Professional Documents

Culture Documents

Api 673 Si

Uploaded by

tutuionutOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Api 673 Si

Uploaded by

tutuionutCopyright:

Available Formats

JOB NO.

ITEM NO.

PURCHASE ORDER NO.

SPECIFICATION NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

1 APPLICABLE TO:

PROPOSAL

PURCHASE

REVISION NO.

PAGE

DATE

OF

AS BUILT

10

BY

REVISION:

2 FOR:

3 SITE:

UNIT:

4 SERVICE:

5 NOTE:

6

NO. REQUIRED:

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER

GENERAL

BY MANUFACTURER

7 FAN MFR.

SIZE

TYPE/ARRANGEMENT

SERIAL NO.

8 DRIVER MFR.

DRIVER TYPE

RATED kW

RPM

MOUNTED BY

PER SPECIFICATION

PER DATA SHEET

9 FURNISHED BY

10 DRIVE SYSTEM

DIRECT COUPLED

OTHER

FAN ROTATION, FROM DRIVEN END

11

12

CW

CCW

OPERATING CONDITIONS

(ALL DATA ON PER UNIT BASIS)

NORMAL

RATED

OTHER CONDITIONS

13

14

OPERATING CONDITIONS/CASE

15

GAS HANDLED (See Page

16

17

DENSITY (kg/m)

DELIVERED mn/h (1 atm & 0C DRY)

18

WEIGHT FLOW Kg/h (WET)

OPEN

AUTOLOCK

19 INLET CONDITIONS:

20

TEMPERATURE (C)

21

RELATIVE HUMIDITY (%)

22

MOLECULAR WEIGHT (MIN.)

23

24

INLET VOLUME (m/s WET)

Cp/Cv (K1) OR (KAVG)

25

COMPRESSIBILITY (Z1) OR (ZAVG)

26

STATIC PRESSURE @ SOUND TRUCK (mm WG)

27

PRESSURE LOSS ACROSS SOUND TRUCK (mm WG)

28

STATIC PRESSURE @ INLET DAMPERS (mm WG)

29

STATIC PRESSURE @ FAN INLET (mm WG)

30 DISCHARGE CONDITIONS:

31

STATIC PRESSURE @ FAN OUTLET (mm WG)

32

STATIC PRESS. @ DISCHARGE DAMPER (mm WG)

33

P ACROSS DISCHARGE DAMPER (mm WG)

34

P ACROSS EVASE (mm WG)

35

STATIC PRESSURE @ EVASE OUTLET (mm WG)

36 PERFORMANCE:

37

BHP REQUIRED @ TEMP. (ALL LOSSES IND.)

38

FAN SPEED (RPM)

39

GUARANTEE POINT

40

PERFORMANCE CURVE NO.

41

STATIC P ACROSS FAN (mm WG)

42

INLET DAMPER/VANE POSITION

43

DISCHARGE DAMPER POSITION

44

FAN STATIC EFFICIENCY (%)

45 FAN CONTROL:

46

AIR SUPPLY

47

CONTROL SIGNAL TYPE

48

ARRANGEMENT DRWG NO.

49 METHOD:

FAN CONTROL FURNISHED BY

INLET DAMPER

SOURCE

OUTLET DAMPER

50

STARTING CONDITIONS

51

START & STOP RESTRICTIONS

52

VENDOR REVIEW OF CONTROL SYSTEM REQUIRED

08/01

SHT 1 OF 10

319681075.xlsx, API673SI

SENSITIVITY

RANGE

CONTROL SIGNAL FAILURE MODE

CLOSE

INLET GUIDE VANES

STARTING METHOD

OTHER

API673SI.XLS

Page 1 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

ITEM NO.

REVISION

PAGE

DATE

2

OF

10

BY

OPERATING CONDITIONS

1

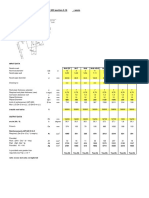

2 GAS ANALYSIS

3

NORMAL

CONDITIONS

RATED

MOL%

REMARKS

MW

5 AIR

28.97

6 OXYGEN

32.00

7 NITROGEN

28.02

8 WATER VAPOR

18.02

9 CARBON MONOXIDE

28.01

10 CARBON DIOXIDE

44.01

11 HYDROGEN SULFIDE

34.08

12 HYDROGEN CHLORIDE

36.47

13 CHLORINE

70.91

14

15

16

17

18 TOTAL

19 AVG. MOL WT.

20 CORROSIVES:

21

CORROSION/EROSION CAUSED BY

22

CORROSION EROSION PROTECTION

23

NACE MR-01-90 MATERIALS REQUIRED

24

LOCATION, SITE DATA

25

SPECIFICATIONS

26 LOCATION:

NOISE SPECIFICATIONS:

27

INDOOR

HEATED

UNDER ROOF

APPLICABLE TO MACHINE:

28

OUTDOOR

UNHEATED

PARTIAL SIDES

See Specification

29

GRADE

MEZZANINE

30

WINTERIZATION REQ'D

APPLICABLE TO NEIGHBORHOOD

TROPICALIZATION REQ'D

31 SITE DATA:

See Specification

ACOUSTIC HOUSING:

32

ELEVATION

BAR

(ABS)/mm Hg A

33

TEMPERATURE

34

WIND LOAD

C SUMMER

C WINTER

35

MINIMUM DESIGN METAL TEMPERATURE

Kg/m

VELOCITY

KPH

YES

NO

APPLICABLE SPECIFICATIONS:

36 UNUSUAL CONDITIONS:

37

DUST

38

OTHER

FUMES

PAINTING:

39

MANUFACTURER'S STD.

40

OTHERS

41

SHIPMENT:

42

DOMESTIC

43

OUTDOOR STORAGE OVER 6 MONTHS

44

ERECTION:

45

SHIPPED

46

ASSEMBLED

EXPORT

EXPORT BOXING REQ'D.

PARTLY ASSEMBLED

OTHER

47

EXTENT OF FIELD ERECTION & ASSEMBLY

48 ELECTRICAL AREA CLASSIFICATION:

49

CLASS

GROUP

MAN HOURS

ZONE

OTHER

50 REMARKS:

51

08/01

SHT 2 OF 10

319681075.xlsx, API673SI

API673SI.XLS

Page 2 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

ITEM NO.

REVISION

PAGE

DATE

3

OF

10

CONSTRUCTION FEATURES

1

2

SPEEDS:

MAX CONT.

MAX TIP SPEEDS

ACCESSORIES:

RPM

TRIP

5

6

LATERAL CRITICAL SPEEDS(2.7.2):

FIRST CRITICAL

RPM

RPM

TYPE

m/s @ MAX. CONT.

END SEALS

UNDAMPED

TRAIN LATERAL ANALYSIS REQUIRED

SUBMIT X - Y PLOT (COUPLED DRIVER & FAN)

TORSIONAL CRITICAL SPEEDS(2.7.3):

11

FIRST CRITICAL

THRUST

JOURNAL

MFG./NO.

API 670

LABYRINTH

DOUBLE CONTACT

THERMOSTATICALLY CONTROLLED HEATERS

DAMPED

10

TEMP DETECTORS (METAL) (OIL)

m/s @ RATED

TYPE

LUBRICATION

CONSTANT LEVEL OILER(2.8.5.1)

PURGE OIL MIST

COOLANT REQUIRED

RPM

SUBMIT X - Y PLOT (COUPLED DRIVER & FAN)

ROTOR:

13

TORSIONAL VIBRATION ANALYSIS FOR FAN & DRIVER

SHAFT LENGTH (mm)

14

TRNS'NT TORS'NAL ANLYS. FOR SYNCHRNS. DRIVER UNITS

NO

PURE OIL MIST

(See Pg. 6)

OTHER

NONE

AIR

WATER

m/h@

DIA. @ WHEEL

mm

MATERIAL

16

ALLOWABLE TEST LEVEL

(Peak To Peak)

17

HOUSING:

SHAFT END MOVEMENTS (TOLERANCE PLUS THERMAL)

18

MATERIAL

BLADES:

19

CONSTRUCTION

No. of BLADES

20

INLET BELL

TYPE (HOLLOW OR SOLID AIRFOIL, SINGLE, THICKNESS, ETC.)

21

EVASE (DETAIL IN PROPSAL)

22

INSULATION REQUIRED

23

INSULATION TYPE

24

FAN HOUSING NEAR-CENTERLINE SUPPORT REQUIRED(2.2.5)

WEAR PLATES

25

DRAINS: No./SIZE

HUB:

26

FAN INLET ACCESS: SPLIT FOR ROTOR REMOVAL

27

MANWAYS:

28

CONSTRUCTION

TIR @ SLEEVE

INSULATION STUDS BY

THICKNESS

mm

COATING TYPE

SIZE

mm TYPE/LOC.

KEY WAY: No.

MATERIAL

SHAFT SLEEVES:

31

BEARINGS

WK(Kg/m)

DIM

mm

C/MIN.

LENGTH (mm)

DIA. (mm)

ANTI-FRICTION

SHRINK FIT

CORROSION RESISTANT MATL.

33

MOUNTING PEDESTALS

YES

NO

SHAFT SEALS:

34

SOLE PLATES

YES

NO

TYPE

35

RADIAL BEARINGS:

MFG./No.

CONSTRUCTION

MAX. HEATING / COOLING RATE

HYDRODYNAMIC

36

KEYED

MATERIAL

ROTOR WT. (Kg)

CONSTRUCTION

MATERIAL

SHRINK FIT

mm TYPE/LOC.

BEARING HOUSING:

mm

DIAMETERS (mm)

MATERIAL

SIZE

30

mm DIA. @ BEARING

TYPE FABRICATION

TYPE/LOC.

29

32

mm

YES

MFG/NO.

12

15

BY

MATERIAL

BUFFER OR EDUCTOR CONNECTIONS

LOAD (N)

L'NGT. (mm)

DIA. (mm)

DETAILS:

37

INBOARD

MAIN

INLET:CONNECTIONS(2.3)

No.

SIZE

AREA (m)

38

OUTBOARD

INLET:

AREA (m)

L-10

HRS

RPM @

No.

SIZE

39

Dn FACTOR

40

LOAD FACTOR

41

MAX. SPEED

42

CLEARANCE

mm

43

BEARING SPAN (CL - CL)

mm

44

THRUST BEARINGS:

LOCATION/ORIENTATION

45

TYPE (Dual Bell, Flat Land, Tapered Land, Tilt-Pad)

EXP. JOINT REQ'D

EXP. JOINT REQ'D

OUTLET:

FURN. BY

SIZE

FLANGE SIZE

MFG./No.

AREA

48

LOADING N/m: ACTUAL

49

Dn FACTOR

50

LOAD FACTOR

51

MAX. SPEED

52

THRUST COLLAR (On Inboard Bearing):

mm

ALLOW

AREA (m)

BOLTING

FURN. BY

MATING FLG BY VENDOR

47

ASME B16.5

ASME B16.47

OTHER CONNECTIONS(2.3):

SERVICE

L - 10

HRS LUBE OIL INLET

RPM @

No.

SIZE

TYPE

LUBE OIL OUTLET

TYPE:

TYPE ATTACHMENT:

54

55

BOLTING

LOCATION/ORIENTATION

46

53

FLANGE SIZE

COOLING WATER INLET

COOLING WATER OUTLET

PRESSURE GAGE

TEMP. GAGE

INTEGRAL THRUST COLLAR REQUIRED(2.8.4.2.2)

08/01 SHT 3 OF 10

319681075.xlsx, API673SI

CONDENSATE DRAINS

API673SI.XLS

Page 3 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

ITEM NO.

REVISION

PAGE

DATE

4

OF

10

BY

CONSTRUCTION FEATURES (Continued)

1

2 NOISE ATTENUATION:

BASEPLATES & SOLEPLATES:

MAX. ALLOW SOUND PRESS LEVEL

DBA@

TRI- DIRECTIONAL ADJUSTING SCREWS FOR EQUIP.

PREDICTED SOUND PRESS LEVEL

DBA@

PILOT HOLES FOR DOWELS

ATTENUATION METHOD

TYPE GROUT

TYPE PRECOAT

SOLEPLATES FOR

FURNISHED BY

SILENCER MFG/MODEL No.

BEARING PEDESTALS

DRIVER

BASE PLATE:

COMMON (Under Fan, Gear, Driver)

10

ACOUSTIC PERF

11

AERODYNAMIC PERF

12

LOSS

13

ACCESSORIES

OTHER

m/s

mm WG.

14 FAN CLEANING SYSTEM(2.1.22):

REQUIRED

CLEANING MEDIUM

16

MFR./MODEL

FURN BY

17

INSTALLED BY

18

DETAILS/DWG.No.

CORROSION

ALLOWANCE

20

21

SHAFT

22

BLADES

23

HUB

24

CENTER PLATE

25

SHROUDS

26

SLEEVES

27

SEALS

28

HOUSING

29

DAMPERS

30

GUIDE VANES

31

RAIN HOODS

32

INLET BELTS

33

EVASE (Discharge, Difuser)

34

SOUND TRUCK

35

INLET DUCT

36

WEAR PLATES

37 COUPLINGS:

FAN ALONE

DIMENSIONS

DECKING

NON SKID

OPEN CONSTRUCTION

DRIP RIM

OPEN DRAIN

SUITABLE FOR

COLUMN or

PERIMETER SUPPORT

LEVELING PADS W/REMOVABLE COVER

15

19 FAN ITEMS:

GEAR

FAN HOUSING SUPPORTS

DRIVER - FAN

SUBSOLE PLATES REQUIRED

SIZE/THICKNESS

(INCL. C.A.)

MATERIAL

GEAR - FAN

MATERIAL

SPECIFICATION

DRIVER - GEAR

38

39

COUPLING & GUARD

40

FURNISHED BY:

41

TYPE

42

MFG.

43

MODEL/NUMBER

44

LUBRICATION

45

MOUNT CPLG. HALVES

46

-FAN

47

-DRIVER

48

-GEAR

49

SPACER LENGTH

50

LTD. END FLOAT REQ'D

51

COUPLING GUARD REQ'D

52

SERVICE FACTOR

53

CPLG. RATING HP/100 RPM

54

KEYED or HYDR FIT

55

ADAPTER (Solo) PLATE

56

MATERIALS

08/01 SHT 4 OF 10

319681075.xlsx, API673SI

API673SI.XLS

Page 4 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

ITEM NO.

REVISION

PAGE

DATE

5

OF

10

BY

CONSTRUCTION FEATURES (Continued)

1

2

ALLOWABLE EXTERNAL LOADS

INLET

FORCE

N

WEIGHTS Kg:

DISCHARGE

MOMT.

N-m

FORCE

N

MOMT.

N-m

FAN

DRIVER

BASE

ROTORS FAN

DRIVER

BASE

GEAR UPPER CASE

AXIAL

SOUND TRUNK

EVASE

VERTICAL

SYSTEMS: LUBE

CLEANING

HORIZ. 90

CONTROL PANEL

9 VIBRATION DETECTORS:

PROVISIONS FOR VIBRATION TRANSDUCERS(THREADED CONN.)

MAX. FOR MAINTENANCE (Identify)

10

11

FLAT SURFACES FOR MAGNETIC MOUNTED TRANSDUCERS

12

13

SEISMIC SENSOR COVER (S) BY

PROVISIONS FOR MOUNTING NON-CONTACTING VIB. PROBES

SPACE REQUIREMENTS (METERS)

14

PER API 670

COMPLETE UNIT

CONTROL PANEL

15 SPEED DETECTORS (On Outdoor Bearing):

TOTAL SHIPPING WEIGHT

16

NON-CONTACT PROBE

SPEED SWITCH

17

OTHER

18

TYPE

19

MFG

STEAM

20

LOCATION

AIR

21

SCALE RANGE

MODEL

UTILITY REQUIREMENTS:

GAS

WATER

ELECTRIC

DRIVER RATING

NET LOADS

RPM

22

MISCELLANEOUS:

23 SHOP INSPECTIONS & TESTS:

REQ'D. OBSERV'D

WIT.

VENDOR'S REVIEW & COMMENTS ON FOUNDATION DESIGN

24 SHOP INSPECTION

VENDOR'S REV. & C'MNTS ON CONTRACTOR'S DUCT DESIGN

25 CLEANLINESS INSPECTION

TORSIONAL ANALYSIS REPORT REQUIRED

26 HARDNESS VERIFICATION

TURNING GEAR, TYPE DRIVER

27 CHARPY IMPACT TESTING

AUTO

28 SHAFT RUN OUT CHECK

RAINHOOD & CAP

29 ROTOR BALANCING

INLET AIR FILTER

30 REBAL. AFTER MOUNTING CPLG.

INLET DAMPER

31 RESIDUAL BALANCE CHECK

INLET GUIDE VANE

32 CALIBRT'N CK. OF BALNC'G EQUIP

INLET TRASH SCREEN

33 NDT EXAMINATION

OUTLET DAMPER

34 ASSEMBLY & FIT UP CHECK

SOUND TRUCK (INLET BOX/ SILENCER)

35 INITIAL &/or FINAL ALIGN

36 GEAR TOOTH CNTCT. CHK. (API 677)

MANUAL ENGAGE

START FROM REST

BOLTING & GASKETS

REMARKS:

37 MECHANICAL RUN TEST

38 FULL UNIT MECHANICAL RUN TEST

39 VIBRATION TEST

40 SOUND LEVEL TEST

41 MAT'L CERTIFICATION

42 SURFACT & SUBSURFACE INSPCT.

43

TYPE

44 PRESSURE TEST:

45

-HOUSING

46

-DUCTING

47

-LUBE OIL SYSTEM

48 RUN & CHECK LUBE CONSOLE

49 SHOP PERFORMANCE TEST

50 PRE-SHIPMENT INSPECTION

51

-DRIVER / AUX. MOUNTED

52 QUALITY CONTROL REVIEW

53 FIELD PERFORMANCE TEST

54 OTHERS:

55

319681075.xlsx, API673SI

Page 5 of 11, Date Printed: 05/30/2016

08/01 SHT 5 OF 10

319681075.xlsx, API673SI

API673SI.XLS

Page 6 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

1

REVISION

PAGE

DATE

6

CIRCULATING LUBE OIL SYSTEM BY

2 PIPING MATERIALS:

4

COMPLETE SYSTEM

DOWNSTREAM OF FILTERS

RETURN PIPING

OF

10

BY

LUBE OIL SYSTEM

CARBON

STEEL

STAINLESS

STEEL

API-614 REQUIRED

STANBY PUMP CONTROL:

RESET

MANUAL

AUTOMATIC

AUTOMATIC START

"ON-OFF-AUTO" SELECTOR SWITCH

RESERVOIR:

7

8

ITEM NO.

MATERIAL

CARBON STEEL SLIP-ON FLANGES ON STNLESS. STEEL PIPING

9 SYSTEM COMPONENT SUPPLIERS:

10

RETENTION TIME

MIN.

BASEPLATE MOUNTED

MANUFACTURER

MODEL

CAPACITY

BAFFLE REQUIRED

INTERIOR COATING

11

MAIN PUMP

FREE SURFACE AREA

12

STANDBY PUMP

HEATER (S)

ELECT.

13

ELECTRIC MOTOR (S)

FLTR./BRTHR.

FLANGED VNT.

14

STEAM TURBINE (S)

PRESS. RELIEF VENT

15

OIL COOLER (S)

SPRING LOADED FILL CAP w/S.S. STRAINER

16

OIL FILTER (S)

17

ACCUMULATOR (S)

AIR

18

SUCT. STRAINER (S)

SINGLE

19

CHECK VALVE (S)

W/ BYPASS & TEMP CNTRL. VALVE

20

SWITCH VALVE (S)

ASME CODE STAMP

21

PUMP COUPLING (S)

HEATING STEAM

22

TEMP. INDICATORS

FOUL. FACTR.: SHELLSIDE

23

L.P. SHUTDOWN SWITCH

MAKE

STREAM

MIN SITE

HEAT-UP TIME

INSULATION SUPPORTS

WATER

m/h @

DESIGN

PSIG

HYDROTEST

26

PUMP RELIEF VALVE (S) SETTINGS

27 BASIC SYSTEM REQUIREMENTS

m/h

SSU @ 38C

AUTO

C

TUBE SIDE

TYPE

W/HR

CODE (S)

PSIG

DESIGN PRESS. PSIG SHELL SIDE

TUBES: O.D.

SSU @ 99C

MANUAL

BAR

PSIG

(NORMAL OIL FLOW)

BAR

SINGLE

DUTY

25

mm

28

LUBE OIL

29

FAN

30

DRIVER

31

GEAR

TUBES

32

COMMON LUBE SYSTEM

TUBE SHEETS

SURFACE

TUBE SIDE

TOTAL SURFACE AREA

WALL THICKNESS (AVE) (MIN)

LENGTH

m

mm

mm NUMBER:

MATERIALS

33 PUMPS:

MAIN

STANDBY

SHELL

34

HORIZONTAL

TUBE SUPPORT

35

VERTICAL

SHELL COVER/FLANGE

36

SUBMERGED

37

MOTOR DRIVEN

SINGLE

MULTI

38

TURBINE DRIVEN

ASME CODE DESIGN

ASME CODE STAMP

39

SHAFT DRIVEN

MATERIAL

40

CENTRIFUGAL

CORROSION ALLOWANCE (mm)

41

GEAR/SCREW

CAPACITY (TOTAL) m

42

FLANGE CONNECTED

PRE-CHARGE PRESS. (BAR)

43

m/h (RATED)

DIRECT CONTACT TYPE

44

@ BAR

BLADDER MATERIAL

45

BHP @ 100 SSU

46

DRIVER kW

47

CASING MATERIAL

SINGLE

TWIN

48

SPEED

ASME CODE DESIGN

ASME CODE STAMP

49

COUPLING

MICRON ()

50

GUARD

FILTER MEDIUM

51

MECH. SEAL

DESIGN PRESS. BAR

ACCUMULATOR:

53

AIR MOTOR DRIVEN

54

SAFETY GUARD REQUIRED

BLADDER TYPE

WITH SUPPLY REGULATOR

FILTERS:

MANU. CHARGE VALVE

MFG:

P CLEAN BAR

52 EMERGENCY LUBE OIL PUMP:

OTHER

P COLLAPSE BAR

CASING MATERIAL

55 REMARKS:

CARTRIDGE INDENT NO.

56

FURNISH SET OF SPARE CARTRIDGE W/ FILTERS

319681075.xlsx, API673SI

C

Hrs.

OIL COOLERS:

24 SYSTEM PRESSURES:

08/01 SHT 6 OF 10

FABRICATED STEEL BASE

API673.XLS

Page 7 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

1

2

ITEM NO.

REVISION

PAGE

DATE

7

OF

10

BY

INSTRUMENTATION

PER API 614

OTHER

3 LOCAL CONTROL PANEL:

4

FURNISHED BY:

VENDOR

PURCHASER

BASE MOUNTED

VIBRATION ISOLATORS

ANNUNCIATOR WITH FIRST OUT INDICATION LOCATED ON LOCAL PANEL

8

9

10

FREE STANDING

OTHERS

WEATHERPROOF

STRIP HEATERS

TOTALLY ENCLOSED

PURGE CONNECTIONS

EXTRA CUTOUTS

WITH DOORS

CUSTOMER CONNECTIONS BROUGHT OUT TO TERMINAL BOXES BY VENDOR

REMARKS:

11 INSTRUMENT SUPPLIERS:

12

PRESSURE GAGES

MFR.

SIZE & TYPE

13

TEMPERATURE GAGES

MFR.

SIZE & TYPE

14

LEVEL GAGES

MFR.

SIZE & TYPE

15

DIFF. PRESSURE GAGES

MFR.

SIZE & TYPE

16

PRESSURE SWITCHES

MFR.

SIZE & TYPE

17

DIFF. PRESSURE SWITCHES

MFR.

SIZE & TYPE

18

TEMPERATURE SWITCHES

MFR.

SIZE & TYPE

19

LEVEL SWITCHES

MFR.

SIZE & TYPE

20

CONTROL VALVES

MFR.

SIZE & TYPE

21

PRESSURE RELIEF VALVES

MFR.

SIZE & TYPE

22

SIGHT FLOW INDICATORS

MFR.

SIZE & TYPE

23

VIBRATION EQUIPMENT

MFR.

SIZE & TYPE

24

TACHOMETER

MFR.

RANGE &TYPE

25

SOLENOID VALVES

MFR.

SIZE & TYPE

26

ANNUNCIATOR

MFR.

MODEL & No. POINTS

27

DAMPER/VANE ACTUATOR

MFR.

MODEL

28

FURNISHED BY

29

TYPE

NOTE:

MAX. TORQUE (N-m)

SUPPLIED BY VENDOR

30 PRESSURE GAGE REQUIREMENTS:

31 FUNCTION

SUPPLIED BY PURCHASER

LOCALLY

LOCAL

MOUNTED

PANEL

FUNCTION

32

LUBE OIL PUMP DISCHARGE

FAN DISCHARGE

33

LUBE OIL FILTER P

CONTROL AIR

34

LUBE OIL SUPPLY

FAN SUCTION

LOCALLY

LOCAL

MOUNTED

PANEL

LOCALLY

LOCAL

MOUNTED

PANEL

35

36

37 TEMP. GAGE REQUIREMENTS:

38 FUNCTION

LOCALLY

LOCAL

MOUNTED

PANEL

FUNCTION

39

LUBE OIL TO BEARINGS

OIL COOLER INLET & OUTLET

40

DISCHARGE FROM EACH

FAN SUCTION

41

PINION JOURNAL BEARING

42

BULL GEAR JOURNAL BEARING

43

FAN THRUST BEARING

44

DRIVER JOURNAL BEARING

45

DRIVER THRUST BEARING

46

GEAR THRUST BEARING

47

FAN JOURNAL BEARING

48

49 SWITCH CLOSURES:

50

ALARMCONTACTS SHALL:

51

SHUTDOWN CONTACTS SHALL:

52

OPEN

CLOSE TO SOUND ALARM AND BE NORMALLY

OPEN

CLOSE TO TRIP AND BE NORMALLY

ENERGIZED

DE-ENERGIZED

ENERGIZED

DE-ENERGIZED

NOTE: NORMAL CONDITION IS WHEN FAN IS IN OPERATION.

53 REMARKS:

08/01 SHT 7 OF 10

319681075.xlsx, API673SI

API673SI.XLS

Page 8 of 11, Date Printed: 05/30/2016

JOB NO.

CENTRIFUGAL FAN (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

ITEM NO.

REVISION

PAGE

DATE

8

OF

10

BY

INSTRUMENTATION (Continued)

1

2 MISCELLANEOUS

3

ALARM AND SHUTDOWN SWITCHES SHALL BE SEPARATE.

ELECTRICAL AND INSTRUMENT CONNECT'NS WITHIN THE CONFINES OF THE FAN BASE SHALL BE BROUGHT OUT TO TERMINAL BOXES.

COMMENTS REGARDING INSTRUMENTATION:

6

7

8 ALARM & SHUTDOWN SWITCHES

9

FUNCTION

ALARM

TRIP

FUNCTION

10

LOW LUBE OIL PRESSURE

FAN VIBRATION

11

HI LUBE OIL FILTER P

FAN AXIAL POSITION

12

LOW LUBE OIL RESERVE LEVEL

DRIVER VIBRATION

13

AUX. LUBE OIL PUMP START

DRIVER AXIAL POSITION

14

HI INLET AIR FILTER P

FAN MOTOR SHUTDOWN

15

HI FAN THRUST BRG. TEMP.

16

HI DRIVER THRUST BRG. TEMP.

ALARM

TRIP

17

18 MISCELLANEOUS INSTRUMENTATION:

19

SIGHT FLOW INDICATORS: EACH JOURNAL & THRUST BEARING OIL RETURN LINE

20

LEVEL GAUGES, LUBE OIL RESERVOIR (S)

21

VIBRATION READOUT EQUIPMENT

22

VIBRATION READ OUT LOCATED ON:

23

FAN SPEED PICK-UP DEVICES

24

FAN SPEED INDICATORS

25

FAN SPEED INDICATORS LOCATED ON:

26

ALARM HORN & ACKNOWLEDGEMENT SWITCH

LOCAL PANEL

LOCAL PANEL

OTHER

OTHER

27

28

29

30 REMARKS:

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

08/01 SHT 8 OF 10

319681075.xlsx, API673SI

API673SI.XLS

Page 9 of 11, Date Printed: 05/30/2016

JOB NO.

ELECTRONIC MOTOR (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

1 APPLICABLE TO:

PROPOSAL

PURCHASE

ITEM NO.

REVISION

PAGE

DATE

9

UNIT

3 SITE

DRIVEN EQUIP.

4 SERVICE

BY

NO. REQUIRED

5 MANUFACTURER

MODEL

SERIAL NO.

6 NOTE: INFORMATION TO BE COMPLETED

BY PURCHASER

BY MANUFACTURER

MOTOR DESIGN DATA

7

8 APPLICABLE SPECIFICATIONS

9

VIBRATION:

NEMA

NEMA STANDARD

10

NOISE

11 SITE DATA:

12 AREA:

NEMA STANDARD

C.L.

GR.

ALTITUDE

ZN.

14 UNUSUAL CONDITIONS

15

10

AS BUILT

2 FOR

13

OF

N-HAZARDOUS

AMBIENT TEMPS:

DUST

FUMES

MAX

MIN

THRUST:

MAX. MOTOR THRUST

REMARKS:

OTHER

16 DRIVE SYSTEM:

DIRECT CONNECTED

17

GEAR

18

OTHER

19 TYPE MOTOR:

20

SQUIRREL CAGE INDUCTION

21

SYNCHRONOUS

22

23

POWER FACTOR REQ'D

EXCITATION:

24

25

NEMA DESIGN

BRUSHLESS

SLIP RING

ACCESSORY EQUIPMENT

FIELD DISCHARGE RESISTOR BY MOTOR MFR.

WOUND ROTOR INDUCTION

26

27 ENCLOSURE:

28

CLASS

29

TEFC

30

TEWAC

BASEPLATE

SOLEPLATE

MFR. STD. FANS

NONSPARKING FANS

STATOR SHIFT

D.C. EXCITATION

GROUP

EXP. PROOF

KW REQ'D.

BY:

TEIGF, USING

GAS

31

DOUBLE WALL CARBON STEEL TUBES

32

WATER SUPP.: PRESS.

33

WATER ALLOW. P

34

WATER SIDE MIN CORR. ALLOW.

35

AND FOUL FACTOR

36

(AIR) (GAS) SUPPLY PRESS.

BAR

VOLTS

PURCHASER

MANUFACTURER

DESCRIPTION

ENCLOSED COLLECTOR RINGS:

TEMP.

BAR & TEMP RISE

PURGED

EXPLOSION-RESISTANT NONPURGED

MEDIUM

mm

FORCE VENTILATION

CFM

BAR

37

PRESS

BAR

mm H2O

PRESS. DROP

BEARING TEMP. DEVICES:

LOCATION

38

WEATHER PROTECTED TYPE

39

FORCED VENTILATION

40

OPEN-DRIPPROOF

41

OPEN

DESCRIPTION

SET @

C FOR ALARM

KW

42

VOLT

PHASE

MAX SHEATH TEMP.

43 BASIC DATA:

44

PHASE

45

NAMEPLATE HP

46

SYNCHRONOUS RPM

47

INSULATION CLASS

48

TEMP. RISE:

HERTZ

THERMISTORS

SERVICE FACTOR

TYPE:

No./PHASE

POS. TEMP. COEFF.

TEMPERATURE SWITCH

TYPE

C ABOVE

FULL VOLTAGE

REDUCED VOLTAGE

51

LOADED

UNLOADED

52

VOLTAGE DIP

NO

No./PHASE

RESISTANCE MAT.

OHM

SLCTR. SWITCH & INDICATOR BY:

50

NEG. TEMP. COEFF

YES

RESISTANCE TEMP. DETECTORS:

C BY

49 STARTING:

319681075.xlsx, API673SI

HERTZ

WINDING TEMPERATURE DETECTORS:

VOLTS

08/01 SHT 9 OF 10

C FOR SHUTDN.

SPACE HEATERS:

PURCHR.

MFR.

MAX. STATOR WINDING TEMPS:

C FOR ALARM

C FOR SHUTDOWN

API673SI.XLS

Page 10 of 11, Date Printed: 05/30/2016

JOB NO.

ELECTRONIC MOTOR (API 673-2ND. EDITION)

DATA SHEET

SI UNITS

ITEM NO.

REVISION

PAGE

DATE

10

OF

ACCESSORY EQUIPMENT, (Cont'd)

10

BY

MANUFACTURER'S DATA, (Cont'd)

2 WINDING TEMP, DETECTOR & SPACE HEATER LEADS:

FIELD DISCHARGE RESISTOR

OHMS

IN SAME CONDUIT BOX

RATED EXCITATION FIELD VOLTAGE

D.C.

IN SEPARATE CONDUIT BOXES

RESISTANCE OF EXCITATION FIELD @ 25C

OHMS

MOTOR ARRANGED FOR DIFFERENTIAL PROTECTION:

SELF-BALANCE PRIMARY-CURRENT METHOD

EXCITATION FIELD AMPS: MAX.

C.T. DESCRIPTION

EXCITATION FIELD

8

9

EXTENDED LOADS

LENGTH

EXCITATION FIELD AMPS @ FULL LOAD & RATED P.F.

MIN.

RHEOSTAT

FIXED RESISTOR REQ'D

SUPPLIED BY

SURGE CAPACITORS

BEARINGS: TYPE

LUBR.

10

LIGHTING ARRESTERS

LUBE OIL REQUIRED:

m/h@

11

C.T. FOR AMMETER

TOTAL SHAFT END FLOAT

12

DESCRIPTION

BAR

LIMIT END FLOAT TO

13 MAIN CONDUIT BOX SIZED FOR:

14

MAIN MOTOR LEADS

15

INSULATED

TYPE

NONINSULATED

MOTOR ROTOR:

SOLID

SPLIT

MOTOR HUB

SOLID

SPLIT

FOR TEWAC &TEIGF MOTORS:

16

C.T.'S FOR DIFF. PROTECT. (MTD. BY

COOLING WATER REQ'D

17

SURGE CAPACITORS (MTD. BY

C.W. TEMP. RISE

C PRESS. DROP

m/h

18

LIGHTNING ARRESTERS (MTD. BY

(AIR) (GAS) REQ'D

mn/h

19

C.T. FOR AMMETER (MTD. BY

20

SPACE FOR STRESS CONES

21

AIR FILTERS

22

MFR.

BAR

mm H2O

PRESS. MAINT.

CURVES REQ'D BASED ON MOTOR SATURATION @ RATED VOLTAGE:

SPEED vs TORQUE (ALSO @

% RATED VOLTAGE)

SPEED vs POWER FACTOR

TYPE

SPEED vs CURRENT

MANUFACTURER'S DATA

23

WEIGHTS (Kg):

24 MANUFACTURER

25 FRAME No.

FULL LOAD RPM (Ind.)

26 EFFICIENCY: F.L.

3/4L

1/2L

27 PWR. FACTOR (Ind.): F.L.

3/4L

28 CURRENT (Rated Volt.): FULL LOAD

NET WEIGHT

SHIPPING WT.

ROTOR WEIGHT

MAX. ERECTION WT.

MAX. MAINT. WT (Identify)

1/2L

DIMENSIONS (METERS):

LOCKED ROTOR

SHOP INSPECTION AND TESTS

29 LOCKED ROTOR POWER FACTOR

30 LOCKED ROTOR WITHSTAND TIME (Cold Start)

REQUIRED

31 TORQUES (FT-LBS): FULL LOAD

OBSERVED

WITNESS

SHOP INSPECTION

32

LOCKED ROTOR

STARTING (Syn.)

TESTING PER NEMA

33

PULL-UP (Ind.)

PULL-IN (Syn.)

MFR. STD. SHOP TESTS

34

BREAKDOWN (Ind.)

PULL-OUT (Syn.)

IMMERSION TEST

35

SPECIAL TESTS (List Below)

36 OPEN CIRCUIT TIME CONSTANT (SEC.)

37 SYMMETRICAL CONTRIBUTION TO 3 TERMINAL FAULT:

38 AT 1/2 CYCLES

AT 5 CYCLES

39 REACTANCES: SUB-TRANSIENT (X"d)

40

TRANSIENT (X'd)

41 A.C. STATOR RESISTANCE

SYNCHRONOUS (X d )

OHMS@

COUPLING:

C

42 RATED KVA

MFR.

43 KVA INRUSH @ FULL VOLT. & LOCKED ROTOR (SYN.)

44 KVA @ FULL VOLTAGE & 95% SPEED

45 MAX. LINE CURR. IN STATOR ON 1st SLIP CYC. @ PULL-OUT

46

SUPPLIED BY

MOTOR MFR.

MODEL

FAN MFR.

PUCH. TO MOUNT MTR. HALF

PAINTING:

MANUFACTURER'S STANDARD

(SYN.)

47 ACCELERATION TIME (Motor Only @ Rated Volt.)

SEC. SHIPMENT:

48 ACCEL. TIME (Motor & Load @ 85% Rated Volt.)

SEC.

49 ROTOR/FIELD WK @ MOTOR SHAFT (Kg-m)

DOMESTIC

EXPORT

EXPORT BOXING REQUIRED

OUT DOOR STORAGE OVER 6 MONTHS

50 ROTATION FACING COUPLING END

51 NO. OF STARTS PER HOUR

52 REMARKS:

08/01 SHT 10 OF 10

319681075.xlsx, API673SI

API673SI.XLS

Page 11 of 11, Date Printed: 05/30/2016

You might also like

- Api 676 UsDocument2 pagesApi 676 UsAbhai Gupta100% (1)

- API 673 3rd Ed Data SheetsDocument27 pagesAPI 673 3rd Ed Data Sheetsjuan ninaNo ratings yet

- Fuel Oil Unloading and Forwarding System Description: I.P.D.C. Project: Shirvan 6×159 M.W. Gas Turbine Power PlantDocument17 pagesFuel Oil Unloading and Forwarding System Description: I.P.D.C. Project: Shirvan 6×159 M.W. Gas Turbine Power PlantepbamdadNo ratings yet

- Orifice Plate Data SheetDocument2 pagesOrifice Plate Data SheethasnacuNo ratings yet

- ASMEDocument109 pagesASMERraffrizal Chands100% (1)

- NPT Thread Chart - NPT & NPS Fittings Dimensions & SizesDocument2 pagesNPT Thread Chart - NPT & NPS Fittings Dimensions & SizesMarc EdwardsNo ratings yet

- Knife Gate Valve - For Reference OnlyDocument16 pagesKnife Gate Valve - For Reference Onlysj_scribdNo ratings yet

- Pump Data SheetDocument6 pagesPump Data Sheeta_s_a_dNo ratings yet

- Native Data Sheet Asme b73.1Document4 pagesNative Data Sheet Asme b73.1Akhmad Faruq Alhikami100% (1)

- VESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedDocument6 pagesVESV1003 - Fabrication of Welded Vessels and Tanks To Be LinedMuhammad Farukh ManzoorNo ratings yet

- Gasket Paking ListDocument1 pageGasket Paking ListIrwansyah MuchtarNo ratings yet

- Pertamina FRP and Ball Valve Specification SheetDocument3 pagesPertamina FRP and Ball Valve Specification Sheetbagus handokoNo ratings yet

- Pressure Relief Valve Data Sheet EssentialsDocument2 pagesPressure Relief Valve Data Sheet Essentialstriked2100% (1)

- Valve Sizing SelectionDocument15 pagesValve Sizing SelectionbariNo ratings yet

- Pressure Gauge Specification SheetDocument1 pagePressure Gauge Specification Sheetsairam2234No ratings yet

- Metal Tapered Tube Plugs: Tube Plug Sizing ChartDocument1 pageMetal Tapered Tube Plugs: Tube Plug Sizing ChartRaghavanNo ratings yet

- Rosemount Twisted Square Thermowell: Vortex-Induced Vibration SolutionDocument16 pagesRosemount Twisted Square Thermowell: Vortex-Induced Vibration Solutionprasanta_bbsrNo ratings yet

- Piping Design InfoDocument273 pagesPiping Design InfoFerry SiswantoNo ratings yet

- Edited - Flange Joint Assembly ChecklistDocument2 pagesEdited - Flange Joint Assembly ChecklistvivekkumarenzoNo ratings yet

- Pressure VesselDocument19 pagesPressure Vesselamitammy19100% (1)

- VEFV3100Document19 pagesVEFV3100adolfocienfuegosNo ratings yet

- SCHA FMECA Demo5 07 10Document3 pagesSCHA FMECA Demo5 07 10Chinh Lê ĐìnhNo ratings yet

- Combustion Gas Turbine Specification SheetDocument10 pagesCombustion Gas Turbine Specification SheettutuionutNo ratings yet

- 1.tbe1 Fire PumpDocument11 pages1.tbe1 Fire Pumpvinoj chandranNo ratings yet

- Line Sizing Factors and Criteria for Liquids and GasesDocument3 pagesLine Sizing Factors and Criteria for Liquids and GasesWade ColemanNo ratings yet

- EGE15B5Document56 pagesEGE15B5Jhonny Rafael Blanco CauraNo ratings yet

- Weld History Sheet: 61D-N CCC Line Abudhabi Gas Development Company LTD 7010-MX-1120 CP12028001ADocument20 pagesWeld History Sheet: 61D-N CCC Line Abudhabi Gas Development Company LTD 7010-MX-1120 CP12028001APramod Athiyarathu100% (2)

- API 2000 5th Vs 6th FinalDocument21 pagesAPI 2000 5th Vs 6th FinalCepopaky CangkrukanNo ratings yet

- Mil STD 1629a Notice 1Document11 pagesMil STD 1629a Notice 1Владимир МалићNo ratings yet

- PFD-P&ID & Standard PDFDocument147 pagesPFD-P&ID & Standard PDFSuzaimi SafeiNo ratings yet

- ISA - TR20 - 00 - 01 - 2001 - Vortex PDFDocument1 pageISA - TR20 - 00 - 01 - 2001 - Vortex PDFDaniel CadenaNo ratings yet

- Intepretation ASME B31.3Document18 pagesIntepretation ASME B31.3abdulloh_99No ratings yet

- Api RP584Document1 pageApi RP584Agustin González AguirreNo ratings yet

- Design of Pressure Vessel NewDocument200 pagesDesign of Pressure Vessel NewneelNo ratings yet

- LS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Document6 pagesLS 164-04 - 6 Identification Traceability of Piping Material On Construction Site (EN)Kreshna Wisnu BrataNo ratings yet

- Cs Globe Valve 600#Document1 pageCs Globe Valve 600#Vijay GaikwadNo ratings yet

- SOP02 - F26 - R00 Pipe Stringing Report 1Document12 pagesSOP02 - F26 - R00 Pipe Stringing Report 1Faiz IshakNo ratings yet

- Control Valve Specification SheetDocument5 pagesControl Valve Specification SheetRahul DevaNo ratings yet

- How To Select ElectrodeDocument2 pagesHow To Select Electrodesbmmla100% (1)

- ASME II - Excel 1ADocument196 pagesASME II - Excel 1Arichward5No ratings yet

- LINE DESIGNATION TABLE FOR MEG TREATMENT FACILITIESDocument5 pagesLINE DESIGNATION TABLE FOR MEG TREATMENT FACILITIESPrashant SinghNo ratings yet

- P P NG Abbrev at Ons: AFC A F CDocument11 pagesP P NG Abbrev at Ons: AFC A F COlajide AkekeNo ratings yet

- Bolt Astm A193Document2 pagesBolt Astm A193Nuzuliana EnuzNo ratings yet

- Rotary Compressor API 619Document26 pagesRotary Compressor API 619EDUARDO25% (4)

- Boq For AS BoilerDocument1 pageBoq For AS BoilerGayan ChathurangaNo ratings yet

- Velosi Proposal For Pressure Vessel Design VerificationDocument5 pagesVelosi Proposal For Pressure Vessel Design VerificationShahbaz Khan33% (3)

- Gasket Calculator 6.0Document20 pagesGasket Calculator 6.0antonio lopezNo ratings yet

- Pressure Vessel: General DescriptionDocument4 pagesPressure Vessel: General DescriptionTiny Tấn MinhNo ratings yet

- Burner - Api 560Document3 pagesBurner - Api 560wado11No ratings yet

- TDS For Deluge ValveDocument2 pagesTDS For Deluge ValveRAGHVENDRA PRATAP SINGHNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- API 674 Pump Data SheetDocument5 pagesAPI 674 Pump Data SheetEason Ng100% (2)

- Data SheetDocument6 pagesData Sheetmkfe2005No ratings yet

- HD Api610Document5 pagesHD Api610Venkat RanganNo ratings yet

- API STD 676-2009 - Hoja de RequisiciónDocument28 pagesAPI STD 676-2009 - Hoja de RequisiciónRicardo CastroNo ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet U.S. Customary UnitsÆmanuel J Silva100% (1)

- Hoja de Datos API-674Document5 pagesHoja de Datos API-674texwan_No ratings yet

- Centrifugal Pump Api-610 Data Sheet Mks Units: Operating Conditions Site and Utility Data (Cot D)Document12 pagesCentrifugal Pump Api-610 Data Sheet Mks Units: Operating Conditions Site and Utility Data (Cot D)sahrilbayunirosidikNo ratings yet

- DATA SHEET MULTIPHASE PUMP REV0 BornermanDocument5 pagesDATA SHEET MULTIPHASE PUMP REV0 BornermanJessika López100% (1)

- Rotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsDocument9 pagesRotary-Type Positive-Displacement Compressor Data Sheet Us Customary UnitsghostamirNo ratings yet

- Isover Cryolene InsDocument8 pagesIsover Cryolene InstutuionutNo ratings yet

- Open Top Tank - Zero Inner PressureDocument1 pageOpen Top Tank - Zero Inner PressuretutuionutNo ratings yet

- 13 394Document14 pages13 394deepakmitrNo ratings yet

- Seismic Design of Inner Tank - FN 14.03.2014Document8 pagesSeismic Design of Inner Tank - FN 14.03.2014tutuionutNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - ColdDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - ColdtutuionutNo ratings yet

- Material Data Sheets For Piping: 1 ForewordDocument50 pagesMaterial Data Sheets For Piping: 1 ForewordhsdeNo ratings yet

- Anchor Straps - Outer Tank - 09.09.2014Document4 pagesAnchor Straps - Outer Tank - 09.09.2014tutuionutNo ratings yet

- Wind Load - ASCE 7-10Document2 pagesWind Load - ASCE 7-10tutuionutNo ratings yet

- Nozzle List - 09.09.2014Document1 pageNozzle List - 09.09.2014tutuionutNo ratings yet

- TECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterDocument1 pageTECHNICAL NOTE 007 Structural Steel Sub-Grades JR, J0 and J2 Does It MatterOM PRAKASH PALNo ratings yet

- Roof Nozzle Reinforcement API 620 Section 5.16 - WarmDocument1 pageRoof Nozzle Reinforcement API 620 Section 5.16 - WarmtutuionutNo ratings yet

- Conversão Metais DIN ASTM Etc PDFDocument1 pageConversão Metais DIN ASTM Etc PDFRafael Perches PierriNo ratings yet

- Vent Guide Website 3.19.13Document36 pagesVent Guide Website 3.19.13Eddy SyahNo ratings yet

- Materials For LNG ServicesDocument10 pagesMaterials For LNG ServicesSung Hyun TakNo ratings yet

- Welding LNG Tank and Vessel in 5 and 9 Nickel SteelDocument4 pagesWelding LNG Tank and Vessel in 5 and 9 Nickel Steelויליאם סן מרמיגיוסNo ratings yet

- Aisc Design Examples v14Document125 pagesAisc Design Examples v14Daniyal Ahmed100% (2)

- New Steel Plate LNGDocument7 pagesNew Steel Plate LNGtutuionutNo ratings yet

- Design Standard - Section 3-3 - Steel Storage Tanks - 12!31!12 - FINALWEBPOST - 201301090858057238Document60 pagesDesign Standard - Section 3-3 - Steel Storage Tanks - 12!31!12 - FINALWEBPOST - 201301090858057238ராபர்ட் ஆன்றோ ரெனிNo ratings yet

- Technical Insulation - Cryolene PDFDocument8 pagesTechnical Insulation - Cryolene PDFtutuionutNo ratings yet

- 9%ni Material FeaturesDocument9 pages9%ni Material FeaturestutuionutNo ratings yet

- Welding LNG Tank and Vessel in 5 and 9 Nickel SteelDocument4 pagesWelding LNG Tank and Vessel in 5 and 9 Nickel Steelויליאם סן מרמיגיוסNo ratings yet

- Guidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) EnglishDocument50 pagesGuidance For Inspection of Atmospheric, Refrigerated Ammonia Storage Tanks (2008) EnglishSteve IpNo ratings yet

- Speed Sensor Data Sheet: Customer Profile Speed SensorsDocument2 pagesSpeed Sensor Data Sheet: Customer Profile Speed SensorstutuionutNo ratings yet

- Bfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingDocument25 pagesBfro0 Oofs2: Storage Tanks - Selection of Type, Design Code and Tank SizingtutuionutNo ratings yet

- AZOBEDocument4 pagesAZOBEtutuionutNo ratings yet

- Api 619 SiDocument9 pagesApi 619 SitutuionutNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocument17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNo ratings yet

- Api 670 MpsDocument4 pagesApi 670 MpstutuionutNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Astm E10-15 PDFDocument32 pagesAstm E10-15 PDFVCNo ratings yet

- Microprogrammed ControlDocument24 pagesMicroprogrammed ControlmaadurimNo ratings yet

- Quakeguard Earthquake Early Warning System: January 17, 1994Document2 pagesQuakeguard Earthquake Early Warning System: January 17, 1994runkirNo ratings yet

- 16-75 BWE, Bodywork Electrical System: Overview - Sheet 1Document13 pages16-75 BWE, Bodywork Electrical System: Overview - Sheet 1lilik sukristianto100% (1)

- All About BatteryDocument4 pagesAll About BatteryCalvin KleinNo ratings yet

- Wawb Im20190924eDocument172 pagesWawb Im20190924eHumberto CervantesNo ratings yet

- Lesson Plan on Reflection and Refraction of Sound WavesDocument5 pagesLesson Plan on Reflection and Refraction of Sound WavesPinky Marie100% (1)

- MS WordDocument65 pagesMS Worddenson123450% (2)

- Pre-Grading Test - Part 1Document3 pagesPre-Grading Test - Part 1Frank BozNo ratings yet

- G TM Iprb&Bipb&Lapd Board Backup Function r1.0Document28 pagesG TM Iprb&Bipb&Lapd Board Backup Function r1.0Mohammad AslamNo ratings yet

- MEP Coordination - SE SponsorshipDocument42 pagesMEP Coordination - SE SponsorshipmoosuhaibNo ratings yet

- How To Read Drum TabsDocument5 pagesHow To Read Drum TabsanuperickujurNo ratings yet

- Nota Principle of CorporateDocument145 pagesNota Principle of CorporateAhmad MustapaNo ratings yet

- SOFEC CALM BUOY FINAL 3page RedDocument3 pagesSOFEC CALM BUOY FINAL 3page RedJ. Jorge TorresNo ratings yet

- Islamabad PDFDocument4 pagesIslamabad PDFpradisevirtueNo ratings yet

- SAP DB2 BLU Deployment Prerequisite: Important Points To Be CheckDocument4 pagesSAP DB2 BLU Deployment Prerequisite: Important Points To Be Checkrajesh.9127276No ratings yet

- Borang KWLDocument2 pagesBorang KWLjp siaNo ratings yet

- Et101 - Electrical TechnologyDocument78 pagesEt101 - Electrical TechnologyNurhidayah JamaluddinNo ratings yet

- Digital GovernansiDocument32 pagesDigital GovernansiAnonymous kpND1j8hNo ratings yet

- Iso 22301 Implementation Guide 2016 PDFDocument12 pagesIso 22301 Implementation Guide 2016 PDFTarnaveanValeriuDan100% (1)

- Manual: Original InstructionsDocument107 pagesManual: Original InstructionsMelanie Gerdes100% (1)

- Space TrussDocument102 pagesSpace TrussSathya MurthyNo ratings yet

- Peoplesoft BasicsDocument338 pagesPeoplesoft BasicsMunib MohsinNo ratings yet

- Nixie Clock Kit For Biquinary Tubes: Assembly Instructions and User GuideDocument31 pagesNixie Clock Kit For Biquinary Tubes: Assembly Instructions and User GuideTrentStewartLaCourNo ratings yet

- 39ED3050CT - RT49S - AP Service ManualDocument31 pages39ED3050CT - RT49S - AP Service Manualبوند بوند100% (1)

- 850k Diagrama ElectricoDocument1 page850k Diagrama Electricollesli17No ratings yet

- Battery Range Summary: Features & Benefits Temperature PerformanceDocument2 pagesBattery Range Summary: Features & Benefits Temperature PerformanceMiguel Bartolo CruzNo ratings yet

- Polymers 14 00280Document24 pagesPolymers 14 00280amirulNo ratings yet

- 121Document4 pages121Oecox Cah DjadoelNo ratings yet

- Lecture-8: Modes of OperationDocument4 pagesLecture-8: Modes of OperationVasavi VaasuNo ratings yet