DISCHARGE PRESSURE, PSIA

23

DISCHARGE TEMP., ADIABATIC F

24

DISCHARGE TEMP., PREDICTED F

25

VOLUMETRIC EFF.,%HE/%CE

26

CALC. GAS ROD LOAD, LBS, C **

27

CALC. GAS ROD LOAD, LBS, T **

28

COMB. ROD LOAD, LBS C (GAS & INERTIA)

29

COMB. ROD LOAD, LBS T (GAS & INERTIA)

30

ROD REV., DEGREES MIN @ X-HD PIN ***

31

BHP/STAGE

32

TOTAL BHP @ COMPRESSOR SHAFT

33

TOTAL HP INCL. V-BELT & GEAR LOSSES

PULSATION SUPPRESSOR FLANGES

34

35

* SHOW OPERATION WITH THE FOLLOWING SYMBOLS:

36

37

HEAD END

38

OR

39

CRANK END

HE

CE

SUCTION VALVE(S) UNLOADED

PLUS

FIXED POCKET OPEN

40

OR

OR

VARIABLE POCKET OPEN

41

42

EXAMPLE:

HE-F/CE-S = HEAD END FIXED POCKET OPEN / CRANK END SUCTION VALVE(S) UNLOADED.

43

* * C = COMPRESSION

44

MINIMUM PRESSURE REQUIRED TO OPERATE CYLINDER UNLOADING DEVICES,

T = TENSION

45 CYLINDER UNLOADING MEDIUM:

46

AIR

*** X - HD = CROSSHEAD

NITROGEN

PRESSURE AVAILABLE FOR CYLINDER UNLOADING DEVICES, MAX/MIN

PSIG

OTHER

/

PSIG

47 REMARKS, SPECIAL REQUIREMENTS, AND/OR SKETCH

48

49

50

51

52

06/95

SHT 3 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

REV 0

Page 3 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION

DATE

PAGE

OF

17

BY

SCOPE OF BASIC SUPPLY

1

2

PURCHASER TO FILL IN

DRIVER

) AFTER COMMODITY TO INDICATE:

):

BY COMPR. MFR.

BY PURCH.

VARIABLE SPEED

SPEED RANGE

RPM TO

RPM

INDUCTION MOTOR

SYNCHRONOUS MOTOR

STEAM TURBINE

ENGINE

API-541

API-546

API-611

API-612

OUTBOARD BEARING

SLIDE BASE FOR DRIVER (

MOTOR STARTING EQUIPMENT

9

10

GEAR (

):

11

V-BELT DRIVE (

13

DRIVE GUARD(S) (

API-613

LOW SPD.

):

HI-SPD.

API-677

KEY-LESS DRV.

MANUFACTURER'S STD.

KEY'D DRV.

OTHER

STATIC CONDUCTING V-BELTS

NON-SPARKING

BANDED V-BELTS

CALIF CODE

API-671 APPENDIX C

OTHER

PULSATION SUPPRESSORS WITH INTERNALS (

):

16

PULSATION SUPPRESSORS WITHOUT INTRNL (

):

18

19

SUPPRESSOR(S) TO HAVE MOISTURE REMOVAL SECTION:

20

ACOUSTICAL SIMUL. STUDY

21

DIGITAL

SUPPORTS

INTERSTAGE

SUPPORTS

INITIAL INLET & FINAL DISCHARGE

SUPPORTS

INTERSTAGE

SUPPORTS

ALL INLET SUPPRESSORS

DESIGN

1,

W/SIMPLIFIED ANALYSIS OF PIPING SYSTEM

APPROACH

2,

SEE 3.9.2.1 AND APPENDIX M

(Check Only One)

3,

SEE 3.9.2.1 AND APPENDIX M

NOTE: SEE APPENDIX N FOR

24

INITIAL INLET & FINAL DISCHARGE

INITIAL INLET ONLY

):

ANALOG

22

23

QUILL SHAFT

SHEAVES & V-BELTS (

):

14

17

); DEFINE

API 671

12

15

SOLE PLATE FOR DRIVER

):

OTHER

PROVISION FOR DRY AIR PURGE FOR OUTBOARD BEARING.

BASEPLATE FOR GEAR

COUPLING(S) (

BY OTHERS

STUDY TO

CONSIDER:

INFORMATION REQUIRED FOR STUDY

ALL SPECIFIED LOAD COND., INCL.

SINGLE ACT., PLUS

COMP.OPER.IN PARALLEL

25

ALTERNATE GASES

WITH EXISTING COMP. AND PIPING SYSTEMS

26

STUDY TO BE WITNESSED

COMPRESSOR VALVE DYNAMIC RESPONSE

27

VENDOR REVIEW OF PURCHASER'S PIPING ARRANGEMENT

PULSATION SUPRESS'N DEVICE LOW CYCLE FATIGUE ANALYSIS

28

PIPING SYSTEM FLEXIBILITY

29

PACKAGED:

30

SKID

31

NO

SOLEPLT.

YES

BASEPLT.

DEFINE BASIC SCOPE OF PACKAGING IN REMARKS SECTION, PAGE 5

BOLTS OR STUDS FOR SOLEPLT. TO FRAME

RAILS

CHOCK BLOCKS

SHIMS

SUITABLE FOR COLUMN MOUNTING (UNDER SKID AND/OR BASEPLATE)

32

LEVELING SCREWS

NON-SKID DECKING

SUB SOLEPLATES

33

DIRECT GROUTED

CEMENTED/MORTAR GROUT

34

INTERCLR(S) (

35

INTERSTAGE PIP. (

36

SEPARATOR(S)

):

EPOXY GROUT; MFG/TYPE

PIPING MATCHMARKED

AFTERCLR(S) (

INTERCOOLERS:

SHOP FITTED

MACHINE MTD.

CONDENSATE SEPARATION & COLLECTION FACILITY SYSTEM PER 3.8.12

(

):

OFF MOUNTED

37

INLET STRAINER(S)

INITIAL INLET

38

MANIFOLD PIPING;

39

RELIEF VALVE(S) (

):

INITIAL INLET

40

RUPTURE DISC(S) (

THRU STUDS IN PIPING FLANGES

41

CRANKCASE RAPID PRESSURE RELIEF DEVICE(S) (

42

SPECIAL PIPING REQUIREMENTS PER 3.7.1.12.24. (DEFINE IN REMARKS SECTION NEXT PAGE)

43

INITIAL INLET,

44

FOR ATMOSPHERIC INLET AIR COMPR. ONLY:

45

PREFERRED TYPE OF CYLINDER COOLING

DRAINS

VENTS

SIDESTREAM INLET

RELIEF VALVES

AIR/GAS SUPPLY

FLANGE FINISH

INTERSTAGE

FINAL DISCHARGE

API-618 FLANGE FINISH

REF 3.9.3.15 > 125 < 250

INTERSTAGE SUCTION PIPING ARR'D FOR:

FLANGE FINISH PER ANSI 16.5

INSULATION

INLET AIR FILTER

(

SPOOL PIECE FOR INLET STRAINERS

):

SPECIAL FINISH

(

FORCED

HEAT TRACING

INLET FILTER -SILENCER

THERMOSYPHON

46 NOTE:

MANUFACTURER SHALL RECOMMEND

STATIC (STAND-PIPE)

47

BEST TYPE OF COOLING AFTER

CYL. COOLING WATER PIPING (

48

FINAL ENGINEERING REVIEW OF ALL

SINGLE INLET/OUTLET MANIFOLD & VALVES

49

OPERATING CONDITIONS

INDIVIDUAL INLET/ OUTLET PER CYL.

50

STAGE CYL'(S)

STAGE CYL'(S)

)

MATCH M'RKED

SIGHT GL'SS(ES)

VALVE(S)

CLOSED SYS. WITH WATER PUMP, C00LER, SURGE TANK, & PIPING

51

SHOP RUN

06/95

SHT 4 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

ARR'D FOR HEATING JACKET AS WELL AS COOLING

REV 0

Page 4 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

PAGE

SEPARATE COOLING CONSOLE (

):

17

BY

DUAL PUMPS (AUX .& MAIN)

ARRANGED FOR HEATING JACKET WATER AS WELL AS COOLING

FRAME LUBE OIL SYSTEM (

):

AUX. PUMP

DUAL FILTERS WITH TRANSFER VALVE

SHOP RUN

CONTINUOUS FLOW IN SENSING LINE TO PRESSURE SWITCHES

5

6

SEPARATE LUBE OIL CONSOLE (

API 614 APPLIES (REFER TO NOTE OF 2.12.2)

):

EXTENDED TO MOTOR OUTBOARD BEARING

NO

SHOP RUN

YES

NOTE: PIPING BETWEEN ALL CONSOLES AND COMPRESSOR UNIT BY PURCHASER

8

9

OF

ONE CMMN TO ALL UNITS

ONE FOR EA. UNIT

3

4

DATE

5

SCOPE OF BASIC SUPPLY (Con't)

1

2

ITEM NO.

REVISION

CAPACITY CONTROL (

):

SEE DATA SHEET PAGE 3 FOR DETAILS

10

SEPARATE MACHINE MOUNTED PANEL

11

PNEUMATIC

12

PROGRAMMABLE CONTROLLER

IN INSTRUMENT & CONTROL PANEL

SEPARATE FREE STANDING PANEL

ELECTRIC

ELECTRONIC

HYDRAULIC

13

14

15

INSTRUMENT & CONTROL PANEL (

):

16

17

18

ONE FOR EACH UNIT

ONE COMMON TO ALL UNITS

MACHINE MOUNTED

FREE STANDING (OFF UNIT)

SEE INSTRUMENTATION DATA SHEETS FOR DETAILS OF PANEL, ADDITIONAL REMARKS, AND INSTRUMENTATION.

NOTE:

19

ALL TUBING, WIRING, & CONNECTIONS BETWEEN OFF-UNIT FREE STANDING PANELS AND COMPRESSOR UNIT BY

PURCHASER.

20

21

22

HEATERS (

):

23

FRAME LUBE OIL

CYL. LUBRICATORS

ELECTRIC

STEAM

COOLING WATER

DRIVER(S)

GEAR OIL

24

(

):

25

BARRING DEVICE

26

ROD PRESSURE PACKING COOLING SYSTEM

27

SPECIAL CORROSION PROTECTION:

28

HYDRAULIC TENSIONING TOOLS

29

MECHANICAL RUN TEST:

MANUAL

PNEUMATIC

):

NO

NO

NO

FLYWHEEL LOCKING DEVICE

FILTERS

MFR'S STANDARD

OTHER

YES

YES

30

YES

ELECTRIC

SEPARATE CONSOLE

MFG'S STANDARD

OTHER

COMPLETE SHOP RUN TEST OF ALL MACHINE MOUNTED EQUIPMENT, PIPING & APPURT.'(S)

31

32

PAINTING:

MANUFACTURER'S STANDARD

33

NAMEPLATES:

U.S. CUSTOMARY UNITS

34

SHIPMENT:

DOMESTIC

35

EXPORT

EXPORT BOXING REQUIRED

STANDARD 6 MONTH STORAGE PREPARATION

36

37

SPECIAL

SI UNITS

OUTDOOR STORAGE FOR OVER 6 MONTHS (

), PER SPEC

), PER SPEC

INITIAL INSTALLATION AND OPERATING TEMP ALIGNMENT CHECK AT JOBSITE BY VENDOR REPRESENTATIVE

38

39

COMPRESSOR MANUFACTURER'S USER'S LIST FOR SIMILAR SERVICE

40

PERFORMANCE DATA REQUIRED PER 5.3.3:

BHP VS. SUCTION PRESSURE CURVES

41

ROD LOAD/GAS LOAD CHARTS

42

VALVE FAILURE DATA CHARTED

43

SPEED/TORQUE CURVE DATA

44

BHP VS. CAPACITY PERFORMANCE CURVES OR TABLES REQUIRED FOR UNLOADING STEPS AND/OR VARIABLE

45

SUCTION/DISCHARGE PRESSURES

46

47

REMARKS:

48

49

50

51

52

06/95

SHT 5 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

REV 0

Page 5 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION

DATE

PAGE

OF

17

BY

UTILITY CONDITIONS

1

2 ELECTRICAL POWER:

AC VOLTS /

PHASE

HERTZ

DC VOLTS

AC VOLTS

PHASE

HERTZ

DC VOLTS

MAIN DRIVER

INSTRUMENT

AUXILIARY MOTORS

ALARM & SHTDWN

HEATERS

6

7

8

9 INSTRUMENT AIR:

10 STEAM

11 INLET:

NORMAL PRESSURE

FOR:

PRESS

12 (NORM.)

TEMP

13 EXH'ST:

PRESS

14 (NORM.)

TEMP

PSIG

MAX/MIN

DRIVERS

PSIG

HEATERS

PSIG

MAX/MIN

MAX/MIN

PSIG

MAX/MIN

MAX/MIN

FOR:

COMPRESSOR CYLINDERS

PSIG INLET:

F

(NORM.)

PRESS

TEMP

PSIG EXH'ST:PRESS

F

(NORM.)

TEMP

PSIG

MAX/MIN

PSIG

MAX/MIN

PSIG

MAX/MIN

PSIG

MAX/MIN

15

16

17 COOLING WATER

18

TYPE WATER

19 SUPP.:

PRESS

20 (NORM.)

TEMP

21 R'T'RN:

PRESS

22 (NORM.)

TEMP

COOLERS

TYPE WATER

PSIG

MAX/MIN

MAX/MIN

PSIG

MAX/MIN

MAX/MIN

PSIG SUPP.:

F

(NORM.)

PSIG R'T'RN:

F

(NORM.)

PRESS

TEMP

PRESS

TEMP

PSIG

MAX/MIN

PSIG

MAX/MIN

PSIG

MAX/MIN

PSIG

MAX/MIN

23

24 COOLING FOR ROD PACKING:

25 TYPE FLUID

SUPPLY PRESS

26 FUEL GAS:

NORMAL PRESSURE

27

COMPOSITION

PSIG @

PSIG

F

MAX/MIN

RETURN

PSIG @

/

PSIG

F

LHV

BTU/FT

3

28

29 REMARKS/SPECIAL REQUIREMENTS:

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

06/95

SHT 6 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

REV 0

Page 6 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION

PAGE

DATE

7

OF

17

BY

CYLINDER DATA AT FULL LOAD CONDITION

1

2 SERVICE/ITEM NO.

3 STAGE

4 INLET PRESSURE, PSIA

5 DISCHARGE PRESSURE, PSIA

6 CYLINDERS PER STAGE

7 SINGLE OR DOUBLE ACTING (SA OR DA)

@ CYLINDER

FLANGES

8 BORE, INCHES

9 STROKE, INCHES

10 RPM:

RATED / MAX ALLOW

11 PISTON SPEED, FT/MIN:

RATED / MAX ALLOW

12 CYLINDER LINER, YES/NO

13 LINER NOMINAL THICKNESS, INCHES

14 PISTON DISPLACEMENT, CFM

15 CYLINDER DESIGN CLEARANCE, % AVERAGE

16 VOLUMETRIC EFFICIENCY, % AVERAGE

17 VALVES, INLET/DISCHARGE, QTY PER CYL.

18 TYPE OF VALVES

19 VALVE LIFT, INLET/DISCHARGE, INCHES

20 VALVE VELOCITY, API 4TH EDITION, FT/MIN

21

SUCTION VALVE(S)

22

DISCHARGE VALVE(S)

23 ROD DIAMETER, INCHES

24 MAX ALLOW. COMBINED ROD LOADING, LBS, C *

25 MAX ALLOW. COMBINED ROD LOADING, LBS, T *

26 CALCULATED GAS ROD LOAD, LBS, C *

27 CALCULATED GAS ROD LOAD, LBS, T *

28 COMBINED ROD LOAD (GAS + INERTIA), LBS, C *

29 COMBINED ROD LOAD (GAS + INERTIA), LBS, T *

30 ROD REV., DEGREES MIN @ X-HD PIN**

31 RECIP WT. (PISTON, ROD, X-HD & NUTS), LBS**

32 MAX ALLOW. WORKING PRESSURE, PSIG

33 MAX ALLOW. WORKING TEMPERATURE, F

34 HYDROSTATIC TEST PRESSURE, PSIG

35 HELIUM TEST PRESSURE, PSIG

36 INLET FLANGE SIZE/RATING

37

FACING

38 DISCHARGE FLANGE SIZE/RATING

39

FACING

40 DISCHARGE RELIEF VALVE SETTING DATA AT INLET PRESSURES GIVEN ABOVE:

41

RECOMMENDED SETTING, PSIG

42

GAS ROD LOAD, LBS, C *

43

GAS ROD LOAD, LBS, T *

44

COMBINED ROD LOAD, LBS, C *

45

COMBINED ROD LOAD, LBS, T *

46

ROD REVERSAL, MIN @ X-HD PIN**

47 NOTE: CALCULATED AT INLET PRESSURES

48

GIVEN ABOVE & RECOMMENDED SETTING.

49

SETTLE-OUT GAS PRESSURE

50

(DATA REQUIRED FOR STARTING)

51

* C = COMPRESSION

* T = TENSION

**X-HD = CROSSHEAD

52 NOTES/REMARKS:

06/95

SHT 7 OF 17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

REV 0

Page 7 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION

PAGE

DATE

8

OF

17

BY

CONSTRUCTION FEATURES

1

2 SERVICE ITEM NO.

3 STAGE

4 CYLINDER SIZE (BORE DIA), INCHES

5 ROD RUN-OUT: NORMAL COLD VERTICAL

6 (per appendix C)

7

MATERIALS OF CONSTRUCTION

8 CYLINDER(S)

9 CYLINDER LINER(S)

10 PISTON(S)

11 PISTON RINGS

12 WEAR BANDS

REQUIRED

13 PISTON ROD(S): MATERIAL/YIELD, PSI

14 THREAD ROOT STRESS @ MACRL * @ X-HD END

15 PISTON ROD HARDNESS, BASE MATERIAL, Rc

X REQUIRED

16 PISTON ROD COATING

17

COATING HARDNESS, Rc

18 VALVE SEATS / SEAT PLATE

19 VALVE SEAT MIN HARDNESS, Rc

20 VALVE GUARDS (STOPS)

21 VALVE DISCS

22 VALVE SPRINGS

23 ROD PRESSURE PACKING RINGS

24 ROD PRESSURE PACKING CASE

25 ROD PRESSURE PACKING SPRINGS

26 SEAL / BUFFER PACKING, DISTANCE PIECE

27 SEAL / BUFFER PACKING, INTERMEDIATE

28 WIPER PACKING RINGS

29 MAIN JOURNAL BEARINGS, CRANKSHAFT

30 CONNECTING ROD BEARING, CRANKPIN

31 CONNECTING ROD BUSHING, X-HD END

32 CROSSHEAD (X-HD) PIN BUSHING

33 CROSSHEAD PIN

34 CROSSHEAD

35 CROSSHEAD SHOES

36 CYLINDER INDICATOR VALVES (X)

37 INDICATOR CONNECTIONS ABOVE 5000 PSI

38 FLUOROCARBON SPRAYED CYLINDER (X)

39 INSTRUMENTATION IN (X) COLD SIDE

40 CONTACT W/PROCESS GAS (X) HOT SIDE

41 * MAXIMUM ALLOWABLE COMBINED ROD LOAD

USE (X) IN APPROPRIATE COLUMN WHERE APPLICABLE

42

DISTANCE PIECE(S):

COMPRESSOR CYLINDER ROD PACKING

43

FULL FLOATING PACKING

44

VENTED TO:

TYPE B

TYPE C

PSIG

SUCTION PRESSURE @

NON-LUBE

ATMOS.

COVERS:

PSIG

CYLINDER COMPARTMENT:

(Outboard Distance Piece)

SCREEN

LOUVERED

VENTED TO

PSIG

PURGED AT

PSIG

PSIG

FORCED LUBRICATED

47

WATER COOLED,

STAGE(S),

GPM REQ'D

PRESSURIZED TO

48

OIL COOLED,

STAGE(S),

GPM REQ'D

WITH RELIEF VALVE

49

WATER FILTER

50

VENT/BUFFER GAS SEAL PACKING ARR.

PROV.FUTURE WATER/OIL COOLING

51

CONSTANT OR

52

BUFFER GAS PRESSURE,

SHT 8 OF17

API618_1.XLS

319680592.xlsx, API618 Page 1 to 8

(Ref: Appndx I FIG I-1)

FRAME COMPARTMENT:

(Inboard Distance Piece)

VARIABLE DISPOSAL SYSTEM

PSIG

SPLASH GUARDS FOR WIPER PACKING

06/95

TFE

SOLID METAL

46

53

TYPE D

Ref: Appendix G, Fig. G-3

FLARE @

45

TYPE A

VENTED TO

PSIG

PURGED AT

PSIG

PRESSURIZED TO

PSIG

WITH RELIEF VALVE

DISTANCE PIECE MAWP

PSIG

REV 0

Page 8 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

OF

17

BY

CONSTRUCTION FEATURES (CONTINUED)

1

2

FABRICATED CYLINDER, HEADS, & CONNECTION

SKETCHES FOR DESIGN REVIEW

BUFFER GAS PACKING ARR.

OIL WIPER PACKING PURGE

BY PURCHASER. (2.14.5.2.8)

INTERMEDIATE PARTITION PURGE

N2

INERT BUFFER PURGE GAS:

6

7

Ref: Appendix I

Figures I-1, I-2 &I-3

VENT, DRAIN, PURGE PIPING BY MFG'R

COUPLING(S)

LOW-SPEED

HI-SPEED

Between Compressor

& Driver or Gear

Between Driver &

Gear

V-BELT DRIVE

OTHER

NO

DRIVE SHEAVE

(Compressor Shaft)

(Driver Shaft)

RPM (EXPECTED)

10

BY MANUFACTURER

PITCH DIA. (Inches)

11

MODEL

QTY & GROOVE X-SEC.

12

TYPE

POWER TRANSMITT'D

Incl. Belt Losses

13

14

API-671 APPLIES

15

INSPECTION AND SHOP TESTS (REF. 4.1.3)

YES

NO

16

DRIVER NAMEPLATE HP RATING

CENTER DISTANCE (INCHES)

REQ'D

WITN.

OBSER.

QTY, TYPE,

17

*SHOP INSPECTION

18

ACTUAL RUNNING CLEARANCES

19

AND RECORDS

20

MFG STANDARD SHOP TESTS

21

CYLINDER HYDROSTATIC TEST

NON-LUBE

22

CYLINDER PNEUMATIC TEST

LUBRICATED

23

CYLINDER HELIUM LEAK TEST

24

CYL. JACKET WATER HYDRO TEST

25

*MECHANICAL RUN TEST (4 HR)

26

BAR-OVER TO CHECK ROD RUNOUT

27

28

*LUBE OIL CONSOLE RUN/TEST (4 HR)

*COOLING H2O CONSOLE RUN/TEST

29

RADIOGRAPHY BUTT WELDS

30

31

YES

DRIVEN SHEAVE

GAS

X-SEC., & LENGTH BELTS

BELT SERVICE FACTOR (RELATIVE TO

DRIVER NAMEPLATE HP RATING)

OIL

CYLINDER LUBRICATION

STAGE(S)/SERVICE

STAGE(S)/SERVICE

TYPE OF LUBE OIL:

SYNTHETIC

X

X

HYDROCARBON

LUBRICATOR

COMP. CRANKSHAFT, DIRECT

DRIVE BY:

CHAIN, FROM CRANKSHAFT

ELECTRIC MOTOR

OTHER

LUBRICATOR MFR

FAB CYLS.

MODEL

MAG PARTICLE/LIQUID

TYPE LUBRICATOR:

SINGLE PLUNGER PER POINT

32

PENETRANT OF WELDS

33

SPECIFY ADDITIONAL

COMPARTM'T, TOTAL QTY.

34

REQUIREMENTS (4.2.1.3)

PLUNGERS (PUMPS), TOTAL QTY.

(2.13)

35

DIVIDER BLOCKS

SPARE PLUNGERS, QTY.

36

QC OF INACCESSIBLE WELDS

37

(2.14.5.2.4)

38

SHOP FIT-UP OF PULSATION SUPPL.

SPARE COMPARTM'T W/OUT PLUNGERS

HEATERS:

ELECTRIC W/THERM.(S)

STEAM

ESTIMATED WEIGHTS AND NOMINAL DIMENSIONS

39

DEVICES & ALL ASSOCIATED

TOTAL COMPR. WT, LESS DRIVER & GEAR

LBS

40

GAS PIPING

WT, OF COMPLETE UNIT, (LESS CONSOLES)

LBS

MAXIMUM ERECTION WEIGHT

LBS

41

*CLEANLINESS OF EQUIP., PIPING,

& APPURTENANCES

42

MAXIMUM MAINTENANCE WEIGHT

43

*HARDNESS OF PARTS, WELDS &

44

HEAT AFFECTED ZONES

DRIVER WEIGHT/GEAR WEIGHT

LUBE OIL/COOLING H2O CONS.

45

*NOTIFICATION TO PURCHASER OF

FREE STANDING PANEL

46

ANY REPAIRS TO MAJOR

47

COMPONENTS

SPACE REQUIREMENTS-FEET:

LBS

LENGTH

LBS

LBS

WIDTH

HEIGHT

COMPLETE UNIT

48

LUBE OIL CONSOLE

COOLING H2O CONSOLE

49

50

*SPECIFIC REQUIREMENTS TO BE DEFINED,

51

FOR EXAMPLE, DISMANTLING, AUX EQUIPMENT

52

OPERATIONAL & RUN TESTS.

53

APPENDIX K COMPLIANCE:

55

SHT 9 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

PISTON ROD REMOVAL DIST.

OTHER EQUIPMENT SHIPPED LOOSE (DEFINE)

54

06/95

FREE STANDING PANEL

VENDOR

PULSATION SUPP., WEIGHT

LBS

PURCHASER

PIPING

LBS

INTERSTAGE EQUIPMENT

LBS

REV 0

Page 9 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

10

OF

17

BY

UTILITY CONSUMPTION

1

2

3

ELECTRIC MOTORS

4

5

6

For Induction

Motors See Note

of 3.1.2.5 and

Motor Data Sheet

MAIN DRIVER

NAMEPLATE

LOCKED ROTOR

FULL LOAD

HP

AMPS

STEADY STATE

MAIN DRIVER NON-STEADY

STATE AMPS AT COMPRES-

AMPS

SOR RATED HORSEPOWER

(Induction Motors Only)

AMPS

10

MAIN LUBE OIL PUMP

@ COMPRESSOR RATED

11

AUX LUBE OIL PUMP

HP OF

12

MAIN COOLING WATER PUMP

@ CURRENT PULSATIONS

13

AUX COOLING WATER PUMP

OF

14

ROD PACKING COOLING PUMP

15

CYLINDER LUBRICATOR

16

17

18

19

ELECTRIC HEATERS

20

21

WATTS

22

FRAME OIL HEATER(S)

23

COOLING WATER HEATER(S)

24

CYL. LUBRICATOR HEATER(S)

VOLTS

HERTZ

25

26

27

28

STEAM

29

30

FLOW

PRESSURE

TEMPERATURE

BACK PRESSURE

31

MAIN DRIVER

LBS/HR @

PSIG

FTT TO

PSIG

32

FRAME OIL HEATER(S)

LBS/HR @

PSIG

FTT TO

PSIG

33

CYL. LUB. HEATER(S)

LBS/HR @

PSIG

FTT TO

PSIG

34

LBS/HR @

PSIG

FTT TO

PSIG

35

LBS/HR @

PSIG

FTT TO

PSIG

36

COOLING WATER REQUIREMENTS

37

38

FLOW

GPM

39

40

CYLINDER JACKETS

41

INTERCOOLER(S)

42

AFTERCOOLER

43

FRAME LUBE OIL COOLER

44

ROD PRESSURE PACKING*

INLET TEMP

F

OUTLET TEMP

F

INLET PRESS

PSIG

OUTLET PRESS

PSIG

MAX PRESS

PSIG

45

46

47

48

TOTAL QUANTITY, GPM

49 REMARKS/SPECIAL REQUIREMENTS:

50

*ROD PACKING COOLANT MAY BE OTHER THAN WATER

51

06/95

SHT 10 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 10 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

PAGE

DATE

11

OF

17

BY

FRAME LUBE OIL SYSTEM

1

2

BASIC LUBE OIL SYSTEM FOR FRAME:

REF: TYPE MAIN BEARINGS:

ITEM NO.

REVISION NO.

PRESSURE SYSTEM:

SPLASH

PRESSURE (FORCED)

TAP'RD ROLL'R

HEATERS REQUIRED:

PRECISION SL'VE

MAIN OIL PUMP DRIVEN BY:

ELEC. W/THERMOSTAT(S)

COMP. CRANKSHAFT

ELEC. MOTOR

PSV FOR MAIN PUMP EXTERNAL TO CRANKCASE

AUX OIL PUMP DRIVEN BY:

HAND OPERATED PRE-LUBE PUMP FOR STARTING

API-614 LUBE SYSTEM:

CONTINUOUS FLOW THROUGH OIL (3.7.2.7)

ELEC. MOTOR

NO

OTHER

OPERATIONAL TEST & 4 HOUR MECH RUN TEST

YES (See Note of 2.12.2)

CHECK VALVE ON MAIN PUMP (FIG G-5)

10

SEP. CONSOLE FOR PRESS. LUBE SYS:

ONE CONSOLE FOR EA. COMP.

11

Note:

CONSOLE TO BE OF DECK PLATE TYPE CONSTRUCTION SUITABLE FOR

MULTI-POINT SUPPORT AND GROUTING WITH GROUT & VENT HOLES.

12

13

14

Instrumentation to be listed on

Instrumentation Data Sheets.

ELECTRICAL CLASSIFICATION : CLASS

GROUP

ONE CONSOLE FOR

DIV

COMPRESSORS

NON-HAZARDOUS

BASIC SYS. REQ'MTS (NORM. OIL FLOWS & VOLUMES)

15

LUBE OIL

FLOW

GPM

16

17

COMPRESSOR FRAME

18

DRIVER

19

PRESSURE

PSIG

VISCOSITY

SSU @ 100F

SSU @ 210F

SUMP VOLUME

GALLONS

GEAR

20

SYSTEM PRESSURES:

DESIGN

21

22

STEAM

OTHER

PSIG

HYDROTEST

PRESSURE CONTROL VALVE SETTING

PIPING MATERIALS:

CARBON

STEEL

23

24

UPSTREAM OF PUMPS & FILTERS

25

DOWNSTREAM OF FILTERS

PSIG

PSIG

PUMP REL'F VALVE(S) SET

STAINLESS STEEL

WITH SS FLANGES

PSIG

STAINLESS STEEL

WITH CARBON STEEL FLANGES

26

27

28

29

PUMPS

(Gear

or Screw Type Only)

30

MAIN

31

AUXILIARY

RAT'D FL'W

GPM

PRESSURE

PSIG

32

PUMP CASING MATERIAL (Ref. 2.12.3.1):

33

GUARD(S) REQ. FOR COUPLING(S):

34

DRIVER

HP

SPEED

RPM

MAIN PUMP

MECH. SEAL

REQ'D

AUX PUMP

MAIN PUMP

AUX PUMP

BY PURCH.

BY MFR.

WIRING TO TERMINAL BOX:

BY PURCH.

BY MFR.

36

SWITCHES

SHELL & TUBE

AUTOMATIC

GUARD TYPE OR CODE

ON-OFF-AUTO SEL. SWITCH:

COOLERS:

MANUAL

COUPLING

REQ'D

35

37

AUXILIARY PUMP CONTROL:

COLD START

REQ'D BHP

SINGLE

TEMA R (API-660

MFG'S STD.

TEMA C

Data Shts Attached)

AIR COOLED W/AUTO TEMP CONTROL (API-661 Data Shts - Attached)

DUAL W/TRANSFER VALVE

38

REMOVABLE BUNDLE

39

WATER COOLED

W/BYPASS & TEMP CONTROL VALVE:

MANUAL

AUTO

SEE SEPARATE HEAT EXCHANGER DATA SHT

FOR DETAILS SPECIFY % GLYCOL ON COOLING

WATER SIDE

40

41

FILTER(S)

SINGLE

RTD'S/THERMOCOUPLES

DUAL W/TRANSFER VALVE

ASME CODE DESIGN

P CLEAN,

43

MICRON RATING,

CARTRIDGE MATERIAL,

CARTRIDGE P/N

44

BONNET MATERIAL,

CASING MATERIAL,

FURN.SPARE CARTR.,QTY

SYS. COMPONENT SUPP.

MANUFACTURER

PSI

P COLLAPSE,

DESIGN PRESSURE,

45

PSIG

ASME CODE STAMPED

42

MODEL

MANUFACTURER

46

MAIN PUMP

OIL COOLER(S)

47

AUXILIARY PUMP

TRANSFER VALVE(S)

48

MECHANICAL SEALS

PUMP COUPLING(S)

49

ELECTRIC MOTORS

SUCTION STRAINER(S)

50

STEAM TURBINES

CHECK VALVE(S)

51

OIL FILTER(S)

06/95

SHT 11 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

PSI

MODEL

REV 0

Page 11 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

PAGE

DATE

12

OF

17

BY

COOLING WATER SYSTEM

1

2

ITEM NO.

REVISION NO.

BASIC COOLING SYS. FOR:

COMPRESSOR CYL.(S)

INTERCOOLER(S)

HEATERS REQ.'D FOR PRE-HEATING:

AFTERCOOLER

PRESSURE FORCED CIRCULATING SYS:

MAIN WATER PUMP DRIVEN BY:

ELEC. MOTOR

STEAM TURBINE

OTHER

AUX WATER PUMP DRIVEN BY:

ELEC. MOTOR

STEAM TURBINE

OTHER

7

8

NOTE:

9

10

11

OPEN, PIPING BY:

SEP. CONSOLE FOR COOLING WATER SYS.:

PURCH.

GROUP

FORCED

COOL'G

14

CYLINDER(S),

STAGE

15

CYLINDER(S),

STAGE

16

CYLINDER(S),

STAGE

17

CYLINDER(S),

STAGE

18

CYLINDER(S),

STAGE

19

CYLINDER(S),

STAGE

20

PISTON ROD PACK'G TOTAL

21

INTERCOOLER(S) TOTAL

22

AFTERCOOLER

23

OIL COOLER(S)

ONE CONSOLE FOR

DIV

BASIC SYS. REQ'MTS (NORM. COOLING WATER FLOW DATA)

13

CLOSED, PIPING BY MFR.

COMP'RS

CONSOLE TO BE OF DECK PLATE TYPE CONSTRUCTION SUITABLE FOR

MULTI-POINT SUPPORT AND GROUTING WITH GROUT & VENT HOLES.

ELECTRICAL CLASSIFICATION : CLASS

12

STEAM

MFR

ONE CONSOLE FOR EA. COMP.

Instrumentation to be Listed on

Instrumentation Data Sheets

OIL COOLER(S)

ELEC.,W/ THERMOSTAT(S)

NON-HAZARDOUS

COOL'G WATER TO BE

THERMO

SYPHON

STAND

PIPE

% ETHYL'NE GLYC'L

FLOW

PRESSURE

INLET TEMP

GPM

PSIG

SITE

OUTLET TEMP

F

FLOW

IND'TR

24

25

TOTAL FLOW

26

SYS. PRESSURES:

27

WATER RESERVOIR:

DESIGN,

PSIG

SIZE,

HYDROTEST,

FT IN DIA X

FT IN HT.

PSIG

RELIEF VALVE(S), SETTING

CAPACITY

GALLONS

@ Normal Operating Level

28

29

RESERVOIR MATERIAL

30

LEVEL GAUGE

31

PUMPS: (Centrifugal Only)

33

MAIN

34

AUXILIARY

INTERNAL COATING, TYPE

LEVEL SWITCH

RAT'D FL'W

GPM

32

PUMP CASING MATERIAL (Ref 2.12.3.1):

MAIN PUMP

36

GUARD(S) REQ.'D FOR COUP'G(S)

MAIN PUMP

AUX.PUMP CONTROL:

MANUAL

AUTO

38

39

COOLING WATER HEAT EXCH.:

DRAIN VALVE

PRESS.

PSIG.

35

37

SHELL & TUBE

REQ'D

BHP

INSPECTION & CLEAN-OUT OPENINGS

DRIVER

HP

SPEED

RPM

COUPLING

REQ'D

GUARD TYPE OR CODE

ON-OFF-AUTO SEL. SWITCH:

BY PURCH.

WIRING TO TERMINAL BOX:

BY PURCH.

SINGLE

DUAL W/TRANSFER VALVE

BY MANUFACTURER

BY MANUFACTURER

TEMA C

41

AIR COOLED EXCHANGER W/AUTO TEMP CONTROL (API-661 Data Sheets Attached)

42

W/BYPASS & TEM. CONTROL VALVE

43

SEE SEPARATE COOLER DATA SHEET FOR DETAILS; SPECIFY % GLYCOL ON BOTH SIDES

OF SHELL & TUBE

45

SYS. COMPONENT SUPP.

MANUFACTURER

MECH.SEAL

REQ'D

AUX PUMP

AUX PUMP

40

44

PSIG

MANUAL

MODEL

AUTO

LOUVERS FOR AIR EXCH.

MANUFACTURER

46

MAIN PUMP

TEMP CONTROL VALVE(S)

47

AUXILIARY PUMP

TRANSFER VALVE(S)

48

MECHANICAL SEALS

PUMP COUPLING(S)

49

ELECTRIC MOTORS

50

STEAM TURBINES

TEMA R(API-660

Data Shts Attached)

MODEL

51

52

06/95

SHT 12 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 12 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

13

OF

17

BY

PULSATION SUPPRESSION DEVICES FOR RECIPROCATING COMPRESSORS

THESE SHEETS TO BE FILLED OUT FOR EACH SERVICE AND/OR STAGE OF COMPRESSION

3 APPLICABLE TO:

PROPOSALS

PURCHASE

AS BUILT

4 FOR/USER

5 SITE/LOCATION

AMBIENT TEMPERATURE MIN/MAX

6 COMPRESSOR SERVICE

NUMBER OF COMPRESSORS

7 COMPRESSOR MFG.

MODEL/TYPE

8 SUPPRESSOR MFG.

9 NOTE:

Ind.Data Comp.'d Purch.

By Compr/Supp.Mfg.w/Proposal

By Mfg(s) after order

By Mfg(s)/Purchaser as Applicable

GENERAL INFORMATION APPLICABLE TO ALL SUPPRESSORS

10

11 TOTAL NUMBER OF SERVICES AND/OR STAGES

12 TOTAL NUMBER OF COMPRESSOR CYL.

TOTAL NUMBER OF CRANKTHROWS

13

ASME CODE STAMP

14

OTHER APPLICABLE PRESSURE VESSEL SPEC. OR CODE

15

LUBE SERVICE

16

RADIOGRAPHY (X-RAY OF WELDS):

17

SHOP INSPECTION

18

STROKE

GOVERNMENTAL CODES OF

NON-LUBE SERV.

NO OIL ALLOWED INTERNALLY

NONE

WITNESS HYDROTEST

WITNESSED

IN. RPM

CODE REGULATIONS APPLY

SPOT

DRY TYPE INTER.CORR.COATING

100%

IMPACT TEST

YES

NO

SPECIAL WELDING REQUIREMENTS

OUTDOOR STORAGE OVER 6 MONTHS

SPECIAL PAINT SPEC

OBSERVED

19

CYLINDER, GAS, OPERATING, AND SUPPRESSOR DESIGN DATA

20

21

SERVICE

STAGE NO.

22

COMPRESSOR MANUFACTURER'S RATED CAPACITY

LBS/HR

SCFM

23

LINE SIDE OPERATING PRESSURE

INLET,

PSIA

DISCHARGE,

24

OPERATING TEMP. WITHIN SUPPRESSORS

INLET,

DISCHARGE,

25

ALLOWABLE PRESSURE DROP THROUGH SUPPRESSORS

PSI

26

MMSCFD

INLET SUPPRESSOR

27

SUPRESSOR TAG NUMBER

28

COMBINATION INLET SUPP SEPARATOR/INTERNALS

29

NO. (QTY) OF INLET & DISCH. SUPP. PER STAGE

30

31

32

DESIGN FOR FULL VACUUM CAPABILITY

33

MIN. REQ'D WORKING PRESSURE & TEMPERATURE

34

NOTE:

PSIA

F

PSI

ALLOWABLE PEAK-PEAK PULSE @ LINE SIDE NOZZLE

PSI

PSI

ALLOWABLE PEAK-PEAK PULSE @ CYL FLANGE NOZZLE

PSI

PSI

NO

NO

YES

NO

%

%

YES

NO

After design, the actual Mawp & temp are to be determined

35

based on the weakest component and stamped on the

36

vessel. The actual Mawp is to be shown on pg.14 line 12

37

YES

YES

DISCHARGE SUPPRESSOR

NO

YES

PSIG,

PSIG,

and on the U1A Forms.

38

INITIAL SIZING VOL. PER FORMULA OF 3.9.2.2.2

39

NOTE:

This is a Reference

FT

FT

FT

FT

40

41

AS BUILT VOLUME (FT)

42

43

44

45

46

47

48

49

50

51

52

06/95

SHT 13 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 13 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION NO.

PAGE

PULSATION SUPPRESSION DEVICES FOR RECIPROCATING COMPRESSORS (CONT'D)

THESE SHEETS TO BE FILLED OUT FOR EACH SERVICE AND/OR STAGE OF COMPRESSION

SUPRESSOR TAG NUMBER

BASIC MATERIAL REQUIRED, CS, SS, ETC.

ACTUAL MATERIAL DESIGNATION

SHELL/HEAD

SPECIAL HARDNESS LIMITATIONS, Rc

YES

CORROSION ALLOWANCE., IN.

WALL THICKNESS, IN.

DISCHARGE SUPPRESSOR

SHELL & HEADS

SHELL/HEAD

PIPE OR ROLLED PLATE CONSTRUCTION

12

ACT. MAX ALLOW. WORKING PRESS. AND TEMPERATURE

13

MINIMUM DESIGN METAL TEMP (2.14.8)

14

INLET SUPRESS. TO BE SAME MAWP AS DISCH'RGE SUPPRESS.

15

MAX EXPECTED PRESSURE DROP( P, PSI / %) LINE PRESS

16

WEIGHT (LBS EACH)

17

INSUL NUTS & ALLOW. FOR INSULATION REQUIRED (X)

18

19

EXPECTED P-P PULSE @ LINE SIDE/CYL FLG, % LINE PRESS

BASED ON FINAL SUPPRESSOR DESIGN

20

(INCH/VOL.FT)

WELDS

SHELL & HEADS

WELDS

SUPPORTS, TYPE/QUANTITY

IN.

IN./

IN.

IN./

IN./

FT

IN./

PIPE

ROLLED PLATE

PSI @

PIPE

IN.

FT

ROLLED PLATE

PSI @

F

YES

P

NO

PSI/

PSI/

LBS

%/

LBS

%/

CONNECTION REQUIREMENTS & DATA

21

22

LINE SIDE FLANGE.

23

COMP CYL FLANGE(S), QTY/SIZE/RATING/FACING/TYPE

24

SIZE/RATING/FACING/TYPE

FLANGE FINISH,

PER 3.9.3.15

>125 <250

25

SPECIAL (SPECIFY)

PER ANSI 16.5

INSPECTION OPENINGS REQUIRED

27

YES

NO

BLINDED

YES

NO

BLINDED

SPEC. QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

28

* QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

VENT CONNECTIONS REQUIRED

30

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

YES

NO

SPEC. QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

31

* QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

DRAIN CONNECTIONS REQUIRED

33

SPEC. QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

34

* QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

PRESSURE CONNECTIONS REQUIRED

36

SPEC. QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

37

38

STAGE NO.

IN.

11

35

BY

SERVICE

REQUIRED

NOM. SHELL DIA X OVERALL LGTH.

32

17

/

NO

10

29

OF

INLET SUPPRESSOR

3 CONSTRUCTION REQUIREMENTS & DATA

26

DATE

14

* QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

TEMPERATURE CONNECTIONS REQUIRED

39

SPEC. QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

40

CYL NOZZLE

41

MAIN BODY

* QTY. SIZE, 6000 LB NPT CPLG./FLG TYPE & RATING

42

43

44

45

OTHER DATA AND NOTES

46

47

COMPRESSOR MFG'S SUPP. OUTLINE OR DRAWING NO.

48

SUPP. MFG'S OUTLINE OR DRAWING NO.

49

NOTES * = AS BUILT

50

51

52

06/95

SHT 14 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 14 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

15

OF

17

BY

INSTRUMENTATION

1

2 PURCHASER TO FILL IN

INSTRUMENT & CONTROL

PANEL

) AFTER COMMODITY TO INDICATE:

ONE FOR EA. UNIT

):

BY COMP. MFR.

BY PURCH.

BY OTHERS

REMOTE

OUTDOORS

ONE COMMON TO ALL UNITS

MACHINE MT'ED

FREE STANDING (OFF UNIT)

PNEUMATIC

ELEC.

NEMA 7, CLASS

, GROUP

I/S BARRIERS (

NEMA 4, WATERTIGHT & DUSTTIGHT

OTHER NEMA

LOCAL

ELECTRONIC

HYDRAULIC

PROGRAMMABLE CONTL'R

, DIVISION

INTRINSICALLY SAFE

PURGED TO NFPA 496 TYPE

LOW PURGE PRESS.

STRIP HEATERS

ALARM

10

VIB, ISOLATORS

11

ANNUNCIATOR W/FIRST-OUT INDICATION LOCATED ON CONTROL PANEL

12

PURCHASER'S CONN. BROUGHT OUT TO TERMINAL BOX BY VENDOR

SHUTDOWN

PURGE CONN.

EXTRA CUTOUTS

13 ADDITIONAL PANEL REMARKS:

14

15

16

17

INSTRUMENTATION SUITABLE FOR:

INDOORS

OUTDOORS

OTHER

18

PREFERRED INSTRUMENT SUPPLIERS, (TO BE COMPLETED BY PURCHASER), OTHERWISE MFR'S STANDARD APPLIES

19

PRESSURE GAUGES

MFR

SIZE & TYPE

MTL

20

TEMPERATURE GAUGES

MFR

SIZE & TYPE

MTL

21

LIQUID LEVEL GAUGES

MFR

22

DIFF. PRESSURE GAUGES

MFR

23

PRESS. TRANSMITTERS

MFR

TYPE

MTL

24

LIQUID LEV. TRANSMITTER

MFR

TYPE

MTL

25

PRESSURE SWITCHES

MFR

TYPE

MTL

26

TEMPERATURE SWITCHES

MFR

TYPE

MTL

27

LIQUID LEVEL SWITCHES

MFR

TYPE

MTL

28

DIFF. PRESSURE SWITCHES

MFR

TYPE

MTL

29

CONTROL VALVES

MFR

TYPE

MTL

30

PRESSURE SAFETY VALVES

MFR

TYPE

MTL

31

SIGHT FLOW INDICATORS

MFR

TYPE

MTL

32

VIBRATION MONITORS & EQUIP.

MFR

TYPE

MTL

33

THERMOCOUPLES

MFR

TYPE

MTL

34

RTD'S

MFR

TYPE

MTL

35

SOLENOID VALVES

MFR

TYPE

MTL

36

ANNUNCIATOR

MFR

37

PROGRAMMABLE CONTROLLER

MFR

TYPE

MTL

38

MFR

TYPE

MTL

39

MFR

TYPE

MTL

TYPE

MTL

SIZE & TYPE

MTL

MODEL & (QTY SPARE POINTS)

40

41

PRESSURE GAUGE REQUIREMENTS

LIQUID FILLED PRESSURE GAUGES:

42

43 FUNCTION

YES

NO

LOCALLY

PANEL

LOCALLY

PANEL

MOUNTED

MOUNTED

MOUNTED

MOUNTED

44

LUBE OIL MAIN PUMP DISCHAR.

45

LUBE OIL AUX. PUMP DISCHARG.

@ EA. STAGE

46

LUBE OIL PRESS. AT FRAME HEADER (

DISCH. PRESS.

47

LUBE OIL FILTER P

@ EA. STAGE

48

COOLING H2O INLET HEADER

49

50

PROCESS GAS: INLET PRESS.

51 REMARKS:

52

06/95

SHT 15 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 15 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

ITEM NO.

REVISION NO.

PAGE

DATE

16

OF

17

BY

INSTRUMENTATION (CONT'D)

1

2 TEMPERATURE MEASUREMENT REQUIREMENTS

3 FUNCTION

LOCALLY

PANEL

GAUGE W/

THERMO

RTD

I/S

MOUNTED

MOUNTED

CAPIL'RY

CPL SYS

SYS

SYS

LUBE OIL

INLET TO

OUT OF

FRAME

LUBE OIL

INLET TO

OUT OF

COOLER

MAIN JRNL BEARINGS (THERMOCOUPLES OR RTD'S ONLY)

MOTOR BEARING(S)

COOLING WATER HEADER:

(THERMOCOUPLES OR RTD'S ONLY)

INLET

CYL. COOLING WATER:

INLET

OUTLET

OUTLET

EA. CYL

10

PROCESS GAS:

INLET

DISCH.

EACH CYL

11

INTERCOOLER(S)

INLET

GAS

WATER

INLET

GAS

WATER

INLET

GAS

WATER

INLET

GAS

WATER

INLET

OUTLET/COOLED PKG CASE(S)

12

13

AFTERCOOLER:

14

15

COOLING WATER

16

PRESS. PGK CASE, CYL PIST ROD (THRM'CPLS OR RTD'S ONLY)

17

COMPRESSOR VALVES

18

19

20

SUCT.

DISCH. TC'S OR RTD'S ONLY

ALARM & SHUTDOWN SWITCH REQ'MTS

NOTE: ALARM & SHUTDOWN SWITCHES SHALL BE INDIVIDUALLY SEPARATE

ANNUNCIATION POINTS

21

ALARM

22

SHUTDOWN

23

IN

IN CTL

IN

IN CTL

TOTAL

24

PNL

ROOM

PNL

ROOM

NO.

25

26

ALARM

FUNCTION

SHUT

BY

DOWN

MFR

27

LOW LUBE OIL PRESS. @ BEARING HEADER

) (

28

HIGH LUBE OIL P ACROSS

FILTERFILTER

P ACROSS

) (

29

LOW LUBE OIL LEVEL, FRAME

) (

30

AUX LUBE OIL PUMP, FAIL TO START

) (

31

CYL LUBE SYSTEM PROTECTION

) (

32

COMPR. VIBRATION, SHUTDOWN ONLY

33

VIBRATION, W/ CONTINUOUS MONITORING

) (

34

ROD DROP DETECTOR, CONTACT TYPE(1/CYL)

) (

35

ROD DROP PROXIMITY PROBE (1/CYL)

) (

36

OIL TEMP OUT OF FRAME

) (

37

HIGH GAS DISCH. TEMP EACH CYLINDER

) (

38

HIGH JACKET WATER TEMP., EA. CYL

) (

39

LOW SUCTION PRESS., FIRST STG INLET

) (

40

HI DISCH. PRESS.

) (

41

HI CYL. GAS P, EACH STAGE

) (

42

HI LIQ. LEV., EA. MOISTURE SEPARATOR

) (

43

LOW PURGE GAS PRESS, DISTANCE PIECE(S)

) (

44

HI X-HD PIN TEMP

) (

45

PRESS PKG CASE (PISTON ROD TEMP)

) (

) (

FINAL

46

EA STG

47

PANEL

OTH'RS

BY

PANEL

MFR

OTH'RS

OF

POINTS

)

TOTAL NUMBER OF ANNUNCIATION POINTS

48

SWITCH CONTACT OPERATION

49

ALARM CONTACTS SHALL:

NOTE: EACH SWITCH SHALL BE MINIMUM SPDT ARRANGEMENT

OPEN ( DE-ENER.) TO SOUND ALARM & BE ENERGIZED WHEN COMPR. IS IN OPERATION

50

CLOSE (ENERGIZE) TO SOUND ALARM & BE DE-ENERGIZED WHEN COMPR. IS IN OPERATION

51

SHUTDOWN CONTACTS SHALL:

OPEN ( DE-ENERGIZED) TO SHUTDOWN & BE ENERGIZE WHEN COMPR. IS IN OPERATION

52

CLOSE (ENERGIZE) TO SHUTDOWN & BE DE-ENERGIZE WHEN COMPR. IS IN OPERATION

53 REF: 3.6.5.1 FOR MINIMUM RECOMMENDED PROTECTION REQUIREMENTS

06/95

SHT 16 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 16 of 17, Date Printed: 05/30/2016

JOB NO.

RECIPROCATING COMPRESSOR

(API 618-4TH) DATA SHEET

U.S. CUSTOMARY UNITS

PAGE

MISCELLANEOUS INSTRUMENTATION

FOR:

PNEUMATIC PRESSURE TRANSMITTERS

FOR:

PRESSURE TRANSMITTERS (ELEC. OUTP.)

FOR:

PNEUMATIC LEVEL TRANSMITTERS

ALARM HORN & ACKN'LMT TEST BUTTON

CONDUIT & WIRING W/JUNCT. BOXES

TEST VALVES

FOR:

10

DRAIN VALVES

FOR:

11

GAUGE GLASS(ES)

FOR:

12

TACHOMETER

13

CRANKSHAFT KEY PHASER

14

AND TRANSDUCER

15

16

(CONSOLES)

SEPARATE LUBE OIL CONSOLE INSTRUMENTATION:

(

20

21

22

23

SEPARATE COOLING WATER CONSOLE INSTRUMENT:

AFTERCLR

CYL JACKET WATER

26

27

28

29

30

H2O CLR

ROD PRESS. PKG CASES

SPEED RANGE

TO

RPM

FOR:

RELIEF VALVES

LOCATION

32

BY

MANUFACTURER

33

34

35

36

37

38

39

40

41

42

NOTES:

TYPE

SIZE

FOR TURBINE DRIVERS USE APPLICABLE API DATA SHEETS

45

FOR GEAR REDUCERS USE APPLICABLE API DATA SHEETS

46

ELECTRICAL & INSTRUMENTATION CONNECTIONS SHALL BE MADE DIRECTLY BY THE PURCHASER TO INDIVIDUAL

47

SETTING

SEE MOTOR DATA SHEET FOR ADDITIONAL MOTOR INSTRUMENTATION REQUIREMENTS

44

48

OIL CLR

PURCH. TO LIST REQ'MTS IN ADDITION TO ANY ABOVE REQ'MTS

25

43

BY

19

31

17

PURCH. TO LIST REQ'MTS IN ADDITION TO ANY ABOVE REQ'MTS

18

24

OF

INTERCLR(S)

SIGHT FLOW IND. (COOLING H2O ONLY)

17

DATE

17

INSTRUMENTATION (CONT'D)

1

2

ITEM NO.

REVISION NO.

INSTRUMENTS ON THE COMPRESSOR

ADDITIONAL INSTRUMENTATION REMARKS/SPECIAL REQUIREMENTS:

49

50

06/95

SHT 17 OF 17

API618_2.XLS

319680592.xlsx, API618 Page 9 to 17

REV 0

Page 17 of 17, Date Printed: 05/30/2016

You might also like

- Centrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)Document9 pagesCentrifugal and Axial Compressor DATA SHEET (API 617-7TH Chapter 2) SI UNITS (1-1.6.5)tutuionutNo ratings yet

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- Rotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsDocument9 pagesRotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsghostamirNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- MPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013Document2 pagesMPCL Flare KOD Pump 11442-DS-103 - IFC2 18-06-2013zohaib_farooqNo ratings yet

- Normal Design: Depressurize From Design Pressure To 50% in 15 MinutesDocument2 pagesNormal Design: Depressurize From Design Pressure To 50% in 15 Minutesmatteo2009No ratings yet

- Datasheet For Vent ScrubberDocument5 pagesDatasheet For Vent ScrubbercliffrajjoelNo ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- Flare Knock Out Drum Sizing SheetDocument2 pagesFlare Knock Out Drum Sizing Sheetsanjay100% (4)

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- Centrifugal Compressor Specification Sheet: Operating ConditionsDocument6 pagesCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- Weymouth Gas Flow CalculationsDocument44 pagesWeymouth Gas Flow CalculationsPierre GermaineNo ratings yet

- Air CompressorsDocument13 pagesAir CompressorsCalin SeraphimNo ratings yet

- Centrifugal Pump Performance CurveDocument6 pagesCentrifugal Pump Performance CurveManish MishraNo ratings yet

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- Recip Compressor Calculations For GCP-3Document4 pagesRecip Compressor Calculations For GCP-3Greg GolushkoNo ratings yet

- PSV Reaction Force - ADocument2 pagesPSV Reaction Force - AAbraham PoolNo ratings yet

- Rupture Disk SizingDocument2 pagesRupture Disk Sizingabhishek shindeNo ratings yet

- API-12J - Horizontal Seperator Sizing OriginalDocument2 pagesAPI-12J - Horizontal Seperator Sizing OriginalMichael HaiseNo ratings yet

- Compressor Design Guide CalculationsDocument30 pagesCompressor Design Guide CalculationsDavid Gustavo Duran TangoNo ratings yet

- Gas Pipeline Blowdown Time CalculatorDocument7 pagesGas Pipeline Blowdown Time CalculatorKarun DasNo ratings yet

- Technical Specification - LT (DP Based)Document4 pagesTechnical Specification - LT (DP Based)ManodipPatilNo ratings yet

- Shell K.O.drum SeparatorDocument11 pagesShell K.O.drum SeparatorChitu Ionut LaurentiuNo ratings yet

- Hydroulics Calculation and Gas PropertiesDocument3 pagesHydroulics Calculation and Gas PropertiesSteve WanNo ratings yet

- Air Blowe DatasheetDocument1 pageAir Blowe DatasheetMoein PNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Press "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged OrificeDocument14 pagesPress "CTRL+M" To Calculate C: Calculation of Theoretical Orifice Flow and C For Sharp Edged Orificehardik033No ratings yet

- Combustion Gas Turbine Specification SheetDocument10 pagesCombustion Gas Turbine Specification SheettutuionutNo ratings yet

- Centrifugal Pumps: Process Calculation / Data SheetDocument3 pagesCentrifugal Pumps: Process Calculation / Data SheetMurali MuthuNo ratings yet

- Atmospheric and Low Pressure Tank Venting RequirementsDocument4 pagesAtmospheric and Low Pressure Tank Venting Requirementshhvg100% (1)

- Thermal Relief Valve Data SheetDocument1 pageThermal Relief Valve Data Sheetmihailspiridon100% (1)

- Prosertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesDocument1 pageProsertec Srl. 4to Anillo #3880 y Av. Roca y Coronado: Fluid PropertiesAlba Duaneth Rocabado MendietaNo ratings yet

- 8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)Document22 pages8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)LongTuanNo ratings yet

- Centrifugal Compresor CalculationDocument2 pagesCentrifugal Compresor CalculationgrabettyNo ratings yet

- Air Consumption Rev 1Document1 pageAir Consumption Rev 1Cahyadi YadiNo ratings yet

- VANEC Vent & Blowdown Silencer Selection GuideDocument19 pagesVANEC Vent & Blowdown Silencer Selection Guidektsnl100% (1)

- Rotary Compressor API 619Document26 pagesRotary Compressor API 619EDUARDO25% (4)

- Elliott Centrifugal CompressorDocument2 pagesElliott Centrifugal Compressorionutlaur86No ratings yet

- CCC1Document5 pagesCCC1Uok RitchieNo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- ENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)Document4 pagesENG-JOB-010-TMS-DSH-03.001 MDS For Pig Launcher (Tanjung Batu)m khaeronNo ratings yet

- Tank Venting Requirements (API 2000) 2Document3 pagesTank Venting Requirements (API 2000) 2RubensBoerngenNo ratings yet

- 1 1515-30-S002 - Draft Specification For Reciprocating Compressors - Rev 4Document20 pages1 1515-30-S002 - Draft Specification For Reciprocating Compressors - Rev 4rutuja100% (1)

- KPD-TAY Integrated Development Project Phase-II DatasheetDocument2 pagesKPD-TAY Integrated Development Project Phase-II Datasheetm.shehreyar.khanNo ratings yet

- PSV Sizing - Blocked Outlet GasDocument1 pagePSV Sizing - Blocked Outlet GasSilas Onyekwe100% (1)

- Fan Power Consumption CalculationDocument1 pageFan Power Consumption CalculationPrakash Warrier0% (1)

- Vent Silencer Specification SheetDocument2 pagesVent Silencer Specification SheetAqeel Bisma100% (1)

- Section 14 - RefrigerationDocument67 pagesSection 14 - Refrigerationwalter alonsoNo ratings yet

- Data Sheet For Flare Package (PK-720)Document3 pagesData Sheet For Flare Package (PK-720)samynatha PrasathNo ratings yet

- Valve Sizing W IEC Noise - Gas VolumetricDocument64 pagesValve Sizing W IEC Noise - Gas VolumetricskalanidhiNo ratings yet

- SCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFDocument3 pagesSCPF-PETW-LIS-P-01001 - Rev0 - Utility Consumption List - CPFSEGUNNo ratings yet

- PSV D-103Document24 pagesPSV D-103DIANTORONo ratings yet

- B 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer PackageDocument12 pagesB 84567 SB MM1 DSR ST 67 0011 - 4 - AOC - Air Compressor and Air Dryer PackagepragatheeskNo ratings yet

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetEason Ng100% (2)

- Turboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP CompDocument6 pagesTurboexpander/Compressor Data Sheet Si Units: Operating Conditions Normal Case Case A Case B EXP Comp EXP Comp EXP ComptutuionutNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - WarmDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - WarmtutuionutNo ratings yet

- Isover Cryolene InsDocument8 pagesIsover Cryolene InstutuionutNo ratings yet

- Seismic Design of Inner Tank - FN 14.03.2014Document8 pagesSeismic Design of Inner Tank - FN 14.03.2014tutuionutNo ratings yet

- 13 394Document14 pages13 394deepakmitrNo ratings yet

- Nozzle List - 09.09.2014Document1 pageNozzle List - 09.09.2014tutuionutNo ratings yet

- Wind Load - ASCE 7-10Document2 pagesWind Load - ASCE 7-10tutuionutNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNo ratings yet

- Anchor Straps - Outer Tank - 09.09.2014Document4 pagesAnchor Straps - Outer Tank - 09.09.2014tutuionutNo ratings yet

- Open Top Tank - Zero Inner PressureDocument1 pageOpen Top Tank - Zero Inner PressuretutuionutNo ratings yet

- 9%ni Material FeaturesDocument9 pages9%ni Material FeaturestutuionutNo ratings yet

- Conversão Metais DIN ASTM Etc PDFDocument1 pageConversão Metais DIN ASTM Etc PDFRafael Perches PierriNo ratings yet

- Material Data Sheets For Piping: 1 ForewordDocument50 pagesMaterial Data Sheets For Piping: 1 ForewordhsdeNo ratings yet

- New Steel Plate LNGDocument7 pagesNew Steel Plate LNGtutuionutNo ratings yet

- Materials For LNG ServicesDocument10 pagesMaterials For LNG ServicesSung Hyun TakNo ratings yet

- Welding LNG Tank and Vessel in 5 and 9 Nickel SteelDocument4 pagesWelding LNG Tank and Vessel in 5 and 9 Nickel Steelויליאם סן מרמיגיוסNo ratings yet

- TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageTECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterOM PRAKASH PALNo ratings yet

- Technical Insulation - Cryolene PDFDocument8 pagesTechnical Insulation - Cryolene PDFtutuionutNo ratings yet

- Api 673 SiDocument11 pagesApi 673 Situtuionut100% (1)

- Design Standard - Section 3-3 - Steel Storage Tanks - 12!31!12 - FINALWEBPOST - 201301090858057238Document60 pagesDesign Standard - Section 3-3 - Steel Storage Tanks - 12!31!12 - FINALWEBPOST - 201301090858057238ராபர்ட் ஆன்றோ ரெனிNo ratings yet

- Welding LNG Tank and Vessel in 5 and 9 Nickel SteelDocument4 pagesWelding LNG Tank and Vessel in 5 and 9 Nickel Steelויליאם סן מרמיגיוסNo ratings yet

- Vent Guide Website 3.19.13Document36 pagesVent Guide Website 3.19.13Eddy SyahNo ratings yet

- Aisc Design Examples v14Document125 pagesAisc Design Examples v14Daniyal Ahmed100% (2)

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- Guidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) EnglishDocument50 pagesGuidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) EnglishSteve IpNo ratings yet

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocument2 pagesSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutNo ratings yet

- AZOBEDocument4 pagesAZOBEtutuionutNo ratings yet

- Api 670 MpsDocument4 pagesApi 670 MpstutuionutNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- Reiki BrochureDocument2 pagesReiki BrochureShikha AgarwalNo ratings yet

- Project On Stones & TilesDocument41 pagesProject On Stones & TilesMegha GolaNo ratings yet

- An Online ECG QRS Detection TechniqueDocument6 pagesAn Online ECG QRS Detection TechniqueIDESNo ratings yet

- Detection and Attribution Methodologies Overview: Appendix CDocument9 pagesDetection and Attribution Methodologies Overview: Appendix CDinesh GaikwadNo ratings yet

- Basic First AidDocument31 pagesBasic First AidMark Anthony MaquilingNo ratings yet

- De Thi HSG Tinh Binh PhuocDocument9 pagesDe Thi HSG Tinh Binh PhuocDat Do TienNo ratings yet

- Indian Patents. 232467 - THE SYNERGISTIC MINERAL MIXTURE FOR INCREASING MILK YIELD IN CATTLEDocument9 pagesIndian Patents. 232467 - THE SYNERGISTIC MINERAL MIXTURE FOR INCREASING MILK YIELD IN CATTLEHemlata LodhaNo ratings yet

- Theoretical and Actual CombustionDocument14 pagesTheoretical and Actual CombustionErma Sulistyo R100% (1)

- 07.03.09 Chest Physiotherapy PDFDocument9 pages07.03.09 Chest Physiotherapy PDFRakesh KumarNo ratings yet

- GIS AccidentsDocument5 pagesGIS Accidentsali110011No ratings yet

- KoyoDocument4 pagesKoyovichitNo ratings yet

- Juan Martin Garcia System Dynamics ExercisesDocument294 pagesJuan Martin Garcia System Dynamics ExercisesxumucleNo ratings yet

- Abdomen - FRCEM SuccessDocument275 pagesAbdomen - FRCEM SuccessAbin ThomasNo ratings yet

- Casio AP-80R Service ManualDocument41 pagesCasio AP-80R Service ManualEngkiong Go100% (1)

- Final Decision W - Cover Letter, 7-14-22Document19 pagesFinal Decision W - Cover Letter, 7-14-22Helen BennettNo ratings yet

- GLOBAL Hydro Turbine Folder enDocument4 pagesGLOBAL Hydro Turbine Folder enGogyNo ratings yet

- Effect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanDocument7 pagesEffect of Some Algal Filtrates and Chemical Inducers On Root-Rot Incidence of Faba BeanJuniper PublishersNo ratings yet

- Lincoln Pulse On PulseDocument4 pagesLincoln Pulse On PulseEdison MalacaraNo ratings yet

- Update On The Management of Acute Pancreatitis.52Document7 pagesUpdate On The Management of Acute Pancreatitis.52Sebastian DeMarinoNo ratings yet

- Railway Airport Docks and HarbourDocument21 pagesRailway Airport Docks and HarbourvalarmathibalanNo ratings yet

- Project Binder 2Document23 pagesProject Binder 2Singh DhirendraNo ratings yet

- Plate-Load TestDocument20 pagesPlate-Load TestSalman LakhoNo ratings yet

- Cost Analysis and Financial Projections for Gerbera Cultivation ProjectDocument26 pagesCost Analysis and Financial Projections for Gerbera Cultivation ProjectshroffhardikNo ratings yet

- Handout Tematik MukhidDocument72 pagesHandout Tematik MukhidJaya ExpressNo ratings yet

- Smart Note Taker Saves Time With Air WritingDocument17 pagesSmart Note Taker Saves Time With Air WritingNagarjuna LokkuNo ratings yet

- Antennas Since Hertz and MarconiDocument7 pagesAntennas Since Hertz and MarconiTaiwo Ayodeji100% (1)

- FP-XH PGRG eDocument936 pagesFP-XH PGRG ebvladimirov85No ratings yet

- Chemistry of FormazanDocument36 pagesChemistry of FormazanEsteban ArayaNo ratings yet

- Evolutionary PsychologyDocument10 pagesEvolutionary PsychologyShreya MadheswaranNo ratings yet

- Validation Master PlanDocument27 pagesValidation Master PlanPrashansa Shrestha85% (13)